Revised BOQ Civil work for Cricket Stadium Saifai

advertisement

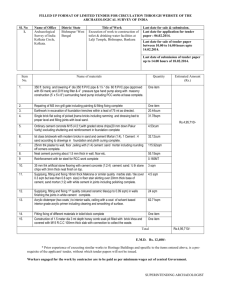

Proposed International Cricket Stadium at Saifai, Etawah

CIVIL WORK AND DEVELOPMENT WORK.

SI. No

Description

Unit

Quantity

Rate

Amount

EARTHWORK

1

2

3

4

5

6

7

Earth work in excavation by mech anical means (Hydraulic excavator)

/ man ual means over a reas (exceeding 30cm in depth . 1.5 m in width

as well as 10 sqm on plan) includi ng d isposal of excavated earth, lead

up to SOm and lift u p to 1.Sm, d isposed earth to be levelled and neatly

d ressed.

All kinds of soil

Cum

Excavation work by mechanical means (Hydraulic excavator)/

m anual means in founda tion trenches or d rains (no t exceeding 1.5m in

width or 10 sqm on plan), includ ing d ressing of sides and ranm1ing of

bottom s, lift up to 1.5 m, including ge tting out the excavated soil a nd

d isposal of surplus excava ted soils as d irected, w ithin a lead of 50 m

H ard rock (requiring blasting)

Extra for every additional li ft of 1.5 m or part thereof in excava tion /

banking excavated o r s tacked m a terials.

All kinds o f soil

Ordinary or ha rd rock

Extra for d isposal o f excavated ma terial for lead beyond 100m t. But

u pto l Km.

Supply and filling of selected good earth

Lead Above up to 10 Km ( Paym ent shall be made as per actual Lead )

Filling availc1ble excava ted ear th (exclud ing rock) in trenches, p linth,

sides of foundation s etc. in layers not exceeding 20cm in depth,

consolidc1ting each deposited layer by ramming and watering, lead up

to 50 m and lift u pto 1.5 m.

Supplying and fill ing in w ith local sand under treds floors; including

watering, ram ming, consolidating and dressing comple te

Cum

125233.00

83.60

10469478.80

750.00

250.35

187762.50

Cum

Cum

18784.95 .

112.5(

9.50

19.00

178457.03

2137.50

Cum

79557.15

94.47

7515763.%

cum

5000.00

314.45

1572250.00

C um

37500.00

57.00

2137500.00

C um

7500.00

864.74

6485550.00

Cum

750.00

5192.99

3894742.50

Cu m

9634.48

4592.59

44247198.13

Sqm

10589.56

617.50

6539053.30

Sqm

15884.34

261.25

4149783.83

sqm

12461 .37

186.63

2325665.71

sqm

963.45

398.08

383529.22

PCC, RCC & STEEL WORK

8

a

b

9

10

11

a

12

Providing and laying in position cement concre te of specified grade

excluding the cost of centering and shuttering - All work up to plinth

level

1:2:4 (1 Cement : 2 coarse sand : 4 graded s ton e aggregate 20

mm nominal s ize)

1:3:6 (1 Cem ent : 3 coarse san d : 6 graded s tone aggregate 20

mm nominal s ize)

60 mm thick stiching slab (1 :2:4) with colour p igm ent and integral

wate r proffing compound and reinforced witl1 weld ed mesh

specification as per d rawi ng comple tein a ll respect as per Engineer In

Charge.

40 mm thick Wa ter proof cemen t p laster in two layer over inside

verticle por tion of risers c1 nd slop portion of wast slab befor fi liing tl1e

area with light weight concrete.

"C entering a11d shuttering including s trutting, p ropping etc. a nd

remova l of form work fo r :

Fo undation, foo tings, bases for columns

Making plintl1 p rotection 50 mm thick of cement concrete 1:3:6 ( 1

Cement :3 coarse sand : 6 grade s tone aggregate 20 mm no minal size)

over 75mm bed of d ry blick ballast 40 mm nominal size well rammed

and consolidated and grouted with fine sand inclu d ing finishing the

top s mooth.

Page 1 of 17

SI.No

Description

Unit

13

Providing and laying in p osition machine ba tched, machine mixed

and machine vibrated design mix cemen t con crete of specified grade

for reinforced cement concrete work including pumping of concre te to

site of laying bu t excluding the cos t of centring, shuttering,

finishing and reinforcement. includ ing Admixtures in recommended

proportions as per IS 9103 to accelerate, retard setting of concrete,

improve worka bility without impairing strength and du ra bility as per

direction of Engineer-in-charge. M-25 grade reinforced ceme nt

concrete.

a

b

14

a

15

16

a

b

c

d

e

f

g

h

17

18

19

All work upto Pli nth level.

All work From Plinth Level & upto floor V level.

Extra for p roviding riche r mixes at all floor levels.

No te:- Excess/ less cement over the specified cement content used is

payable / recoverable separately.

Providin g M-30 grade concre te instead of M-25 grade BMC/RMC.

Extra for concreting of slope su rface above 15°

Centring and shu ttering including strutting, propping etc. and

removal of form for :

Foundations, footings, bases of columns, etc. for mass con crete.

Walls (any thickness) inclu ding attached pflasters, butteresses, plinth

and string courses e tc.

Suspended floors, roofs, landings, balconies and access platform.

Lintels, bea ms, plinth beams, girders, bressumers and cantileve rs.

Columns, Pillars, Piers, Abubn ents, Posts and Struts.

Stairs, (excluding lan dings) excep t spiral-staircases.

Extra for shuttering in circular wor k (20% of respec tive centering

an d shu ttering items)

Shuttering in elliptical/ p rojectile kind of safe on rakker column with

steel mou lds shuttering at different heigh t including necessary staging

and support

Exh·a for addi tional height in centring, shuttering where ever required

wi th adequa te bracing, propping etc. including cos t of de-shu ttering

and d ecentring a t all levels,over a height of 3.5 m, for every additional

heiirht of 1 meh·e or nart th ereof (Plan area to be

Suspended floo~s, roofs, landing, beams and balconies (Pla n area to be

measured).

Steel reil1forcement (Thermo-Mechanically Trea ted bar Fe-500) for

R.C.C. work including straightening, cutting, bend ing, placing in

position and binding all complete upto supe rstructure.

Providing,fabricating , transpor ting, assembling & erection in position

of Steel members for steel colunms, built up beams using structural

tu bular sections ( round, square or rectangular hollow tu bes etc.

confirming to IS 4923 / IS 1161 , Yield strength 310 MPa as per latest IS

Code ) to the required profile & shape as called for as per the

drawing & specifications.This item also includes the shear con nectors

I studs & fusion weld to top of h orizon tal member . This item also

includes prepration of shop drawings & their approval, necessary

templa tes,adequate temporary su pports, scaffolding & staging,all

cutting, grinclin g,sliding & all labour ,tools,plants& equjpments &

operations etc. required to complete the job as per d rawing &

specification. every precaution to be taken to p revent rusting of

sections. This item also incl udes all tes t on materials & welded

fabricated ..pa rts as per specifica tion & direction of Engineer - in Charge . Temporary bolts & nuts ( grade EN 8 ) to be used during

assembling & shall be removed before site erection.All site erection

bolts shall be HSFG type only. The item to include cost of sand

blasting on materials, application of p rimer & various coa ts of internal

& external painting in fabrica tion shop & final painting on site

including all touch up works after erection as per technical

specification.

A) The scope of work for this i tem includes :

Quan tity

Ra te

cu m

cu m

18981.00

22230.00

5724.57

5954.46

108658063.17

132367645.80

Cl\111

Cum

43380.00

7000,00

313.50

255.60

13599630.00

1789200.00

sqm

39960.00

186.63

7457734.80

sqm

sqm

sqm

sqm

sqm

16639.80

48799.26

58320.02

94714.67

6317.77

342.76

381.57

315.54

430.68

375.87

5703458.53

18620334.02

18402300.12

40791714.51

2374661.67

sqm

11014.50

86.14

948789.03

Sqm

6500.00

864.50

5619250.00

sqrn

48799.26

151.10

7373568.34

MT

6073.20

64695.00

392905674.00

MT

525.00

118750.00

62343750.00

-

AG

Page 2 of 17

Am ount

SI.No

Unit

Description

Quantity

Rate

Amount

a ) Design & fabrication of any additional temporary structure

20

including all type of Lifting bracke ts, supporting brackets ,which will

be required for transportion & erection in position / launching of

fabrication part or complete element in position.

b) Making provision & arrangement for required opening / inserts for

fixing lights fixtures & funning cable conduits .

c) All incidentials .labour , eq uipement & plants required to execute &

complete the job from fabrication to erection at final position as per

drawing ,specification & direction of Engineer - in -Charge.

d) Cleaning & removing of all spoil , temporary anangementa for

casting of deck slab.

e) All safety measures required to execute & complete the work.

f ) Procurement of all materials from approved manufactures &

fabrication. Complete meth odology for structural steel work. Name of

workshop fo r fabrication works. Testing facilities & erection

IProcedures etc.to be in timated for approval of Engineer - in - Charge.

g ) The p rovision of tem porary bearing / sand jacks for supporting

steel members during erection.

h ) Provision of stability during erection against wind load or any

other type of loading on structurnl steel members during erection.

