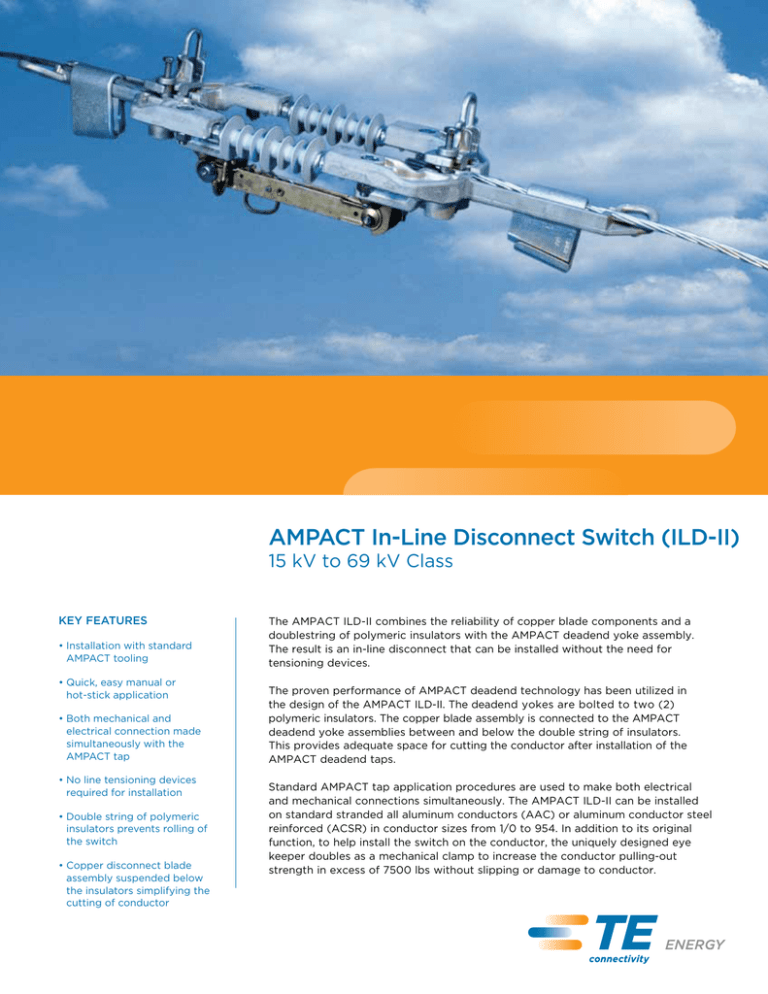

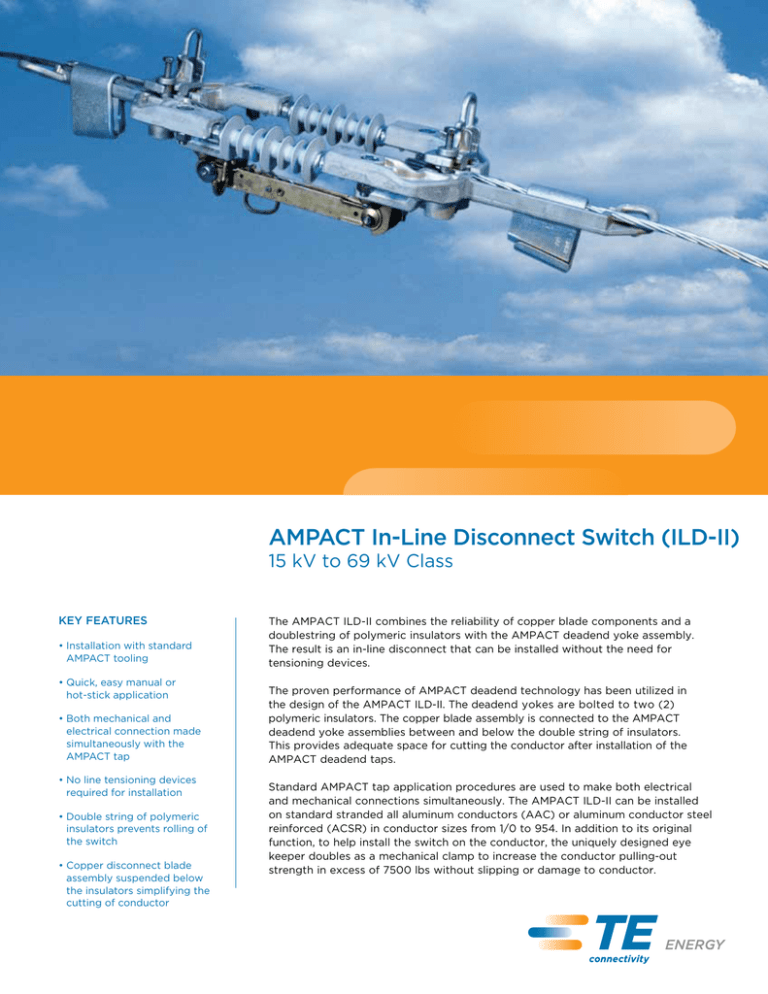

AMPACT In-Line Disconnect Switch (ILD-II)

15 kV to 69 kV Class

KEY FEATURES

•Installation with standard

AMPACT tooling

•Quick, easy manual or hot-stick application

•Both mechanical and electrical connection made

simultaneously with the AMPACT tap

•No line tensioning devices

required for installation

•Double string of polymeric

insulators prevents rolling of the switch

•Copper disconnect blade

assembly suspended below the insulators simplifying the

cutting of conductor

The AMPACT ILD-II combines the reliability of copper blade components and a doublestring of polymeric insulators with the AMPACT deadend yoke assembly. The result is an in-line disconnect that can be installed without the need for tensioning devices.

The proven performance of AMPACT deadend technology has been utilized in the design of the AMPACT ILD-II. The deadend yokes are bolted to two (2)

polymeric insulators. The copper blade assembly is connected to the AMPACT

deadend yoke assemblies between and below the double string of insulators. This provides adequate space for cutting the conductor after installation of the

AMPACT deadend taps.

Standard AMPACT tap application procedures are used to make both electrical

and mechanical connections simultaneously. The AMPACT ILD-II can be installed

on standard stranded all aluminum conductors (AAC) or aluminum conductor steel

reinforced (ACSR) in conductor sizes from 1/0 to 954. In addition to its original

