International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 7, July 2013)

Embedded Power Supply Controller

Amrish Singh1 , Prof. A. P. Mankodia2

1

PG EC Student: U.V. Patel College of Engineering, Mehsana, Gujarat, India

Assistant professor, EC: U.V. Patel College of Engineering, Mehsana, Gujarat, India

2

Abstract— Small level of power supply controller (PSC)

using an embedded system is planned that will control the

parameters, monitor their status and protect the power

supply under the fault conditions during the operation.

Field Programmable Gate Array (FPGA) with soft

processor will be used to develop the PSC. FPGA allows the

fast signal manipulation and decision making (Protection)

and the soft processor that is developed on the FPGA allows

the control and acquisition through communication

protocol. Discrete components (ADC, DAC, Comparators)

are used to allow the analog signals to interface to digital

circuits and vice versa. Basically the GUI running on the PC

will send the control command to FPGA through processor

and FPGA will than control the power supply and send the

status of the signals back to the PC through processor. For

the fast protection the FPGA monitor the signals against the

safe limit and stop the power supply under fault.

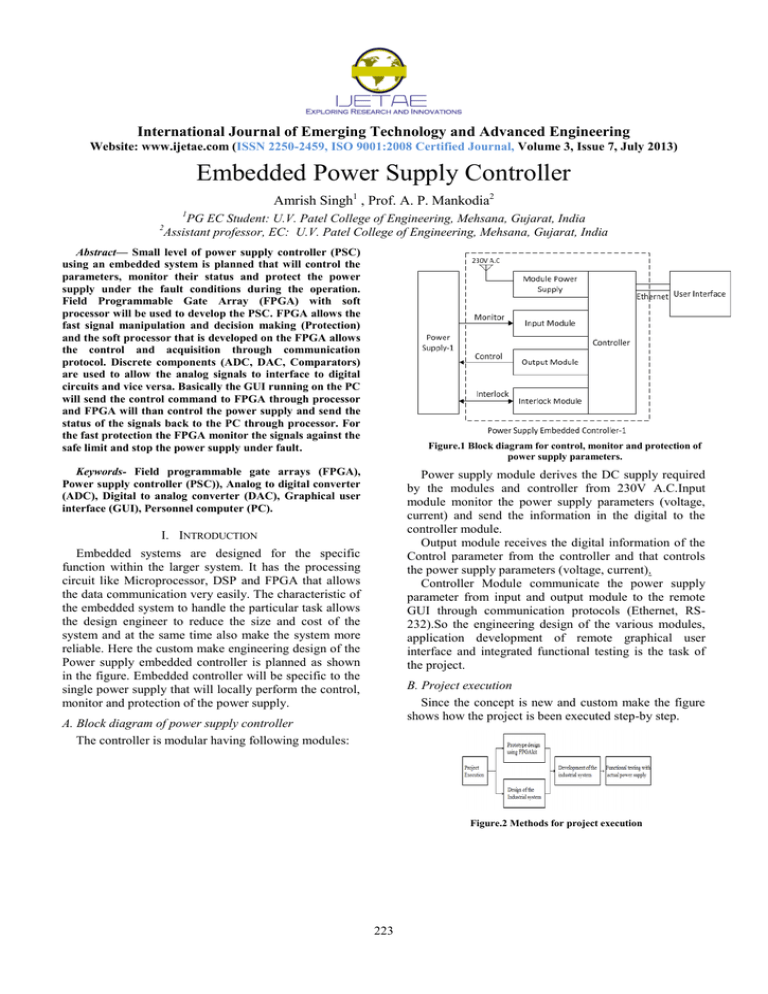

Figure.1 Block diagram for control, monitor and protection of

power supply parameters.

Keywords- Field programmable gate arrays (FPGA),

Power supply controller (PSC)), Analog to digital converter

(ADC), Digital to analog converter (DAC), Graphical user

interface (GUI), Personnel computer (PC).

Power supply module derives the DC supply required

by the modules and controller from 230V A.C.Input

module monitor the power supply parameters (voltage,

current) and send the information in the digital to the

controller module.

Output module receives the digital information of the

Control parameter from the controller and that controls

the power supply parameters (voltage, current).

Controller Module communicate the power supply

parameter from input and output module to the remote

GUI through communication protocols (Ethernet, RS232).So the engineering design of the various modules,

application development of remote graphical user

interface and integrated functional testing is the task of

the project.

I. INTRODUCTION

Embedded systems are designed for the specific

function within the larger system. It has the processing

circuit like Microprocessor, DSP and FPGA that allows

the data communication very easily. The characteristic of

the embedded system to handle the particular task allows

the design engineer to reduce the size and cost of the

system and at the same time also make the system more

reliable. Here the custom make engineering design of the

Power supply embedded controller is planned as shown

in the figure. Embedded controller will be specific to the

single power supply that will locally perform the control,

monitor and protection of the power supply.

