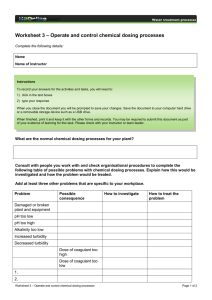

CHEMICAL DOSING UNIT STANDARD SPECIFICATION

advertisement