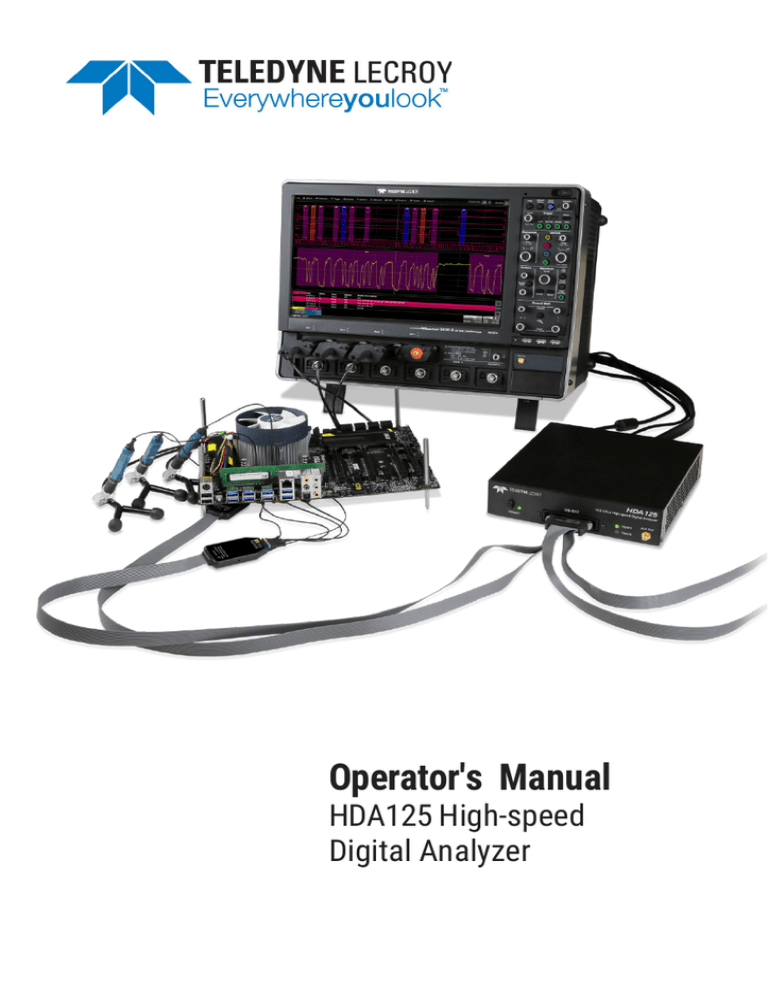

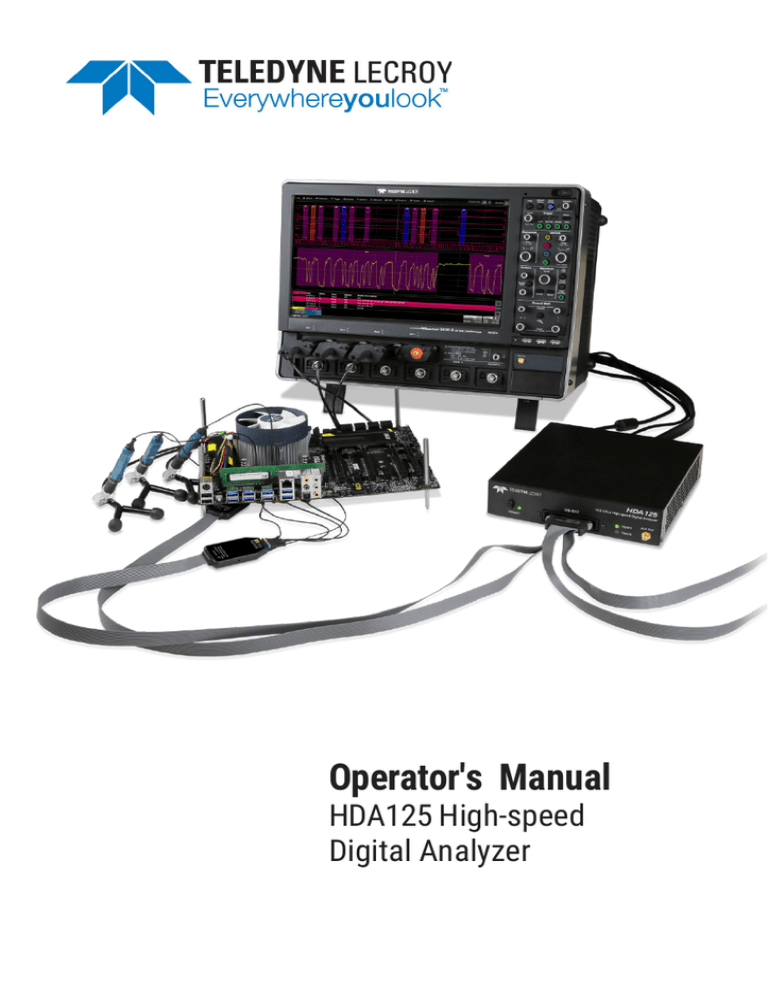

Operator's Manual

HDA125 High-speed

Digital Analyzer

HDA125 High-speed

Digital Analyzer

Operator's Manual

August, 2016

HDA125 High-speed Digital Analyzer Operator's Manual

© 2016 Teledyne LeCroy, Inc. All rights reserved.

