BD01 Busbar Trunking System

advertisement

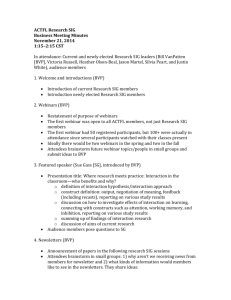

BD01 Busbar Trunking System 40A to 160A SIVACON 8PS 4 © Siemens AG 2008 BD01 System – 40 ... 160 A 4/2 4/3 4/3 4/6 Introduction Overview Benefits Design Accessories 4/9 General data Technical specifications 4/11 Trunking units Selection and ordering data 4/12 Junction units Selection and ordering data 4/12 Feeder units Selection and ordering data 4/13 Tap-off units for international use Selection and ordering data 4/19 Ancillary equipment units for international use Selection and ordering data 4/21 Tap-off units and ancillary equipment units for Belgium Selection and ordering data 4/22 Tap-off units and ancillary equipment units for Denmark Selection and ordering data 4/23 Tap-off units for France Selection and ordering data 4/24 Tap-off units for the United Kingdom Selection and ordering data 4/25 Tap-off units for Switzerland Selection and ordering data 4/27 Accessories Selection and ordering data 4/29 4/30 4/32 Configuration information Overview Design Function 4/34 Project planning aids Dimensional drawings Siemens LV 70 · 2009 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction ■ Overview 2 1 4 5 3 NSV0_00041 4 6 1 4 2 3 4 4 5 6 Version Type-tested low-voltage switchgear and controlgear assembly (TTA) according to • IEC/EN 60439-1 • IEC/EN 60439-2 Degree of protection • High degree of protection IP54 with tap-off points at sides and bottom • Degree of protection IP50 with tap-off points at the top • Degree of protection increase to IP55 with optional equipment Trunking unit Junction unit Feeder unit Tap-off unit Ancillary equipment unit Accessories Feeder units • Universal infeed Tap-off units • Up to 63 A • With built-in parts or for customized device installation • For 3, 4 or 8 modular widths (MW) • With or without device installation unit Components Ancillary equipment units • For 4 or 8 modular widths (MW) • With or without device installation unit • With or without socket assembly Trunking units • 5-wire system • 2 or 3 tap-off points spaced 1 m apart • 4 or 6 tap-off points spaced 0.5 m apart • Lengths of 2 m and 3 m Accessories • Mounting sets for degree of protection IP55 • Fixing and suspending • Coding sets • Fire protection kit S90 Junction units • Flexible change of direction 4/2 Siemens LV 70 · 2009 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction ■ Benefits 7 7 7 7 7 7 7 7 7 7 7 Connections Flexible power supply Easy and quick planning Time-saving mounting Reliable mechanical and electrical connection High stability, low weight Few basic modules required Storage-friendly system Variable change of the direction of the busbar line Versatile tap-off units Positive opening and closing of tap-off points Optional equipment for increasing the degree of protection to IP55 for extreme environmental conditions ■ Design Trunking units NSV0_000 45 Assembly of the trunking units, also with end flanges and feeder units, is fast and inherently secure. The trunking unit or end flange is simply inserted in the lower housing of the joint block. Once the upper part of the joint block or feeder unit is fitted, a secure connection is established by tightening four screws. The PE path is established automatically when the enclosures are connected. An expansion compensation mechanism is built into the joint block. Trunking units are available in 2 m and 3 m lengths. They consist of a galvanized metal enclosure with a light gray (RAL 7035) painted finish. They are equipped with 4 busbars for L1, L2, L3 and N (aluminum conductors; copper for 160 A; silver-plated copper pick-up and connection contacts). The enclosure of the trunking unit also serves as PE conductor. Five levels of current are available in only one frame size: 40 A, 63 A, 100 A, 125 A and 160 A. NSV0_00046 NSV0_00042 End flanges The end flanges provide touch protection against direct contact at the ends of the busbar line. They are suitable for use with all systems. Two end flanges are supplied as standard with each feeder unit. Junction units NSV0_00047 The tap-off points are spaced at regular intervals of 0.5 m or 1 m on one side. The 2 m lengths have two or four tap-off points, the 3 m lengths have three or six. L1 L3 N NSV0_00043 L2 The junction units, which consist of flexible conducting paths, are available in versions for 100 A and 160 A, each in 0.5 m and 1 m lengths. PE Flexible junction units mean that the busbar line can be routed in any direction. The 0.5 m version is recommended for right angles, the 1 m version for fitting around obstacles or for adapting to variations in