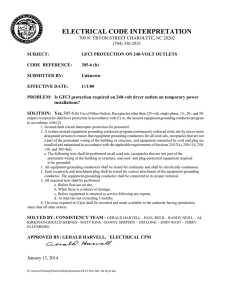

2002 NEC Code Changes

advertisement

2002

National Electrical Code

Changes

Developed and Presented by:

The Codes and Standards Group of

Schneider Electric

Where We Started

1

Development Timeline

Proposal Deadline

November 5, 1999

Code-Making

Panels Meet

Jan 10-22, 2000

Written Ballots Due

Feb 17 (or 24),

2000

Technical Correlating

Committee Meeting

May 8-12, 2000

NEC Report on

Comments Available

July 14, 2000

Public Comment

Development Timeline

Public Comments

Due to NFPA

October 27, 2000

Code-Making

Panels meet

Dec 4-16, 2000

Written Ballots Due

Jan 5 (or 12), 2001

Technical Correlating

Committee Meeting

Feb 25 - Mar 1

NEC Report on

Comments Available

April 16, 2001

NFPA Annual

Meeting

May 13-17, 2001

Standards Council hears

Appeals on July 11, 2001

2002 NEC Issued with

Effective date of August 2, 2001

2

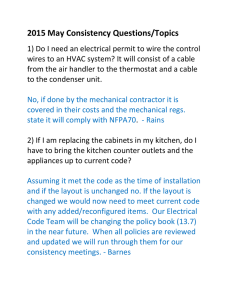

Use of the 2002 NEC

l

l

l

l

2002 is the Latest Edition of NFPA 70

Most jurisdictions specify what edition of

the NEC they follow

Adoption process must recognize the 2002

edition in order for it to be the “active”

document in the locality

Some jurisdictions have already completed

process to utilize the 2002 edition on

January 1, 2002

n e.g. North Carolina, Massachusetts

l

Other jurisdictions may not adopt the 2002

edition until some future date

Numbering Format

From Dash to Dot

3

Acronyms

l

l

2002 NEC will use standard acronyms

Examples

n RMC – Rigid Metal Conduit

n RNMC – Rigid Nonmetallic Conduit

n EMT – Electrical Metallic Tubing

n LFMC – Liquidtight Flexible Metal Conduit

n ENT – Electrical Nonmetallic Tubing

n IMC – Intermediate Metal Conduit

n NUCC – Nonmetallic Underground Conduit with Conductors

n AC – Armored Cable

n NM – Nonmetallic sheathed cable

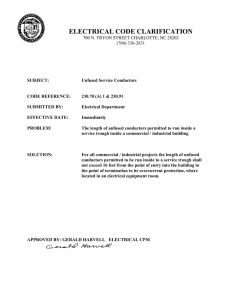

Article 80 (New)

Administration and Enforcement

l

l

Provides a set of model administrative rules to

apply and enforce the NEC

Covers

n Inspection

n Investigation of electrical fires

n Review of construction plans, drawings and

specifications

n Design, alteration, modification, construction,

maintenance and testing

n Regulation and control of special events

l

Article 80 is informative only (not part of the

Code) unless specifically adopted by the

jurisdiction

4

90.1(D) - Purpose

Relation to International Standards

l

l

NEC addresses fundamental principles

of protection for safety contained in IEC

60364-1, Section 131

Protection against:

n Electrical shock

n Thermal effects

n Overcurrent

n Fault-currents

n Overvoltage

90.2(B)(5) – Scope

Under exclusive

control of a utility:

Not Covered

Service drops or

laterals and

associated metering

Located in legally established

easements, rights of way, etc and

recognized by regulatory agencies

On property owned or leased by the utility for

purpose of communications, metering, generation,

control, transformation, transmission, or distribution

of electric energy.

5

90.3

Code Arrangement

Chapter 1 - General

Chapter 2 - Wiring and Protection

Chapter 3 - Wiring Methods and Materials

Chapter 4 - Equipment for General Use

Supplements or modifies

Chapters 1 through 4

Chapter 9 - Tables

Annex A through Annex D

Chapter 5 - Special Occupancies

{

Chapter 8 - Communications Systems

}

Applies generally to all

electrical installations

Chapter 6 - Special Equipment

Chapter 7 - Special Conditions

Chapter 8 is not subject to the

requirements of Chapters 1

through 7 except as specifically

referenced in Chapter 8

}

} Applicable as referenced

} Information only not mandatory

90.4

Enforcement

l

l

l

The authority having jurisdiction can

waive specific requirements or permit

alternative methods

Only allowed where “equivalent safety”

is assured

Now requires “special permission”

n Special permission as defined in Article

100 requires written consent of the

authority having jurisdiction

6

90.7

Examination of Equipment for Safety

Definition of “Listed” in Article

100 states that products must meet

appropriate designated standards.

90.7 states that examination of

equipment for safety under standard

conditions provide a basis for

approval.

90.7 FPN No. 3 notes that

Annex A contains and

informative product standards

list

Annex A – Product Safety

Standards

• Informative only

• List of standards used for

product listing

What are the “appropriate”

designated standards?

• Makes the connection

between the Code rules and

properly evaluated products

90.9 – Units of Measurement

Compliance

l

l

NEC now has metric as the first dimension listed

The conversions are not exact

n e.g. 1m (3 ft)

l

l

The installation can be made to either the SI (metric) or the

“inch-pound” units

Wire sizes did not change – still AWG and kcmil

7

Article 100 – Definitions

Authority Having Jurisdiction

l

l

l

The organization, office, or, individual

responsible for approving equipment,

materials, an installation, or a procedure.

This term is standardized through out the

NFPA system

Examples include

n Public safety – electrical inspector, fire marshal,

fire chief, building official, others having

statutory authority

n Insurance purposes – insurance inspection

department, rating bureau

n Others – property owner or designee

n Government – commanding officer,

departmental official

Article 100 - Definitions

Ground-Fault Circuit Interrupter

Definition now makes it clear that a

device intended to provide protection of

personnel must be a Class A device.

8

Article 100 - Definitions

Luminaire

A complete lighting unit consisting of a lamp or lamps together with

the parts designed to distribute the light, to position and protect the

lamps and ballast (where applicable), and to connect the lamps to the

power supply.

