Integral

forms

for wall

construction

Another innovation

A

new, simple but versatile system has

been developed that incorporates specially designed formwork as a permanent

part of a wall. Essentially, it involves setting in

place, bracing, and filling with concrete some

unique forms that become integral with conc re t e. These special forms are made of expanded metal lath spot-welded to steel channels connected with trusses. All that is

required after concreting is to remove the

bracing and finish with plaster.

The method not only introduces

economies but also speeds construction of

small buildings to the extent that they can

compete in both cost and rapidity of erection

with systems steel buildings which draw their

popularity largely from the rapidity of their

assembly. Costs of the integral form walls are

said to be 10 to 50 percent lower than those

for standard cast-in-place concrete construction.

The method has been almost seven years in

development, including four and a half years

for perfecting the machinery to produce the

needed materials, acquiring patents and getting the product approved by major codewriting bodies. It is now available for use in building walls, floors, foundations, retaining walls,

dams and seawalls.

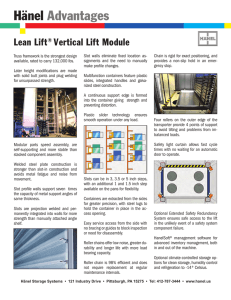

The system produces an insulated concrete

wall in place, complete with electrical conduit

and plumbing, that can be finished on both

sides. A completed wall consists of plastered

concrete with skins of metal lath near each

surface and a layer of insulation near one surface. Because the two metal skins are connected by a steel truss system little additional

steel is req u i red .

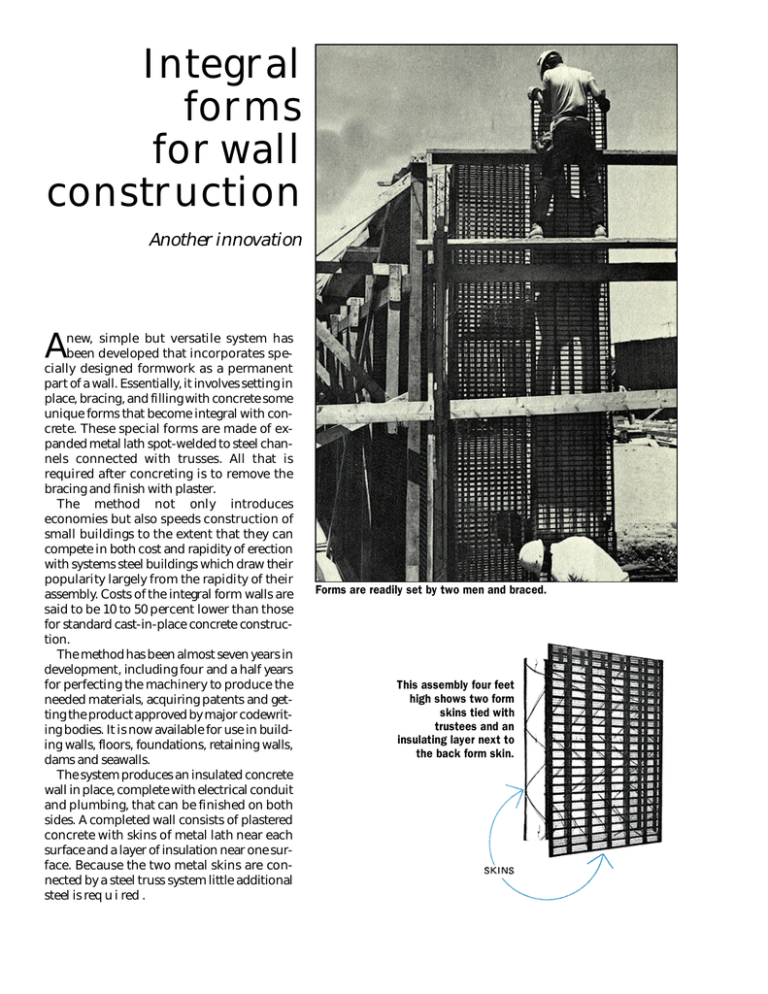

Forms are readily set by two men and braced.

This assembly four feet

high shows two form

skins tied with

trustees and an

insulating layer next to

the back form skin.

Construction sequence

The new method needs no conventional forms so it saves the labor

of stripping, cleaning and storing

forms for reuse. The forms are manufactured from expanded metal lath

and steel channels in 24-inch

widths and long enough for the wall

height desired. These are installed

by two men who can readily handle

forms long enough to make walls up

to 24 feet high. The form is attached

with a 10-inch clip at the bottom

and another at the top. Corners are

framed out and attached to bracing

that is set plumb. The forms are

available in thicknesses of four

inches through 12 inches (in oneinch increments) to provide the desired wall thickness. Window

f ra m e s, doors, electrical conduit,

plumbing and any required vertical

reinforcing steel are installed in the

form system prior to erection. After

the concrete has been cast the form

remains in place as part of the wall.