function, to help install the switch on the conductor, the uniquely designed eye

keeper doubles as a mechanical clamp to increase the conductor pulling-out

strength in excess of 7500 lbs without slipping or damage to conductor.

TE Connectivity

AMPACT In-Line Disconnect Switch (ILD-II)

The integral pulling eye on the body of

the AMPACT deadend yoke assembly

is provided to the attachment of line

tensioning devices if removal of the

AMPACT ILD switch is required. The

tensile rating of the pulling eye is 6,000 lbs, while the AMPACT dead-

end yoke assembly is rated at 10,000 lbs tensile.

Electrical ratings are provided in the

performance characteristic tables.

back, or if using the new keepers, it can

be cut flush on each end.

The unique AMPACT ILD design allows for positioning of cutters between the double insulator assembly. The conductor can be cut between the AMPACT deadend yoke assemblies and the ends bent • A load break tool can be used up to 35 kv utilizing the attachment

hooks provided.

Performance Characteristics

Technical Documents

Approvals

Voltage: 15 kV (110 kV BIL), 29 kV (150 kV BIL), 35 kV (200 kV BIL), 46 kV (250 BIL), 69 kV (350 kV BIL)

Current: 900

Frequency: 60Hz

Momentary Current: 40,000 Amps

Short Time Current: 25,000 Amps, 3 sec.

Instruction Sheet: PII 56078

Engineering Test Report: 502-47376

RUS Listed

ANSI: C119.4, C37.32, C37.34

IEEE: C37.30

CSA: C83.71

Conductors Accommodated

Replacements

Taps

Construction

Part numbers shown below use

Victor Insulators and Royal Blades except when otherwise indicated.