Fixture

Luminaire

Lighting fixture

Article 100 – Definitions

Qualified Person

One who has the skills and knowledge

related to the construction and operation of

the electrical equipment and installations

and has received safety training on the

hazards involved.

9

Article 100 – Definitions

Structure

l

l

l

“That which is built or

constructed”

Not previously defined in

the NEC

Compatible with other

building codes and

standards

110.12(A) – Mechanical Execution of Work

Unused Openings

l

l

l

l

Combines the requirements in

Article 110 with the requirements

covering cabinets and cutout

boxes

Applies to boxes, raceways,

auxiliary gutters, cabinets, cutout

boxes, meter socket enclosures,

equipment cases and housings

Must be substantially equivalent to

the wall of the equipment

Metallic plugs in nonmetallic

enclosures must be recessed at

least 6 mm

Box

Close all unused openings

10

110.14(C) – Electrical Terminations

Temperature Limitations

Ampacity of the conductor (for ambient

adjustment and derating) is permitted to be based

on appropriate table (e.g. 310.17 for single

conductors in free-air)

Ampacities for conductors at

equipment terminations must be

based on Table 310.16

110.15 (new)

High-leg Marking

l

l

New section added to require the

marking of the high- leg of a 4wire delta connect system with

orange color or other effective

means

Identification required at each

point on the system where a

connection is made if the

grounded conductor is also

present

120V

120V

208V

11

110.16 (New)

Flash Protection

Switchboards, panelboards, industrial control panels, and motor control centers

that are likely to be worked on while energized

DANGER Arc -Flash Hazard

Protective Equipment required

in accordance with NFPA 70E

Failure to use proper equipment

can result in serious injury or death

Field Marked with a label to warn of potential electric arc flash hazards

Equipment in dwelling units is not included in the requirement

110.26(C)(2) – Entrance to Working Space

Large Equipment

Where the entrance to

the space has a

personnel door, it must

open in the direction of

egress and be equipped

with panic bars, pressure

plates, etc.

Similar rule for over 600V

equipment in 110.33

Equipment over 1200A and over 6 feet wide

12

110.26(F) – Spaces about Electrical Equipment

Dedicated Equipment Space

Piping

Drip

protection

Space above the dedicated

space up to the structural

ceiling is permitted to have

foreign systems, provided

protection from leaks or

breaks is provided

Dedicated space extends 6

feet above the height of

the equipment. Only

electrical equipment

allowed in this space.

Space is the same width

and depth as the

equipment.

110.31

Enclosure for Electrical Installations

l

l

l

Fence shall not be less than 7ft in height

Table 110.31 Minimum Distance from Fence to Live Parts

Does not apply to enclosed equipment

Minimum Distance to

Live Parts

Nominal Voltage

601 - 13,799

13,800 -230,000

Over 230,000

m

3.05

4.57

5.49

ft

10

15

18

13

110.58 – Tunnel Installations over 600V

Disconnecting Means

l

A switch or circuit breaker shall be installed within sight of

each transformer or motor location to serve as the disconnect.

200.6

Means of Identifying Grounded Conductors

l

l

l

The word “natural” has been deleted

from “natural gray”

Gray conductors are now permitted as

grounded conductors

Allows “gray” to be used for an

ungrounded conductor to distinguish one

system from the other

n e.g. white for 120/240V and gray for

480Y/277V

14

210.6(E) – Voltage Limitations

Over 600 Volts Between Conductors

Over 600V circuits can supply

utilization equipment in installations

where conditions of maintenance and

supervision ensure that qualified persons

will service the installation.

4160V

Compressor

210.7

Branch Circuit Receptacle Requirements

New Article 406 covering

Receptacles

1999 NEC

210-7 covered:

• Requirements for

grounding type

receptacles

• Methods of grounding

receptacles

Moved to

• Replacement of

receptacles

15

210.7(C) – Receptacle Requirements

Multiple Branch Circuits

Supplied by more than one branch

circuit (can be multiple single circuits

or a multi-wire circuit)

More than one

receptacle on a yoke

Ø

Ø

N

Must be provided with a means to

simultaneously disconnect the

ungrounded conductors at the

panelboard where the circuits

originate

210.8(A)(5) Exception No. 3 – Dwelling Units

Unfinished Basements

Omission of GFCI protection

Fire and/or

Burglar Alarm

Control Panel

Remove tab to

limit to one

receptacle

Receptacle supplying

only a permanently

installed fire alarm or

burglar-alarm

16

210.8(A)(8) – Dwelling Units

Boathouses

15- and 20-ampere receptacles in boathouses

on dwelling unit property are required to have

GFCI protection.

Article 555 now excludes private,

noncommercial docking facilities for singlefamily dwellings

210.8(B)(3) – Other than Dwelling Units

Kitchens

GFCI protection now required for 15 and 20A receptacles in

kitchens located in other than dwelling unit

17

210.12

Arc-Fault Circuit-Interrupter Protection

Requirements:

•

All branch circuits supplying 15 or 20A outlets in

the bedroom

•

NOTE: see definition of “outlet” in Article 100,

this includes lighting outlets

•

AFCI must be listed to provide protection of the

entire branch circuit

210.19(B) – Minimum Ampacity and Size

Branch Circuits Over 600 Volts

l

l

l

Ampacity in accordance with Table

310.15 and 310.60

Size conductors at not less than 125% of

the “designed potential load” of

equipment to be operated

simultaneously

OR

Sized by the engineer for supervised

installations

n Design and installation are under

engineering supervision

n Qualified persons with documented training

and experience in over 600V systems

provide maintenance, monitoring, and

servicing of equipment

18

210.23

Permissible Loads

l

l

No change to the code language

Panel Statement is significant:

n The 80% limitation on any single cord- and plug-connected appliance

on a circuit with two or more receptacles applies to both continuous or

intermittent loads

210.52

Dwelling Unit Receptacle Outlets

Modified to indicate this section provides requirements

for 125-volt, 15 and 20 ampere receptacle outlets.

19

210.52(C)

Countertops

Receptacle installed in appliance garage

does not count as one of the required

outlets.

Must be not more than 24” to meet

210.52(C)(1)

210.52(C)(5) Exception - Countertops

Receptacle Outlet Location

Where a receptacle is

mounted above the cabinets,

it must be within 20” of the

countertop to be counted as

one of the required

receptacles.