B ) Measurement shall be only for structural steel which is erected & is

part of permanent sh·ucture & paid as per approved shop

drawings.All wastages , temporary works , Jigs ,temporary assembly

bolts e tc. are deemed to be incl uded in quoted rates . No allowence or

increse in weigh t for welding, nuts & bolts etc will be applicable.

Providing testing & tigthtening of high strength friction grip bolts

(HSFG bolts ) of class/ grade EN 8 up to proof load as per IS 4000,

including required threading, using automatic calibra ted torque

wrench at all locations & a il heights , & U1eir compitable nuts &

washers all complete required to execute the job. All HSFG bolts, nuts

& washers confirming to IS 1367, IS 6610 & IS 4000 shall be used . The

measurement shall be made for complete assembly of bolt, nut &

compitable washers used in u en nanent works.

2000.00

118.75

237500.00

917.81

3722.20

3416285.04

6750.50

6067.60

40959333.80

sqm

32000.00

95.00

3040000.00

sqm

37000.00

164.16

6073920.00

sqm

83000.00

95.00

7885000.00

Sqm

2000.00

42.75

85500.00

Kgs

MASONRY WORKS

21

22

Random rubble masonry w iU1 hard stone in foundation and plinth

including levelling up with cement concrete 1:6:12 (1 cement: 6 coarse

sand : 12 graded stone aggregate 20 mm nominal size) upto plinU1

level wiU1

Cum

Cement mortar 1:6 (1 cement : 6 coarse sa nd)

Providing and laying au toclaved aerated cemen t blocks masonry with

100mm up-to 300111 thick AAC blocks in super structuJ'e a bove plinth

level up to floor V level in cemen t mortar 1:4 (1 cement: 4 coarse sand

) The rnte includes providing and placing in position 2 Nos. 6 mm dia

Cwn

M.S. bars at everv third course of masonry work.

PLASTER WORKS

23

24

25

26

12 mm cement plaster of mix :-Ceiling

1:6 (1 cemen t : 6 fine red sand)

15 mm cement plaster on the rough side of si ngle or half brick wall of

mix :-External

1:6 (1 cement: 6 fine red sand)

12 mm -cement plaster of mix :-Internal

1:6 (1 cement: 6 fine red sand)

Providing and fixing approved quality chicken wire mesh 12mm x

12mm x 20 gau ge at the junction of concrete & masonry with all lead &

lifts including cost of materials, labour charges, conveyance etc.,

complete

Page 3 of 17

SI. No

Description

Unit

j

Quantity j

Rate

Amount

FLOORING & WALL FINISHES

27

28

29

30

31

32

33

34

Providing and laying gang saw cut 18 mm thick, mirror polished pre

moulded and pre polished machine cut granite stone of required size

and shape of approved shade, colour and texture in flooring cut

granite stone of required size and shape of approved shade, colour

and texture in footpath, and similar locations, laid over 20mm thick

base of cement mortar 1:4 (lcement: 4 coarse sand) including grouting

the joints wiU1 white cement mixed with match ing pigment, epoxy

touch ups etc. complete as per di rection of Engineer-in-Charge as per

design, pattern in hvo or three colours.

Sqrn

52 mm thick cement concrete flooring with concrete hardener topping,

under layer 40 mm U1ick cement concrete 1:2:4 (1 cement : 2 coarse

sand : 4 grad ed stone aggrega te 20 mm nominal size) and top layer 12

mm thick cement hardener consisting of mix 1:2 (1 cement hardener

mix : 2 graded s tone aggregate 6 mm nominal size) by volume,

hardening compound mixed @ 2 li tre per 50 kg of cement or as per

manufachirer's specifications. This includes cost of cement slurry, bu t

Sqrn

excludinP the cost of nosin1> of s tens e tc. com ole te

P & L Vih·ified AntiSkid tiles 600x600 mm laid on 20mm thick cement

Sqm

mo rtar 1:4 incl g routing the joints with white cement

Providing and laying vitrified floor tiles/ s kirting in different sizes

(thi ckness to be specified by the manufacturer) with water absorption

less U1an 0.08% and conformin g to IS : 15622, of approved make, in all

colours and shades, laid on 20mm thick cement mortar 1:4 (1 cement :

4 coarse sand), including grouting the joints with white cement and

matching pigments etc., !BEL or Equivalent complete.-300mm

X300mm/300mm X600mm/600mm X600mm

Sqm

Providing and Laying Kota Stone Flooring in Approved pattern

leather finis h on a bed of 1:6 CM i/ c cement float, filling joints with

nea t cement slurry, curing and polishing i/ c cost a nd conveyance of

all ma terials, seigneraige charges, labour charges, cleaning etc.

complete in cill respect w ih lea ther finish .

25 mm thick

Sqm

Providing and fixing Glazed Ceramic wall tiles of 200 x 200mm and

300 M x 300M size ond 6mm thick and of approved colour, shade,

Matt finished pa ttern for Dado on 12mm thick backing coat of 1:4

cement plaster and neat cement float using polymer based tile

adhesives of approve make including filling joints with white cement

mixed with pigm ent to match the colours, curing, acid cleaning

including cos t, seigniorage & conveyance of all materials & labour

Sq rn

charges e tc. com olete fo r finished item

Chequere d terrazo tiles 22 inm thick with grad ed marble ch ips of size

up to 6 mm in floors, jointed w ith neat cement slurry mixed with

pigment to match the sh ade of the tiles, including rubbing and

polishing comple te, on 20 mm thick bed of cement mortar 1:4 (1

cement :4 coarse sand) :

Medium shade pigment using 50% white cement, 50%

Sqm

ordinary cement

Providing and laying machine cut mirror po lished Granite Slab of

various sizes and dolour and 18-20mm thick in approved colour and

shade for wall cladding in requi red pattern fixed with SS dowels and

polymer based adhisive compound, filling joints with neat coloured

cement slurry, cleaning am.I as per a rchitects d rawing and design

including cost, conveyance a nd labo ur charges and s taging e tc.

complete as per Instruction of Engineer lncharge.

i)

Sqm

Ground Floor

Page 4 of 17

5000.00

2991.12

14955600.00

4000.00

508.49

2033960.00

1552.72

1377.50

2138871.80

15000.00

1335.65

20034750.00

1586.65

1084.33

1720452.19

3480.78

794.82

2766589.59

400.00

896.52

358608.00

1828.00

3515.00

6425420.00

~ ::f> I ~

\JL r,10

~U .

l,.l ~ J'O \

•

0 ~ 0

~ l[c:f>T~. ~c.Tcll

Unit

Description

SI. No

Providing and fixing granite stone slab with table rubbed, edges

35

rounded and polished, of size 1200mm high x 40 mm deepand 1.8 cm

U1ick, fixed in urinal partitions by cutting a chase of appropriate width

with chase cutter and embedding the stone in the chase with epoxy

grout or with cement concrete 1:2:4 (1 cement : 2 coarse sand : 4

graded stone aggregate 6 nun nominal size) as per d irection of ngineer Sqm

Providing & fixing MS heavy duty grill + Gates at entrance gate with

36

MT

painting as per detail drawing.

Quantity

Rate

Amount

150.00

3099.85

464977.50

32.45

71250.00

2312062.50

Sqm

Kgs

638.00

6000.00

1820.44

427.50

1161440.72

2565000.00

Sqm

638.00

642.58

409966.04

Sqm

120.00

2035.00

244200.00

Sqm

45.00

297.92

13406.40

Sqm

Each

45.00

25.00

688.61

417.00

30987.45

10425.00

765.00

385.61

294991.65

85.00

1001.49

85126.65

DOORS & WINDOWS

37

38

39

40

41

42

43

44

45

Providing and fixing !SI marked flush door shutters comfirming to

15:2202 (Part - I) non decorative type, core of block board

constructionwith frame of first class hard wood & well matched

commercial 3 p ly veneering with vertical grains of cross band and face

veneers on both faces of sh utters: 35mm thick including IS! marked

stainless steel butt hings with necessa1v screws.

35 mm thick including ISi marked Stainless Steel butt hinges with

necessa ry screws

Aluminium frame with bead for item no 9.21 for duct area only.

Providing and fixing 1.0 mm U1ick decorative high presure laminated

sheet of plain / wood grain in gloos / matt / suede finish witl1 high

density protective surface layer and reverse side of adhesive bonding

quali ty conforming to IS : 2046 type S including cost of adehsive of

approved qualitv.