Unauthorized duplication of Teledyne LeCroy documentation materials other

than for internal sales and distribution purposes is strictly prohibited. However,

clients are encouraged to distribute and duplicate Teledyne LeCroy

documentation for their own internal educational purposes.

HDA125, WaveSurfer, WaveRunner, WavePro, WaveMaster, LabMaster, and

Teledyne LeCroy are trademarks of Teledyne LeCroy, Inc. Other product or brand

names are trademarks or requested trademarks of their respective holders.

Information in this publication supersedes all earlier versions. Specifications are

subject to change without notice.

927294-00 Rev A

August, 2016

Operator’s Manual

Contents

Introduction .............................................................................................................................. 1

Safety........................................................................................................................................ 2

Technical Overview .................................................................................................................. 4

HDA125 Set Up ........................................................................................................................ 5

Standard Parts.................................................................................................................. 5

Oscilloscope Software ..................................................................................................... 5

Handling the Digital Leadset ........................................................................................... 6

Order of Operations .......................................................................................................... 6

Connecting the Digital Leadset ....................................................................................... 7

Connecting HDA125 to the Oscilloscope........................................................................ 8

Connecting QL-SI Tips to the Digital Leadset ............................................................... 10

Connecting QL-SI Tips to the QuickLink Adapter ......................................................... 11

Deskewing ....................................................................................................................... 12

Digital Setup ........................................................................................................................... 16

Digital Logic Setup ......................................................................................................... 16

Digital Group Setup ........................................................................................................ 17

Renaming Digital Lines .................................................................................................. 18

Displaying Digital Traces ............................................................................................... 18

Digital Triggering.................................................................................................................... 20

Accessing the Trigger Dialogs ....................................................................................... 20

Edge Trigger .................................................................................................................... 20

Pattern Trigger ................................................................................................................ 21

Maintenance........................................................................................................................... 23

Cleaning .......................................................................................................................... 23

Calibration ....................................................................................................................... 23

Firmware Updates .......................................................................................................... 23

Technical Support .......................................................................................................... 24

Returning a Product for Service ...................................................................................... 25

Certifications .......................................................................................................................... 26

Warranty ................................................................................................................................. 29

Contact Us .............................................................................................................................. 30

Notes ...................................................................................................................................... 31

i

HDA125 High-speed Digital Analyzer

Welcome

Thank you for purchasing a Teledyne LeCroy HDA125 High-speed Digital

Analyzer.

The HDA125 is a powerful solution for the challenge of measuring multiple,

mixed signals in a single oscilloscope. An accessory for the Teledyne LeCroy Zi

series oscilloscopes, the HDA125 extends their testing range by adding 9 or 18

digital channels for waveform display or triggering.

This manual assumes that you have a basic understanding of discrete

electronics, logic analyzers, and Teledyne LeCroy oscilloscopes, specifically the

model you will use with the HDA125. When necessary, details on specific

oscilloscope features are included in this manual.

Contact your nearest Teledyne LeCroy customer service center or national

distributor if anything is missing or damaged. We can only be responsible for

replacement if you contact us immediately.

Sincerely,

David C. Graef

Vice President and General Manager, Oscilloscopes

ii

Operator’s Manual

Introduction

The HDA125 High-speed Digital Analyzer is a complete system that adds digital

acquisition and triggering capabilities to Teledyne LeCroy Zi series oscilloscopes.

The HDA125 is optimized for acquiring high-speed digital signals, with a sample

rate of 12.5 GS/s on all 18 input channels. Accurate digital interpretation of highfrequency analog signals is ensured by the high input sensitivity (150 mV

minimum signal swing) and low-loading, oscilloscope-style QuickLink probing

system.

The HDA125 is ideally suited for embedded system testing where there is a

proliferation of analog signals coincident with digital signals. You can easily

debug signals using standard oscilloscope tools such as cursors, measurement

parameters, and zooming.

Oscilloscopes compatible with the HDA125 feature large, bright color displays

to facilitate signal viewing, plus all the connectivity and documentation

capabilities needed to quickly record and distribute information.

Compatibility

The HDA125 is compatible with LabMaster 9 Zi and 10 Zi systems,

WaveMaster 8 Zi, WavePro 7 Zi, and WaveRunner 6 Zi series oscilloscopes

equipped with LBUS.

It is not compatible with WaveRunner 8000, HDO, MDA, WaveSurfer 3000 or

other legacy model oscilloscopes.

Specifications

Detailed specifications are listed on the product datasheet at

teledynelecroy.com. Specifications are subject to change without notice.

Operating Environment

Temperature:

5 to 40 °C

Humidity:

Maximum relative humidity 80% (non-condensing) for

temperatures up to 31° C, decreasing linearly to 50% relative

humidity at 40° C

Altitude:

Up to 2,000 m

1

HDA125 High-speed Digital Analyzer

Safety

Observe these instructions to keep the product operating in a correct and safe

condition. Follow generally accepted safety procedures in addition to the

precautions specified here. The overall safety of any system incorporating this

product is the responsibility of the assembler of the system.