Not more than 20”

20

210.52(D)

Bathrooms

l

l

l

Receptacle now permitted to

be installed on a partition or

a wall

Wall or partition must be

“adjacent” to the basin or

basin countertop

The receptacle must be

within 3 feet of the outside

edge of the basin

Wall

Half-wall or

partition

210.52(G)

Basements

GFCI Protected

Unfinished portion

GFCI Protected

Finished Basement normal receptacle

placement

Unfinished portion

A receptacle must be placed in each unfinished portion of the basement

21

210.63

Heating, AC, and Refrigeration Equipment Outlet

Receptacle

required within

25’ of all heating,

AC or

refrigeration

equipment

regardless of the

type of installation

25’ max

210.70(A)(2)(c) – Dwelling Units

Lighting Outlet Switch Locations

Switch required at landing level if there is an

entry at the landing.

22

215.2(B) – Minimum Rating and Size

Feeders Over 600 Volts

l

l

l

l

Ampacity in accordance with 310.15 and 310.60

Transformers – conductors supplying transformers shall not

be less than the nameplate rating of the transformer

Transformers and utilization equipment - Size conductors at

not less than 125% of the “designed potential load” of

equipment plus the nameplate ratings of the transformers

OR

Sized by the engineer for supervised installations

n Design and installation are under engineering supervision

n Qualified persons with documented training and experience in over

600V systems provide maintenance, monitoring, and servicing of

equipment

225.26

Vegetation as Support

Support of overhead conductor spans by vegetation is not permitted.

The exception for temporary wiring has been deleted.

23

230.6

Conductors Considered Outside the Building

Installed under not less

than 2” of concrete

beneath a building or

structure

Installed in conduit and

under not less than 18”

of earth beneath a

building or structure

Encased in not less

than 2” of concrete

or brick

Installed in a vault that meets Article 450 Part III

230.40 Exception No. 1 – Service Entrance Conductors

Number of Service Entrance Conductor Sets

Occupancy #1

Occupancy #2

240V Service

Occupancy #3

480V Service

Permits a set of service entrance conductors run to each occupancy for each

service of different characteristics as defined in 230.2(D)

24

230.70(A)(3) - Location

Remote Control

Shunt trip or

“remote control”

The service equipment must still

be located at a readily accessible

location where the conductors

enter the building

230.82

Equipment Connected to the Supply Side of Service Equip

l

Additional Equipment

Supply

n Meter sockets

n Meter disconnect switches rated 600

Volts max

n Fuel Cell Systems

l

Surge Protective Devices removed

from list of permitted devices

n Surge Arresters are still included in the

Meter

disconnect

switch

480Y/277V

Typical

permitted list of devices

n Removed in order to clarify TVSS

products are not permitted

On to service

equipment

25

230.212

Over 35,000 Volts

l

l

Section previously applied when

voltage exceeded 15,000 volts

Where service conductors enter a

building they must terminate in

metal-enclosed switchgear

compartment or a vault complying

with Article 450 Part III

240.2

Definitions

l

Coordination

n The proper localization of a fault condition to restrict outages to the

equipment affected, accomplished by the choice of selective faultprotective devices

l

Current limiting overcurrent protective device

n Moved from 240.11

l

Supervised industrial installation

n Moved from 240.91

l

Tap conductors

n Moved from 240.3(D)

n Clarified to exclude service conductors

26

240.21(B)(5)(4)c – Feeder Taps

Outside Taps of Unlimited Length

Feeder Tap

Conductors

installed in

accordance with

230.6

Equipment at a readily

accessible location where

the conductors enter

240.21(C)(6) – Transformer Secondary Conductors

Secondary Conductors Not Over 25’ Long

Primary conductors

protected at their

ampacity

Conductors terminate in a single

CB or set of fuses that limit load

current to the ampacity of the

secondary conductors

200A

480V

240V

25’ max

150A conductors

Secondary conductors have an ampacity that is at

least 1/3 the rating of the primary device when

multiplied by the voltage ratio

150A

27

240.24(B) Exception No. 2 – Location In Premises

Occupancy

l

l

General rule requires that

each occupant have ready

access to overcurrent

devices that supply that

occupancy

Exception recognizes that

occupants of hotel/motel

rooms do not need access

if the building is under

continuous building

management supervision

240.83(D) - Marking

Used as Switches

l

l

Requires a breaker listed and

marked as HID (high intensity

discharge) to be used as a switch

for HID lighting

Florescent lighting can be

switched with breakers marked

SWD or HID

28

240.85 – Circuit Breakers

Applications

Clarifies that “slash” rated

breakers should be applied

only in solidly grounded

circuits

Slash Rated

Breaker OK

Article 240 Part VIII

Supervised Industrial Installations

At least one service more

than 150V to ground and

300V phase-to-phase

Conditions of maintenance and

engineering supervision ensure

that only qualified persons monitor

and service the system

System has at least 2500 kVA of load

used in industrial process and/or

manufacturing (calculated in

accordance with Article 220)

Does not apply to

offices, garages,

warehouses, etc.

29

240.92(B)(1)(1) – Transformer Secondary Conductors

Short-Circuit and Ground-Fault Protection

Primary overcurrent device not more than 150% of the

secondary conductor ampacity multiplied by the

secondary to primary voltage ratio

Secondary conductor length

changed from 50 feet to 100 feet

See 240.92(B)(2) for overload

protection requirements

240.92(B)(1)(2) – Transformer Secondary Conductors

Short-Circuit and Ground-Fault Protection

Differential

Relay

Conductor secondary

is now permitted to be

of any length

See 240.92(B)(2) for overload

protection requirements

30

240.92(B)(1)(3) – Transformer Secondary Conductors

Short-Circuit and Ground-Fault Protection

Secondary conductors considered protected if calculations made under

engineering supervision determine that the system overcurrent devices will

protect the conductors within the recognized time-current limits for ALL shortcircuit and ground-fault conditions.