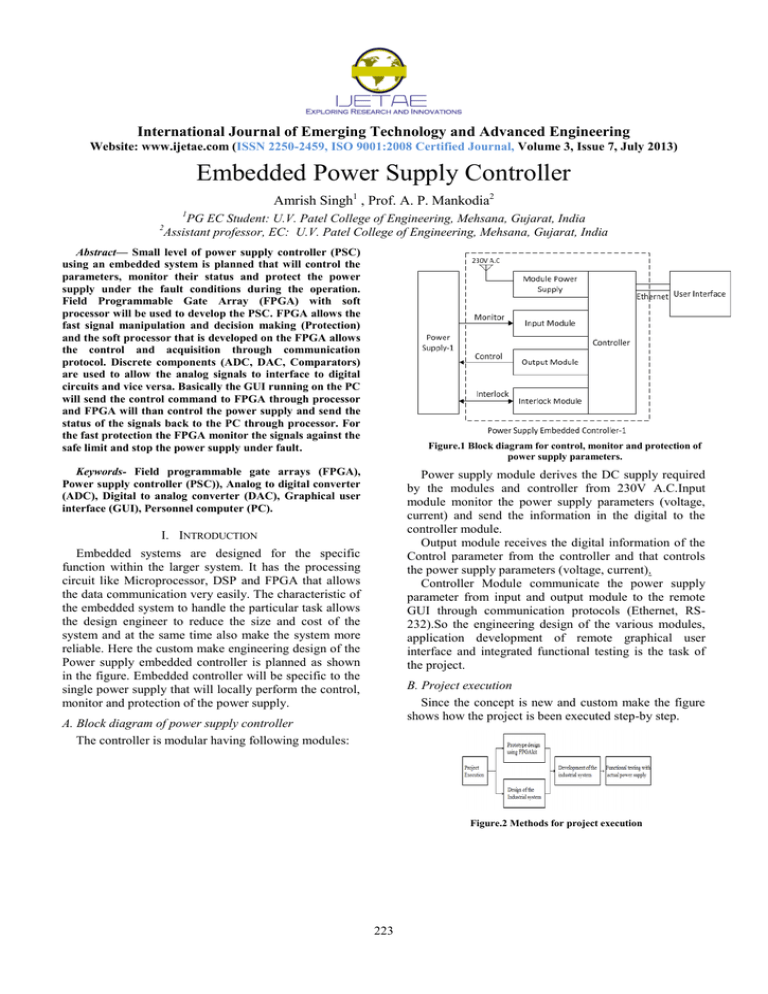

B. Project execution

Since the concept is new and custom make the figure

shows how the project is been executed step-by step.

A. Block diagram of power supply controller

The controller is modular having following modules:

Figure.2 Methods for project execution

223

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 7, July 2013)

The first step is to prove the concept with prototype

design. So the whole concept is designed using the

Spartan-3an FPGA starter kit [6] and it is tested with

dummy signal. Also application program for remote

operation is developed in Lab View software.

In parallel to prototype design the circuit design for

industrial system is carried out. The whole system is then

developed considering the industrial method and then

tested with actual power supply of ECH&CD system.

Figure.5 SPI Timing When Communicating with preamplifier[6]

II. PROTOTYPE DESIGN OF INPUT MODULE USING

SPARTAN 3 AN KIT

B. SPI Communication Interface for ADC (analog to

digital converter)

When the AD_CONV signal goes high, the ADC

simultaneously samples both analog channels. The results

of this conversion are not presented until the next time

AD_CONV is asserted, a latency of one sample. The

maximum sample rate is approximately 1.5MHz. The

ADC presents the digital representation of the sampled

analog values as a 14-bit, two’s complement binary

value.

Spartan-3an starter kit is used to perform prototype

design. As shown below the kit has 14-bit ADC (analog

to digital converter) that will act as input module for

power supply parameters monitoring.

Figure.3 input module on SPARTAN 3AN kit [6]

A. SPI(serial to peripheral interface) Communication

Interface for preamplifier

The gain for each amplifier is sent as an eight-bit

command word, consisting of two four-bit fields. The

most-significant bit, B3, is sent first.

Figure.6 SPI Timing When Communicating with

preamplifier [6]

C. Equations

The analog representation of the output is given by:

D [13:0]

(1)

=

8192XGAINX

(VIN

–

1.65)/1.25

D [13:0]: 14 bit representation of analog input.

GAIN: Gain of preamplifier.

1.65V: Reference voltage for each ADC.