height. NSV0_00044 The tap-off points are finger-safe. They are opened automatically by the tap-off units and close by themselves when the tap-off units are removed. Siemens LV 70 · 2009 4/3 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction Feeder units Insulated tap-off units NSV0_00048 Common features • Molded-plastic enclosure • Partially transparent cover for protective devices • Power pick-up through silver-plated lyre-shaped contacts • Reliable prevention of incorrect mounting • Cable entry is from one side only (use plastic cable glands with strain relief, not included in scope of supply). • The tap-off unit must first be removed from the trunking before it can be opened and the cable can be connected. • The connecting cable should be supported separately if necessary. There is one version each for 100 A and 160 A. The feeder unit can be used as: • Entry feeder unit Tap-off units with components fitted • One size for 1 cylindrical fuse (10 × 38 mm), phase assignment L1, L2 or L3 freely selectable • One size for 3 cylindrical fuses (10 × 38 mm) • One size with 3 MW (1 MW = 18 mm; MW = modular width) NSV0_000 49 There are various versions with fuse bases, miniature circuit breakers, Schuko and CEE socket outlets up to 32 A • End feeder unit 52 00 _0 V0 NSV0_00050 NS 4 BD01-AK01X/ZS • Center feeder unit 3 05 00 0_ V NS NSV0_0 0051 BD01-AK02X/ZS3 Two end flanges are included in the scope of supply with each unit. M32, M40 and M50 cable entries are possible from four sides. For 160 A, an M63 cable entry can be fitted in a side. Plastic cable glands with strain relief must be used (not included in scope of supply). 54 00 _0 V0 S N BD01-AK02M0/CEE165A163 4/4 Siemens LV 70 · 2009 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction Tap-off units for free arrangement of components • Two sizes with 4 MW and 8 MW (1 MW = 18 mm; MW = modular width) • With or without device installation unit for external operation (two sizes with 4 MW and 8 MW respectively) • Installation of devices (e.g. miniature circuit breakers) according to DIN 43871 possible up to 63 A. NSV0_00057 NSV0_00055 Tap-off units for free arrangement of components • One size with 3 MW; can be operated from outside through hinge switch incorporated in cover (1 MW = 18 mm; MW = modular width). • Installation of devices (e.g. miniature circuit breakers) according to DIN 43871 possible up to 32 A. BD01-AK02M0/F Aluminum tap-off units BD01-AK1M1/A161 Common features Ancillary equipment units Common features: • The enclosure is made from aluminum and molded plastic at both ends. • A standard mounting rail is built-in for component mounting. • Power pick-up through silver-plated lyre-shaped contacts • The isolator built into the tap-off unit ensures that the tap-off unit is voltage-free when the cover is open. • The tap-off unit can only be fitted to or removed from the tapoff point with its cover open (contacts retracted). • Reliable prevention of incorrect mounting • Cable entry is possible from three directions (use plastic cable glands with strain relief; not included in scope of supply). • Can be combined with ancillary equipment units for additional functions. • The connecting cables should be supported separately if necessary. Common features • The enclosure is made from aluminum and molded plastic at both ends. • Cable entry is possible from four directions (use plastic cable glands with strain relief; not included in scope of supply). • The connecting cable should be supported separately if necessary. • Can be combined with tap-off or feeder units • A standard mounting rail is built-in for component mounting. • Two sizes with 4 MW and 8 MW (1 MW = 18 mm; MW = modular width) • Without or with Schuko or CEE socket outlets • With or without device installation unit for external operation (two sizes with 4 MW and 8 MW respectively) • Installation of devices (e.g. fuse bases) according to DIN 43871 possible up to up to 35 A. NSV0_00058 Tap-off units with components fitted • Two sizes with 4 MW or 8 MW (1 MW = 18 mm; MW = modular width) • Various versions with fuse bases, miniature circuit breakers up to 63 A, with Schuko and CEE socket outlets up to 32 A. • Versions with fitted miniature circuit breaker have a device installation unit. NSV0_00059 NSV0_00056 BD01-GK2X/F BD01-AK2M1/CEE165A163 BD01-GK2X/2SD163CEE165 Siemens LV 70 · 2009 4/5 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction ■ Accessories Optional equipment for IP55 Trunking units The higher degree of protection is achieved by means of additional seals and a flange at the tap-off point or connection point. With mounting