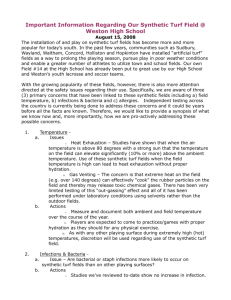

Sources of Heat in Synthetic Turf Systems - Trace

advertisement