BERGEN COUNTY UTILITIES AUTHORITY

advertisement

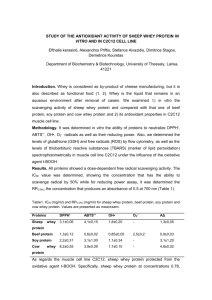

BERGEN COUNTY UTILITIES AUTHORITY DIGESTS CHEESE WHEY – GETS GAS AN ENERGY-COMMUNITY WIN-WIN Ralph Eschborn1 (Corresponding Author*), Mohammad Abu-Orf1, Metin Duran2, Keith Weisman3, Michael Williams4 1 AECOM; 2Villanova University; 3Alaimo Group; 4Bergen County Utilities Authority (BCUA) *1700 Market Street, Suite 1700, Philadelphia, PA 19103 ABSTRACT Bergen County Utilities Authority (BCUA) operates a 413 ML/d (109 MGD) wastewater treatment facility in Little Ferry, New Jersey. Digester gas produced in the anaerobic digesters is fed to a Combined Heat and Power (CHP) facility. Increasing digester gas production has the immediate benefit to BCUA of reducing purchased natural gas used to operate the Internal Combustion (IC) engines. Two major producers of cheese products are located just 5 km (3 miles) away. BCUA engaged a study team to perform bench scale testing to experimentally determine the potential for increased gas production from whey co-digestion as well as potential deleterious effects on digester operation. Bench testing consisted of Biochemical Methane Potential (BMP) and nutrient deficiency testing. Based on the encouraging bench testing findings, BCUA commenced a full-scale demonstration of CW co-digestion in October, 2010. Primary objectives were to confirm gas production potential and assess the impact on solids generation, which represents an off-setting cost to the savings from reduced natural gas purchases. Preliminary results, while qualitative, were quite favorable, and extended full scale testing has continued through June 2011. No significant adverse effects have been noted during extended testing. Drawing firm conclusions with respect to additional gas produced and net solids generated has proved challenging for reasons discussed below. The most demonstrable benefits are a “win-win” for the community. The cheese producers are no longer faced with intolerable costs for disposing of the whey. One has abandoned plans to relocate, and the other is now expanding production. KEYWORDS Co-digestion, Anaerobic Digestion, Cheese Whey, Digester Gas, Combined Heat and Power, Thermal Dispersion Gas Metering, Biochemical Methane Potential INTRODUCTION Bergen County Utilities Authority (BCUA) operates a 413 ML/d (109 MGD) wastewater treatment facility in Little Ferry, New Jersey, in a densely populated area. The facility has a service area population in excess of one-half million people. Solids processing consists of Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 1 of 19 feeding, a blend of thickened primary and secondary solids at rates ranging from 1325 to 1893 m3/d (350,000 to 500,000 gallons per day) to 5 anaerobic digesters, with a combined capacity of 18,395 m3 (4.86 million gallons). Detention times range from 10 to 14 days, with an average of 12. Digester gas is utilized to provide heating and generate electricity. Since 2008, digester gas produced in the anaerobic digesters is fed to a Combined Heat and Power (CHP) facility consisting of two, dual fuel (digester and natural gas) Internal Combustion (IC) engines. Increasing digester gas production has the immediate benefit to BCUA of reducing purchased natural gas used to operate the IC engines. One means of increasing digester gas production is the co-digestion of readily biodegradable substrates, such as concentrated waste streams from food processing operations. Fortuitously, a major producer of cheese products, Biazzo Dairy, is located just 3 miles (5 km) away, and is seeking a lower cost disposition of their by-product cheese whey. The locations of the Little Ferry facility and the Dairy are shown in Figure 1. Biazzo Dairy BCUA Little Ferry Wastewater Treatment Facility Figure 1 Locations of the Little Ferry WWTF and Biazzo Dairy (~ 3 driving miles apart) While the thought of generating immediate savings through reduced natural gas purchases was tempting, BCUA was concerned that their digesters were already heavily loaded. Bench Study Goals and Approach Recognizing that an assessment of the digestibility of cheese whey prior to a full scale trial would improve the likelihood of success and minimize risks, BCUA engaged a Study Team comprised of the Alaimo Group, AECOM and Villanova University to perform bench scale testing to experimentally determine the potential for increased gas production as well as potential deleterious effects on digester operation. Secondary objectives included identifying the preferred form of the cheese whey byproduct stream to co-digest and assessing any other cost impacts – specifically the potential for increased solids generation. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 2 of 19 The Alaimo Group (Alaimo) is the General Consulting Engineer to the BCUA. Alaimo engaged the services of AECOM to draw on their specialized expertise in digester process engineering. AECOM, in turn, contracted with Villanova University and Dr. Metin Duran to perform the bench testing. Villanova investigated the feasibility of co-digestion of primary and secondary solids and cheese whey using Biochemical Methane Potential (BMP) testing. In addition, a nutrient deficiency study was conducted on anaerobic digester biomass operated by BCUA to assess whether there were any possible micro- and macronutrient supplementation needs for the anaerobic biomass in the BCUA digesters for optimal metabolism. Two cheese whey streams were sampled for study: a hot, dilute, pre-reverse osmosis (RO) material generated in cheese manufacture; and this same stream after it is cooled to ambient and concentrated by RO. These two different locations represent alternate sources of byproduct cheese whey from the dairy with a trade-off in attributes: the higher temperature of the hot CW is an advantage in that it reduces the pre-heating burden on the digesters; however, it is more dilute. The RO step concentrates the biodegradable material by removing over one-half of the water. Since the BCUA digesters have short detention times, adding the more dilute hot CW stream would have a greater impact on shortening the detention time and potentially reducing volatile solids destruction. Reduced volatile solids destruction would not only reduce gas production, it would increase digested solids and solids disposal cost. Whey and Biosolids Sampling In preparation for bench scale testing, Villanova researchers visited the BCUA and Biazzo Dairy facilities and collected the following samples: Digester solids (for use as “seed” for the BMP testing) Thickened primary/secondary solids (digester feed) Cheese Whey before centrifugation (Hot CW) Cheese Whey after Reverse Osmosis treatment (Cold CW) Samples were preserved on ice and transported to Villanova and refrigerated on the same day as they were collected. (Note: “Hot” as the designation for the pre-centrifuge CW refers to the temperature at the time of sampling. All samples were chilled for transport after being taken.) Characteristics of these streams as well as the BCUA solids to be co-digested are shown in Table 1. Hot and Cold CW samples (“before” and “after” the RO process) were analyzed in terms of Total Chemical Oxygen Demand (CODT), Total Solids (TS), Volatile Solids VS, pH, alkalinity, ammonia and total phosphate. It is important to note that “hot” CW sample is CW prior to centrifuging, which removes particulate matter, especially fats and colloidal material, from the CW. Thus, more accurately, these samples are “pre-centrifuge” and “after RO”. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 3 of 19 Table 1 Characteristics of CW samples, digester contents, and feed Sample Digester (Seed sludge) Feed sludge CW before centrifuge (hot) CW after RO (cold) CODT (mg/L) 22600 TS (mg/L) 20700 VS (mg/L) 14200 pH Alkalinity Ammonia (mg/L CaCO3) (mg/L) 7.05 4600 NA Total P (mg/L) NA 45500 72500 36200 65200 27800 56100 NA 5.75 NA 1400 NA 20 NA 2360 195000 177700 153900 5.87 2600 24 THTM NA: Not analyzed, THTM: To high to measure and dilution causes loss of sensitivity The data show that both CW samples have highly oxidizable (potentially biodegradable) organic matter as measured by CODT regardless of the RO treatment. CW before centrifuge (“hot” CW) contains 72,500 mg/L of total COD and the RO process concentrates these organics 2.7 fold. METHODOLOGY Bench Testing Methods and Apparatus Co-digestion feasibility was determined according to the standard Biochemical Methane Potential (BMP) test using 165 mL capacity serum bottles (Owen et al., 1979). Each serum bottle contained seed (biomass from BCUA digester), feed sludge, several initial concentrations of “hot” and “cold” CW, and tap water for normalizing the total liquid volume. The bench-scale testing used165-ml capacity serum bottles each with 60 mL operating liquid volume. Each parameter was tested in triplicate to ensure data quality. Four different initial concentrations were tested for each CW sample. These concentrations, along with the corresponding CW to feed sludge ratios, are reported in Tables 2 and 3 for “cold” and “hot” CW samples, respectively. These ratios were selected to cover the ranges that would be experienced if up to roughly 200% of the Biazzo Dairy cheese whey were co-digested with current BCUA primary and secondary solids production. For example, the expected average “hot” CW flow of 189 m3/d (50,000 GPD) that could be co-digested by the BCUA would represent roughly 12% of digester feed volume. Lower feed volume ratios were used for cold CW, to adjust for the higher concentration of biodegradable material. Table 2 Ratios of cheese whey (CW) after RO (“cold”) and feed sludge tested Cheese whey (mg/L COD eq.) Cheese whey/ Feed Sludge (COD CW/ COD feed as %) 195 488 975 1950 4.3 10.71 21.4 43 Cheese whey/ Feed sludge (% by volume) Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 4 of 19 1 2.5 5 10 Table 3 Ratios of cheese whey (CW) before centrifuge (“hot”) and feed sludge tested Cheese whey Cheese whey/ Feed Sludge Cheese whey/ Feed sludge (mg/L COD eq.) (COD CW/ COD feed as %) (% by volume) 145 363 726 1452 3.2 8 16 32 2 5 10 20 Total biogas production from serum bottle reactors was monitored for the 30-day incubation period and the gas phase was analyzed for its CH4 and CO2 content. Total gas was measured via a volume displacement device – see Figure 1. Biogas produced was analyzed for its CH4 and CO2 using a Hewlett Packard™, Model 6890 gas chromatograph equipped with a thermal conductivity detector (TCD). Recognizing that food processing byproducts are frequently deficient in nutrients needed to support the anaerobic biomass, nutrient deficiency testing was also conducted using a slightly modified form of anaerobic toxicity assay (ATA) testing (Owen et al., 1979). Various concentrations of iron, nickel, and cobalt as well as a “cocktail” of micro- and macro-nutrients were tested. The micro- and macro-nutrients (Fe, Ni, Co, Cu, Se, Mo) were added with a synthetic substrate and compared to performance with no additives. Figure 2 Liquid displacement device for total gas measurements Full Scale Whey Handling and Testing As discussed in detail below, the bench testing showed rapid increases in gas production with proportional increases for the amount of CW fed indicating that there were no initial inhibitory effects and the CW is highly co-digestible. The nutrient deficiency (ATA) testing showed no deficiencies – the treatment facility’s biomass contained a sufficient nutrient reserve to accommodate the needs of anaerobic whey co-digestion. The testing also showed that the gas production potential of the pre-centrifuge whey was considerably higher than the post-centrifuge whey. Based on the encouraging bench testing findings, the study team recommended a fullscale co-digestion trial based on the addition of hot, pre-centrifuge whey. In the course of scoping the logistics of a full-scale trial, it was determined that the Biazzo dairy’s storage system was not set up to conveniently store and load pre-centrifuge whey, so BCUA commenced a fullscale demonstration of post-centrifuge, hot (pre-RO) cheese whey co-digestion in October, 2010. Biazzo was able to make a dedicated tank truck available for transporting CW from the dairy to the BCUA. A full load represents approximately 21 m3 (5,500 gallons) of whey. Transporting all of Biazzo’s hot, pre-RO cheese whey production to BCUA would involve transporting 9 Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 5 of 19 loads per day. BCUA has two 198 m3 (5,240 gallon) stainless steel grease storage tanks which are idle. These tanks are suitable for running a full-scale trial and for routine operation for an interim period. The tanks are equipped with small pumps 0.3 – 1.0 L/s (5-15 gpm) to feed the digesters. See Figure 3. Figure 3A Unloading whey to storage tanks Figure 3B Whey transfer pump While the bench testing provided strong encouragement to proceed with a full scale trial, BCUA elected to start conservatively with one tank truck per day feeding as single digester and using the other 4 digesters as controls. This approach provided confidence in what is added, and minimized overall exposure. After several weeks of operation with no observed undesirable impacts, this level was increased to two tank trucks per day. Averaging in weekend and other interruptions to delivery, the average monthly rate of sustained whey co-digestion has been ~ 25 m3/d (6500 gallons per day). At this level, feeding a single digester, the volumetric ratio of whey to facility primary/secondary solids is ~ 8%. On a COD (substrate) basis, the feed ratio is ~ 11%. Second Source After full scale trials commenced using Biazzo Dairy whey, a second cheese manufacturing dairy, Montena-Taranto was identified also within 5 driving km (3 miles) of the facility. Figure 4 shows the location of Montena-Taranto. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 6 of 19 Figure 4 Location of Montena Taranto Dairy The Montena Taranto (M-T) whey characteristics are similar to the Biazzo whey, as shown in Table 4. The M-T whey VS content and COD were comparable. The M-T whey pH was slightly lower, but this is balanced by a higher Alkalinity. Beginning in April 2011, BCUA converted to co-digestion of M-T whey for continued full scale trials. Table 4 Comparison of Biazzo and Montena Taranto wheys Sample CODT TS VS pH Alkalinity Ammonia (mg/L) (mg/L) (mg/L) (mg/L CaCO3) (mg/L) Digester (Seed 22600 20700 14200 7.05 4600 NA sludge) NA M-T after 64100 63000 52400 5.4 4700 centrifuge (hot) CW* before 72500 65200 56100 5.75 1400 20 centrifuge (hot) CW* after RO 195000 177700 153900 5.87 2600 24 (cold) *Biazzo Dairy Total P (mg/L) NA NA 2360 THTM RESULTS Bench Testing – BMP Findings The cumulative CH4 generations from serum bottles that received feed sludge and Cheese Whey (CW) at various initial concentrations are presented in Figure 5 and Figure 6 for “cold” and “hot” Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 7 of 19 CW, respectively. Each data point in these figures is the average cumulative methane production in triplicate serum bottles. Figure 5 Cumulative CH4 production from co-digestion of “cold” CW (after RO) at various concentrations and feed sludge Figure 6 Cumulative CH4 production from co-digestion of feed sludge and “hot” CW (before centrifuge) at various concentrations As expected, cumulative CH4 production increases with the increasing initial concentrations of CW added to the serum bottles. This is true for both CW before centrifuge and after RO treatment. The fact that the active reactors supplemented with high doses of CW produced Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 8 of 19 nearly proportionately more CH4 than the low dose reactors clearly indicates that CW had no inhibitory effect on digestion of primary and waste activated sludge at the levels tested, as well as indicating the ready anaerobic digestibility of CW. Comparing the gas production for hot CW fed at a 10% volumetric feed ratio (representing approximately the feed ratio for co-digestion of 100% of Biazzo cheese whey) indicates that gas production would be boosted approximately 40% over current gas production resulting from digestion of primary and secondary solids alone. It is important in co-digestion feasibility studies to assess the optimal loading rate of the codigestion candidate that could be applied without any detrimental effect on the overall metabolism of digester biomass. The COD recovery at different loading rates is useful in that regard. Percent COD recovery is based on COD equivalent of CH4 and it is the ratio of CH4 generated (in COD equivalent) to the COD added. The COD equivalent of CH4 is 395 mL of CH4 per gram COD at 35 0C (incubation temperature), which is derived from the stoichiometry of CH4 oxidation. The estimate does not account for the fraction of substrate used for cell synthesis, which is typically less than 10% of the substrate digested. The COD recovery is based on net CH4 generated by digestion of CW. Net CH4 from digestion of CW is the difference between cumulative CH4 from active reactors and that from the seed control. Two control samples used in the study were seed and feed control. Seed control accounts for the CH4 that resulted from digestion of residual volatile solids in the digester sample (seed) collected from the BCUA plant. Feed control, on the other hand, was used to determine the amount of CH4 from digestion of sewage sludge. Figure 7 presents the percent COD recovered as a function of CW loading, expressed as initial CW to feed sludge ratio in the feed. Figure 7 Relationship between % COD recovery and CW to feed sludge ratio expressed as % by volume Feeding Cold CW (after RO) at full feed rate would be approximately 4% by volume; and feeding Hot CW (pre-centrifuge) at full rate would be approximately 12% by volume. At these values, the %COD recovered (as a percentage of theoretical) was approximately 75% and 130% Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 9 of 19 respectively. Figure 7 indicates that CW before the centrifuge treatment (“Hot” in Figure 3) has a higher COD recovery, and thus, had higher specific CH4 production, at all loadings compared to CW after the RO (“Cold” CW in Figure 3). The COD recovery in excess of 100% for the addition of Hot CW suggests that co-digestion of with Hot CW has a synergistic effect leading to greater mass of sludge digestion. However, the solids and CODT concentrations measured at the end of the incubation period were more or less the same in the control and “Hot” CW added bottles indicating that there was no greater degree of feed sludge digestion. The most likely explanation for greater than 100% COD recovery from “Hot” CW is the fact that fats, which would be removed during centrifuging, have a higher energy content, on a mass per mass basis, than carbohydrates and proteins, upon which the theoretical estimate is based. Therefore, Hot CW, having greater fat content than the Cold CW samples, shows a greater than 100% CH4 recovery compared with theoretical levels when it is anaerobically digested. Based on this higher gas yield and greater COD content, and the absence of any observable inhibitory effect (as discussed in Section 2.4, below), running full-scale trials with the