Supplying and fixing rolling shutters of approved make made of

rewuired size M.S. toge ther through their entire length and jointed

togeth er at the end by end locks mounted on specially designed pipe

shaft with brackets, side guides and arrangements for inside and

outside locking with push and pull operation complete including the

cost of providing and fixing necessary 27.5 cm long coil springs grade

No. 2 and M.S. top cover of required thickness for rolling shutters.

80xl.25mm M.S. laths with 1.25mm thick top cover.

Extra fo r providing grilled rolling shutters manufactured out of 8mm

dia. M.S. bar instead of laths as per design approved by Engineer-inCharge. (area of grill to be measured)

Extra for providing mechnical device chain and crank operation

rolling shutters, Exceeding 10.00 sqm and upto 16.80 swm in the area.

Providing and fixing ball bearing for rolling shutters.

Providing and fixing aluminium work for ventilators and louvers

with exh·uded built up standard tubular section/ appropriate sections

and otl1er sections of approved make conforming to lS:733 and IS :

1285, fixed with raw! plugs and screws or with fixing clips, or witl1

expansion hold fash1ers including necessary fillings up of gaps a t

junctions, at top, bottom and sides with required PVC/neoprene felt

etc. Aluminium sections shall be smootll, rust free, straight, mitred

and jointed mechanically wherever required including cleat angle,

Aluminium snap beading for glazing / paneling, C.P. brass I

stainless steel screws, all complete as per architectural drawings and

the directions of Engineer-in-Charge. (Glazing and paneling to be paid

separately) : Natural anodised aluminium (minimum thickness of

anodising shall be of AC15)

Overall portion treated as fixed.

Anodised aluminium (anodised transparent or dyed to required shade

Kg

according to IS: 1868, Minimum anodic coating of grade AC 15)

Providing and fixing glazing in aluminium door, window, ventilator

shutters and partitions etc. with EPDM rubber / neop rene gasket etc.

complete as per the aJchitectural drawings and the directions of

engineer-in-charge.

Sqm

With float glc1ss pc1nes of 5.50 mm thickness

Page 5 of 17

SI. No

46

47

Description

Unit

Frameless Glass Doors: Design, fabrication and installation of

frameless glass doors consisting of 12nu11 thick clear toughened glass

and providing & fixing with DORMAmake PT STANDARD Patch

fit tings such as Top pivot(PT34), top patch(PT20), Bottom Patch

(PTlO), Corner Lock with EPC(US 10), Lock keeper pla te, SS finish

"D" shape Pull Handle 300mm x 22mm(TGDI 300225) and double

action floor spring BTS75v .and making necessary holes etc. for fixing

required door fittings, all complete as per direction of Engineer-incharge (door handle, lock and stopper etc to be paid

separately.) (NOTE: max Door size 1100mm x 2400mm, for high er

height overpanel to be provided.) Design Calculation authority to be

furnished by supplier for approval by Clien t / Consultant. ,Final

certifications of products should be submitted be from the product

manufacture r for the originality of the product and manufacturer

should be have its own service team .Installtion of the work should be

done by Donna certified partner ,who has sucessfully accomplised

similar works before . The above work complete in all respect as per

approved drawings and to the satisfac tion of Architect /Engineer-inCharge.

Sqm

Frameless Suspended Glazing with Spider Fittings:

Design,

Supply and Installation of frameless glazed fai;ade suspended from

the top of the opening provided with finishing/ shading as per

Consultant / Architect approval incorporatingtougnrd / laminated

glass panes 13.5 mm thick(12.00mm+l.52mm) as per approved

drawing and fins as stabilizers used at each vertical joint to provide

lateral stiffness against wind loading, deflections and other specified

loads expected including frame work structural supports wherever

necessary and hardware all othe r accessories in the glazing with a ll

extrusions, fittings, suspension brackets, DORMA spider fittings of

"PFF" series, "V" Series with 4,3,2,1 points spiders & FHB / FHAB M12

stainless steel bolts as per design. The "PFF" Series Spiders shall have

a curvi-linear design to reduce stress concentration a t transition

points,Sleek & twisted arm design for higher torsional moment of

resistance & better aesthetic fea tures. The spid ers shall be fastened to

the fin glass with high tensile stren gth SS 316 Countersunk Allen

bol ts. The Flat head bolts for facade glass shall be of SS 316 with an

outer diameter of 38nun and all necessary accessories.

The spiders shall be manufactured by investment casting process of

grade SS 316 as per EN Norms All screws, all weather elements such

11s flashing, coping, approved Dow Corning sealants, e tc to make the

system completely waterproof. All spider fi ttings should be designed

to support the weight of th e glass by direct bearing on the bolts

wherein the structure should be designed as per the relevant codes

and should be able to withstand the relevant thermal movements.

Design Calculation authority to be furnished by supplie r fo r approval

by Client / Cons ultant. ,Final certifica tions of products should be

submitted be from U1e p roduct manufacturer for the originali ty of the

product and manufacturer should be have its own service team

.lnstalltion of the work should be d one by Dorma certified partner

,who has sucessfully accomplised similar works before . The above

work complete in all respect as per approved drawings and to the

sa tisfaction of Architect /En1?i11eer-in-Charge.

4 to 4.5 metre heigh t

Sqm

4.5 to 6 metre height

Sqm

Page 6 of 17

Quantity

Rate

Amount

315.00

6840.00

2154600.0Q

375.00

235.00

9110.50

9566.50

3416437.50

2248127.50

Unit

Description

SI.No

48

Providing and Fixing Dorma Wall Connecting Profile -Non Secured

Version on top a nd bottom of the fixed glass , w.c.p would have

alumunium base rail with clamping parts a nd screws and EPDM

gasket for 12mm glass The p rofile would have clip on cover of

Stainless steel Grade 304 of 40 mm on both sides , having a standard

lenth. of 3 me tre,The above work complete in all respect as per

approved d rawings and to the satisfaction of Architect /Engineer-inCharge. Design Calcula tion authori ty to be furnished by supp lier for

approval by Client / Consultan t. ,Final certifica tions of prod ucts

should be submitted be from the prod uct manufacturer for the

originality of the product and manufacturer should be have its own

service team .lnstalltion of the work should be done by Dorma

certified partner ,who has sucessfully accomplised similar works

before . The above work complete in all respect as per approved

drawings and to the satisfaction of Architect /Engineer-in-Char ge.

49

50

51

2.5 to 3 metre h eight

Frameless Suspended Glazing with Spider Fittings:

Design,

Supply a nd Installation of frameless glazed fa<;ade suspended from

the top of the opening p rovided with finishing/ shading as per

Consultant / Architect approval incorporatingtougnrd glass panes

12.00mm as per approved drawing and fins as stabilizers used a t

each vertical joint to provide lateral stiffness against wind load ing,

deflections and other specified loads expected including fram e work

sh·uctural supports wherever necessary and hardware all other

accessories in the glazing with all exh·usions, fi ttings, suspension

brackets, DORMA spider fittings of "PFF" series, "V" Series with 4,3,2,1

points spiders & FHB / FHAB M12 stainless steel bolts as per design.

The "PFF" Series Spiders sha ll have a curvi-linear design to reduce

stress concenn·ation at h·ansition points,Sleek & twisted arm design for

higher torsional moment of resistance & better aesthetic fea tures. The

spiders shall be fastened to the fin glass with high tensile strength SS

316 Countersunk Allen bolts. The Flat head bolts for facade glass shall

be of SS 316 with a n outer d iameter of 38mm and all necessary

accessories.

3 to 4 metre height

Providing a nf fixing bright finished brass hanging type flooi· door

stopper with necessarv screw e tc comple te as approved bv the EiC.

Providing anf fi xing door locks of Dorma or Equivalent as approved

by the EiC necessary screw etc complete

Q uantity

Rate

Amount

Sqm

505.00

8141.50

4111457.50

Sqm

275.00

8676.35

2385996.25

Each

250.00

300.44

75110.00

Each

75.00

1744.20

130815.00

75.00

376.20

28215.00

75.00

2453.61

184020.75

450.00

86.64

38988.00

52

53

54

Providing anf fixing stainless steel door handles of 200mm customized

Each

make as approved by the EiC necessary screw etc comp lete

Provid ing and fixing double action hydrulic floor spring of approved

brand and manufactures IS : 6315 marked, for door including cost of

cutting floors as required, embedding in floors an d cover plate with

brass pivot and single piece M.S. sheet outer box with slide plate etc

comple te d irection of Engineer-in-charge with stainless steel cover

Each

plate ..

Filling the gap in between aluminium frame & ad1acent

RCC/ Brick/Stone work (up to 5mm depth and 5mm width) by

providing wea ther silicon sealant over backer rod of approved quality

Rmt

as per architectural drawings com ple te.

