COMOS automation interfaces

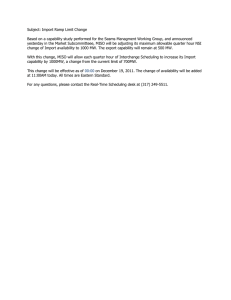

advertisement