Secondary conductor length

limitation removed

240.92(D) – Location in Circuit

Protection by Primary Overcurrent Device

l

l

l

Secondary conductors are

permitted to be protected by the

primary overcurrent device

Primary device time-current

characteristics multiplied by the

effective primary to secondary

voltage ratio must effectively

protect the secondary conductors

Difficult to use with transformers

that have greater than a 1:1 ratio

of primary L-L voltage to

secondary L-L voltage

31

250.4(B) – General Requirements for Grounding

Ungrounded Systems

l

l

l

Material moved from 250.2

where it was mixed with

grounding system

requirements

Ground all non-current

carrying conductive

materials of electrical

equipment

Bond together all noncurrent carrying conductive

materials together to create a

permanent, low- impedance

path for ground-fault current

1st fault

grounds the

system

250.20

AC Circuits and Systems to Be Grounded

l

l

l

Specifies what systems are

required to be grounded

Notes that other systems are

permitted to be grounded

Now clarifies that if a system is

grounded (either required or

permitted) the grounding must

comply with Article 250

32

250.30(A)(2)(b) and (3) – Sep Derived Systems

Grounding Electrode Conductor

l

Allows a common grounding

electrode for multiple

separately derived systems

l

Must use exothermic weld,

irreversible compression or

connect to copper bus bars

Keep main grounding

electrode conductor without a

splice or joint

l

Separately Derived Systems

Size common grounding electrode

conductor based on 250.66 using

the total area of largest derived

phase conductor from each system

Size “tap” conductors based on

250.66 based on the derived

phase conductor size

Grounding Electrode

(example shown is

water pipe)

250.32(E) – Two or More Buildings/Structures

Grounding Electrode Conductor

Service Equip - Bldg #1

Bldg #2

Grounding electrode

conductor sized by

250.66 based on largest

ungrounded supply

conductor.

33

Article 250

Part III – Grounding Electrode system

l

250.52 establishes the electrodes

PERMITTED for grounding

n Metal underground water pipe

n Metal frame of the building or structure

n Concrete encased electrode

n Ground ring

n Rod and Pipe electrodes

n Plate electrodes

n Other local metal undergrounds systems

or structures

l

250.52(B) establishes electrodes

NOT permitted for grounding

n Metal underground gas piping

n Aluminum electrodes

Gas Pipe

250.53(C) – Grounding Electrode System Installation

Bonding Jumper

• Install – 260.64(A), (B) and (E)

• Size - 250.66

• Connect – 250.70

34

250.102(E) – Equipment Bonding Jumper

Installation

Equipment bonding jumper permitted longer than 6’

permitted to bond isolated sections of metal raceways

Rigid metal conduit

Rigid nonmetallic conduit

250.104(A) – Bonding of Piping Systems

Metal Water Piping

Requires bonding of water

pipe that is “installed in”

or “attached to” a building

or structure.

“Attached to”

“Installed in”

35

250.104(B)

Bonding of Other Metal Piping

l

l

l

l

Deleted old 250-104(c) that required

bonding of all metal gas piping to the

grounding electrode

Gas piping now covered under

240.104(B) which requires bonding of

piping that is “likely to become

energized”.

Bonding jumper sized based on the

overcurrent device protecting the circuit

that is likely to energize the piping.

The equipment grounding conductor of

the circuit is permitted to serve as the

bonding means

Gas Piping

Branch Circuit

250.122(B) – Equipment Grounding Conductors

Increase in Size

Now requires proportional increase in equipment grounding

conductor when phase conductors are increased for any reason.

36

250.146(A)

Surface Mounted Box

Box must be mounted “on” the surface

Previous code allowed a box

mounted “at” the surface to

use metal to metal contact.

Now a yoke must be listed

to establish the grounding

path for other than surface

mounted boxes.

Direct metal to metal

contact acceptable for

grounding the receptacle

Article 285

Transient Voltage Surge Suppressors (TVSS)

l

l

l

Service. The TVSS shall be connected on the load side of a

service disconnect overcurrent device

Separately Derived System. The TVSS shall be connected

on the load side of the first overcurrent device in a separately

derived system.

Short Circuit Current Rating. The TVSS shall not be

installed at a point on the system where the available fault

current exceeds the marking on the equipment.

37

285.1 - TVSS

Article Scope

l

Covers

n general requirements

n installation requirements

n connection requirements

l

Permanently installed only

285.3 - TVSS

Uses Not Permitted

l

l

l

Circuits exceeding 600 volts.

Ungrounded electrical systems as

permitted in Section 250.21.

Where the rating of the TVSS is less

than the maximum continuous phaseto-ground power frequency voltage

available at the point of application.

38

285.5 - TVSS

Listing

l

l

The TVSS shall be Listed.

Most TVSS products will reference:

n UL 1449 2nd Edition on the product.

285.6 - TVSS

Short Circuit Current Rating

l

The TVSS shall be marked with a short circuit current rating...

n DO NOT confuse the Short Circuit Current Rating (SCCR) with the

Surge Current (Capacity) Rating !!!

The Surge Current Rating is the maximum transient current level that can

be suppressed by the TVSS.

u The Short Circuit Current Rating is the available and sustainable power

current level that can flow in the circuit, at the point of connection to the

system, during a fault condition until the circuit is opened.

u

39

Chapter 3 Reorganization

Articles Moving to Different Chapters

Moving to

305

527

380

404

384

408

Chapter 3 Reorganization

Wiring Method Article Renumbering

l

l

See new Annex F for cross-reference

Articles 312-314 covers boxes and enclosures

n Outlet boxes, cabinets, etc.

l

Articles 320-340 covers cables

n MI, MC, AC, NM, UF, etc.

l

Articles 342-356 covers conduits

n RMC, RNMC, FMC, etc.

l

Articles 358-362 covers tubing

n EMT, ENT, FMT, etc.

l

Articles 366-390 covers other methods

n Busway, cable bus, etc.

l

Articles 392-398 covers open wiring

n Knob and tube, open wiring on insulators, etc.

40

Chapter 3 Reorganization

Common Number Method for all articles

.1 Scope

.2 Definitions

.6 Listing Requirements

Part B Installation

.10 Uses Permitted

.12 Uses Not Permitted

.16 Temperature Limits

.30 Securing and Supporting

.60 Grounding

Part C - Construction Specifications

.110 Corrosion Protection

.120 Markings

300.1(C)

Metric Designators and Trade Sizes

Neither the metric designator

nor the trade size relate to

actual dimensions of the

conduit or tubing.

