FC4A22050L - Panasonic Corporation

advertisement

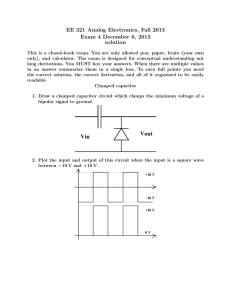

FC4A22050L FC4A22050L Gate Resistor installed Dual N-Channel MOS Type Unit: mm For lithium-ion secondary battery protection circuit Features y Low source-source ON resistance:Rss(on)typ .= 19.5 mΩ (VGS = 4.5V) y CSP package:smallest & thinnest size y Halogen-free / RoHS compliant (EU RoHS / UL-94 V-0 / MSL:Level 1 compliant) Marking Symbol: 11 Packaging 1. Source (FET1) 2. Gate (FET1) FC4A22050L Embossed type (Thermo-compression sealing): 5 000 pcs / reel (standard) Panasonic JEITA Code 3. Gate (FET2) 4. Source (FET2) MBGA004-W-1717APA - Absolute Maximum Ratings Ta = 25 °C Internal Connection Parameter Symbol Rating Unit VSS VGS IS ISp PD Tch Tstg 24 ±12 3.5 35 0.4 150 -55 to +150 V V A A W °C °C Source-source Voltage FET1 Gate-source Voltage FET2 Source Current (DC) *1 Source Current (Pulsed) *1,*2 Total Power Dissipation *1 Overall Channel Temperature Storage Temperature Range Thermal Resistance,Channel to Ambient Note FET2 3 1 4 Pin Name Thermal Characteristics Parameter FET1 2 Symbol Rating Unit Rth (ch-a) 312 °C/W 1. Source (FET1) 2. Gate (FET1) 3. Gate (FET2) 4. Source (FET2) *1 Mounted on FR4 board (25.4 mm × 25.4 mm × t1.0 mm). Surface Mounted on FR4 Board using the minimum recommended pad size(Cu area = 47 mm 2 including traces). *2 t = 10 μs, Duty Cycle ≤ 1 % Publication date: October 2012 Ver. BED 1 FC4A22050L Electrical Characteristics Ta = 25 °C ± 3 °C Parameter Source-source Breakdown Voltage Zero Gate Voltage source Current Gate-source Leakage Current Gate-source Threshold Voltage Source-source On-State Resistance Input Capacitance *1 Output Capacitance *1 Reverse Transfer Capacitance *1 Turn-on Delay Time *1,*2 Rise Time *1,*2 Turn-off Delay Time *1,*2 Fall Time *1,*2 Total Gate Charge *1 Gate-Source Charge *1 Gate-Drain Charge *1 Note: Symbol Conditions VSSS ISSS IGSS Vth RSS(on)1 RSS(on)2 RSS(on)3 Ciss Coss Crss td(on) tr td(off) tf Qg Qgs Qgd IS = 1 mA, VGS = 0 V VSS = 24 V, VGS = 0 V VGS = ±8 V, VSS = 0 V IS = 1.0 mA, VSS = 10 V IS = 3.0 A, VGS = 4.5 V IS = 3.0 A, VGS = 3.1 V IS = 3.0 A, VGS = 2.5 V Min Typ Max 24 0.4 14 15 18 VSS = 10 V, VGS = 0 V, f = 1 MHz VDD = 10 V, VGS = 0 to 4.0 V IS = 3 A VDD = 10 V, VGS = 4.0 to 0 V IS = 3 A VDD = 10 V, VGS = 0 to 4.0 V, IS = 3.5 A 0.85 19.5 23 27 1 780 410 407 0.8 1.5 6 3 15 4.1 3.8 1.0 ±10 1.5 28 32 37 Unit V μA μA V mΩ pF μs μs nC *1 Assured by design *2 See Test circuit DESTRUCTION CURRENT Condition Operation test Destruction current VGS = 3.8 V t = 3 ms, IS = 40 A VGS = 3.8 V t = 11 ms, IS = 15 A VGS = 3.8 V t = 3 ms VGS = 3.8 V t = 11 ms Result PASS PASS 55 A 35 A Ta = 25 °C, Mounted on FR4 board (25.4 × 25.4 × t1.0 mm). Surface Mounted on FR4 Board using the minimum recommended pad size(Cu area = 47 mm 2 including traces). Ver. BED 2 FC4A22050L VDD = 10 V *2 Test circuit RL = 2.5 Ω IS = 3.0 A Vout S2 4V PW = 10 μs D.C. ≤ 1 % Vin 0V G2 G1 Vin 50 Ω S1 90 % Vin 10 % 90 % Vout 10 % td(on) tr td(off) Ver. BED tf 3 FC4A22050L 10 14 4.5 V VSS = 10 V 12 10 8 VGS = 2.5 V 6 3.8 V 4 2 1 Source Current IS (A) Source Current IS (A) 3.1 V 0.1 25 °C Ta = 85 °C 0.01 Single Pulse Single Pulse 0 0.001 0 0.5 1 Source-source Voltage VSS (V) 0 1.5 0.5 1 1.5 Gate-source Voltage VGS (V) IS - VSS 80 Source-source On-state Resistance RSS(on) (mΩ) Source-source On-state Resistance RSS(on) (mΩ) 2 IS - VGS 80 IS = 3.0 A 60 Ta = 85 °C 40 20 25 °C - 40 °C 0 VGS = 2.5 V 60 3.1 V 40 3.8 V 20 4.5 V 0 0 1.5 3 4.5 0 5 Gate-source Voltage VGS (V) 10 15 Source Current IS (A) RSS(on) - VGS RSS(on) - IS 1.E-02 Gate-source Leakage Current IGS (A) 100 Single Pulse Diode Forward Current IF (A) -40 °C 10 Ta = 85 °C - 40 °C 1 25 °C 0.1 0.01 0 0.5 1 1.5 Body Diode Forward Voltage VF(s-s) (V) IF - VF(s-s) 1.E-03 Ta = 85 °C 1.E-04 25 °C 1.E-05 1.E-06 -40 °C 1.E-07 1.E-08 1.E-09 1.E-10 0 3 6 9 12 Gate-source Voltage VGS (V) 15 IGS - VGS Ver. BED 4 5 1.E-03 VSS = 8 V 1.E-04 1.E-05 Gate-source Voltage VGS (V) Zero Gate Voltage source Current ISSS (A) FC4A22050L Ta = 125 °C 1.E-06 85 °C 1.E-07 1.E-08 25 °C 1.E-09 4 10 V 3 12 V 2 1 - 40 °C 1.E-10 0 0 10 20 30 Source-source Voltage VSS (V) 40 0 ISSS - VSS 5 10 15 Total Gate Charge Qg (nC) 20 Dynamic Input/Output Characteristics 10 Normalized Effective Transient Thermal Impedance tp tp D=― T 1 T Duty Cycle = 0.5 0.2 0.1 0.1 0.05 0.02 Single Pulse 0.01 0.0001 0.001 0.01 Ta = 25 °C, Mounted on FR4 board (25.4 × 25.4 × t1.0 mm) Surface Mounted on FR4 Board using the minimum recommended pad size 2 (Cu area = 47 mm including traces) 0.1 1 10 100 Square Wave Pulse Duration (s) Thermal Response 100 Limited by RSS(on) (VGS = 3.8 V) Single Pulse IS Source Current (A) Thermal Resistance Rth (°C/W) 1000 100 10 1 Ta = 25 °C, Mounted on FR4 board (25.4 × 25.4 × t1.0 mm) Surface Mounted on FR4 Board using the minimum 10 1 PW = 500 μs 1 ms 3 ms 0.1 0.01 recommended pad size(Cu area = 47 mm 2 including traces) 0.1 0.0001 0.001 0.1 1 10 100 1000 Pulse Width tsw (s) 100 ms 1s DC (Cu area = 47 mm2 including traces) 0.001 0.01 11 ms Ta = 25 °C, Mounted on FR4 board (25.4 × 25.4 × t1.0 mm). Surface Mounted on FR4 Board using the minimum recommended pad size 0.1 1 10 100 Source-source Voltage (V) Rth -tsw Safe Operating Area Ver. BED 5 FC4A22050L MBGA004-W-1717APA Unit: mm Land Pattern (Reference) (Unit: mm) Ver. BED 6 Request for your special attention and precautions in using the technical information and semiconductors described in this book (1) If any of the products or technical information described in this book is to be exported or provided to non-residents, the laws and regulations of the exporting country, especially, those with regard to security export control, must be observed. (2) The technical information described in this book is intended only to show the main characteristics and application circuit examples of the products. No license is granted in and to any intellectual property right or other right owned by Panasonic Corporation or any other company. Therefore, no responsibility is assumed by our company as to the infringement upon any such right owned by any other company which may arise as a result of the use of technical information described in this book. (3) The products described in this book are intended to be used for general applications (such as office equipment, communications equipment, measuring instruments and household appliances), or for specific applications as expressly stated in this book. Consult our sales staff in advance for information on the following applications: – Special applications (such as for airplanes, aerospace, automotive equipment, traffic signaling equipment, combustion equipment, life support systems and safety devices) in which exceptional quality and reliability are required, or if the failure or malfunction of the products may directly jeopardize life or harm the human body. It is to be understood that our company shall not be held responsible for any damage incurred as a result of or in connection with your using the products described in this book for any special application, unless our company agrees to your using the products in this book for any special application. (4) The products and product specifications described in this book are subject to change without notice for modification and/or improvement. At the final stage of your design, purchasing, or use of the products, therefore, ask for the most up-to-date Product Standards in advance to make sure that the latest specifications satisfy your requirements. (5) When designing your equipment, comply with the range of absolute maximum rating and the guaranteed operating conditions (operating power supply voltage and operating environment etc.). Especially, please be careful not to exceed the range of absolute maximum rating on the transient state, such as power-on, power-off and mode-switching. Otherwise, we will not be liable for any defect which may arise later in your equipment. Even when the products are used within the guaranteed values, take into the consideration of incidence of break down and failure mode, possible to occur to semiconductor products. Measures on the systems such as redundant design, arresting the spread of fire or preventing glitch are recommended in order to prevent physical injury, fire, social damages, for example, by using the products. (6) Comply with the instructions for use in order to prevent breakdown and characteristics change due to external factors (ESD, EOS, thermal stress and mechanical stress) at the time of handling, mounting or at customer's process. When using products for which damp-proof packing is required, satisfy the conditions, such as shelf life and the elapsed time since first opening the packages. (7) This book may be not reprinted or reproduced whether wholly or partially, without the prior written permission of our company. 20100202