GE Digital Energy

Power Quality

Introduction

I

Voltage spikes and surges from both external and

internal sources can cause damage to all electronics

and directly affect the performance and life expectancy

of connected equipment. From electronic lighting

ballasts to computer servers, if there is a printed circuit

board inside, it can be susceptible to transient voltage

surge damage. As microprocessors and components

that make up this equipment grow smaller and faster with

each new generation, their susceptibility to transient

voltage surge damage becomes ever greater.

Available in ratings from 65kA - 300kA per mode,

(130kA - 600kA per phase) the TR7000 series is the

perfect surge suppression product for protecting critical

sensitive electronic equipment throughout your facility.

The full-featured TR7000 Series with its advanced

monitoring, disconnect and enclosure options has been

designed to handle the highest levels of surge activity

found in the most demanding commercial and industrial

facilities. These units are ideal for both new and retrofit

applications where performance cannot be compromised.

TR7000 Series

Surge Protective Device (SPD)

with Enhanced Thermal Protection

Recommended installation locations are service entrance

and primary and secondary distribution. The TR7000

Series has been third-party tested to the ANSI/IEEE C3

(10kA, 8x20μs) service entrance level transient surges

including all components. The entire TR7000 line up

has been engineered to the highest standards and is

designed for rigorous duty and long life as evidenced

in our outstanding minimum repetitive surge current

capacity test results.

Features and Benefits

Applications

> Thermally protected MOVs eliminate the need for

additional upstream overcurrent protection

> The TR7000 provides maximum surge protection with

outstanding clamping characteristics for ultra high,

high, medium and low exposure locations with the

use of industrial-grade MOV architecture.

> Third-party tested per IEEE C62.62 and NEMA LS-1

for the rated 8x20μs surge current, per mode with

fusing included.

> Fast rise-times, high frequency transients and

electrical line noise are reduced with standard

EMI / RFI filtering technology.

> Maximum installation flexibility is achieved in the

TR7000 through its high surge suppression kA to

small footprint ratio.

> 10 modes of protection (L-N, L-G, N-G, L-L)

> Service Entrance

> Distribution Equipment

> Green phase protection status LEDs with

Red alarm LED

> NO/NC Form C Dry Contacts for remote monitoring

> Industrial sized MOV technology

> Audible alarm with push-to-test switch,

enable/disable function

> Standard LCD surge counter

> Optional 200kA surge rated disconnect

> NEMA 1, 12, 4 and 4X enclosures available

> Surface and flushmount-style enclosures

> 5 year limited warranty (standard),

10 year limited warranty (optional)

> Branch Panel

> New Construction and Retrofits

> System Expansions

Standards

> UL 1449 3rd Edition, Type 1 and 2

> UL 1283, EMI/RFI noise filter

> UL 96A, Lightning Protection System

> cUL, CSA C22.2

> ANSI/IEEE C62.62

> ANSI/IEEE C62.41 - ANSI/IEEE C62.45

> NEMA LS-1 - 1992 (R2000)

> MIL-STD-220B

> ANSI/NFPA70

Technical Specifications

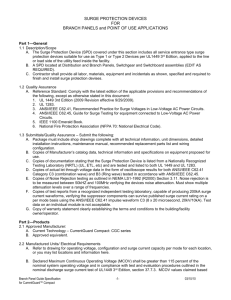

Nominal Discharge Current (In)

20kA

Short Circuit Current Rating (SCCR)

200kA

Operating Frequency

50/60 Hz

Minimum Repetitive

Surge Current Capacity

(Per ANSI/IEEE C62.62)

The TR7000 Series is capable of surviving the following

impulses, at one-minute intervals, without failure and

with less than 10% change in protective characteristics.

> 20,000 Category C3 impulses 20kV/10kA,

8x20μs for devices rated 125-300kA per mode

> 5,000 Category C3 impulses 20kV/10kA,

8x20μs for devices rated 65-100kA per mode

DEA-434 • Page 2

Connection

6 to 2/0 AWG Lugs, Parallel Connected

Operating Temperature

-40° F to 149° F (-40° C to +65° C)

Operating Humidity

0% to 95% Non-Condensing

Weight by Enclosure

WMN1D

WMN12S, 12F, 4S

WMN4X

WMN4D

63 lbs. (28.5 kg)

44 lbs. (20.0 kg)

50 lbs. (22.7 kg)

56 lbs. (24.5 kg)

PR 7

BLANK = UL Type 2

T1

= UL Type 1

MCOV

System Max. Continuous

Operating

Voltage

Voltage

Configuration L-N/G (Vrms)

Nominal

Voltage

(Volts RMS)