Hot CW stream as a co-digestion feedstock would be the preferred choice. The downside of the Hot CW feedstock is its greater volume, which will reduce detention time and adversely affect volatile solids destruction, but based on the kinetic constants derived from the BMP testing (see Section 2.5), this effect is expected to be modest, i.e., on the order of 1-2%. Volatile solids destruction was measured for the serum bottle tests. Results are shown in Table 5. Table 5 Serum bottle Volatile Solids (VS) in/out and % VS removed (VSr) FEED Feed VS in Whey VS in (mg) % VS r (mg) No Whey 167 Hot CW 5% bv 167 Hot CW 10% bv 167 VS out* 35% 100 17 (+10%) 36% 101 34 (+20%) 36% 102 * Normalized to 100% While the precision of this testing does not support drawing quantitative conclusions, the increase in VS out with increasing Hot CW loading suggests that solids production will increase modestly as a result of co-digestion with BCUA solids. Any increase in digester effluent solids as a result of reduced detention time would add to the VS increase due to CW addition. The combined effect of these factors suggests that digested solids production will increase by 2-4%. This represents a cost increase that has to be weighed against the value of increased gas production, and confirming the increase in digested solids became a key co-objective of a full scale trial, along with documenting a gas production increase. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 10 of 19 Nutrient Deficiency Testing Findings As with many food processing byproducts, cheese whey is rich in COD but may lack the nutrients necessary for biomass development. Successful co-digestion will rely on an adequate supply of nutrients being provided by the primary and secondary solids. To account for potential nutrient deficiencies, nutrient deficiency assays were conducted. These assays involve running BMP tests to observe whether added micro- and macro-nutrients have beneficial effect on biogas production. If no additional biogas production results with the addition of micro- or macronutrients, a satisfactory level provided by the primary and secondary solids is indicated. The effects of nutrient supplementation on BCUA anaerobic digester biomass were evaluated by slightly modified form of anaerobic toxicity assay (ATA), originally developed by Owen et al., (1979). Various concentrations of iron, nickel, and cobalt as well as a “cocktail” of micro- and macro-nutrients were tested. Each serum bottle contained seed (biomass from BCUA digester), feed sludge, 224 mg acetate as the primary substrate for methanogens, nutrients and tap water for normalizing the total liquid volume. Similar to the BMP bottles, the total liquid volume was 60 mL and each parameter was tested in triplicate. Figure 8 shows the results for various nutrient “cocktails” added as digester supplements. Cumulative CH4 (mL) 250 200 150 Control Acetate Ctrl. 100 Micronutrient Macronutrient 50 Vanderbilt 0 0 10 20 30 40 Time (day) Figure 8 Effects of macro-nutrient and micro-nutrient cocktails, and a combination of macronutrient and trace metal cocktails (Vanderbilt Media) on BCUA digester biomass Figure 4 shows that methane production was virtually unchanged relative to the control that had the same level of acetate (readily biodegradable substrate) added but without the supplements. This is a strong indication that co-digestion of cheese whey with BCUA solids will not be Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 11 of 19 hindered by nutrient deficiencies. A number of similar scouting tests were run with the same favorable finding. Kinetic Modeling While it may be misleading to use batch data gathered from batch Biochemical Methane Potential (BMP) tests to predict performance of a intermittently fed Continous Stirred Tank Reactor (CSTR), which is the typical configuration for full-scale anaerobic digestors, a model based on first order degradation kinetics may provide some qualilative insight on methane yield as a function of time for full-scale co-digestion of cheese whey (CW). Based on the previous findings which suggested that Hot CW was the preferred feedstock for co-digestion, modeling was carried out only for Hot CW. The model developed is an exponential growth model that predicts CH4 yield as a function of time and may roughly represent hydraulic retention time (HRT) of full-scale digesters. It is expressed as follows. Y = Ymax(1-e-kt) Equation (1) where; Y: Cumulative methane yield (cubic feed of methane at 35 oC per cubic foot of active digester volume) Ymax: Maximum methane yield (cf CH4/cf digester volume) r: First order reaction rate constant (1/time) t: Time To develop a model, for each CW loading, cumulative CH4 production was normalized per unit active reactor volume. Then, the exponential growth model expressed by Equation 1 was applied to the normalized cumulative CH4 production data using Curve Expert curve fitting software to determine the constants Ymax and k for each CW loading. It is important to note that Y in the model includes CH4 from degradation of feed sludge as well as of CW. These constants are presented in Table 6. In each case, data fit well to the model as indicated by r2 values 0.98 or above. Table 6 Kinetic constants, under various CW load, for exponential growth model Cheese whey loading Ymax (cf CH4/cf active digester volume) (% volume CW/total feed volume) 0 (feed sludge only) 2.87 2 2.96 5 3.13 10 3.27 20 3.46 Figure 9 shows an example best fit for CW loading of 5% of total feed volume. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 12 of 19 k (1/day) .3401 .3489 .3483 .4089 .4239 Methane yield (cf/cf reactor vol.) S = 0.17818128 r = 0.98962264 3.6 6 3.0 5 2.4 4 1.8 3 1.2 2 0.6 1 0.0 0 0.0 5.5 11.0 16.5 22.0 27.5 33.0 Time (days) Figure 9 Model results for 5% “hot” cheese whey in feed (vol./vol.) This kinetic model may prove useful to compare predicted versus actual performance in full scale trials. Full Scale Trials When full scale trials were commenced in October 2010, the first observation was a noticeable rise in digester floating cover height with the addition on whey. This phenomenon has been routinely observed throughout extended full scale testing. Figure 10 shows cover rises observed during feeding of the first truckload of whey received on each day for a representative16 day period in May, 2011. A load of whey is unloaded over a 5hour period. During that period the whey-receiving digester also received its share of primary/secondary solids. In all but one instance, the cover rise exceeded the level increase that would have occurred due to liquid addition, alone. The average cover rise during this period was 165% of the rise due to liquid addition alone, clearly showing that rapid gas evolution was taking place during whey pumping. Gas composition is monitored by BCUA for the combined 5 digester gas stream. The BCUA staff has noticed a slight dip in methane content during periods of whey addition – methane content is approximately 1% lower. This would translate to a 5 percentage-point drop in methane content for the whey-receiving digester. This drop is attributed to the low pH of the whey, which would shift the dissolved/gaseous CO2 equilibrium during whey addition. Even with discounting for the increase in CO2, the majority of the gas evolution during whey addition is methane. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 13 of 19 Cover Rise (Inches) (First Load ‐‐ 5 hour feed) Maximum Rise due to liquid addition 20 18 16 14 12 10 8 6 4 2 0 May 3‐18 Figure 10 Whey receiving digester floating cover rises during whey addition Where’s the Gas? Each BCUA digester is equipped with a thermal dispersion gas flow meter. Integrated gas flow is recorded for each digester. Table 7 shows the measured gas production for Digester 1, the whey receiving Digester, compared to the average gas production for the other four digesters for April and May 2011. The April – May period was selected as a period of steady whey codigestion. Table 7 April-May 2011 Digester Data – Volatile Solids (VS) fed and Gas Production VS – lbs/d & Δ% April May 2-Mo. Average Gas – KCFD & Δ% VS fed Gas VS fed Gas VS fed Gas Digester 1 155 24,268 157 23,897 156 23,526 +2% +3% +1% +5% +1% +4% Digester 2 – 5 avg 23,101 150 24,145 150 23,623 150 While a modest increase in gas production was noted, these results are not in line with expected gas production. Digester 1 loading is shown in Table 8. Table 8 Digester 1 Whey and Primary + Secondary solids feed, Apr-May 2011 Digester 1 Feed April May 2-Mo. Average Volume & COD Volume – gpd Volume COD Volume COD Volume COD COD – lbs/d & Δ% Digester 1 8,541 4,566 6,273 3,354 7,407 3,960 Whey +10.3% +14.5% +7.2 +10.2% +8.7% +12.3% Digester 1 82,842 31,436 86,966 33,001 84,904 32,219 Primary + Secondary Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 14 of 19 Based on a COD loading of 12% over the primary + secondary solids feed to Digester 1 during the April – May period, the high biodegradability for the whey would suggest an increase in gas production more like +20%, five times higher than the measured gas increase of 4%. These results beg the questions: What is going on? Where is the gas? Volatile Solids Destruction Volatile Solids (VS) destruction was calculated for the Digester 1 versus Digesters 2-5. VS destruction data for Apr-May 2011 is presented in Table 9. Table 9 April-May 2011 Digester Data – VS Destruction (VSr) & predicted Gas Production* VSr – lbs/d & %VSr April May 2-Mo. Average Gas – KCFD & Δ % VSr Gas VSr Gas VSr Gas Digester 1 8,402 126 8,092 121 8,247 124 35.6% +19% 33.2% +16% 34.4% +18% Digester 2 – 5 7,041 6,943 