Symbols

These symbols appear on the product or in its documentation to alert you to

important safety considerations.

CAUTION of potential damage to product, or WARNING of potential

bodily injury. Attend to the accompanying information to protect against

injury or damage. Do not proceed until conditions are fully understood

and met.

High-voltage WARNING. Risk of electric shock or burn.

Electrostatic discharge (ESD) hazard CAUTION. Contains parts and

assemblies susceptible to damage if anti-static measures are not taken.

Measurement ground connection.

Safety (protective) ground connection.

Alternating current.

Direct current.

Precautions

Use proper power supply adapter. Use only the AC adapter shipped with this

instrument. Using an alternate AC adapter can potentially damage the instrument

due to pin out variations among external AC adapters.

Use proper power cord. Use only the power cord shipped with this instrument and

certified for country of use.

Maintain ground. This product is grounded through the power cord grounding

conductor. To avoid electric shock, connect the external AC adapter only to a

2

Operator’s Manual

grounded mating outlet.

Connect and disconnect properly. Do not connect/disconnect probes or test leads

while they are connected to a live voltage source.

Exercise electrostatic discharge (ESD) precautions. The digital leadsets and probe

tips are sensitive to ESD. When making connections to the device under test,

always wear a grounding wrist strap.

Handle with care. Avoid putting excessive strain on any cable or probe tips. Avoid

bending cables sharply. Prevent damage to the solder-in probe tips by carefully

storing them in the plastic protective storage case when not in use.

Observe all terminal ratings. Do not apply a voltage to any input that exceeds the

maximum rating of that input. Refer to the front of the instrument for maximum

input ratings.

Use indoors only. The accessory is intended for indoor use and should be

operated in a clean, dry, environment. Do not use in wet/damp or explosive

atmospheres.

Keep product surfaces clean and dry. See Cleaning on p.23 for instructions.

Do not block the cooling vents.

Do not remove the covers or inside parts. Refer all service to qualified service

personnel.

Do not operate with suspected failures. Do not use the product if any part is

damaged. Obviously incorrect measurements behaviors might indicate

impairment due to hazardous live electrical quantities. Cease operation

immediately and sequester the instrument from inadvertent use.

Cooling

The instrument relies on forced air cooling with internal fans and vents. Internal

fan control circuitry regulates the fan speed based on the ambient temperature.

This is performed automatically after start up.

Take care to avoid restricting the air flow to any part of the instrument. Around

the sides and rear, leave a minimum six-inch (15 cm) gap between the

instrument and the nearest object. The feet provide adequate bottom clearance.

Do not block the cooling vents. Always keep the area beneath the

instrument clear of paper and other objects.

3

HDA125 High-speed Digital Analyzer

Technical Overview

The HDA125 is an external device that digitally samples waveform data at up to

12.5 GS/s (enabling acquisition of digital signals up to 6 Gb/s). Unlike a logic

analyzer, it operates only in a Timing Analysis mode, so it requires oversampling

to determine the correct digital edge position, and does not require the user to

input a clock.

While in SINGLE or NORMAL, trigger mode, the HDA125 repeatedly samples

each digital channel’s voltage level. If the voltage is greater than the threshold

voltage, the HDA125 stores a 1 in internal memory. Otherwise, a 0 is stored.

The threshold voltage at which a signal is classified as a digital 0 or 1 value is

set by the user – the value can range from -5V to +5V with 5mV setting

resolution. A hysteresis control is also available, with a minimum value of 50mV

(for very fast signals) and a maximum value of 600mV (for very noisy signals).

Digital signals can also be deskewed to accommodate staggered probing

configurations. All of these adjustments can be made on a per-channel basis.

The HDA125 keeps sampling its inputs until the oscilloscope is put into STOP

trigger mode. Data is stored in internal memory that is periodically transferred

to the oscilloscope via the USB3.1 cable. If the oscilloscope is triggering in

SINGLE or NORMAL trigger mode, data is acquired and transferred only when

the trigger condition is satisfied. The captured data is then displayed on the

oscilloscope grid in a time-aligned fashion.

The HDA125 both samples incoming data and searches for trigger conditions.

The USB3.1 cable provides downloading of trigger conditions from the

oscilloscope to the HDA125 and uploading of digital data from the HDA125 to

the oscilloscope.

4

Operator’s Manual

HDA125 Set Up

Standard Parts

The HDA125 is delivered as either a 9-channel kit or an 18-channel kit with the

following hardware.