Metric Designator

12

16

21

27

35

Trade Size

3/8

½

¾

1

1¼

41

53

63

78

91

103

129

155

1½

2

2½

3

3½

4

5

6

41

300.4(B)(1) – Protection Against Physical Damage

NM Cable and EMT Through Metal Framing Members

Metal Stud

A listed bushing or grommet

must cover all metal edges and

be securely fastened to the

opening

300.5(D)(3) – Underground Installations

Service Conductors

18” or more

18” or more

At least 12”

Warning

Ribbon

Applies to all underground service conductors

42

300.5(K) – Protection Against Physical Damage

Directional Boring

Cables and raceways installed using

directional boring equipment shall

be “approved” for the purpose.

300.6(A) – Protection Against Corrosion

General

Where threads are cut in the field, the

threads shall be coated with an approved,

electrically conductive, corrosion resistant

compound.

Located in an area where corrosion protection is necessary

43

300.7(A) – Raceways Exposed to Different Temperatures

Sealing

Raceway

Interior - 72°F

Exterior - 25°F

Fill raceway with approved material

to prevent circulation of warm air to

cold air region

300.11(C) – Securing and Supporting

Cables Not Used as Means of Support

Cable wiring method (e.g. MC cable)

Other cable or raceway (e.g. Class 2 circuit)

Cable wiring methods are not permitted to support other cables or raceways

44

300.22(B) – Wiring in Ducts, Plenums or Other Spaces

Ducts or Plenums Used for Environmental Air

Change specifically prohibits

conduit with an overall

nonmetallic coating

Ducts or plenums in

300.22(B) are those

specifically fabricated to

transport environmental

air.

300.22(C) – Other Spaces Used for Env Air

Wiring Methods

Return Air Space

Suspended ceiling

Rigid metal conduit with a nonmetallic coating now prohibited

45

310.15(B)(2) – Exception No. 5

Adjustment Factors – AC or MC Cable

MC or AC cable

No adjustment factor required

where not more than 20 current

carrying conductors are in the

stack or bundle.

• #12 AWG conductors

• Not more than 3 current

carrying conductors per cable

• No overall outer jacket

For more than 20 current carrying

conductors, a 60% adjustment factor applies

Table 312.6(B)

Minimum Wire Bending Space at Terminals

The table now recognizes smaller wire bending space for compact stranded

AA-8000 aluminum conductors

Using an example of a 400A circuit:

1999 NEC

2002 NEC

Cu – 3/0 - 6 ½ inches

Cu – 3/0 - 6 ½ inches

Al – 250 kcmil – 8 ½ inches

Al – 250 kcmil – 6 ½ inches

46

314.20

In Wall or Ceiling

Surface of concrete, tile, gypsum, plaster or

other noncombustible material

Box not set back more than ¼”

from the finished surface

For surfaces of wood or other combustible

material, the box must be flush with the

finished surface

314.23(B)(1) – Structural Mounting

Nails and Screws

Where nails or screws are used to fasten a box, the

nail or screw must pass thru a bracket outside of

enclosure or must pass through the inside with ¼” of

the back of the enclosure.

47

314.27(A) Exception

Boxes at Luminaire Outlets

Use #6 screws minimum

Permits mounting of luminaire to a “standard” outlet box where the

luminaire does not weigh more than 6 lb. Dimensional limitation on

the fixture has been removed.

314.27(B) – Outlet Boxes

Maximum Luminaire Weight

Outlet box identified

for luminaire (fixture)

support

Luminaire weighing not more

than 50 lbs.

Luminarie’s weighing over 50 lbs must be supported independently of

the outlet box

48

330.10(13) – Uses Permitted

Single-Conductor MC

Installation of single-conductor MC

must comply with NEC 300.20.

Single-conductor MC is

required to have a nonmagnetic

sheath or armor (NEC 330.116)

Where single conductor MC is

used, the phase and neutral (if

used) conductors shall be

grouped together to minimize

induced voltage

332.80 – Ampacity

Single Type MI Conductors Grouped Together

Not less than 2.15 times

diameter of largest conductor

in the group

Open runs or on a messenger in a triangle or square configuration

Permitted to use Table 310.17 ampacities for the MI cable.

Temperature limitation of equipment terminations must be considered.

Ampacity will be required to be reduced back to Table 310.16 levels before

terminated within equipment.

49

334.6 – NM Cable

Listed

NM Cable is required to be listed

334.10(2) – NM Cable

Uses Permitted

Multifamily dwellings and other buildings

that are of Type III, IV or V construction.

New Appendix E will contain a table from

NFPA 220 to explain the different

building Types

The building code in effect locally will

also define the building types

In general, this permits NM to be used in

4-story apartment buildings (typically R-2

buildings, Type III and IV)

50

Annex E

Types of Construction

l

l

l

Type III – typically

constructed of

noncombustible,

limited-combustible, or

other approved

combustible material

Type IV – typically

timber frame

construction

Type V – typical stick

built construction

Explanation of Headers – Example = 211 Construction

2 = 2 hr fire rating of exterior load bearing walls

1 = 1 hr fire rating of columns, beams, girders that support bearing walls

or loads from more than one floor

1 = 1 hr fire rating of floor

334.12(A)(1) – Uses Not Permitted

Types NM, NMC and NMS

Space above suspended ceiling in

other than one, two and multi-family

locations

NM cable not permitted in this

space

51

338.10(B)(4) – Uses Permitted

Installation Methods for Branch Circuits and Feeders

l

l

l

Applies installed as a

branch circuit or feeder

Must be installed in

accordance with Article

334 (NM Cable) Parts I

and II

Specifically excludes

334.80 requirement that

limits ampacity of NM

cable to 60C

342.22

Number of Conductors

IMC

Conductor fill must comply with Table 1, Chapter 9

Cables are permitted to be installed where such use is permitted

by the respective cable articles.