position at the side, the higher degree of protection is achieved by means of additional seals and an edge protector at the sides of the feeder unit. When the feeder unit is installed at the end of a busbar line, just one seal and one edge protector are needed. NSV0_ 00974 Mounting position at the side: 2 × BD01-KS NSV0_ 00971 Tap-off point: BD01-FAS NSV0_ 00975 Mounting position at the side and end of a busbar line: BD01-KS Tap-off units 4 NSV0_ 00972 The higher degree of protection is achieved by means of additional seals and an edge protector at the sides of the tap-off unit. Connection point: BD01-FS NSV0_ Feeder units 00976 With mounting position at the bottom, the higher degree of protection is achieved by means of additional seals and a flange at the connection point. BD01-AK01X-IP55, BD01-AK02X-IP55 NSV0_ 00977 NSV0_ 00973 Mounting position at the bottom: BD01-FES 4/6 Siemens LV 70 · 2009 BD01-AK1X-IP55, BD01-AK2X-IP55 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction Fixing Suspension brackets Universal fixing brackets The universal fixing brackets can be used for wall and ceiling mounting. The maximum fixing interval at normal mechanical loads is 3 m for edgewise and 1.5 m for flat mounting. The suspension brackets can be used for wall, ceiling and suspension mounting of the system. They can be fitted at any point of the trunking unit. The maximum fixing interval at normal mechanical loads is 3 m for edgewise and 1.5 m for flat mounting. At higher mechanical loads (e.g. pulling of plugs), an intermediate support with an additional fixing bracket at the trunking unit is recommended. At higher mechanical loads (e.g. pulling of plugs), an intermediate support with an additional fixing bracket at the trunking unit is recommended. NSV0_00060 NSV0_00062 Once the fixing point is decided, the tabs on the fixing bracket are pushed in to fix the busbar line. BD01-BA BD01-B Hanger brackets NSV0_00061 These fixing brackets can be used for suspension of flatmounted trunking units. Also they can be fastened at the connection points in order to increase the mechanical rigidity of the trunking units. 4 BD01-BAP Siemens LV 70 · 2009 4/7 © Siemens AG 2008 BD01 System — 40 ... 160 A Introduction Coding Fire protection The systems can be coded for different frequencies or voltages. For this purpose, the BD01-K coding set can be fitted by the user to the installed system at each tap-off point. Four coding positions are possible. If the busbar system is routed through a fire wall or ceiling, fire protection must be fitted. Depending on the customer's requirements, Siemens offers fire protection with a fire resistance rating of S90 (see page 4/28). Factory-fitted equipment: • External fire protection as kit for mounting by the customer Mineral mortar or fire protection material to seal any gaps between the busbar trunking element and the component must be provided by the customer. NSV0_000 NSV0_01459 63 Coding on the tap-off point Tap-off units can be coded on site by adapting the front face. NSV0_00064 BD01-S90 fire protection Coding on the tap-off unit 4 Sealing Every tap-off point on the trunking unit can be sealed. Feeder, junction, tap-off and ancillary equipment units can be made sealable with additional components (please inquire). Cable glands For the feeder, tap-off and ancillary equipment units, use plastic cable glands with strain relief (not included in scope of supply). Terminals We recommend the use of Weidmüller or Phoenix screw terminals for the N and PE conductor connections in tap-off and ancillary equipment units. 4/8 Siemens LV 70 · 2009 The approval papers for Germany must be ordered separately: • BD01-S90-ZUL-D approval kit (certificate of approval, wall-mounted signs and declaration of conformity) © Siemens AG 2008 BD01 System — 40 ... 160 A General data ■ Technical specifications General technical specifications Type BD01-... Standards and specifications IEC/EN 60439-1 and -2 Climatic proofing Damp heat, constant, according to IEC 60068-2-78 Damp heat, cyclic, according to IEC 60068-2-30 Ambient temperature, min./max. °C -5/+40 Degree of protection acc. to IEC/EN 60529 • Edgewise; tap-off points at the side IP54, increase to IP55 with optional equipment • Flat; tap-off points at the bottom IP54, increase to IP55 with optional equipment • Flat; tap-off points at the top IP50, increase to IP55 with optional equipment Material • Trunking unit enclosures Galvanized, painted sheet steel • Busbars Al or Cu • Pick-up and connection contacts Cu, silver-plated Mounting position Edgewise or flat Weights See "Selection and Ordering Data" Overload