Page7 of1 7

Unit

Description

SI. No

Fabrication, supply and fix ing in position fully glazed door partly

55

fixed on sides & top and with double lea f s hutters for central opening

on floor springs using extruded aluminium anodised (approved tint)

sections as per drawing and IS mark fixtures with suitable screws,

bolts, nuts, wooden plugs a t the coru,ections, etc. with U,e following

sections of approved make ....mm thick reflective glass. The door

should be fabricated using standard size galvanised screws in teak

wood plugs including cost of all materials, labour charges for

fab rication and fixing in position and all incidental & operational

charges and conveyance charges etc. complete. Fabrication, supply

Sqm

and fixi1111 in oositi n

Fabrication, supply and fixing in position fully glazed fixed windows

56

using ex truded a lu. anodized sections as per drawings and !SI mark

fixtures with suitc1ble screws, bolts, nuts, wooden plugs for connect

ions etc., complete with the flooring section of approved make. d. 5.5m

thick plain glass fitted using suitable rubber beadings. The window

should be fabricated using s tandard size galvanised screws in teak

wood plugs incl uding cost of all materials, labour charges for

fab rication and fixing in position and all incidental and operational

charges and conveyance charges etc., complete - Window 'W3' of size

Sqm

., nn v 1 ?Om

Providing and fixing alu. top hw,g fully glazed windows and

57

ventilators as per detailed drawing & design and as d irected by

Architect including approved section with 4mm thick p lain sheet glass

fixed witJ1 double gasket with stainless steel pin and fix tures and

Sqm

fi ttin2 etc. comole te

Qua nti ty

Amount

Rate

150.00

5035.00

755250.00

75.00

4096.88

307266.00

50.00

4370.00

218500.00

SQM

37000.00

85.50

3163500.00

SQM

2500.00

85.22

213050.00

SQM

115000.00

48.12

5533800.00

SQM

115000.00

34.06

3916900.00

SQM

2500.00

139.13

347825.00

SQM

3000.00

70.68

212040.00

SQM

154000.00

85.17

13116180.00

For all water proofin g work describe below. The contractor shall

Provide 10 yeaars Guarantee for water tightness of the complete

sys tem in the manner as provided in the specification, Gradin g roof

for water Proofing treahnent with Cement concre te 1:2:4 (1 cement: 2

SQM

coarse sand: 4graded stone aggregate 20mm nominal size).-1 00 mm

1197.00

617.50

739147.50

PAINTING WORKS

58

Finishing walls with Acrylic Smooth ex terior paint o f required shade :

New work (fwo or mo re coat applied @ 1.67 ltr/10 sqm over and

including priming coat of exterior primer applied @ 2.20 kg/ 10 sqm).

59

60

61

62

63

64

Distempering wiU1 oil bound washable distemper of approved brand

and manufacture to 2ive an even s hade

New work (two or more coats) over a nd including water thinnable

priming coa t with cement primer.

Distempering w ith 1st quality acrylic d istemper (ready mixed) of

approved manufacturer, of required shade and colour complete, as

per m anufacturer's soecification.

Two or more coa ts on new work.

Applying one coat of water thiru,able cement primer of approved

brand and manufacture on wall surface :

Water thinnable cement orimer.

Finishin2 walls with textured exterior paint of required shade:

New work (Two or more coats applied @ 3.28 ltr/10 sqm) over and

including priming coat of exterior primer applied @2.20kg/10 sqm.

Painting witJ, synthetic enamel paint of approved brand and

manufacture to 2ive an even s hade:

T°wo or more coats on new work.

Providing and applying white cement based putty of average

thickness 1 mm, of approved brand and manufacture r, over the

plastered wall surface to p repare the surface even and smooth

complete.

WATER PROOFING WORKS

65

Page 8 of 17

S I. No

Description

Unit

66

Proving and laying water proofing 'treatment in toilet e'tc by applying

cement shuTy mixed with water proofing cement compound

consisting of applying :a) First layer of slurry of cement @ 0.488

kg/sqm mixed with water proofing cement compound @ 0.253

kg/sqm. TI1is layer will be allowed to air cure for 4 how·s. b). second

layer of slurry cement @ 0.242 kg/ sqm mixed with water proofing

cement compound @ 0.126 kg/sqm. This layer will be allowed to air

cure for 4 hours followed with water curing for 48 hours. The rate

includes preparation of surface, treatment and sealing of all joints,

corners, junctions of pipes and masonry with polymer mixed slurry.

SQM

67

Proving and laying water proofing treatment on roofs of slab by

applying cement slurry mixed with water proofing cement compound

consisting of applying :a) after surface p reparation First layer of slurry

of cement @ 0.488 kg/sqm mixed with water proofing cement

compound @ 0.253 kg/sqm b) laying second layer of Fibre glass cloth

when the first layer is still green. Overlaps of joints of fibre cloth

should be less then 10cm. c) third layer of 1.5 mm thickness consisting

of slurry of cement @ 1.289 kg/sqm mixed with water proofing

cement compound @0.670 kg/sqm and coarse sand@ 1.289 kg/sqm.

111is will be allowed to air cure for 4 hours followed with water curing

for 48 hours. The entire treatment will be taken up-to 30cm on parapet

wall and trucked into groove in parapet all around. d) fourth layer of

cement plaster cement mortar (which will be paid for seprately For the

purpose of measurement the entire treated s urface will be measured).

SQM

Providing and fixing down gusge iricluding finishing wiU1 cement

mortar 1:3 (1 cement: 3 coarse sand) as per standard design in

1---..-175x75mm deep chase.

SQ:v1

69

Makingk hur~5x45 cm with average minimum thickness of 5cm

cement concrete 1:2:4 (1 cement: 2 coarse sand: 4graded stone

aggregate 20mm nominal size) over PVC sheet 1 m x 1m 1400 micron,

SQ:\1

finished with 12mm cement.

Quantity

Rate

Amount

1197.87

215.16

257733.71

1166.25

256.74

299423.03

550.00

81.94

45067.00

750.00

20~.58

155685.00

68

ROOFING

70

Providing and Fixing Multilayer '3DLite' Panel System 22mm thick·

(minimum) confirming to specifications mentioned below; complete in

all respects.

- Panel shall be 22mm thick (min.)

- Panel Width shall be 600 mm to ensure best performance for wind

uplift, vibration; oil canning and visual appearance.

- The panels shall be uniform in colour with an integral Multilayer

core. ~ The panels shall have 3 cells and 4 walls.

- Both outer walls shall be in clear color.

- Mid dle cells shall have the alternate horizontal walls in white or

approved colour. - Weight of panel shall not be less than 2500 grams

per square meter.- Panels shall be manufactured with Vertical

Standing Seam at both sides of the panel. The height of the standing

seam shall not be more than 16mm to ensure best connector

engagement. Welding or gluing of up stands or s tanding seam is not

acceptable.- Snap-on co1m ector to interlock the panels shall have a

grip-lock double tooth locking mechanism to ensure maximum uplift

capability & shall be of same color as that of panel for aesthetit appeal.

..

- End-cap/ Aluminium U-Profile (mill finish) for ends.

.- Panels sha,11 be co-e?<trude<;!.Jl,\( protec,_te_d,."'.:-----:--:---:-~-:---:---~ .--.ii - -- ,.j.-Panel manufacturer should have project reference in India which is at :

least 10 years ok{ for a single project not less than 1,500 m2.

- Panels shall have 10 years limitec! warranty from manufacturer with

produ c\ / batch details etc engraved for fu ture warrantee reference/

claims. Th e panel system shall be bent to reqllirect profile and fix ed in

position, to the structural steel frc,mew ork, using self-drilling screws,

accessories and Aluminum profiles etc. strictly as per approved

Sqrn

architectural d rawing DANPALON or Equivalent.

I

Page 9 of 17

- -- . , . t - - - ---it, - - - - -- - - - 1

1800.00

7400.00

13320000.00

SI. No

71

Descri p ~ion

Un it

SAIL SH ADE CANOPY STRl,JCTURE.

Providing and fixing at site as per Design & Drawings Sail Shades, of

Ferrari Mesh Fabric 592 color (Moss Green-2158), weigh t 1050 GSM.

Tensile Strength - 500/500 DAN/ SCM

Porosity - 23%

Sh·uctural steel -Mild steel with 2 coats epoxy + top PU coat.

Cables, end fi ttings and accessories.

Cables single standrad cable (1 x 19) with a minimu m tensile strength

of1570 MPa.

End fittings and accessories - GI coated steel.

connection to the main aa-s - on plates that are al ready welded to the

main arcs.

Fixed to main structural steel members with cables / end fittings &

accessories complete work. As per satisfaction of Engineer - in Charge.

Contractor to provide Design Engineering fabrication drawings & get

them approved. All steel to be cut to shape on CNC Machines not

hand cutting shall be allowed.

All work to be carried out as per technical specification (Refer Part-A,

Section-10).