52

344.24

Bends – How Made

l

l

One shot and Full shoe

benders contained in one

table

Minimum radius is now

measured to the centerline

of the conduit

362.10(2) Exception – Installation

Uses Permitted

ENT

15 minute finish rating not

required

NFPA 13 sprinkler system throughout

the building

53

400.8(5)

Uses Not Permitted

Flexible cord not permitted above a

suspended or drop ceiling

404.6(C)

Connection of Switches

l

l

General rules says that blades must

be de-energized when in the open

position

New text recognizes that a bottom

fed bolted pressure switch can have

energized blades if barriers are

provided

54

404.8(B) – Accessibility and Grouping

Voltage Between Adjacent Devices

l

l

l

Applies to switches grouped in an

enclosure with other switches, receptacles

or similar devices

Voltage between adjacent devices must

not exceed 300V

A permanently installed barrier can be

used to separate devices where the

voltage does exceed 300V

404-14(E)

Dimmer Switches

Dimmer switches are permitted to supply only

permanently installed incandescent luminaries,

unless listed for the control of other loads.

55

404.15(B) – Marking

Off Indication

If a switch has a marked off

position, it shall disconnect all

ungrounded conductors

Off

On

Auto

406.4(E)

Receptacles in Countertops and Similar Work

Surfaces in Dwelling Units

Receptacles not permitted to be mounted face-up in any

countertop or work surface in a dwelling unit

56

406.8(B)(1)

15- and 20-Ampere Outdoor Receptacles

Requires the use of a “weatherproof”

while in use cover in all outdoor wet

locations.

Applies to 15 and 20 ampere, 125 and 250-volt receptacles

406.8(B)(2)

Other Receptacles

Requires the use of a “weatherproof”

while in use cover in all outdoor wet

locations where the product intended to be

plugged in is not attended while in use

(e.g. sprinkler controllers, landscape

lighting, holiday lighting, etc.

For applications where the plugged in

equipment will be attended while in use

(e.g portable tools), a basic weatherproof

cover can be used.

Applies to receptacles other than 15 and 20 ampere, 125 and 250-volt

57

408.4

Circuit Directory

l

l

l

All circuits or circuit

modifications shall be

legibly identified as to their

purpose

Located on the panel face

or inside the panel door

Located at each switch on a

switchboard

Now applies to both switchboards

and panelboards!

408.21

Grounded Conductor Terminations

l

Each grounded conductor

must terminate in an

individual terminal

n Do not put two “neutrals” in

one terminal

n Do not put a neutral and an

equipment ground in one

terminal

l

Multiple equipment

grounding conductors can

still be terminated in a

terminal if the panel is

identified to allow the

multiple connection

58

410.18(B) Exception – Exposed Luminaire Parts

Made of Insulating Material

Separate equipment

grounding conductor

installed in accordance

with 250.130(C)

Grounding means not

available at the outlet

Replacement luminaire.

Permitted to have conductive

parts.

Grounding Electrode

430.32(C) – Continuous Duty Motors

Selection of Overload Relays

Sep Overload

Device

115% to 125%

Thermal

Protector

140% to 170%

One HP or less,

automatically

started

115% to 125%

Approved for

use with the

motor

430-32(A) and

(B)

130% to 140%

NA

NEC

430-32(A)

Covers

More than 1HP

430-32(B)

430-32(C)

Clarifies that the sensing element or the setting of the overload

relay can be increased if the values in 430.32(A) and (B) are

not sufficient to start the motor.

59

430.52(C)(1) – Rating or Setting

In Accordance with Table 430.52

Table moved from 430-152 to become

Table 430.52

430.53(D) – Several Motors or Loads

Single Motor Taps

Group Installation:

multiple motors installed on

one branch circuit

Not more than 10’ in length

Branch shortcircuit/ground-fault

device

Conductors not less

than 1/10 the rating

of the branch SC/GF

device

Listed manual motor

controllers additionally

marked “suitable for tap

conductor protection in

group installations”

Conductors sized by

430.22

60

430.62(A) Exception No. 2 – Rating or Setting

Specific Load

Feeder device must have a

rating or setting that does

not exceed the rating of the

MCC main power bus (see

430.92)

Feeder overcurrent device

supplying a Motor-Control

Center

430.102(B) – Disconnect Location

Motor

430.102(B) requires a

disconnect in sight of the

motor

430.102(B) Exception allows

omission of the disconnect in

sight of the motor if one of

the following applies:

(a) the location is

impracticable or

introduces additional

hazards

430.102(A) requires the

disconnect in sight of the

controller

(b) Industrial installation

with maintenance and

supervision and written

safety procedures

61

430.102(B) Exception

Motor Disconnect

l

Where the exception is used to

eliminate the disconnect at the

motor the controller disconnect

must be

n Capable of being locked in the open

position

n Each disconnect must be

individually lockable

n The locking means must be

permanently installed on or at the

switch or circuit breaker

440.65 – Room Air Conditioners

LCDI or AFCI Protection

l

l

Single-phase cord- and

plug-connected room air

conditioners

Must be provided with

factory- installed

n LCDI (Leakage Current

Detection and Interruption)

n or AFCI (Arc-Fault Circuit

Interrupter)

LCDI

Must be integral with the attachment cap

or located within 12” of the attachment

cap

62

500.7(K) – Protection Techniques

Combustible Gas Detection System

Detection system restrictions:

l In industrial establishments with restricted

public access and

l Where conditions of maintenance and

supervision ensure only qualified persons

service installation

l System is listed for detection of specific gas

or vapor

Permitted equipment with detection system:

l

Inadequate Ventilation establishes Class I, Div. 1 location

– Electrical equipment suitable for Class I, Div. 2

l

l

Interior of Building with opening into Class I, Div. 2

– Electrical equipment for unclassified locations

Interior of Control Panel – Instrumentation measuring gas

– Electrical equipment suitable for Class I, Div. 2

500.8(A)(1) – Suitable for Class and Properties

Identified

l

Suitability of Identification by

n Equipment listing or labeling

n Evidence of equipment

evaluation from a qualified

testing lab or inspection agency

n Evidence acceptable to the AHJ

such as a manufacturer’s selfevaluation or owner’s

engineering judgment

63

501.4(B)(3) – Class I Division 2

Nonincendive Field Wiring

Unclassified Location

Classified Location

Nonincendive field wiring –

not capable of igniting

(through arcing or thermal

effects) flammable gas or

vapor under normal operating

conditions.