and short-circuit protection Busbar trunking systems must be protected against overload and short-circuits. Fuses and miniature circuit breakers must be selected so that the admissible current carrying capacity corresponding with the ambient conditions is not exceeded. For overload and short-circuit protection, we recommend the use of motor protectors or circuit breakers. Tap-off units Type BD01-AK... Version 3- or 5-pole Rated current Ie A 63 Switching capacity of the built-in switch-disconnector acc. to IEC/EN 60947-3 at 400 V • Utilization category AC-20B Feeder and tap-off units, conductor cross-sections Version Feeder units Tap-off units Type L1, L2, L3 N 4 PE min. mm2 max. mm2 min. mm2 max. mm2 min. mm2 max. mm2 BD01-E 6 (so, st) 50 (st) 6 (so, st) 50 (st) 6 (so, st) 50 (st) BD01-160-E 25 (st) 95 (st) 25 (st) 95 (st) 16 (st) 50 (st) BD01-AK01X/ZS 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) BD01-AK02X/ZS3 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) BD01-AK02M0/A163 0.75 (so, st) 16 (so) 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) BD01-AK02M0/A323 0.75 (so, st) 16 (so) 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) BD01-AK1M1/A101 0.75 (so, st) 16 (so) 0.75 (so, f) 2.5 (so, f) 0.75 (so, f) 2.5 (so, f) BD01-AK1M1/A161 0.75 (so, st) 16 (so) 0.75 (so, f) 2.5 (so, f) 0.75 (so, f) 2.5 (so, f) BD01-AK1M1/A321 0.75 (so, st) 16 (so) 0.75 (so, f) 2.5 (so, f) 0.75 (so, f) 2.5 (so, f) BD01-AK1M1/A... 0.75 (so, st) 16 (so) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so) BD01-AK1M1/A...N 0.75 (so, st) 16 (so) 0.75 (so, st) 16 (so) 0.75 (so, st) 16 (so) BD01-AK1X/S14 0.5 (f, st) 4 (so) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so) BD01-AK1X/S18 0.5 (f, st) 16 (so, f, st) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so) BD01-AK1X/GB... 0.75 (so, st) 16 (so) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so) BD01-AK2X/F1451 0.75 (so, st) 16 (so) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so) BD01-AK2X/S27 0.75 (f, st) 10 (so, f, st) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so) BD01-AK2HX/S33 1.5 (f, st) 25 (f, st) 0.75 (f, st) 10 (so, f, st) 0.75 (so, st) 16 (so, st) f = finely stranded with end sleeve, so = solid, st = stranded Siemens LV 70 · 2009 4/9 © Siemens AG 2008 BD01 System — 40 ... 160 A General data Trunking units Type BD01-40 BD01-63 BD01-100 BD01-125 BD01-160 Conducting paths Rated insulation voltage Ui V AC/DC 400/400 Overvoltage category/degree of pollution 400/400 400/400 400/400 400/400 III/3 III/3 III/3 III/3 III/3 Rated operational voltage Ue V AC 400 400 400 400 400 Frequency Hz 50 ... 60 50 ... 60 50 ... 60 50 ... 60 50 ... 60 Rated current Ie Ⳏ conventional thermal current at max. 40 °C and 35 °C on a 24 h average A 40 63 100 125 160 Impedance of conducting paths at 50 Hz and 20 °C busbar temperature • Resistance R20 m:/m 3.960 1.936 0.938 0.910 0.578 • Reactance X20 m:/m 0.280 0.324 0.286 0.300 0.273 • Impedance Z20 Impedance of conducting paths under event of a fault m:/m 3.970 1.968 0.994 1.000 0.642 • AC resistance RF m:/m 5.991 4.128 2.841 2.420 2.189 • Reactance XF • Impedance ZF m:/m 1.396 1.248 1.186 0.940 0.973 m:/m 6.151 4.312 3.078 2.600 2.395 Zero sequence impedance acc. to IEC/EN 60909 (VDE 0102) • Resistance R0 Phase to N m:/m 15.904 7.911 4.115 3.810 3.167 • Reactance X0 Phase to N m:/m 2.128 2.058 1.797 1.630 1.656 • Impedance Z0 • Resistance R0 Phase to N m:/m 16.045 8.175 4.490 4.140 3.574 Phase to PE m:/m 10.086 8.565 6.648 5.430 5.343 • Reactance X0 Phase to PE m:/m 2.909 3.338 3.067 2.320 2.355 • Impedance Z0 Short-circuit strength Phase to PE m:/m 10.498 9.183 7.322 5.910 5.839 Rated impulse withstand current Ipk kA 2.55 6.30 15.30 15.30 15.30 Rated short-time withstand current Icw (t = 1 s) kA 0.58 1.15 2.50 2.50 2.50 Rated short-time withstand current Icw (t = 0.1 s) kA 1.70 4.20 9.00 9.00 9.00 4 4 4 4 4 Conductors Number of active conductors 4 Conductor cross-section • L1, L2, L3 mm2 7.9 15.7 34.1 34.1 34.1 •N mm2 7.9 15.7 34.1 34.1 34.1 • PE (enclosure) Ⳏ Cu mm2 20.0 20.0 20.0 20.0 20.0 Al Al Al Al Cu Conductor material Fire load kWh/m 0.76 0.76 0.76 0.76 0.76 Max. thermal load, I2t value A2s × 106 0.29 1.76 8.10 8.10 8.10 Max. fixing intervals at normal mechanical load m • Edgewise m 3 3 3 3 3 • Flat m 1.5 1.5 1.5 1.5 1.5 • Flat with BD01-BAP m 3 3 3 3 3 4/10 Siemens LV 70 · 2009 © Siemens AG 2008 BD01 System — 40 ... 