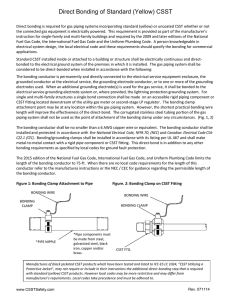

Validation of Installation Methods for CSST Gas Piping to

advertisement