72

Providing and fixing fa lse ceiling at all height including providing

and fixing of frame work made of special sections, er pressed from

M.S. sheets and galvanized with zinc coating of 120 gms/sqm (both

side inclusive) as per rs :277 and onsisting of angle cleats of size 25

mm wide x 1.6 mm thick with flanges of 27 mm and 37mm, at 1200

mm centre to centre, one flange fixed to the ceilin g with dash fastener

12.5 mm dia x 50mm long with 6mm d ia bolts,other flange of cleat

fixed to the angle hange rs of 25x10x0.50 mm of required length with

nuts & bolts of required s ize and other end of angle hanger fixed with

intermedia te G.I. channels 45x15x0.9 mm running at the spacing of

1200 mm centre to centre, to which the ceiling section 0.5 mm thick

bottom wedge of 80 mm with tapered flanges of 26 mm each havin g

lips o f 10.5 mm, at 450 mm centre to centre, shall be fixed in a direction

perpendicular to G.l. in termediate channel with connecting clips made

out of 2.64 mm dia x 230 mm long G.I. wire at every junction,

including fixing perimeter channels 0.5 mm thick 27 mm high having

flanges of 20 mm and 30 mm long, the perimeter of ceiling fixed to the

board with recommend ed jointing compound , jointing tapes ,

finish ing wiU1 jointing comp ound in 3 layers covering upto 150 mm on

both sides of joint and two coats of primer suitable for board, all as per

manufacturer's specification and also including the cost of making

openings for ligh t fittings, grills, diffusers,cutouts made with frame of

perimeter ch annels suitably fixed, all complete as per drawings,

pecification and d irection of the Engineer in Charge but

excluding the cost of painting with :

a

12.5 nun thick tapered edge gypsum fire resistant board conforming to

IS: 2095- Part 1

Page 10 of 17

Quantity

Rate

Amount

Sqm

750.00

10318.90

7739175.00

sqm

4500.00

971.80

4373100.00

SI. No

Description

Unit

'Supplying and Fixing of Suspended ceiling system components with

73

Moist Resistant Board, This includes Ultraframe Perimeter Channel

(0.55mm thick having one flange of 28mm and another flange of

18mm and a web of 30mm) screw fixed to brick wall/partition with

the help of approved screws at 600nun centers. Then suspending

universal section u sed as in termediate channel (45nun x 0.55mm thick

with two flanges of 27mm each) from the soffit at 1220mm centers

with Ceiling Angle (24x24mmx0.55mm thick) fixed to RCC Slab with

Soffit Cleat and Approved Fasteners @ 600mm Centers respectively,

Ultraframe universal Ceiling Section (having knurled web of 45mm

and two flanges of 27mm each) are then fixed to the ultraframe

universal Intermediate channel with the help of four point connecting

clip (0.8mm thick) and iJ1 perpendicular direction to the intermediate

channel at 457mm centers. 12.5mm thick moist resistent gypsum

boards (as per BS 1230· part 1, 1985 type 3) is screw fixed with 25mm

long Drywall screws at 230 mm centers and water absorption, shall

not be greater than 5% , The screw fixing of gypsum boards to the

metal framing at the periphery, openings and cut edges should be at

15011m1 centers. All the Standard boards must be staggered. All jomts

to be taped & finished with Paper tape & All Purpose Joint Compound

confirming to ASTM C475. USG Bora! (Moist Block Gypsum) or

Equivalent.

74

Quantity

Rate

Amount

Sqm

2500.00

1006.53

2516325.00

Sqm

5400.00

1566.69

8460126.00

Providing and Fixing 15 mm thick densified tegular edged eco

friendly light weight calcium silicate false ceiling tiles of approved

texture spin tone/ cosmos/ Hexa or equivalent of size 595 x 595 mm in

true horizontal level, suspended on inter locking metal grid of hot

dipped galvanised steel

sections (galvanising @ 120 grams per sqm including both side)

consisting of main 'T' runner suitably spaced at joints to get required

length and of size 24x38 mm made from 0.33 mm thick (minimum)

sheet, spaced 1200 mm centre to centre, and cross "T" of size 24x28

mm made out of 0.33 mm (Minimum) sheet, 1200 mm long spaced

between main'T' a t 600 mm centre to centre to form a grid of 1200x600

mm and secondary cross 'T'

of length 600 mm and size 24 x28 mm made of 0.33 mm thick

(Minimum) sheet to be inter locked at midd le of th e 1200x 600 mm

panel to from grid of size 600x600 mm, resting on periphery walls

/ partitions on a Perimeter wall angle pre-coated steel of

size(24x24X3000 mm made of 0.40 mmthick (minim um) sheet with the

help of raw! plugs at 450 mm centre to centre with 25 mm long dry

wall screws @ 230 mm interval and laying 15 mm thick densified

edges calicum silicate ceiling tiles of approved texture (Spintone /

Cosmos/hexa) in the grid, including, cutting/ making opening for

services like diffusers, grills, light fittings, fixtures, smoke detectors

etc., wherever required. Main 'T' runners to be suspended from

ceiling

Note :- Only calcium silicate false ceiling area will be measured from

wall to wall. No deduction shall be made for exposed frames / opening

(cut outs) having area less than 0.30 sqm.The calcium silicate ceiling

tile shall have NRC value of 0.50 (Minimum), light reflection > 85%,

noncombustible as per B.S. 476 part IV, 100% humidity resistance and

a lso having thermal conductivity <0.043 w / m O KC, USG Bora! or

Eauivalent.

'3'o

~

~q,,,

~o

f;: RO ftlo

!J"'f I~

~o a

-~ {~rt. ~

Page 11 of 17

SI. No

Description

Providing and injecting chemical emulsion

0.5% chloropyriphos

75

emulsifiable concentrate as per latest IS 6313 Part-I for preconstruction antitermite treatment and creating a chemical barrier

under and areound the column pits, wall trenches, basement

excavation, plinth Providing and injecting chemical emulsion of 0.5%

chloropyriphos emulsifiable concentrate as per latest IS 6313 Part-I for

pre-construction antitermite treatment and creating a chemical barrier

under and areound the column pits, wall trenches, basement

excavation, plinth filling, treatment of junctions of walls at floor,

treatment of soils along ex ternal perimeter of building, treatment of

soils surrounding pipes and conduits etc. with 10 years guarantee.

Payments will be made on the measw-ed plinth area of ground floor in

the filling, treatment of junctions of walls at floor, treatment of soils

along external perimeter of building, treatment of soils surrounding

g pipes and conduits etc. wi th 10 years guarantee. Payments will be

made on the measured plinth area of G.F

of

Unit

Quantity

Amount

Rate

Sqm

56852.13

66.50

3780666.71

cum

4608.00

83.60

385228.80

sqm

7680.00

77.2.3

593126.40

Cum

3456.00

9.64

33315.84

cum

2304.00

2013.91

46400-18.64

Cum

1152.00

6455.25

7436448.00

660.00

213.66

141015.60

ROAD WORK & PARKING AREA DEVELOPMENT

76

77

78

79

80

81

Earth work in excavation by mechanical means (Hydraulic excavator)

/ manual means over areas (exceeding 30cm in depth. 1.5 min width

as well as 10 sqm on plan) including disposal of excavated earth, lead

upto 50m and lift up to 1.5m, disposed earth to be levelled and neatly

dressed.

All kinds of soil

Preparation and consolidation of sub grade with power road roller of

8 to 12 tonne capacity after excavating earth to a n average of 22.5 cm.

depth, dressing to camber and consolidating with road roller

including making good the undulations etc. and re-rolling the sub

ITrarlP and di~nn~:.t of surnlus ea rth with !earl t1nto c;n metre!;.

Extra for compaction of earth work in embankment under optimum

moisture conditions to give at least 95% of the maximum dry density

(proctor density).

Construction of granular sub-base by providing close graded Material

conforming to specifications, mixing in a mechanical mix plant at

OMC, carriage of mixed material by tippers to work site, for all leads

& lifts, spreading in uniform layers of specified thickness with motor

grader on prepared surface and compacting with vibratory power

roller to achieve the desired density, complete as per specifications

and directions of Engineerin-Charge.

Providing and laying design mix cement concrete of M-30 grade, in

roads/ taxi tracks/ runways, using cement content as per design mix,

using' coarse sand and graded stone aggregate of 40 mm nominal size

in appropriate proportions as per approved & specified design

criteria, providing dowel bars wiU, sleeve/ tie bars wherever

required, laying at site, spreading a nd compacting mechanically by

using needle and surface vibrators, levelling to requ ired slope/

camber, finishing wiU, required texture, including steel form work

with sturdy M.S. channel sections, curing, making provision for

contraction/ expansion, construction & longitudinal joints ( 10 mm

wide x 50 mm deep) by groove cutting machine, providing and filling

joints with approved joint filler and sealants, complete all as per

direction of Engineerin-charge (Item of joint fillers, sealants, dowel

bars with sleeve/ tie bars to be paid separately).