160 A Trunking units ■ Selection and ordering data Version Rated current Length A m 40 3 Tap-off points Number Trunking units Sheet-steel enclosure, color similar to RAL 7035 (light gray), codable tap-off points 2 63 NSV0_00241 3 2 100 3 2 125 3 2 160 3 2 DT Type Order No. PS* Distance m Weight per unit approx. kg 6 0.5 A BD01-40-3-0,5 BVP:034253 1 unit 4.350 3 1 A BD01-40-3-1 BVP:233551 1 unit 4.350 4 0.5 A BD01-40-2-0,5 BVP:034254 1 unit 3.000 2 1 A BD01-40-2-1 BVP:233552 1 unit 3.000 6 0.5 A BD01-63-3-0,5 BVP:034255 1 unit 4.600 3 1 A BD01-63-3-1 BVP:233553 1 unit 4.600 4 0.5 A BD01-63-2-0,5 BVP:034256 1 unit 3.200 2 1 A BD01-63-2-1 BVP:233555 1 unit 3.200 6 0.5 A BD01-100-3-0,5 BVP:034257 1 unit 5.200 3 1 A BD01-100-3-1 BVP:233556 1 unit 5.200 4 0.5 A BD01-100-2-0,5 BVP:034258 1 unit 3.600 2 1 A BD01-100-2-1 BVP:233557 1 unit 3.600 6 0.5 A BD01-125-3-0,5 BVP:090163 1 unit 5.200 3 1 A BD01-125-3-1 BVP:233559 1 unit 5.200 4 0.5 A BD01-125-2-0,5 BVP:090161 1 unit 3.600 2 1 A BD01-125-2-1 BVP:233560 1 unit 3.600 6 0.5 A BD01-160-3-0,5 BVP:090164 1 unit 8.000 3 1 A BD01-160-3-1 BVP:233563 1 unit 8.000 4 0.5 A BD01-160-2-0,5 BVP:090162 1 unit 5.400 2 1 A BD01-160-2-1 BVP:233567 1 unit 5.400 4 * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/11 © Siemens AG 2008 BD01 System — 40 ... 160 A Junction units Feeder units ■ Selection and ordering data Version Rated current Length A m DT Type Order No. PS* Weight per unit approx. kg Junction units 100 NSV0_00274 Flexible change of direction Version 160 0.5 A BD01-R1 BVP:034260 1 unit 1.200 1 A BD01-R2 BVP:034261 1 unit 2.050 0.5 A BD01-160-R1 BVP:090166 1 unit 1.750 1 A BD01-160-R2 BVP:090167 1 unit 3.050 Rated current Conductor cross-section A mm2 DT Type Order No. PS* Weight per unit approx. kg Feeder units Molded-plastic enclosure, with 2 end flanges Can be fitted at all connection terminals and the end of the busbar run, can be combined with BD01-GK... ancillary equipment units 100 501) A BD01-E BVP:034259 1 unit 1.000 160 952) A BD01-160-E BVP:090165 1 unit 1.400 NSV0_00242 • 6 cable entries from 4 sides NSV0_00243 • Cable entry from 2 sides 4 Use plastic cable glands with strain relief (not included in scope of supply). 1) Use M32, M40 or M50 cable glands. 2) Use M63 cable glands. 4/12 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for international use ■ Selection and ordering data Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V 16 400 A BD01-AK01X/ZS BVP:087483 1 unit 0.300 32 400 A BD01-AK02X/ZS3 BVP:085090 1 unit 0.400 kg Tap-off units, molded plastic, size 01 NSV0_00244 With fuse base for 1 cylindrical fuse 10 mm × 38 mm Tap-off units, molded plastic, size 02 NSV0_00245 With fuse base for 3 cylindrical fuses 10 mm × 38 mm Tap-off units, molded plastic, size 02, with device installation unit With 3-pole miniature circuit breaker 16 A, characteristic B 16 400 A BD01-AK02M0/A163 BVP:085089 1 unit 0.800 16 400 A BD01-AK02M0/ CEE165A163 BVP:085092 1 unit 0.980 With 3-pole miniature circuit breaker 32 A, characteristic C 32 400 A BD01-AK02M0/A323 BVP:085094 1 unit 0.800 NSV0_00246 • Without socket outlet NSV0_00246 NSV0_00247 • With 1 CEE socket outlet 16 A, 5-pole Fuse links are not included in scope of supply. Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/13 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for international use Version Rated current Rated operational voltage A V DT Type Order No. PS* Weight per unit approx. kg Tap-off units, molded plastic, size 02, with device installation unit With 1-pole miniature circuit breaker 16 A, characteristic B 16 230 A BD01-AK02M0/ 2SD163A161 BVP:085096 1 unit 0.700 16 230 A BD01-AK02M0/ CEE163A161 BVP:090170 1 unit 0.700 16 230 A BD01-AK02M0/ 2SD163FIA161 BVP:090168 1 unit 0.950 16 230 A BD01-AK02M0/ 2SD163S14 BVP:085095 1 unit 0.800 16 230 A BD01-AK02M0/ CEE163S14 BVP:090169 1 unit 0.800 Freely assignable (Pv max. 13 W), 3 MW (MW = modular width), 32 with integrated standard mounting rail 400 A BD01-AK02M0/F BVP:085093 1 unit 0.500 NSV0_00248 • With 2 Schuko socket outlets 16 A NSV0_00247 • With 1 CEE socket outlet 16 A, 3-pole NSV0_00248 • With 2-pole RCCB 16 A/30 mA and with 2 Schuko socket outlets 16 A With 1-pole fuse base D01 NSV0_00248 • With 2 Schuko socket outlets 16 A NSV0_00247 • With 1 CEE socket outlet 16 A, 3-pole NSV0_00246 4 Adapter ring/screw adapter, fuse links and screw cap are not included in scope of supply. Use plastic cable glands with strain relief (not included in scope of supply). 