The prefabricated trusses installed between the form skins serve

first as form ties and later as reinforcing trusses in the concrete. Vertical form bracing is attached at

spacings of 10 feet or less, and diagonal bracing is attached at the top of

the wall and, on walls over 16 feet

high, at the middle as well.

For most work vertical deformed

bars are not needed because the

panels contain more steel than required by the ACI Building Code,

provided concrete of 3000 psi or

greater strength is used. If hori zo ntal bars are required, they must be

placed according to specifications

and the architectural drawings.

These are threaded through the

truss system and do not require ties

of any kind.

Walls of any height up to 30 feet

are cast in a single lift, using concrete of four- to six-inch slump

which is introduced at the top of the

wall by pumping. Some of the concrete extrudes through the expanded metal form skin, thereby bonding

to it and at the same time providing

a mortar layer on the exterior surface which can be finished by troweling. Disappearance of voids can

be monitored by watching them

through the expanded metal form

skin during placement. External viThe structure takes shape as forms are

set. Form assemblies are stored in piles.

A finished building.

Concreting is placed to

the full height of the wall

by pumping.

bration may be used to control the

amount of mortar coming through

the expanded metal form skin, and

to provide the quantity necessary

for the kind of finish intended.

The fresh surface is darbied and,

if desired, can be scratched to improve the base for the finish coat of

plaster. Almost any kind of finish

can be produced after the wall is

completed.

Finishing

For finishing, portland cement

plaster is used conforming to ASA

42.2 (four parts sand to one part

portland cement and 1/10 part lime

by volume). The mortar extruding

through the lath serves as the

scratch coat, so it is not necessary

to apply another. A brown coat is

applied to level the surface according to accepted plastering stand a rd s. The finish coat can be applied by hand or spray application

and given the desired texture. Control joints in the cast-in-place concrete wall and the wall plaster

should be detailed by the architect.

Interior surfaces can be finished

with either portland cement plaster

or gypsum plaster applied directly

without furring.

This small buttressed dam was built

with integral wall forms.

Materials.

The through-the-wall form system weighs a total of 2.11 pounds

per square foot of wall. This is made

of rib lath turned 90 degrees from

the usual direction of application so

that the ribs, located 1 5/8 inches on

centers, run horizontally. The channels, of 24-gage cold rolled steel, are

located four inches on centers running vertically and have been spot

welded to these ribs. The channels

form slots into which trusses fit.

Truss chords are made from 24gage cold rolled steel strips joined

with 10-gage (0.135-inch diameter)

bright basic commercial quality

wire.

The package of integral components can be supplied with or without polystyrene insulating sheets. A

oneinch-thick insulating sheet is

normally used in all building walls

but not in such structures as dams

and retaining walls. The insulating

sheet is cut to slide into the wall vertically and fit between the ve rt i c a l

steel channels.

Wall characteristics

The engineering data for bearing

Extruded mortar is darbied. This is later scratched and covered

wit two coats of portland cement plaster.

Sufficient mortar extrudes through form to provide the scratch coat

for portland cement plaster.

walls have been summarized in

Table I. The thermal conductivities

of walls containing a one-inch sheet

of polystyrene insulation are 0.20

Btu per inch per square foot per degree F per hour for walls of six- or

eight-inch thickness and 0.19 for

walls of 10- or 12-inch thickness.

Allowable compressive loads on

bearing walls made with concrete of

3000 psi strength are given in Table

II.

TABLE I Engineering data for bearing walls

4-inch thick 6-inch thick 8-inch thick 10-inch thick

wall

wall

wall

wall

Maximum allowable

height, feet

10

15

65

115

Maximum unsupported

width or height,

feet-inches

1 0-0

124

16-8

20-10

Distance between

suppor ting and

enclosing members of

panel walls, feet

10

15

20

25

Ver tical steel required,

square inches per

foot of wait length*

0.072

0.108

0.144

0.180

0 120

0 180

0.240

0.180

18

13

10

7

Horizontal steel

required, square inches

per foot of wait

height**

Optional horizontal

spacing of no. 4 Bars,

inches

*Vertical steel included in the three trusses and associated six channels in each foot of

width is 0.377 square inches.

**Area of expanded metal is 0.378 square inches per foot of height. (Not all local codes

allow credit for this steel in the horizontal direction, so additional horizontal steel may be required.)

TABLE II Compressive loads allowable on bearing walls, psi

(Concrete strength 3000 psi)

Wall height,

feet-inches

4-inch thick

wall

6-inch thick

wall

8-inch thick

wall

10-inch thick

wall

8

9

10

11

530

468

390

632

614

590

563

557

649

639

628

666

662

657

651

12

12-5

13

14

529

510

489

443

614

605

597

577

643

639

635

625

15

16

16-8

17

390

555

529

510

500

614

600

590

585

467

431

390

568

550

529

510

18

19

20

20-10

PUBLICATION #C730213

Copyright © 1973, The Aberdeen Group

All rights reserved

21

22

23

24

25

506

481

454

423

390