Confidential

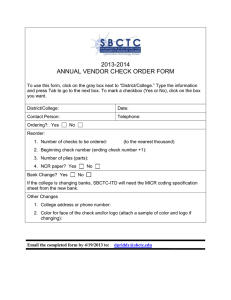

advertisement