4/14 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for international use Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V 16 230 A BD01-AK1X/ 2SD163S14 BVP:034268 1 unit 1.400 16 230 A BD01-AK1X/ CEE163S14 BVP:034270 1 unit 1.380 16 400 A BD01-AK1X/S14 BVP:034264 1 unit 1.400 35 400 A BD01-AK1X/S18 BVP:034265 1 unit 1.400 16 230 A BD01-AK1X/ 2SD163A161 BVP:034269 1 unit 1.470 16 230 A BD01-AK1X/ CEE163A161 BVP:034271 1 unit 1.435 Freely assignable (Pv max. 13 W), 4 MW (MW = modular width), 35 with integrated standard mounting rail 400 A BD01-AK1X/F BVP:034272 1 unit 1.000 kg Tap-off units, aluminum, size 1 With 1-pole fuse base D01 NSV0_00250 • With 2 Schuko socket outlets 16 A NSV0_00251 • With 1 CEE socket outlet 16 A, 3-pole NSV0_00249 With 3-pole fuse base 3 × D01 NSV0_00249 With 3-pole fuse base 3 × D02 With 1-pole miniature circuit breaker 16 A, characteristic B NSV0_00250 • With 2 Schuko socket outlets 16 A NSV0_00249 NSV0_00251 • With 1 CEE socket outlet 16 A, 3-pole Adapter ring/screw adapter, fuse links and screw cap are not included in scope of supply. Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/15 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for international use Version Rated current Rated operational voltage A V DT Type Order No. PS* Weight per unit approx. kg Tap-off units, aluminum, size 1, with device installation unit 400 A BD01-AK1M1/A101 BVP:203098 1 unit 1.600 400 A BD01-AK1M1/A161 BVP:034266 1 unit 1.600 400 A BD01-AK1M1/A323 BVP:034267 1 unit 1.600 400 A BD01-AK1M1/F BVP:034273 1 unit 1.000 NSV0_00252 With 3 ×1-pole miniature circuit breaker 10 A, characteristic B 10 NSV0_00252 With 3 ×1-pole miniature circuit breaker 16 A, characteristic B 16 NSV0_00252 With 3-pole miniature circuit breaker 32 A, characteristic C 32 NSV0_00253 Freely assignable (Pv max. 13 W), 4 MW (MW = modular width), 35 with integrated standard mounting rail 4 Use plastic cable glands with strain relief (not included in scope of supply). 4/16 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for international use Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V • With 3-pole fuse base S27, gauge screw system 25 400 A BD01-AK2X/S27 BVP:034274 1 unit 1.700 • With 3-pole fuse base S33, gauge screw system 63 400 A BD01-AK2HX/S33 BVP:233568 1 unit 1.700 With 2 × 1-pole fuse base D01 and with 4 Schuko socket outlets 16 A 16 230 A BD01-AK2X/ 4SD163S14 BVP:034277 1 unit 2.000 16 400 A BD01-AK2X/ CEE165S14 BVP:034279 1 unit 1.850 32 400 A BD01-AK2X/ CEE325S18 BVP:034281 1 unit 2.000 kg Tap-off units, aluminum, size 2 NSV0_00255 NSV0_00254 With 3-pole fuse base S27/S33 NSV0_00256 With 3 × 1-pole fuse base D01 and with 1 CEE socket outlet 16 A, 5-pole NSV0_00256 With 3 × 1-pole fuse base D02 and with 1 CEE socket outlet 32 A, 5-pole 16 230 A BD01-AK2X/ 4SD163A161 BVP:034278 1 unit 2.100 NSV0_00255 With 2 × 1-pole miniature circuit breaker 16 A, characteristic B, and with 4 Schuko socket outlets 16 A 4 NSV0_00254 Freely assignable, 8 MW (MW = modular width), with integrated standard mounting rail • Freely assignable (Pv max. 16 W) 35 400 A BD01-AK2X/F BVP:034283 1 unit 1.300 • Freely assignable (Pv max. 22.5 W) 63 400 A BD01-AK2HX/F BVP:233570 1 unit 1.300 Adapter ring/screw adapter, fuse links and screw cap are not included in scope of supply. Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/17 © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for international use Version Rated current Rated operational voltage A V DT Type Order No. PS* Weight per unit approx. kg Tap-off units, aluminum, size 2, with device installation unit 230 A BD01-AK2M1/ 2SD163FIA161 BVP:034276 1 unit 2.000 400 A BD01-AK2M1/ CEE163FIA161 BVP:660867 1 unit 2.000 400 A BD01-AK2M2/ CEE165FIA163 BVP:660866 1 unit 3.500 400 A BD01-AK2M1/ CEE165A163 BVP:034280 1 unit 2.000 400 A BD01-AK2M1/ CEE325A323 BVP:034282 1 unit 2.100 NSV0_00257 With 1-pole miniature circuit breaker 16 A, characteristic B, 16 with 2-pole RCCB 16 A/30 mA and with 2 Schuko socket outlets 16 A NSV0_00258 With 1-pole miniature circuit breaker 16 A, characteristic C, 16 with 2-pole RCCB 25 A/30 mA and with 1 CEE socket outlet 16 A, 3-pole NSV0_01473 With 3-pole miniature circuit breaker 16 A, characteristic C, 16 with 4-pole RCCB 25 A/30 mA and with 1 CEE socket outlet 16 A, 5-pole With 3-pole miniature circuit breaker 16 A, characteristic C, 16 and with 1 CEE socket outlet 16 A, 5-pole NSV0_00258 4 NSV0_00258 With 3-pole miniature circuit breaker 32 A, characteristic C, 32 and with 1 CEE socket outlet 32 A, 5-pole NSV0_00259 Freely assignable, 8 MW (MW = modular width), with integrated standard mounting rail • Freely assignable (Pv max. 16 W) 35 400 A BD01-AK2M2/F BVP:034284 1 unit 1.360 • Freely assignable (Pv max. 22.5 W) 63 400 A BD01-AK2HM2/F BVP:233571 1 unit 1.360 Use plastic cable glands with strain relief (not included in scope of supply). 