Cable or wiring method permitted

for unclassified location

Nonincendive field

wiring apparatus

• Install in accordance with the control drawings

• Install in separate cables, cables where each conductor has a grounded

metal shield or in multi-conductor cables where each conductor has a min

of .25mm of insulation

504.80(B) – Intrinsically Safe Systems

Identification of Wiring

Intrinsic Safety

Wiring

l

l

l

Labels located at least every 25 feet

Visible after installation

Must appear in every section separated by walls, partitions,

etc.

64

511.1 – Commercial Garages

Scope

l

l

l

Includes locations used for

service and repair operations

Self-propelled vehicles

Flammable liquids or

flammable gases used for

propulsion

511.3(B)(2) – Classified Locations

Within 18” of the Ceiling

18”

Class I Division 2 unless provided with four

air changes per hour

CNG Vehicle

65

Articles 513 and 515

Zone Classification

Article 513

Aircraft Hangers

Zone 0

Div 1 Zone 1

Div 2 Zone 2

Article 515

Bulk Storage Plants

Zone

classification

system now

permitted

514.1 – Motor Fuel Dispensing Facilities

Scope

Scope and title changed from “Gasoline Dispensing” to “Motor Fuel Dispensing”

Now includes: gasoline, LNG, CNG, etc.

66

517.2 – Definitions

Health Care Facilities

l

l

Definition correlates with NFPA 99

Buildings or portions of buildings that include:

n

n

n

n

n

n

l

Medical

Dental

Psychiatric

Nursing

Obstetrical

Surgical

Includes (but not limited to):

n

n

n

n

n

n

Hospitals

Nursing homes

Limited care facilities

Clinics

Medical and dental offices

Ambulatory care

517.18 – Tamper Resistant Receptacles

Pediatric Locations

l

l

l

Applies to ALL receptacles in

patient care areas of pediatric wards,

rooms or areas

Listed tamper resistant receptacle, or

Listed tamper resistant cover

67

517.30(E) – Essential Electrical Systems

Receptacle Identification in Hospitals

Identification required for receptacles

supplied from the emergency system.

Identification shall be of the cover plate

or the receptacle itself.

Distinctive color or marking so as to be

readily identifiable

Similar requirement exists for emergency receptacles in nursing

homes and limited care facilities [see 517.41(E)]

517.32(G) – Life Safety Branch

Automatic Doors

Connect to the

life safety branch

EXIT

EXIT

Automatically

operated doors used

for building egress

68

517.34 Exception

Equipment System Connection to Alternate Power Source

Requirement for time-lag

interval for the equipment

system is not required for

essential systems of less

than 150kVA

Omission of the time-lag

interval allows a single

transfer switch to be used

520.1 – Theaters

Scope

Scope now includes performance

areas and applies to both indoor

and outdoor locations

69

Article 527

Temporary Installations

Temporary Wiring has been renamed

Temporary Installations

The article covers more than just

wiring methods allowed. GFCI’s,

receptacle grounding, disconnecting

means, etc. are also covered.

527.3(B) – Time Constraints

90 Days

The new wording now reflects that the 90 day time limit applies to all

holiday wiring, not just Christmas.

70

527.6(A) – Ground-Fault Protection for Personnel

Receptacle Outlets

l

GFCI Protection Required for all 125- volt, 15, 20 and 30

ampere receptacle outlets

n Used by personnel during construction, remodeling, maintenance,

repair or demolition

n GFCI in cords sets is acceptable

l

Exception for Industrial establishments where

n Qualified personnel are involved

n Assured Equipment Grounding Conductor Program is applied

n Only permitted for receptacle outlets where having GFCI protection

would be a greater hazard or equipment is not compatible with GFCI

protection

527.6(B) – Ground-Fault Protection for Personnel

Use of Other Outlets

l

l

Applies to all receptacles other than 15, 20 and 30-ampere

125-volt

Requires either

n GFCI, or

n Assured Equipment Grounding Conductor Program [527.6(B)(2)]

71

547.5(G) – Wiring Methods

Receptacles

l

Requires GFCI protection on all

125-volt, 15 and 20-ampere

general purpose receptacles

installed in

n Areas having an equipotential plane

n Outdoors

n Damp or wet locations

547.9 – Power Distribution

Electrical Supply to Buildings/Structures from Distribution Point

Site isolating device (may

be a pole-top disconnect)

Disconnects permitted to be

located at distribution point

– treat like a feeder (250.32

and Article 225)

Alternatively,

disconnects may be

located at the buildings

instead of the

distribution point –

547.9(B)(1)

72

547.10

Equipotential Plans and Bonding of Equipotential Planes

l

Required where the

following exist

n Concrete floor of

confinement area

n Animals have access to

metal equipment

n The metal equipment is

likely to become

energized

l

Must be bonded to the

electrical grounding

system

550.25(B) – AFCI Protection

Bedrooms of Mobile Homes and Manufactured Homes

l

l

l

Requires AFCI protection on branch circuits that

supply 15 and 20 ampere, 125 volt outlets in

bedrooms

Parallel with 210.12 requirement

HUD rules govern the construction of

manufactured homes. HUD does not yet include

the AFCI requirement.

73

Article 555

Marinas and Boatyards

l

l

l

Revised to be more consistent with NFPA 303 –

Fire Protection for Marinas and Boatyards

Specifically excludes private, noncommercial

docking facilities associated with single-family

dwellings

Relates electrical requirements to the “electrical

datum plane”

n 2 ft above highest tide level for area under normal

circumstances

n 2 ft above highest water level under normal

circumstances

n 30” above water level at floating pier or landing stage

and a minimum of 12” above the level of the deck

555.19 – Receptacles

Shore Power and Other than Shore Power

l

Receptacles for shore power must be

n Not less than 30 amps

n single outlet type

l

l

l

Receptacles that are 30 to 50 amps must be

of the locking and grounding type

Receptacles 60 to 100 amperes must be of

the pin and sleeve type

GFCI protection required for receptacles

other than shore power located

n Outdoors

n In boathouses

n Buildings used for storage, maintenance or repair

where electrical hand tools or diagnostic

equipment are to be used.

74

600.21(F) – Ballasts, Transformers and…

Suspended Ceilings

Flexible

cord not

permitted

Securely supported in place

and not dependent on

suspended ceiling grid for

support

Power supply

for electric sign

Support wires

604.6(E) – Construction

Support

New requirement clarifying that manufactured wiring systems

shall be supported in accordance with the applicable cable or

conduit article.

