KJE-3900

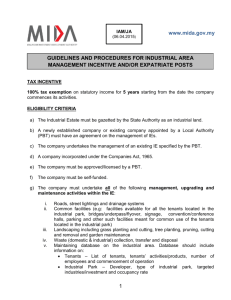

advertisement