Providing and filling in position bitumen mix filler of Proportion 80

kg of hot bitumen, 1 kg. of cement and 0.25 cubicmetre of coarse sand R<1te per

for depth per expansion joints.

cm depth

per cm

width

per 100

Page 12 of 17

Description

SI. No

Painting road surface markfng with adequate nos of coats to give

82

uniform finish with ready mixed road marking paint conforming to IS

: 164 on bituminous surface in white/vellow shade

. includinv

.

.

'

New work (Tv.;o or more coats)

Providing and laying 'a t or 11ear ground level factory 1nade kerb stone

83

of M-25 grade cement concrete in position to the required line, level

and curvature, jointed with cement mortar 1:3 (1 cement: 3 coarse

sand), including making joints with or without grooves (thickness of

joints except a t sharp curve shall not to more than 5mm), including

making drainage opening wherever required complete etc. as per

direction of Engineer-in-charge (length of finished kerb edging shall

be measured for payment). (Precast C.C. kerb s tone shall be approved

bv Engineer-in-~harge}. .

. .

Providing, laying and making kerb channel 30 cm wide and 50 mm

84

thick with cement concrete 1:3:6 (1 cement: 3 coarse sand:6 graded

stone aggregate 20 mm nominal size) over 75mm bed of dry brick

ballast 40 mm nominal size, well rammed and consolidated and

grouted with fine sand, including finishing the top smooth etc.

complete and as per direction of Engineer-in-charge

Providing and laying non-pressure NP2 class (light duty) R.C.C. pipes

85

with collars jointed with stiff mixture of cement mortar in the

proportion of 1:2 (1 cement: 2 fine sand) including testing of joints etc.

complete :450 mm dia. R.C.C. eiee

Providing ai1d laying non-pressure NP2 class (light duty) R.C.C. pipes

86

with collars jointed with stiff mixture of cement mortar in the

proportion of 1:2 (1 cement: 2 fine sand) including testing of joints etc.

complete :600 mm dia. R.C~e

87 . Steel reinforcen1ent for R.C.C. work including sh·aightening, cutting,

bending, placing in posi tion and binding all complete above plinth

level.

The.rmo-Mechanically Treated bars

Cement concrete flooring 1:2:4 (1 cement : 2 coarse sand : 4 graded

88

stone aggregate) finished with a floating coat of neat cement,

including cement slurry, but excluding the cost of nosing of steps etc.

com

·40 mm thick with 20 mm nominal size stone aP"PTegate

Providing and laying 60mn1 thick fadory made cement concrete

89

interlocking paver block of M -30 grade made by block making

machine with strong vibratory compaction, of approved size, design

& shape, laid in required colour and pattern over and including

50mm thick compacted bed of coa rse sand, filling the joints with fine

sand etc. all complete as per the direction of Engineer-in-charge.

Grass Paver Providing &. laying 80 min thick reflective type open

90

jointed (grass) paver block of m inimum compressive strength of 400

kg/sq.cm in uni paver shape of approved make. The rates are

inclusive of providing & laying/spreading approved quality average

50mm thick sand bedding including compaction & filling joints with

san~ at site. The edges are to be neatly trimmed to fit within kerbs

EXTRA ITEMS

.

91

Supply and installation of spike resistant 9mm thick full PUR flooring

with skid free top coat to the utility of players toilets.

92

Providing and laying synthetic Cricket pitch GREEN HF--13 of CC

Grass for Indoor Practice Area.

Gymriasiam flooring conipur (HGEC0-2)

Providing and fixing gymnasiam flooring Elastic Indoor surfacing

system with cone. Primer base, elestic layer, pore sealer and fabric

layer, Intermediate wating laye r a nd top layer and final sealing laquer

~ C(?NICA C_O!"J~PUR HG ECO or e9_

uiv~lent_.

.

Providing and fixing in position Bitumineous Paper baring for slabs

as per aperoved drawing and conforminl?: to IS; 1398

Provi~irig arid ~!:plying two :coats of Enamit'Paint over .primer coat

Pr?vidin~ and fixing of Synthe tic water tank

93

94

95

96

Page 13 of 17

Unit

Quantity

Amount

Rate

Sqm

528.00

116.04

61269.12

Cum

356.40

5031.11

1793087.60

Sqm

1584.00

336.49

533000.16

RM

625.00

670.61

419131.25

RM

375.00

1310.48

491430.00

MT

32.50

64695.00

2102587.50

Sqm

5b73.75

335.68

1703156.40

Sqm

4287.50

572.09

2452835.88

Sqm

2686.50

1365.63

3668765.00

Sqm

220.00

6008.75. ,

1321925.00

sqm

945.00

2115.65

1999289.25

Sqm

..

770.00

4750.00

3657500.00l

Sqm

Sq·m

264.00

944.bO

5600.00

38.00

71.25

6.65

10032.00

67260.00

37240.00

Lts

~co~

-

r,n

Bo ~o xro Ro Pru ,"'A""'

#~ ~ -:"' . {'e.Nr i,

SI. No

Description

Unit

97

Providing and fixing on piece construction w hite Vitreous Squatting

p lae with an integran longitudnal flushing pipe white automatic

cystren including all necessary fi ttings (Ladies (Jrinals)

Nos

98

Providing and fixing chalk board/ notice board with alfa frame incl. all

labour charges and material etc complete

Sqm

99

Providing & Fixing of 3" PVC Nahani Trap as per instructions of

Engineer lncharge

Nos

100 RCC Holes cutting manually 15 x 15 ems in RCC floor including holes

making leak proof finishing comple te. as per the directions of

Engineer lncharge

Nos

101 Providing and fixing 50mm and 40mm dia (2mm thick) Stain less Steel

work railing (tubular sec tion pipe with stain less steel brackets of same

dia and base p late including anchor bolts conforming to IS

specification and as p er direction of Engineer - in - charge including

cost and conveyru1ce of all materials and labour charges etc. complete.

as per Instruction of Engineer lncharge.

JcSg.

102

103

FOR EXPOSED TO WEATHER- EXP ANS ION JOINT ( EJ -1)

Providing and fixing of Expansion joint system for Exposed to

Weather location as per drawin g and d irection of Engineer in-charge.

The material shall be such that it provides a n Expansion Joints System

suitable for horizontal and vertical in the building with no sloping

down tendency amongst the component of the joint system. The joint

include PVC water Stop (250 mm wide -Serrated), Backer rod and fill

with poly sulphite (Pidiseal 41G) including with Aluminium Strip 16

Gauge.

(Material shall be confirmed to ASTM 6063).

(Note - Shop drawing to be submitted to the architect or engineer In

Charge for final approval before doing_ the J ob)

a) 80 mm gap (maximum)

Metre

Expansion Joint exposed to weather (E J - 2)

Providing and tixing ot Expansion joint system tor Exposed to

Weather location as per drawing and direction of Engineer in-charge.

The materia l shall be such that it provides an Expansion Joints System

suitable for horizontal and vertical in the building with no sloping

down tendency amongst the component of the joint system. The joint

include PVC water Stop (250 mm wide -Serra ted) , filler with

expanded polymer board ,Backer rod and fill with poly sulphite (

Pidiseal 41G) including with Alu minium Strip 16 Gauge. (Material

shall be confirmed to ASTM 6063).

(Note -Shop drawing to be submitted to the architect or engineer In

Charge for final approval before d oing the Job)

a) 80 nu11 gap (maximum)

Metre

Expansion Joint not exposed to weather (EJ - 3)

Quantity

Rate

Amount

4.00

6008.75

24035.00

36.00

4588.50

165186.00

287.00

63.65

18267.55

549.00

172.90

94922.10

3034.45

464.55

1409653.75

257.50

6175.00

1590062.50

70.00

5035.00

352450.00

145.00

5700.00

826500.00

4325.00

81.70

353352.50

104

105

Providing and fi xing of Expansion joint system for Exposed to

Weather location as per drawing and direction of Engineer in-charge.

The material shall be such that it provides an Expansion Joints System

suitable for horizontal and vertical in the building with no sloping

down tendency amongst the component of the joint system. The joint

filler with expanded polymer board including with Alu minium Strip

16 Gauge (Material shall be confirm to ASTM 6063).

(Note - Shop drawing to be submitted to the architect or engil1eer In

Charge for final approval before doing the Job)

a) 80 nungap (maximum

Metre

RAILING R-1

Providing and fixing MS railing 500 mm high made of 50 mm dia ms

pipe hand rail and two nos 25 mm dia M S pipe supported on vertical

member 60mmx10mm thick MS Flat @1200 mm C/C on oval shape M

S base plate 12 mm thick out of 125mm x 100 111111 with 12 mm dia dash

fastners on top of 500 mm high & 100 mm thick R CC parapet at 1200

mm c/ c ( all fittings shall be factory made and hot dipped galvanized)

complete fixed in position to the satisfaction of the site Engineer/

Arch itects.

Kg.