75

645.5(D)(5)(c) – Under Raised Floors

ITC Cable

l

l

l

Type ITC Cable is now permitted under raised floors to

supply IT equipment.

Equipment grounding conductor may be either green

insulation or green insulation with one or more yellow stripes

Driven by more use of computer systems in instrumentation

and control of industrial locations

645.5(D)(6) – Under Raised Floors

Abandoned Cables

Abandoned cables beneath a raise floor assembly shall be

removed unless contained within a metal raceway.

76

Article 647

Sensitive Electronic Equipment

l

l

l

l

New Article

Material from Part G of Article 530

Covers the installation and wiring of

separately derived systems operating at

120V line-to-line and 60V to ground for

sensitive electronic equipment

Expands the permitted use of this system

outside television and motion picture

venues.

60V 60V

120V

Article 680

Swimming Pools, Fountains, and Similar Installations

l

l

l

l

l

l

l

Article completely revised

Part I – General

Part II – Permanently Installed

Pools

Part III – Storable Pools

Part IV – Spas and Hot Tubs

Part V – Fountains

Part VI – Pools and Tubs for

Therapeutic Use

77

680.6

Grounding

“Pool” changed to “specified body of water”

n

Grounding requirements for all bodies of water covered

under the scope of 680 now grouped in 680.6

680.12

Maintenance Disconnecting Means

Maintenance disconnect within

sight of the electrical equipment

(not the pool or spa itself)

5ft minimum distance from pool moved to 680.22(C)

78

680.23(F)(1) Exception – Branch-Circuit Wiring

Wiring Methods

LFNC-B permitted to be used in lengths

longer than 6ft where connecting a

transformer to pool lights.

X-fmr

680.26(B)(1) – Bonded Parts

Metallic Structural Components

l

l

l

Basic rule requires bonding

of steel structure of a pool

(i.e. rebar)

If rebar is insulated by

encapsulation it is not be

required to be bonded

Provisions shall be made for

an alternate means to

eliminate voltage gradients

n

Example: installation of a #8

AWG bare copper conductor

throughout the structure

79

680.26(B)(4) – Bonded Parts

Electrical Equipment

Double-insulated motor

No. 8 copper

l

l

l

Basic rule requires bonding of all equipment associated with

the circulating system

Double insulated pumps are permitted

Where a double insulated pump is installed, a #8 AWG

bonding conductor is required at the pump location for use

with a replacement motor.

680.27(B)(1) – Electrically Operated Pool Covers

Motors and Controllers

Controls for an electrically operated pool cover shall be located so that

the operator has full view of the pool

80

680.44(B) – Spas/Hot Tubs – Protection

Other Units

GFCI protection required for outlets

that supply a:

• self-contained spa or hot tub

• packaged spa or hot tub

• field assembled spa or hot tub

with a heater load of 50A or

less

Listed assemblies with integral

GFCI protection for all electrical

parts do not require additional GFCI

at the outlet.

A spa or hot tub rated greater than

250V or 3-phase shall not require

GFCI protection.

680.57(C)(2) – Location

Portable Signs

5 ft

Portable electric signs shall not be placed within the pool or

fountain, or within 5 ft (1.52 m ) measured horizontally from

the inside walls of the pool or fountain

81

Article 692

Fuel Cells

Includes requirements for:

• Listing of the fuel cell

• Identification of multiple power sources

• Circuit requirements

• Etc.

700.12(B)(6) – Generator Sets

Outdoor Generator Sets

l

l

Allows disconnect at a generator to also serve

as the disconnect for a building or structure

Comply with the following:

n Generator disconnect must be readily accessible

n Must be “within sight” of the building (visible and

not more than 50 feet away)

n Must still meet the requirements for a building

disconnect in Article 225 (e.g. 225.36 requires that

disconnect be suitable for use as service equipment)

Similar language in 701.11(B)(5)

for legally required systems

82

702.1 – Optional Standby Systems

Scope

l

... The systems covered by this article consist of those that are

permanently installed in their entirety, including prime

movers, and those that are arranged for a connection to a

premises wiring system from a portable alternate power

supply.

702.6

Transfer Equipment

l

Transfer equipment required for

n permanently installed standby systems

n and where an electric-utility supply is

either the normal or standby source

l

l

Must prevent the inadvertent

interconnection of supplies

Supplementary overcurrent protective

devices shall be part of a listed

transfer equipment.

n Not a substitute for branch circuit or

feeder overcurrent protection

l

Comply with Article 705 if system

will be operated in parallel

83

725.3(A) – Locations and Other Articles

Number and Size of Conductors in Raceway

l

l

l

References 300.17 for all of

Article 725

This extends the raceway wire fill

restrictions to Class 2 and 3

circuits

Applies Chapter 9, Table 1

through references

725.6

Mechanical Execution of Work

Class 1, 2 or

3 circuits

Support wires

l

l

l

Installed in a neat and workmanlike manner

Support to structural components

Use proper straps, hangers or similar fittings

84

725.52(A) Exception No. 2 – Load Side of Class 2 or 3

Class 1 Wiring Methods and Materials

l

l

l

l

Can reclassify Class 2 and Class

3 circuits as Class 1 circuits

Must install as Class 1

Class 2 and Class 3 markings

required in Section 725-42 are

eliminated

Entire circuit is installed using

the wiring methods and materials

in accordance the requirements

for Class 1 circuits

800.48 – Communications Wiring within Buildings

Communications Raceways

New Exception 2: Conduit fill restrictions shall not apply.

85

Annexes

l

l

l

l

l

l

l

Annex A – Product Standards

Annex B – Application of 310.10(A) formula

Annex C – Conduit and Tubing Fill Tables

Annex D – Examples

Annex E – NFPA 220 Table for Building

Types

Annex F – Chapter 3 Cross Reference from

1999 to 2002 NEC

The Annex material is for information only

and is not part of the Code requirements

Square D Company

Codes and Standards

l

l

l

The Codes and Standards group can offer on-site custom

training on the NEC and related topics

Our staff has extensive involvement in codes and standards

development, interpretation and application

Excellent resource for resolution of field issues

86