Voltage

Code

Maximum Surge

Current Capacity

Per Mode

Per Phase

Suffix

Enclosure

Description

NEMA

Painted Steel

Mounting Disconnect

120S

120/240

1 Ph, 3 W + G

150

06

65kA

130kA

1D

1

Surface

Yes

120Y

120Y/208

3 Ph, 4 W + G

150

08

80kA

160kA

12S Painted Steel 12

Surface

No

220Y

220Y/380

3 Ph, 4 W + G

320

10

100kA

200kA

12F Painted Steel 12

Flush

No

3 Ph, 3 W

270

12

125kA

250kA

4D

Fiberglass

4X

Surface

Yes

15

150kA

300kA

4S

Painted Steel

4

Surface

No

4X

Stainless Steel 4X

Surface

No

240D

240 Delta

240H

120/240 Delta HL

240Y

240Y/415

3 Ph, 4 W + G

320

20

200kA

400kA

277Y

277Y/480

3 Ph, 4 W + G

320

25

250kA

500kA

347Y

347Y/600

3 Ph, 4 W + G

420

30

300kA

600kA

480D

480 Delta

3 Ph, 3 W

550

3 Ph, 4 W + G 150/270 HL

Catalog # example:

TPR7277Y25WMN1D

Phase Rating = (L-N + L-G)

For details, please contact GE Power Quality Customer Service at 800 637 1738.

–

–

–

–

Note: 150V (L-N/G) Phase A & C

270V (L-N-G) Phase B

277Y/480 V, 3 Ph, 4 W + G

250kA per mode, 500kA per phase

Surface mount, NEMA 1 enclosure with disconnect

Painted steel

Protection Ratings

120S / 120Y

Voltage Code

240D

L-L

L-G

240H

L-L

220Y / 240Y / 277Y

L-N HL-N L-G HL-G N-G

L-L

HL-L

L-G

N-G

L-L

L-N

L-G

N-G

480D

Protection Mode

L-N

L-G

N-G

UL 1449, 3rd Edition

Voltage Protection Ratings (VPR)

(assigned UL rating)

900

800

700 1200 1200 1800 1000 1200 800 1200 700 2000 2200 1500 1200 1200 2000 1500 1500 1500 2500 1800 3000

UL 1449, 2nd Edition

Suppression Voltage Ratings (SVR) 400

(assigned UL rating) *

400

400

700

800 1500 500

700

400

700

400

N/A

800

800

800 1500 1200 1000 1000 2000 1500 3000

B3 Ring Wave Clamping

Voltage @ 6kV, 500A

470

463

452

752

750 1240 465

N/A

466

N/A

476 1025 N/A

763

836

828 1393 883 1000 1000 1723 1223 1800

C3 Combo Wave Clamping

Voltage @ 20kV, 10kA

793

670

680 1007 890 1640 775

N/A

670

N/A

680 1163 N/A 1170 1073 1180 1827 1467 1240 1240 2220 1607 2933

900

L-N

347Y

L-L

L-G

L-L

* NOTE: SVR Ratings are no longer assigned by UL and are included in the table above for reference purposes only.

Dimensions

12.00 [304.80]

9.50 [241.30]

WMN1D

Suffix

9.28 [235.61]

2X 0.44 [ 11.18]

1.22 [30.99]

0.62 [15.87]

1.25 [31.75]

0.86 [21.84]

24.00 [609.60]

26.50 [673.10]

5.00 [127.00]

A

A

2X

0.44 [

0.62 [15.87]

11.18] HOLES

NOTE:

All dimensions are for reference only

and are shown in Inches [millimeters]

A

“A” = Recommended conduit entry areas

12.00 [304.80]

12.01 [305.18]

Page 3 • DEA-434

Dimensions

0.86

[21.77]

9.91 [251.76]

21.50 [546.10]

2.74

[69.57]

WMN4D

Suffix

A

A

24.00

[609.60]

25.50

[647.70]

0.76 [19.26]

12.65

[321.34]

A

20.00 [508.00]

15.33 [389.38]

8x

WMN12F

Suffix

0.28 [ 7.16] HOLES

14.19 [360.38]

11.63 [295.30]

8.98

[228.04]

1.85 [47.04]

0.57 [14.50]

18.19

[461.98]

16.00

[406.40]

11.63

[295.30]

4.00

[101.60]

A

6.00

[152.40]

19.33

[490.98]

A

3.85

[97.84]

15.33

[389.38]

4.00

[101.60]

6.00 [152.40]

0.57 [14.50]

8.98

[228.04]

A

12.00

[304.80]

WMN12S,

WMN4S,

WMN4X

Suffix

10.40 [264.14]

9.23 [234.33]

16.00 [406.37]

19.12 [485.61]

A

4x 0.38

[ 9.65] HOLES

17.66 [448.53]

4.00 [101.59]

6.00 [152.39]

12.00 [304.77]

NOTE:

All dimensions are for reference only

and are shown in Inches [millimeters]

6.00 [152.39]

A

9.23 [234.33]

“A” = Recommended conduit entry areas

GE Digital Energy – Power Quality

830 W 40th Street, Chicago, IL 60609 USA

800 637 1738 www.gepowerquality.com

Information subject to change without notice. Please verify all details with GE.

© 2010 General Electric Company All Rights Reserved

DEA-434 (3/10)