III. PROTOTYPE DESIGN OF OUTPUT MODULE USING

SPARTAN 3AN KIT

Figure .4 SPI Control Interface for preamplifier[6]

The SPI bus communication with the amplifier is

shown in fig.4. Which starts on the falling edge of

AMP_CS and the data is actually read on SPI_MOSI

signal on the rising edge of the serial clock SPI_SCK

signal just after 30 ns, after the data is read then then

actual data is write on AMP_MOSI signal on the falling

edge of the SPI_SCK signal.

The DAC device is a Linear Technology LTC2624

quad DAC with 12-bit unsigned resolution. The four

outputs from the DAC shown in Figure 7

224

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 7, July 2013)

The LTC2624 DAC transmits its data on the

DAC_OUT signal on the falling edge of SPI_SCK. The

FPGA captures this data on the next rising SPI_SCK

edge. The High-going edge starts the actual digital-toanalog conversion process within the DAC.

C. Equations

VOUT=

(2)

VEREFERNCEX

D[11:0]/4096

VOUT=12 bit analog output voltage representation

VREFERNCE: Reference voltage available for each

DAC.

Figure.7 SPI Timing When Communicating with preamplifier [6]

A. SPI (serial to peripherel interface) for DAC(digital to

analog converter)

FPGA uses a Serial Peripheral Interface (SPI) to

communicate digital values to each of the four DAC

channels. A bus master the FPGA in this example drives

the bus clock signal (SPI_SCK) and transmits serial data

(SPI_MOSI) to the selected bus slave the DAC in this

example. At the same time, the bus slave provides serial

data (SPI_MISO) back to the bus master.

IV. EXPERIMENTAL RESULTS

Figure.10 Test bench result of preamplifier and I complete

clock cycle is 400ns

Figure.8 Digital-to-Analog Connection Schematics[6]

B. SPI Communication Details

After driving the DAC_CS slave select signal Low,

the FPGA transmits data on the SPI_MOSI signal, MSB

first.

Figure.11 result of preamplifier on CRO and the one clock cycle is

also 400ns

Figure.9 SPI Communication Details[6]

The LTC2624 captures input data (SPI_MOSI) on the

rising edge of SPI_SCK; the data must be valid for at

least 4 ns relative to the rising clock edge.

225

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 7, July 2013)

Figure.14 Test bench waveform of DAC

Figure.12 ADC SPI Control timing with timing between the 2 rising

edges of clock is 480 ns on Xilinx software

Figure.15 DAC SPI Control timing on CRO

Figure.13 ADC SPI Control timing on CRO

226

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 7, July 2013)

V. CONCLUSION

REFERENCES

Journal Paper References:

Since embedded power supply controller is used as a

localized solution for individual power supply so it

provide the customized approach to control number of

power supply by designing specific controller as per the

power supplies. Embedded power supply controller also

reduces number of cables and connection required for

controlling the power supplies and also reduction in size

and cost of the system by improving the reliability and

performance. Hence we came to conclude that as an

option by following the above features merits and desired

results from the embedded power supply controller which

are same by using COTS(commercially available off the

shelf system) systems using PLC and PXI we can use

embedded power supply controller.

[1]

[2]

Amine Mezghani and Josef A. Nossek. “How to

choose the

ADC resolution for short range low power communication,

publication year 2010 by IEEE conference publication

IEEE, IEEE Standard VHDL Language Reference Manual (IEEE

Srd 1076-2001), Institute of Electrical and Electronics Engineers,

2001.

Book References:

[3]

[4]

[5]

J. Bhasker, A VHDL Primer, 3rd Edition, Pearson Prentice Hall,

New Delhi, 2006

P. J. Ashen den, The Designer’s Guide to VHDL, 2nd ed.,

Morgan Kaufmann, 2001

J. 0. Hamblen et al., Rapid Prototyping of Digital Systems:

Quartus@ II Edition, Springer, 2005.

Datasheet Reference

[6]

Spartan-3A/3AN FPGA Starter Kit Board User Guide/UG334

(v1.1) June 19, 2008

[7] Complete, Quad, 12-/14-/16-Bit, Serial Input, nipolar/Bipolar

Voltage Output DACs 5754R

[8] Ultra low Distortion, Ultra low Noise Op Amp 2.5 V/3.0 V High

Precision Reference AD780 AR

[9] 5V to 3.3 V voltage converter IC 3303.

[10] 2-Channel, Software-Selectable, True Bipolar Input,1 MSPS, 12Bit Plus Sign ADC 7322

Acknowledgement

I would like to thank all who have been instrumental

in my growth as engineering professional.My great

obligations remain towards Prof. Anand.P.Mankodia, for

being a constant source of inspiration, and acting as a

guide, helping me throughout my stint in the college,

participating actively in the report development process,

providing me with all the facilities, and who has done

much beyond expectations to bring out the best in me.

227