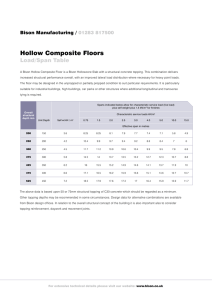

CONCRETE FLOORING - Bison Manufacturing Limited

advertisement