Parts

HDA125-18LBUS

HDA125-09LBUS

HDA125-18SYNC

HDA125-09SYNC

HDA125 High-speed Digital Analyzer

1

1

1

1

HDA-DLS-18QL 18-channel Digital Leadset

1

0

1

0

HDA-DLS-18QL 9-channel Digital Leadset

0

1

0

1

QuickLink Solder-in Tips (QL-SI)

18

9

18

9

LBUS Cable

1

1

0

0

SYNC Cable

0

0

1

1

BNC Cable

0

0

1

1

USB3 Cable

1

1

1

1

Power Cable

1

1

1

1

PCF200 Deskew Fixture

1

1

1

1

Replacement Tip Resistors

10

5

10

5

Adhesive Pads

40

20

40

20

QuickLink Tip Labels

40

20

40

20

Oscilloscope Software

The HDA125 requires version 8.1.x.x or higher of the oscilloscope system

software in order to be correctly recognized. We always recommend using the

latest version of software on your oscilloscope, available for free at:

teledynelecroy.com/support/softwaredownload

5

HDA125 High-speed Digital Analyzer

Handling the Digital Leadset

Exercise care when handling and storing the digital leadset and QuickLink

solder-in tips. Avoid putting excessive strain on any cable or interconnect lead

or bending the cables sharply. Store the solder-in probe tips in the plastic

protective storage case when not in use.

The digital leadset and probe tips are sensitive to Electrostatic

Discharge (ESD). Avoid causing damage by always following anti-static

procedures (wear wrist strap, etc.) when using or handling the

equipment.

Order of Operations

To ensure that all components (HDA125 and leadset) are correctly identified by

the system software, the following order of operations is recommended:

1. Close the oscilloscope application, or shut down the oscilloscope.

2. Connect the digital leadset to the HDA125.

3. Connect the HDA125 to the oscilloscope.

4. Power up the HDA125.

5. Launch the oscilloscope application (or power up the oscilloscope if it

was powered down).

6

Operator’s Manual

Connecting the Digital Leadset

Connect the digital leadset to the digital input on the front of the HDA125. Push

the connector until it “snaps” into place.

When removing the leadset, press the tabs on both sides of the connector head,

then pull out.

Press in tabs to remove the digital leadset.

7

HDA125 High-speed Digital Analyzer

Connecting HDA125 to the Oscilloscope

Oscilloscopes with an LBUS Interface

Connect the LBUS cable from the LBUS connector on the back of the HDA125 to the

LBUS connector on the back of the oscilloscope. Be sure the head is turned so

that the wedge fits into the groove at the top of the connector. Fasten the

thumb screws.

Connect the USB3 cable into USB ports on both instruments.

NOTE: The USB3 cable will work on oscilloscopes with USB2 ports, but the

transfer speed will be reduced. We recommend using the rear USB3 ports on

WaveMaster 8 Zi-B oscilloscopes.

Connect the power cable to DC IN and plug it into a grounded outlet.

Back of HDA125 with cables attached

8

Operator’s Manual

Oscilloscopes with a ChannelSync Interface

The ChannelSync interface is used to connect the HDA125 to LabMaster

systems.

NOTE: In systems based on the LabMaster Master Control Module, be sure to

connect at least one Acquisition Module to the MCM Zi (as described in the

LabMaster Operator’s Manual) before connecting the HDA125.

1. Connect the SYNC cable from the first available SYNC connector on the

LabMaster MCM Zi to the SYNC connector on the HDA125.

2. Connect the BNC cable from the “REF OUT 10 MHz” connector on the

back of the MCM Zi to the “REF IN/OUT” connector on the back of the

HDA125.

3. Connect the USB3 cable into USB ports on both instruments.

4. Connect the power cable to DC IN and plug it into a grounded outlet.

9

HDA125 High-speed Digital Analyzer

Connecting QL-SI Tips to the Digital Leadset

Solder the QL-SI tips to the device under test, then insert the connector head of

the tip into the leadset pod, matching the tip color to the port color.

Inserting QL-SI tips into the digital leadset pod.

The tips use five repeating colors. You can change the color-coding clips on the

tips if desired to switch them into different ports after soldering.

For 9 channels, connect five tips to one pod and four tips to the other pod.

For 18 channels, repeat the sequence using all four pods.

10

Operator’s Manual

Connecting QL-SI Tips to the QuickLink Adapter

Any QL-SI tip can be connected to a WaveLink™ Low-bandwidth or Mediumbandwidth Modular Differential Probe using the QuickLink™ Adapter (sold

separately from the HDA125) in order to view the signal as an analog waveform.

There is no need to remove the tip from the device under test; just remove the

QL-SI connector head from the digital leadset pod and insert it into the

QuickLink Adapter.

Switching a QL-SI tip to a WaveLink probe using the QuickLink Adapter.

11

HDA125 High-speed Digital Analyzer

Deskewing

Before using the HDA125, it is crucial to deskew the signal path to ensure

proper signal timing.

Since the HDA125 is typically used in embedded applications, it is assumed that

it will be used in conjunction with differential analog probes capturing signals

on the oscilloscope’s analog channels. The deskew procedure outlined here is

optimized for this use-case, but can be easily adapted for other situations.

Note that for the same reasons, the default “reference plane” for signals

acquired by the HDA125 corresponds to the nominal propagation delay of a

Teledyne LeCroy WaveLink probe. This means that only fine-grained deskew

should be necessary when the HDA125 is being used in conjunction with

WaveLink probes.