Page 14 of 17

l,ln it

Description

S I. No

106

RAILI NG R-1 A

!Providing and fi xing M S railin g 450 mm high made of 50 mm dia m s

pipe h and rail and o ne nos 25 mm dia MS pipe supported on vertical

member 60mmx10mm th ick M S Fla t @1200 mm C/ C on oval sha pe M

S base p la te 12 m m thick ou t of 125mm x 100 mm with 12 mm dia dash

fastners on top of 450 mm high & 100 mm thick R CC parapet at 1200

mm c/c ( all fi ttings shall be factory made and ho t dipp ed galvanized)

complete fixed in p osition to the sa tisfac tion of the site Engineer /

Kg.

Architec ts.

107

RAILING R-2

Provid ing and fix ing M S railing 300 mm h igh made of 50 mm dia m s

pipe h and rail and o ne nos 25 mm dia MS pipe supported on vertical

member 60mmx10mm thick M S Flat @lOOO mm C/C on oval shape M

S base p late 12 mm thick ou t o f 125mm x 100 mm with 12 mm dia dash

fastners on top of 700 mm high & 150 mm thick R CC p arape t at 1000

mm c/c ( nil fittin gs sha ll be fac to ry made a nd hot dipped galvanized )

complete fixed in p osition to th e satisfaction of the site Engin eer/

Kg.

Architects.

108

RAILING R-2A

Providing and fixing MS railing 250 mm h igh mad e of 50 m m dia ms

pipe hand rail on ve rtical mem ber 60mmx10nun thick M S Flat @1000

mm C/ C on o val sha pe M S base plate 12 mm thick out of 125mm x

100 mm with 12 mm dia d ash fas tners on top of 750 mm high & 150

mm th ick R CC p arapet a t 1000 mm c/ c ( all fittin gs shall be factory

made and h ot dipped galva nized) complete fi xed in position to the

satis faction of the site Engi neer/ Architects.

Kg.

109

RAILING R-3

P rovid ing and fixin g M.S. railing 1000111111 h igh made of 50mm d ia

M.S. pipe hand rail on 30mmX50mmX3mm thick M.S. curved piece

w elded on 25mmX25mm square M.S. bar fi xed on 100mm0 X8mm

thick M.S. base plate at 1200mm c/c w ith 12mm dia. Dash fas tners (all

fit tin gs sh all be fa ctory made and ho t d ipped galvanized) comple te

fixed in position to the satisfactio n of the Site Engineer/ Architect.

110

2620.00

74.58

195399.60

2260.00

72.20

163172.00

2605.00

71.73

186856.65

Kg.

2730.00

81.70

2230H.OO

Kg.

2060.00

81.70

168302.00

Kg.

2750.00

74.58

205095.00

Kg.

2260.00

72.20

163172.00

RA ILING R-6

Providing and fi xing M S ra iling mad e of 50 mm d ia M S pipe hand

rail and 3 nos 15 mm d ia ms bars welded o n 30 mm dia M S pipe

balus ters on each tread fi x.e d on 150x100x12 mm thick ms plate with

12 mm dia dash fastners ( a ll fittings shall be factory made and h ot

dipped galvanized) com ple te fi xed in position to the satisfaction of the

s ite Engineer/ Architec ts.

113

Amount

R AILING R-5

Providing and 'fix ing M S railing 900 mm h igh mad e o f 50 mm d ia ms

pipe hand rail on 50 mm x 16 mm MS Pla te welded on 50 mm d ia M S

Stanch ion on alterna te h·ead and 600 mm c/c fixed on 125 x150x12mm

thick M S base pla te with 12 mm dia dash fastners ( all fittings shall be

factory made and ho t dipp ed galvanized ) comple te fixed in position to

the satisfaction of the site EnrrineerI Architects.

112

Ra te

RAILING R-4

Prov id ing and fixing M S railing 850 mm high m ad e o f 50 mm dia ms

pipe hand rail on 40 mm x 16 mm MS Pla te a nd 2 nos 25 mm dia M S

pipe welded on 40 m m dia M S S tanchion on centre line of each tread

on 100x150x10mm thick MS ba se p la te 12 mm dia d ash fas tners on

150 mm h igh & 100 mm thick R CC parapet wall( all fittings shall be

factory mad e and ho t dipped galvanized) complete fixed in p osition to

th e satisfaction of the site Engineer/ Architects.

111

Quantity

RAILING R-7

Page 15 of 17

SI. No

114

115

116

117

118

119

120

121

Description

Unit

Providing and fixing M S railing 370 mm high made of 50 mm dia ms

pipe hand rail on 50 mm x 10 mm thick support made to shape on 100

mm dia x8mm thick ms base plate a t 1200 mm c/c wi th 12 mm dia

dash fastners on 750 nun high R C C parape t wall( all fittings shall be

factory made and hot dipped galvanized) complete fixed in position to

Kg.

•hn c::, tisfactinn of the site -· - '·- --- I Architect~

Grassing (Supply & Planting) in Play Field Area with Bermuda 419

Grass springs including fine dressing of ground dump maure, mixing

earth & sludge or manure in proporation specified by curator.

Uprooting foreign material & disposal of foreign mate rial/vegetation,

watering till the grass forms a thick lawn/ carpet free from weeds & fi t

for palying including specified soil if needed (Good earth shall be paid

separetely) as per instructions of Engin eer lncharge.

Sqm

Grassing (Supply & Planting) in Pitch Area with Bermuda Tiff Way

Grnss springs including fine dressing of ground dump maure, mixing

earth & sludge o r manure in proporation specified by curator.

Uprooting foreign material during maintenance & disposal of foreign

material/vegetation, watering a nd maintenance of ti for three months

or more till the grass fo rms a thick lawn/ carpet free from weeds & fit"

for palying including specified soil if needed (Good earth shall be paid

separelely) as per instructions of Engineer Incharge.

Sqm

Providing and fixing machine molded aluminum covering of

approved pattern & design, made out of machine cut Aluminum Sheet

a nd mad, ine holed fo r receiving screws, over expansion joints o

verticals surface / ceiling with fl threaded, cadmium pla ted steel

screws 4mm d ia stem. 30mm long and aluminum washers 2mm thick,

15mm dia a t a staggered pitch of 200mm centre to centre incl. drilling

hoes in the receiving surface and providing expandable plastic sleeves

in holes e tc. complete. Anodized aluminum sheet 2.5mm thick

(anodized transparent or dyed to required sh ade according to 15:1869,

minimum ru,odic coating of grade AC 15).

Kg

Providing and fixing 12mm dia (HILTI) Anchor Bolts for MS hand

railing work including drilling holes, fixing reparing & finishing e tc.

complete as per direction of Engineer lncharge.

Nos

Providing RCC Core drilling by Dia mond cu tter machine.

Nos

Providing and injecting Chemical Grouting at Truss base including

all materials, labour cost etc complete.

Each

Providing & Fixing Glass Strips 40mm X 4mm for IPS flooring - for

lOmts length

Mts

Providing and fixing 20mm dia Chemical Anchor Bolts including

conveyance ma terial, labour etc.complete as per direction of Engineer

Nos

Jncharl!e.

Quantity

Rate

Amount

2125.00

71.25

151406.25

9299.83

237.50

2208709.63

464.52

237.50

110322.31

659.03

351.50

231647.29

2621.00

10.00

186.20

1764.15

488030.20

176-ll.50

54.50

998.45

54415.53

1828.60

19.00

34743.40

241.50

1159.00

279898.50

14622.51

83.60

12224..Jl.79

23952.87

57.00

1365313.83

88.13

4592.59

4047..J-1.96

EXTERNAL AREA DEVELOPMENT WORKS

AREA LEVELING

122 Earth work in excavation by mechanical means (Hydraulic excavator)

/ manual means over areas (exceeding 30cm in depth. 1.5 min widili

as well as 10 sqm on pla n) incl uding disposal of excava ted earth, lead

upto 50m and lift upto 1.5m, disposed earth to be levelled and neatly

dressed.

Cum

All kind od soil

123 Filling available excava ted earth (excluding rock) in trenches, plinth,

sides of foundations etc. in layers not exceeding 20cm in depth,

consolidating each deposited layer by ramming and watering, lead up

Cum

to 50 m and lift uoto 1.5 m.

124

Providing and laying in position cement concrete of specified grade

excluding the cost of centering and shuttering - All work up to plinth

level

1:3:6 (1 Cement : 3 coc1rse sand : 6 graded stone aggregate 20

Cum

mm nominal size)

Page 16 of 17

SI. No

Un it

Description

Quantity

Rate

Amotmt

SEATING ARRANGEMENT

125

Providing and fixing of Floor Mounted Stad ium chair with aims

having injection moulded polypropylene Vinayl fabric upholstered

seat, back with auto ti p up seat. Armrest with injection polyprnpylene.

Chair of size 595mmx670mmx865mm complete all respect. Godrej

make (INTERACT) Or Equivalent approved by competent authority.