6,992 106 104 105 average 30.5% 28.8% 29.7% * Gas production based on 0.93 m3/kg, VS destroyed (15 cu. ft. biogas/lb., VS destroyed) As shown in Table 9, the percent Volatile Solids destruction (%VSr) increases substantially when whey is added – from a %VSr of 29.7% for the non-whey receiving control digesters Digesters 2-5) to 34.4% for Digester 1, the whey receiving digester. Typical values for biogas production range from 0.74 – 1.12 m3/kg, VSr (12-18 cu. ft./lb., VSr) (Metcalf & Eddy 3rd Edition, 1991). Using a mean value of 0.93 m3/kg (15 cu. ft./lb.), VSr, gas production from Digester 1 was estimated to be 18% greater than gas production from the non-whey receiving control digesters, consistent with the expected gas production indicated by bench BMP testing. So, qualitatively by cover rise, and quantitatively by bench testing and gas production calculated by Volatile Solids destruction, co-digestion of whey is resulting in a substantial increase in gas production; however, this has not been confirmed directly by gas flow measurements. Solids Production Mass balances were prepared around the digesters to estimate the incremental solids production resulting from co-digestion of whey. Taking small differences between large numbers can lead to large errors, but the use of mass balances provides a semi-quantitative estimate of additional solids produced. Table 10 presents mass balance data for Digester 1 for the April – May 2011 period of steady whey co-digestion. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 15 of 19 Table 10 Solids production Data for Digester 1 – Apr – May 2011 Total Solids (TS) – April May 2-Mo. Average lbs./d & Δ% Digester 1 measured 21,559 22,905 22,232 TS out +4.9% +4.3% +4.6% Digester 1 Calculated 755 555 655 Solids from Whey +3.7% +2.5% 3.1% Non-Volatiles Digester 1 Estimated 20,557 21,960 21,259 Solids without whey* * Solids generation estimated based on VS destruction achieved in Digesters 2-5 for the same Apr-May period, and Primary + Secondary solids fed to Digester 1 The indicated increase in solids production is 4-5%, with as Table 10 shows, about two-thirds of the solids coming from non-volatiles in the whey. The net solids production increase, excluding the non-volatiles in the whey, of under 2% shows that the whey is highly biodegradable under full scale conditions and/or that the adverse impact on volatile solids destruction for the primary + secondary solids due increased hydraulic loading is quite modest. Detention times for Digester 1 during the April – May period were reduced by 9% due to the addition of the whey stream. To determine the actual impact on biosolids production, the estimated 4-5% increase in solids production needs to be corrected for Total Dissolved Solids (TDS). The diary whey is “salty” and these dissolved solids show up in a Total Solids (TS) measurement, but would be largely removed during dewatering prior to biosolids transport. DISCUSSION The discrepancy between the rapid digester cover rises during whey addition and the nearly 20% increase in gas production indicated by volatile solids destruction on one hand, and the less than 5% increase in gas production indicated by direct measurement of gas flow prompted an inquiry into gas metering. Figure 11 shows a comparison of Digester 1gas flow, as measured, and gas flow, as calculated using volatile solids destruction. Monthly total measured gas flow was compared to calculated flow based on monthly volatile solids destruction data. Two periods were examined: a ninemonth period just prior to the start of whey co-digestion, and the Apr – May 2011 period of steady whey co-digestion. The red diagonal in Figure 11 is the “identity line”, i.e., if there was perfect agreement between measurements and calculations, all points would fall on this line. What is immediately evident from the graphical portrayal of Figure 11, is that estimated gas production based on volatile solids destruction, varied by roughly 300% during the period preceding whey co-digestion, while measured gas production varied by only 25% between the highest and lowest readings. All calculated values were below the identity line. Estimated gas production during the April – May period of whey co-digestion showed the closest approach to identity, but were still below measured values. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 16 of 19 Since gas production is expected to vary no more than +/- 20% per unit of volatile solids destroyed (Metcalf & Eddy, 3rd Edition, 1991) and estimating volatile solids destruction using % volatiles in and out (the Van Kleeck method) is expected to have only modest error when taking monthly averages, a strong inference is drawn that the gas flow meter is largely insensitive to gas flow. Figure 11 Calculated versus measured Gas Production in KCF per month Several potential causes for this apparent metering error have been identified: Mis-calibration Change in gas composition Asymmetric or swirled flow due to upstream bends or fittings Moisture in the digester gas impinging on the meter’s probe Thermal Dispersion Mass flow meters are commonly used for measuring gas flow, as they have the virtue of being insensitive to temperature and pressure changes; however, they require calibration and are subject to errors due to changes in gas composition and asymmetric flow. With respect to mis-calibration and asymmetric flow these sources of error are expected to impart bias more than the substantial insensitivity observed and are thought to be only minor contributors to the observed error. Gas composition can have a significant effect on readings, but given the fact that the insensitivity was clearly found prior to the co-digestion of whey, the normal variation in digester gas composition would not result in the insensitivity observed. Ruling out the first three sources of error strongly points to moisture from the wet digester gas compromising readings. Figure 12A and 12 B show the flow meter installation on Digester 1 and the vendor recommended installation for Thermal Dispersion meter probes. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 17 of 19 Figure 12A – Digester 1 Flow Meter Figure 12B – Flow Meter Mounting Positions Based on vendor mounting guidance for meters in wet gas service, the BCUA meters are mounted in a manner that may allow moisture to impinge on the meter probes and descend on to the measuring elements, where the mass of the liquid will have a significant cooling effect, creating the high and insensitive flow measurements observed. CONCLUSIONS Based on both bench and full scale trials, BCUA has found that cheese whey co-digestion promises to deliver a substantial increase in gas production. While there is a lot of “noise” in the full scale trial data, increased gas production is estimated to be between 4 and 18%. The lower figure is based on direct gas flow measurement, but these gas flow meter readings are suspect, based on data generated before whey co-digestion commenced. Full scale trial addition levels are about one-half of the goal level which was bench tested with satisfactory results, indicating that expansion of the co-digestion program to include all digesters and higher digester loading rates could increase overall gas production by over 30%. Whey co-digestion is accompanied by increased solids production. While it is estimated to be less than 5%, this represents a significant potential cost off-setting the value of the gas generated. Further trials are needed to refine gas and solids production estimates. Based on the workable logistics demonstrated for whey receipt, storage and digester feeding, and the absence of any observed undesirable side effects in digester operation, BCUA plans to extend full scale trials. Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 18 of 19 Perhaps the biggest payoff of the whey co-digestion program is the community “win-win” that has resulted from converting high strength waste streams from two nearby diaries to a “green” source of power. One dairy was investigating relocating out-of-state, to be closer to milk production and reduce hauling costs for waste whey. With the development of a local outlet for the whey, they have shelved relocation plans. The other dairy, whose economics were compromised by the high cost of whey disposal, did not see sufficient justification to expand their operations, but with the prospect of local disposition of their whey are now exploring expansion. ACKNOWLEDGEMENTS The authors would like to express their appreciation to Robert Laux, Executive Director of the Bergen County Utilities Authority (BCUA) and Eric Anderson, Director of the BCUA Water Pollution Control Division and Chief Engineer for their support of the cheese whey co-digestion program. Conducting full scale trials of cheese whey co-digestion would not have possible without the full cooperation and concerted efforts of the BCUA Little Ferry wastewater treatment facility staff. In particular, the authors would like to express their appreciation to Walter Paul, Plant Manager, Edward Switay, Assistant Plant Manager, Michael Williams, Manager of Permits and Regulatory Affairs, David Hudspeth, Chief Sewerage Plant Operator, and Thom Chaiket, SCADA Engineer for their contributions to the Program. REFERENCES Owen, W.F., Stuckey, D.C., Healy J.B., Jr., Young L.Y., McCarty, P.L. 1979. Bioassay for monitoring biochemical methane potential and anaerobe toxicity. Water Res. 13:485–492 Metcalf & Eddy, Third Edition, 1991. “Wastewater Engineering, Treatment, Disposal, Reuse” Eschborn, Ralph Bergen County Utilities Authority Digests Cheese Whey – Gets Gas Page 19 of 19