Required Equipment

•

WaveLink probe(s)

•

PCF200

•

50 Ω terminator

NOTE: Alternatively, an LPA-K-A adapter and an SMA cable can be used

to terminate the PCF200 into an available oscilloscope channel.

12

Operator’s Manual

Methodology

Before beginning, warm the oscilloscope for at least 20 minutes.

1. Set the V/div and offset of the analog channels appropriately for the

signal to be acquired. On the Channel Probe dialog, be sure to make the

correct selection for the tips you are using.

2. Connect the upper signal path of the PCF200 (with the black clip) to the

oscilloscope’s Fast Edge output.

3. Attach a QL-SI tip (not already attached to your test board) to the

PCF200 by placing the solder-in tips under the clip. The positive side

must be connected to the signal trace (in between the two white strips),

while the negative side is connected to the ground plane (outside of the

white strips). The positive polarity is indicated on the tip by a plus sign.

4. Apply a 50 Ω terminator to the end of the upper signal path. If a 50 Ω

terminator is not available, an SMA cable can be used to terminate the

PCF200 to one of the oscilloscope’s outputs.

5. Connect the QL-SI tip to one of the empty slots in the HDA125

connector pods.

6. Go to Vertical > Digital1 Setup and create the Digital1 group with only

the line that you connected to the PCF200. Turn on the Digital1 Line

display. See the procedures later in this manual for instructions.

7. On the Logic Setup tab, set the line’s Threshold to -100 mV.

8. Touch the Trigger descriptor box to open the Trigger dialog. Set the

oscilloscope Trigger Type to “Edge”, the Trigger Source to “FastEdge”.

13

HDA125 High-speed Digital Analyzer

9. Touch the Timebase descriptor box to open the Timebase dialog. Adjust

the timebase to about 2 ns/div so that a rising or falling edge can be

seen on screen. Set timebase Delay to 0.

Once everything is properly set up, the oscilloscope display should look

similar to the figure below.

10. Touch the Digital1 descriptor box to open the Digital1 dialog, then touch

Store to save the FastEdge trace to memory.

11. Disconnect the HDA125 connector pod from the PCF200 adapter, and

connect the first probe to be deskewed.

14

Operator’s Manual

12. Touch the Cx descriptor box to open the channel dialog and adjust the

channel’s Deskew value so that the 50% rising edge point matches the

rising edge stored in memory, as shown below:

13. Now, decrease the timebase to around 20 ps/div and adjust the Deskew

value so that the 50% rising edge point is centered in time.

14. Repeat Steps 11 through 13 for each probe to be used.

15

HDA125 High-speed Digital Analyzer

Digital Setup

After the physical connections are made, on the oscilloscope go to Vertical >

Digital1 Setup to access the mixed-signal setup dialogs.

Digital Logic Setup

The Digital Logic Setup tab allows configuration of the logic acquisition system,

affecting how the probed analog input signals are interpreted as digital data.

For each digital line, enter the logic threshold level, hysteresis level, and

digital skew.

NOTE: None of these adjustments are “software only”–all take place directly in

the digital acquisition system, so they will affect triggering. This means that the

skew controls in particular are extremely useful for coping with probes that

have been soldered in a “staggered” fashion.

Threshold Level

The threshold level determines how the input signal is interpreted. Input

voltages less than the threshold are converted to 0, while input voltages greater

than the threshold are converted to 1.

Levels can be set between –5.0 V and +5.0 V.

Hysteresis (Minimum Voltage Swing)

The default hysteresis setting is 100 mV, and should work well on most signals.

If an input signal is very noisy, you may wish to increase the hysteresis to make

the digital acquisition less noise-sensitive. If the input signal is very high-speed

but low-amplitude, a lower hysteresis value is recommended to ensure correct

interpretation of logic levels.

Skew

The Skew setting is useful in cases where the HDA125 is being used to acquire

several signals that are time-aligned, but the QL-SI tips have been soldered to

the bus in a “staggered” fashion, thus introducing skew between the signals.

The Skew setting allows these signals to be realigned in hardware, enabling

correct interpretation and triggering.

NOTE: The intrinsic skew of the HDA125 inputs is extremely low, less than 1 sample

period, so there is no need to use this setting to correct for instrument skew.

16

Operator’s Manual

Digital Group Setup

This procedure organizes the digital lines into groups, which correspond to

buses. Lines generally correspond to the physical QL-SI tips, although any tip

can be assigned to any line number (and color) to make it easier to assemble

groups without having to disconnect tips from the test device.

You can set up a total of four, distinct groups: Digital1 to Digital4. Each group is

designated by its own Digital setup dialog. Lines can be assigned to one or

more digital groups.

1. Go to Vertical > Digital 1 Setup to Display the Digital Setup dialogs.

2. Open the dialog for the group you wish to configure (e.g., Digital1).

3. Check the box for each line to be added to the group. If you do not see

the line number, touch the Left or Right Arrow button until it is shown.

Use the All Lines Off and All Lines On buttons to quickly deselect/select

lines.