126

Providing and fixing of Floor Mounted Stadium chair with arms

having PU foam moulded seat & back with auto tip up seat. Armrest

with PU foam, under structure MS powder coated. Chair of size

600mmx540mmx890mm complete all respect. Godrej make

(JUPITER 23421X) Or Equivalent approved by competent authority.

127

Each

1000.00

11500.00

11500000.00

Each

11000.00

9500.00

104500000.00

Providing and fixing of Floor (Riser) Mounted Stadium seats HOPE

Hot blow moulding UV resistance in appropriate colour Chair of size

420mmx450mmx3 IOmm. With back fram of Aluminium Alloy

complete all respect. Godrej make (JN-Z055) Or Equivalent approved

by competent authority.

Each

28000.00

5230.00

Total

146440000.00

1421710023.50

(A)

.

'

Page17of17

Proposed International Cricket Stadium at Saifai, Etawah

Public Health Engineering Work & Extra Item

SI. No

Description

Unit

1

Providing a nd fi xing Stainless S teel A ISi 304 (18/8) kitch en sink as per IS

13983 with C.I . bracke ts a nd s ta inless steel plug 40 mm incl uding p ainting

of fittings and brackets, cu tting a nd ma king good the walls wherever

req uired :

Kitchen Sink w ith di·ain board Size 510x1040 mm bowl deoth 200mm.

Providing a nd fixing Chlo rina ted Polyviny l C hloride (CPVC) pipes, havin g

thermal stability for ho t & cold water s upply including a ll CPVC plain &

brass threaded fittin gs including fixing th e pipe with clamps at 1.00 m

s pacing. This includes jointing o f pip es & fittings with one s tep CPVC

solvent cem ent and testing of joints complete as per d irection of Engineer in

Chante.

Internal work - Exposed on wall

15 mm nominal o u ter dia .Pipes.

20 mm nomina l ou ter d ia .Pioes.

25 mm nomina l ou ter dia .Pioes.

32 mm nominal o u ter d ia .Pipes.

40 mm n ominal o u ter dia .Pipes.

50 mm n ominal ou ter dia .P ipes.

Provid ing and fix ing Chlorina ted Po lyvinyl Chlorid e (CPVC) pipes, having

therm al sta bility for ho t & cold wa ter supply including all CPVC p lain &

brass thread ed fittings i/ c fix ing U1e p ipe with clamps a t l.00 m spacing.

This includ es jointin g of pipes & fi ttings with one step CPVC solvent

ceme nt and the cost of cuttin g chases and m aking good the same including

tes ting o f joi nts comp lete as pe r direction of Engineer in Charge.

Quantity

Rate (Rs.)

Amount- (Rs.)

Internal Plumbing Works ( Main Pavilion)

1.1

2

2.1

2.2

2.3

2.4

2.5

2.6

3

Each

6.00

5667.84

34007.04

Meter

Meter

Me ter

Meter

Meter

Me ter

10.00

150.00

300.00

175.00

200.00

250.00

155.33

181.02

219.74

281.81

387.51

552.47

1553.30

27153.00

65922.00

49327.25

77502.00

138117.50

Me ter

Me ter

Me ter

Meter

490.00

1000.00

400.00

750.00

256.50

281.58

333.74

401 .28

125685.00

281580.00

133496.00

300960.00

Me tre

2050.00

871 .86

178731 1.00

Each

260:00

318.9b

82929.60

Each

100.00

352.78

35278.00

Each

40.00

592.61

2370-1.40

Each

400.00

547.39

218956.00

Each

10.oc

412.78

41 27.80

Each

760.00

302.-13

229846.80

Each

426.00

231.56

9864e!.56

Each

10.00

65.17

651.70

Ead1

200.00

933.12

18668-1.00

Mete r

500.00

36.72

18360.00

Concealed work including cutti ng ch ases and ma king good the walls etc.

3.1

3.2

3.2

3.3

4

5

6

7

8

9

10

11

12

13

14

15 mm nominal o uter d ia .Pipes.

20 mm nominal outer dia .Pipes.

25 mm nominal o ute r dia .Pipes.

32 mm nominal oute r dia .Pioes.

Providing a nd fixing soil, was te and vent oioes.

100mm d ia Centrifu gally cast (s pw1) iron socketed p ipe as per IS: 3989.

Providing a nd fixin g pla in bend of required d egree

100mm d ia San d cas t iron S&S as per IS:3989

Providing a nd fixinl!: heel rest sanita rv be nd .

100mm dia Sand cast iron S&S as oer IS:3989

Providing a nd fixing single equal plain ju nction of required degree with

acess door insertion rubber washer 3mm thick bolts and nu ts com nle te.

100x100x100mm dia Sand cast iron S&S as ocr IS:3989

Prov iding and fixing single eq ual plain junction o f req uired degree.

100x100x100mm d ia Sand cast iron S&S as per IS:3989

Providing and fixing term inal gua rd .

100mm dia Sand cast iron S&S as oer IS:3989

Providmg and fix ing coller

100mm dia Sa n d cast iro n S&S as per IS:3989

Providing lead cau lked joints to sa nd cast iron / centrifugally cast (spun)

iron pipes and fittings of dia me ter.

a) 100 mm

Prov idin'g and fixing M.S stays and clamps for san d cast Iron / centrifugally

cast (spun) iron pipes of d ia me ter:

a) 100 mm

Providing a nd fixing sand cas t iron trap of self cleansing design with sand

cast iron screwed down or hinged grating with or witho ut ven t arm

complete, including cost of cutti111! a nd m akinl!: 1?:ood the walls and floo rs.

a) 100mm inlet and 100 mm ou tlet san d cast iron S&S as oer IS:3989

Painting of cast iron/ centri fugally cast iron (spun) iron soil, was te, vent

pip es and fi ttings with paint of a ny colo ur such as chocola te, grey or buff

etc. over a coat of orimer (of aoorovcd oualitv) for new w ork.

a) 100 mm d iam ete r p ipe

Page 1 of 18

SI. No

Description

15 Providing and fixing square-mou th S.W. gully trap classSP-1 complete with

C.J. grating brick masonry chamber with water tight C.l. cover wi th frame

of 300 x300 mm size (inside) the weight of cover to be not less than 4.50 kg

and frame to be not less than 2.70 ko as ner standard desi1m:

With common burnt clay·F.P.S. (non modular) bricks of class designation 7.5

16 Providi°ng, laying and jointing glazed stoneware pipes class SP-1 wi th stiff

mixture of cement mortar in the proportion of 1:1 (1 cement : 1 fine sand)

including testing of joints etc. comolete :

16.1 100 mm diameter

17 Providing and laying cement concrete 1:5:10 (1 ce111ent: 5 coarse sand : 10

graded stone aggregate 40 mm nominal size) a ll-round S.W. pipes including

bed concrete as per standard design:

100 mm diameter S.W. pipe

18 Providing and fixing G.l. pipes complete with G.l. fittings and clamps, ijc

cutting and making good the walls etc.(External Work)

18.1 25 mm d ia. nommal bore

18.2 32 mm d ia. nominal bore

18.3 40 mm d ia. nominal bore

18.4 50.mm d ia. non1inal bore

18.5 65 nun dia. nominal bore

19 Painting G. I. pipes and fi ttings with synthetic enam el white paint with two

coats over a ready mixed priming coa t, both of approved quality for new

work

19.1 25 mm dia. nominal bore

19.2 32 mm d ia. nominal bore

19.3 40 mm dia. nominal bore

1°9.4 50 mri1 dia. nomii1al bo/e

19.5 65 mm dia. nominal bore

20 Providing and placing on terrace (at all floor levels) polyethylene water

storage tank, ISi : 12701 mclrked, with cover and suitable locking

arrangement and making necessary holes for inlet, outlet and overflow

IPioes but without fittings and the base suooort for tank.

21 Providing and fixing white vitreous china pedestal type water closet

(European type) with seat and lid, 10 lih·e low level white vitreous china

flus hing cistern & C.P. flush bend with fittings & C l.brackets, 40 mm flush

bend, overflow arrangement with specials of standard make and mosquito

proof coupling of approved municipal design complete, including painting

of fittings and brackets, cutting and making good the walls and floors

wherever required: W.C. pan with ISi marked white solid plastic seat and

lid

22 Providing and fixing water closet squa tting pan (Indian type W.C. pan )

wi th 100 mm sand cast Iron P or S trap, 10 iih·e low level white P.V.C.

flushi ng cistern, including flush pipe, with manually controlled device

(handle lever)

confo1n1ing to IS : 7231, with all fittings and fixtures complete, including

cutting and making good the walls and floors wherever required: 17.1 .1

White Vitreous china Orissa pattern W.C. pan of size 580x440 nun with

intertral tvoe foot rests

White Vitieou·s china Orissa pa ttern W.C. pan of size 580x440mm with

integral type foot rests.

23 Providing and fixing wash basin with C.I. brackets, 15 mm C.P. brass pillar

taps, 32' mm C.P. brass waste of standard pattern, including painting of