15 kV, 110 kV BIL

1/0

1-83843-0

1710723-1

SMALL

3/0 (6/1)

4/0 (6/1)

4/0

83843-7

1710723-2

SMALL

266.8 (18/1)

266.8

83843-1

1710723-3

SMALL

266.8 (26/7)

336.4 (18/1),

(26/7), (30/7)

397.5,

336.4, 350

83843-2

1710723-4

LARGE

397.5 (18/1),

(24/7), (26/7),

(30/7)

477.0 (18/1)

450, 477,

500

83843-3

1710723-5

477.0 (26/7)

556.5 (18/1)

556.5

83843-4

1710723-6

1710727-6

1710731-6

1710735-5*

1710737-5*

600, 636,

650, 700

83843-5

1710723-7

1710727-7

1710731-7

1710735-6*

1710737-6*

X-LARGE

605 (30/19)

636 (26/7),

(24/7), (30/19)

666.6 (24/7),

(26/7)

795 (36/1),

(42/7), (45/7),

X-LARGE

795 (24/7),

(26/7), (30/7),

(30/19),

(54/7),

1710727-1

w/o Taps

1710726-1

1710727-2

1710722-2

1710727-3

1710731-1

1710726-2

1710730-1

1710731-3

1710730-2

w/o Taps

w/Taps

w/o Taps

____

____

____

____

1710735-2*

1710734-1*

1710737-2*

1710737-4*

1710736-2*

1710734-2*

1710730-4

1710736-1*

1710737-3*

1710735-4*

1710730-3

1710726-4

1710737-1*

1710735-3*

1710731-5

1710726-3

w/Taps

1710735-1*

1710731-4

1710727-5

1710722-4

w/o Taps

1710731-2

1710727-4

1710722-3

w/Taps

69 kV, 350 kV BIL

X-SMALL

1710722-1

w/Taps

46 kV, 250 kV BIL

1/0 (6/1)

2/0 (6/1)

X-LARGE

w/o Taps

35 kV, 200 kV BIL

ACSR

477.0 (30/7)

556.5 (24/7),

(26/7), (30/7)

605 (24/7),

(26/7)

636 (18/1),

(36/1)

w/Taps

29 kV, 150 kV BIL

Body Size

LARGE

AAC

• For Hotsticking Applications C & Wedge Holder 69900 and Piggy Back Clamp 69883 are needed for installation.

1710734-3*

1710736-3*

715.5, 750,

795

83843-6

1710723-8

1710727-8

1710731-8

1710735-7*

1710737-7*

954

1-83843-1

1710723-9

1710727-9

1710731-9

1710735-8*

1710737-8*

* Royal Blades

TE Technical Support Center

USA:

+1 (800) 327-6996

Canada:

+1 (905) 475-6222

Mexico

+52 (0) 55-1106-0800

Latin/S. America: +54 (0) 11-4733-2200 UK: +44 (0) 800-267666

France: +33 (0) 1-3420-8686

Netherlands:

+31 (0) 73-6246-999

China: +86 (0) 400-820-6015

energy.te.com

© 2005, 2007, 2010-2012 Tyco Electronics Corporation, a TE Connectivity Ltd. Company. All Rights Reserved.

8-1773456-9 E379 05/2012

AMPACT, TE Connectivity and TE connectivity (logo) are

trademarks. Other logos, product and/or company names

might be trademarks of their respective owners.

While TE has made every reasonable effort to ensure the accuracy of the information in this brochure, TE does not guarantee that it is

error-free, nor does TE make any other representation, warranty or guarantee that the information is accurate, correct, reliable or current. TE

reserves the right to make any adjustments to the information contained herein at any time without notice. TE expressly disclaims all implied

warranties regarding the information contained herein, including, but not limited to, any implied warranties of merchantability or fitness for a

particular purpose. The dimensions in this catalog are for reference purposes only and are subject to change without notice. Specifications

are subject to change without notice. Consult TE for the latest dimensions and design specifications.