Along the bottom of the dialog is a line activity indicator for each line. All 18

possible lines are shown on the dialog, even if only D0-D8 are active. As lines

are added to the group, the indicator is enabled, so you can always see which

lines are currently in the group, even if their button is not displayed.

17

HDA125 High-speed Digital Analyzer

Renaming Digital Lines

You can give each line a user-defined name to make the interface more intuitive.

Touch the Dx button immediately below the Dx selection checkbox (the words

"Change Line Name" appear at the far left of the row). Use the virtual keyboard

that appears on the touch screen to enter a new name. When finished, click OK.

The new line name now appears on the Dx button, instead of the original line

number. The number remains over the checkbox.

NOTE: The number of letters that appear will depend on the resolution of your

oscilloscope display. Keep names short so lines are easily identifiable.

Displaying Digital Traces

When Trace On is enabled, digital Line traces show the state of each line relative

to the threshold.

Individual traces may be displayed by checking the box below the line number

(D0-D17). The D0-D8 and D9-D17 buttons display the controls for each lead

bank.

Position Traces

In Position, enter the number of divisions (positive or negative) relative to the

zero line of the grid where the digital display begins. The top of the first trace

appears at this position.

In Line Height, enter the total number of grid divisions each line should occupy.

The selected traces (Line or Bus) will appear in this much space.

Individual traces are resized to fit the total number of divisions available. In the

example below, each trace takes up one division.

To move the entire group of traces to another grid, touch the Next Grid button at

the bottom right of the dialog.

18

Operator’s Manual

Change Trace Style

You can also change the Display Mode setting to view a digital Bus trace that

collapses all the lines in a group into their Hex values, or both Lines and Bus.

The size and placement of the lines depend on the number of lines, and the

Vertical Position and Line Height settings.

Digital line traces 1 division high starting at position 4 (top of grid).

Digital Bus trace 1 division high starting at position 4.

Store Display

To store the entire group and display setup to an internal memory, touch the

Store button at the far right of the dialog. You can recall this setup to the grid in

the future by choosing Math > Memory Setup and selecting Trace On for the

respective memory.

19

HDA125 High-speed Digital Analyzer

Digital Triggering

Accessing the Trigger Dialogs

To access the Trigger setup dialogs, do one of the following:

•

Touch the Trigger descriptor box

•

Press the front panel Trigger Setup button

•

Choose Trigger > Trigger Setup from the menu bar

The main Trigger dialog contains the trigger type selections. Other controls will

appear depending on the trigger type selection (e.g., Slope for Edge triggers).

These are described in the set up procedures for each trigger.

Edge Trigger

Edge triggers upon a achieving a certain voltage level in the positive or negative

slope of the waveform. It is the default trigger selection on standard

oscilloscopes.

On the Trigger dialog, select Edge trigger type to display the controls.

1. Choose the Source digital line.

2. Choose the Slope (edge) upon which to trigger.

3. If you’ve not yet set up logic, touch Go to Digital Logic Setup and set the

Threshold, Hysteresis, and Skew on the trigger source line.

20

Operator’s Manual

Pattern Trigger

Digital Pattern is the default trigger when the HDA125 is connected to the

oscilloscope.

However, a Pattern trigger can also be set on a user-defined pattern of High or

Low voltage levels on analog channels (including the External Trigger input), or

a combination of digital and analog patterns.

On the Trigger dialog, select Pattern trigger type. Open the Digital Pattern dialog

to display the controls.

Digital Pattern Using Logic Bus

The Logic Bus method simplifies pattern set up by utilizing digital groups and

logic you have already defined on the Digital Setup dialogs. A digital pattern is

set on a single bus (group) manually or by applying a hexadecimal value, while

the remaining lines are disabled ("Don't Care").

1. At the far right of the Digital Pattern dialog, choose Logic Bus.

2. Select the digital group as the Source.

3. Enter the hex Value that defines the pattern.

21

HDA125 High-speed Digital Analyzer

Digital Pattern Using Logic

If you have not set up digital groups, you can set a digital pattern line by line

using the Logic method. All available lines remain active for selection.

1.

At the far right of the Digital Pattern dialog, choose Logic.

2. Optionally, deselect Filter Out Unstable Conditions. This default filter

ignores short glitches in logic state triggers that last less than 320 ps.

This is useful in the case where the transition between logic states is

not entirely synchronized, causing unintended states to be acquired

during transitions.

3. Enter the Hex value of the pattern. Lines will take a logical 1, 0, or X

("Don't Care") according to the pattern. Disabled lines will remain X.

4. Touch the Dx button for each active line, and select whether it must be

High or Low compared to the logic threshold. Depending on your

selection, a logical 1 (High) or 0 (Low) now appears on the dialog. Leave

X selected for any line you wish to exclude from the pattern.

TIP: Use the Left and Right Arrow buttons to display other digital lines.

Edge Conditions

As an alternative to a digital logic pattern, you may set edge conditions on any

line. Touch the Dx button and choose the edge. Edge conditions always assume

a logical OR in the overall trigger criteria.

