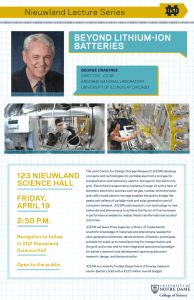

Technology Overview on Electricity Storage

advertisement