Logic Setup

If you have not already set up group logic, open the Levels dialog and touch Go

to Digital Logic Setup. Set the Threshold, Hysteresis, and Skew for each line.

See Digital Logic Setup.

NOTE: Digital lines inherit the Logic Setup made when defining digital groups.

22

Operator’s Manual

Maintenance

Cleaning

Clean only the exterior of the product using a soft cloth moistened with water or

an alcohol solution. Do not use harsh chemicals or abrasive elements. Under no

circumstances submerge the device or allow moisture to penetrate it.

CAUTION. Do not attempt to clean internal parts. Refer to qualified

service personnel.

Calibration

Your HDA125 hardware does not need periodic calibration.

However, we do recommend that the oscilloscope used with the HDA125 be

returned for annual factory calibration. See Returning a Product for Service.

Firmware Updates

Teledyne LeCroy offers state-of-the-art performance by continually improving

our oscilloscope capabilities. We release frequent oscilloscope firmware updates

that include accessory support.

Download free firmware updates for your oscilloscope platform from:

teledynelecroy.com/support/softwaredownload

Because our software is continually changing, and accessories often may be

used with several different oscilloscopes, the dialogs you see in this manual may

not exactly match what is seen on your oscilloscope. Rest assured, however,

that the functionality is the same. Where relevant, we will note platform-specific

information in the instructions.

23

HDA125 High-speed Digital Analyzer

Technical Support

Phone

Registered users can contact their local Teledyne LeCroy service center at the

number listed in this manual to make Technical Support requests by phone or

email.

Web

You can also submit Technical Support requests via the website at:

teledynelecroy.com/support/techhelp

Teledyne LeCroy publishes a free Technical Library on its website. Manuals,

tutorials, application notes, white papers, and videos are available to help you

get the most out of your Teledyne LeCroy products. Go to:

teledynelecroy.com/support/techlib

The Datasheet published on the product page contains the detailed product

specifications.

24

Operator’s Manual

Returning a Product for Service

Contact your local Teledyne LeCroy service center for calibration or other

service. If the product cannot be serviced on location, the service center will

give you a Return Material Authorization (RMA) code and instruct you where to

ship the product. All products returned to the factory must have an RMA.

Return shipments must be prepaid. Teledyne LeCroy cannot accept COD or

Collect shipments. We recommend air-freighting. Insure the item you’re

returning for at least the replacement cost.

1. Remove all accessories from the device. Do not include the manual.

2. Pack the product in its case, surrounded by the original packing

material (or equivalent).

3. Label the case with a tag containing:

•

The RMA

•

Name and address of the owner

•

Product model and serial number

•

Description of failure or requisite service

4. Pack the product case in a cardboard shipping box with adequate

padding to avoid damage in transit.

5. Mark the outside of the box with the shipping address given to you by

Teledyne LeCroy; be sure to add the following:

•

ATTN: <RMA code assigned by Teledyne LeCroy>

•

FRAGILE

6. If returning a product to a different country:

•

Mark the shipment as a "Return of US manufactured goods for

warranty repair/recalibration."

•

If there is a cost for the service, list the cost in the Value column

and the original purchase price "For insurance purposes only."

•

Be very specific about the reason for shipment. Duties may have to

be paid on the value of the service.

25

HDA125 High-speed Digital Analyzer

Certifications

Teledyne LeCroy certifies compliance to the following standards as of the time

of publication. For the most current certifications, please see the EC Declaration

of Conformity certificate shipped with your product.

EMC Compliance

EC DECLARATION OF CONFORMITY - EMC

The product meets the intent of EC Directive 2014/30/EU for Electromagnetic

Compatibility. Compliance was demonstrated to the following specifications as

listed in the Official Journal of the European Communities:

EN 61326-1:2013, EN 61326-2-1:2013 EMC requirements for electrical

1

equipment for measurement, control, and laboratory use.

Electromagnetic Emissions:

23

EN 55011:2010, Radiated and Conducted Emissions Group 1, Class A

EN 61000-3-2/A2:2009 Harmonic Current Emissions, Class A

EN 61000-3-3:2008 Voltage Fluctuations and Flickers, Pst = 1

Electromagnetic Immunity:

EN 61000-4-2:2009 Electrostatic Discharge, 4 kV contact, 8 kV air, 4 kV

4

vertical/horizontal coupling planes

EN 61000-4-3/A2:2010 RF Radiated Electromagnetic Field, 3 V/m, 80-1000 MHz;

3 V/m, 1400 MHz - 2 GHz; 1 V/m, 2 GHz - 2.7 GHz

EN 61000-4-4/A1:2010 Electrical Fast Transient/Burst, 1 kV on power supply

4

lines, 0.5 kV on I/O signal data and control lines

4

EN 61000-4-5:2006 Power Line Surge, 1 kV AC Mains, L-N, L-PE, N-PE

EN 61000-4-6:2009 RF Conducted Electromagnetic Field, 3 Vrms, 0.15 MHz-80 MHz

EN 61000-4-11:2004 Mains Dips and Interruptions, 0%/1 cycle, 70%/25 cycles,

45

0%/250 cycles

1. To ensure compliance with applicable EMC standards, use high quality shielded interface cables.

2. Emissions which exceed the levels required by this standard may occur when the instrument is

connected to a test object.

3. This product is intended for use in nonresidential areas only. Use in residential areas may cause

electromagnetic interference.

4. Meets Performance Criteria “B” limits of the respective standard: during the disturbance, product

undergoes a temporary degradation or loss of function or performance which is self-recoverable.

5. Performance Criteria “C” applied for 70%/25 cycle voltage dips and 0%/250 cycle voltage

interruption test levels per EN61000-4-11.

26

Operator’s Manual

European Contact:*

Teledyne LeCroy Europe GmbH

Im Breitspiel 11c

D-69126 Heidelberg

Germany

Tel: (49) 6221 82700

AUSTRALIA & NEW ZEALAND DECLARATION OF CONFORMITY—EMC

The product complies with the EMC provision of the Radio Communications Act

per the following standards, in accordance with requirements imposed by

Australian Communication and Media Authority:

AS/NZS CISPR 11:2011 Radiated and Conducted Emissions, Group 1, Class A.

Australia / New Zealand Contacts:*

RS Components Pty Ltd.

Suite 326 The Parade West

Kent Town, South Australia 5067

RS Components Ltd.

Unit 30 & 31 Warehouse World

761 Great South Road

Penrose, Auckland, New Zealand

* Visit teledynelecroy.com/support/contact for the latest contact information.

Safety Compliance

EC DECLARATION OF CONFORMITY—LOW-VOLTAGE

The product meets intent of EC Directive 2014/35/EU for Product Safety.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61010-1:2010 Safety requirements for electrical equipment for

measurement, control, and laboratory use – Part 1: General requirements

EN 61010-2:030:2010 Safety requirements for electrical equipment for

measurement, control, and laboratory use – Part 2-030: Particular requirements

for testing and measuring circuits

EN 61010-031:2015 Safety requirements for electrical equipment for

measurement, control, and laboratory use – Part 031: Safety requirements for

hand-held probe assemblies for electrical measurement and test

27

HDA125 High-speed Digital Analyzer

Environmental Compliance

END-OF-LIFE HANDLING

The product is marked with this symbol to indicate that it complies

with the applicable European Union requirements to Directives

2012/19/EU and 2013/56/EU on Waste Electrical and Electronic

Equipment (WEEE) and Batteries.

The product is subject to disposal and recycling regulations that vary

by country and region. Many countries prohibit the disposal of waste electronic

equipment in standard waste receptacles. For more information about proper

disposal and recycling of your Teledyne LeCroy product, please visit

teledynelecroy.com/recycle.

RESTRICTION OF HAZARDOUS SUBSTANCES (ROHS)

The product and its accessories conform to the 2011/65/EU RoHS2 Directive.

28

Operator’s Manual

Warranty

THE WARRANTY BELOW REPLACES ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS, OR ADEQUACY FOR ANY PARTICULAR PURPOSE

OR USE. TELEDYNE LECROY SHALL NOT BE LIABLE FOR ANY SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER IN CONTRACT OR

OTHERWISE. THE CUSTOMER IS RESPONSIBLE FOR THE TRANSPORTATION

AND INSURANCE CHARGES FOR THE RETURN OF PRODUCTS TO THE SERVICE

FACILITY. TELEDYNE LECROY WILL RETURN ALL PRODUCTS UNDER

WARRANTY WITH TRANSPORT PREPAID.

The product is warranted for normal use and operation, within specifications, for

a period of three years from shipment. Teledyne LeCroy will either repair or, at

our option, replace any product returned to one of our authorized service

centers within this period. However, in order to do this we must first examine

the product and find that it is defective due to workmanship or materials and

not due to misuse, neglect, accident, or abnormal conditions or operation.

Teledyne LeCroy shall not be responsible for any defect, damage, or failure

caused by any of the following: a) attempted repairs or installations by

personnel other than Teledyne LeCroy representatives or b) improper

connection to incompatible equipment, or c) for any damage or malfunction

caused by the use of non-Teledyne LeCroy supplies. Furthermore, Teledyne

LeCroy shall not be obligated to service a product that has been modified or

integrated where the modification or integration increases the task duration or

difficulty of servicing the oscilloscope. Spare and replacement parts, and

repairs, all have a 90-day warranty.

Products not made by Teledyne LeCroy are covered solely by the warranty of the

original equipment manufacturer.

29

HDA125 High-speed Digital Analyzer

Contact Us

For a complete list of offices by country, including our sales & distribution partners, visit:

teledynelecroy.com/support/contact

Teledyne LeCroy

700 Chestnut Ridge Road

Chestnut Ridge, NY, 10977, USA

teledynelecroy.com

Sales and Service:

Ph: 800-553-2769 / 845-425-2000

FAX: 845-578-5985

contact.corp@teledynelecroy.com

Support:

Ph: 800-553-2769

customersupport@teledynelecroy.com

30

Operator’s Manual

Notes

31

HDA125 High-speed Digital Analyzer

32

927294-00 Rev A

August, 2016