4/18 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Ancillary equipment units for international use ■ Selection and ordering data Version Rated operational voltage DT Type Order No. PS* V Weight per unit approx. kg Ancillary equipment units, aluminum, size 1 Freely assignable (Pv max. 13 W), 4 MW (MW = modular width), with integrated standard mounting rail 400 A BD01-GK1X/F BVP:034285 1 unit 0.800 400 A BD01-GK1X/4SD163 BVP:034287 1 unit 1.200 400 A BD01-GK1X/CEE163 BVP:660808 1 unit 0.950 400 A BD01-GK1X/CEE165 BVP:660809 1 unit 1.000 NSV0_00260 Can be used for • Overvoltage protection • Remote control/remote switching • Intelligence • Electronic control equipment NSV0_00261 With 4 Schuko socket outlets 16 A NSV0_01474 With 1 CEE socket outlet 16 A, 3-pole NSV0_01474 With 1 CEE socket outlet 16 A, 5-pole 400 A BD01-GK1X/CEE325 BVP:660810 1 unit 1.040 A BD01-GK1M1/F BVP:034286 1 unit 0.800 NSV0_01474 With 1 CEE socket outlet 32 A, 5-pole 4 Ancillary equipment units, aluminum, size 1, with device installation unit Freely assignable (Pv max. 13 W), 4 MW (MW = modular width), with integrated standard mounting rail 400 NSV0_00262 Can be used for • Remote control/remote switching • Intelligence • Electronic control equipment • Device installation unit for mounting devices, e.g. miniature circuit breakers M50 cable grommets and screws for connecting the enclosure are included in scope of supply with ancillary equipment units. Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/19 © Siemens AG 2008 BD01 System — 40 ... 160 A Ancillary equipment units for international use Version Rated operational voltage DT Type Order No. PS* V Weight per unit approx. kg Ancillary equipment units, aluminum, size 2 Freely assignable (Pv max. 16 W), 8 MW (MW = modular width), with integrated standard mounting rail 400 A BD01-GK2X/F BVP:034288 1 unit 1.100 400 A BD01-GK2X/ 2SD163CEE165 BVP:034291 1 unit 1.600 400 A BD01GK2X/2SD163CEE325 BVP:660811 1 unit 1.800 400 A BD01-GK2X/ CEE163CEE165 BVP:034290 1 unit 1.500 A BD01-GK2M2/F BVP:034289 1 unit 1.100 NSV0_00263 Can be used for • Overvoltage protection • Remote control/remote switching • Intelligence • Electronic control equipment NSV0_00264 With 2 Schuko socket outlets 16 A and 1 CEE socket outlet 16 A, 5-pole NSV0_00264 With 2 Schuko socket outlets 16 A and 1 CEE socket outlet 32 A, 5-pole NSV0_00265 Ancillary equipment units, aluminum, size 2, with device installation unit Freely assignable (Pv max. 16 W), 8 MW (MW = modular width), with integrated standard mounting rail 400 Can be used for • Remote control/remote switching • Intelligence • Electronic control equipment • Device installation unit for mounting devices, e.g. miniature circuit breakers NSV0_00266 4 With 1 CEE socket outlet 16 A, 3-pole, and 1 CEE socket outlet 16 A, 5-pole M50 cable grommets and screws for connecting the enclosure are included in scope of supply with ancillary equipment units. Use plastic cable glands with strain relief (not included in scope of supply). 4/20 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units and ancillary equipment units for Belgium ■ Selection and ordering data Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V 16 230 X BD01-AK1X/ 2PC163A162 BVP:203115 1 unit 1.620 16 230 X BD01-AK1X/ CEE163A162 BVP:203114 1 unit 1.620 kg Tap-off units, aluminum, size 1 With 2-pole miniature circuit breaker 16 A, characteristic C NSV0_00250 • With 2 socket outlets 16 A NSV0_00251 • With 1 CEE socket outlet, 16 A, 3-pole NSV0_00252 Tap-off units, aluminum, size 1, with device installation unit With 1-pole miniature circuit breaker 16 A, characteristic C 16 230 X BD01-AK1M1/A161/1 BVP:203106 1 unit 1.600 With 2-pole miniature circuit breaker 16 A, characteristic C 16 230 X BD01-AK1M1/A162 BVP:203110 1 unit 1.720 With 3-pole miniature circuit breaker 16 A, characteristic C 16 400 X BD01-AK1M1/A163 BVP:203107 1 unit 1.850 With 3-pole and N pole miniature circuit breaker 16 A, characteristic C 16 400 X BD01-AK1M1/A163N BVP:203111 1 unit 1.970 With 1-pole miniature circuit breaker 20 A, characteristic C 20 230 X BD01-AK1M1/A201 BVP:203108 1 unit 1.600 With 2-pole miniature circuit breaker 20 A, characteristic C 20 230 X BD01-AK1M1/A202 BVP:203112 1 unit 1.720 With 3-pole miniature circuit breaker 20 A, characteristic C 20 400 X BD01-AK1M1/A203 BVP:203109 1 unit 1.850 With 3-pole and N pole miniature circuit breaker 20 A, characteristic C 20 400 X BD01-AK1M1/A203N BVP:203113 1 unit 1.970 16 230 X BD01-AK2X/ 4PC163A162 BVP:203116 1 unit 2.320 – 400 X BD01-GK1X/4PC163 BVP:203117 1 unit 1.200 Tap-off units, aluminum, size 2 NSV0_00255 With 2 × 2-pole miniature circuit breaker 16 A, characteristic C, with 4 socket outlets 16 A Ancillary equipment units, aluminum, size 1 NSV0_00261 Pv max. 13 W, with 4 socket outlets 16 A M50 cable grommets and screws for connecting the enclosure are included in scope of supply with ancillary equipment units. Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/21 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units and ancillary equipment units for Denmark ■ Selection and ordering data Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V 13 230 X BD01-AK1X/ 2DKS103S14 BVP:203099 1 unit 1.400 13 230 X BD01-AK1X/ 2DKS103A131 BVP:203100 1 unit 1.500 13 230 X BD01-AK2X/ 4DKS103S14 BVP:203102 1 unit 2.000 13 230 X BD01-AK2X/ 4DKS103A131 BVP:203103 1 unit 2.200 230 X BD01-AK2M1/ 2DKS103FIA131 BVP:203101 1 unit 2.000 – 400 X BD01-GK1X/4DKS103 BVP:203104 1 unit 1.200 – 400 X BD01-GK2X/ 2DKS103CEE165 BVP:203105 1 unit 1.600 kg Tap-off units, aluminum, size 1 NSV0_00250 With 1-pole fuse base D01 and with 2 socket outlets 10 A NSV0_00250 With 1-pole miniature circuit breaker 13 A, characteristic C, and with 2 socket outlets 10 A Tap-off units, aluminum, size 2 NSV0_00255 With 2 × 1-pole fuse base D01, with 4 socket outlets 10 A NSV0_00255 With 2 × 1-pole miniature circuit breaker 13 A, characteristic C, and with 4 socket outlets 10 A 4 Tap-off units, aluminum, size 2, with device installation unit NSV0_00257 With 1-pole miniature circuit breaker 13 A, characteristic C, 13 with 2-pole RCCB 16 A/30 mA and with 2 socket outlets 10 A Ancillary equipment units, aluminum, size 1 NSV0_00261 Pv max. 13 W, with 4 socket outlets 10 A Ancillary equipment units, aluminum, size 2 NSV0_00264 Pv max. 16 W, with 2 socket outlets 10 A and 1 CEE socket outlet, 16 A, 5-pole Adapter rings/screw adapters, fuse links and screw cap not included in scope of supply with tap-off units. M50 cable grommets and screws for connecting the enclosure are included in scope of supply with ancillary equipment units. 4/22 Siemens LV 70 · 2009 Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for France ■ Selection and ordering data Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V 32 400 X BD01-AK2X/F1451 BVP:203126 1 unit 1.700 230 X BD01-AK2M1/ 2PCUTE16AFI40 BVP:214821 1 unit 2.000 kg Tap-off units, aluminum, size 2 NSV0_00254 With 3-pole fuse base SP51, for 3 cylindrical fuses 14 mm × 51 mm Tap-off units, aluminum, size 2, with device installation unit NSV0_00257 With 2-pole miniature circuit breaker 16 A, characteristic B, 16 with 2-pole RCCB 40 A/30 mA and with 2 socket outlets 16 A Fuse links are not included in scope of supply. Use plastic cable glands with strain relief (not included in scope of supply). 4 * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/23 © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for the United Kingdom ■ Selection and ordering data Version Rated current Rated operational voltage DT Type Order No. PS* Weight per unit approx. A V 32 230 X BD01-AK1X/GB321 BVP:203119 1 unit 1.100 13 230 X BD01-AK1X/ 2BS133GB131 BVP:203121 1 unit 1.900 32 400 X BD01-AK1X/GB323 BVP:203120 1 unit 1.300 13 230 X BD01-AK1X/ 2BS133A131 BVP:203122 1 unit 1.720 32 400 X BD01-AK1M1/A321 BVP:203118 1 unit 1.600 • With 1 CEE socket outlet 16 A, 5-pole 16 400 X BD01-AK2X/ CEE165GB163 BVP:203124 1 unit 2.000 • With 1 CEE socket outlet 32 A, 5-pole 32 400 X BD01-AK2X/ CEE325GB323 BVP:203125 1 unit 2.100 230 X BD01-AK2M1/ BS133FIA131 BVP:203123 1 unit 2.500 kg Tap-off units, aluminum, size 1 With 1-pole fuse base NNS-32 NSV0_00249 • Without socket outlet NSV0_00267 • With 2 socket outlets BS1363 13 A NSV0_00249 With 3-pole fuse base 3 × NNS-32 NSV0_00267 With 1-pole miniature circuit breaker 13 A, characteristic B, and with 2 socket outlets BS1363, 13 A Tap-off units, aluminum, size 1, with device installation unit With 3 × 1-pole miniature circuit breaker 32 A, characteristic C NSV0_00252 Tap-off units, aluminum, size 2 NSV0_00256 With 3 × 1-pole fuse base NNS-32 Tap-off units, aluminum, size 2, with device installation unit With 1-pole miniature circuit breaker 13 A, characteristic B, 13 with 2-pole RCCB 16 A/30 mA and with 1 socket outlet BS1363, 13 A NSV0_00268 4 Fuse links are not included in scope of supply. Use plastic cable glands with strain relief (not included in scope of supply). 4/24 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for Switzerland ■ Selection and ordering data Version Rated current Rated operational voltage A V DT Type Order No. PS* Weight per unit approx. kg Tap-off units, aluminum, size 1, with device installation unit With miniature circuit breaker, characteristic C 13 400 X BD01-AK1M1/A133 BVP:611317 1 unit 1.600 • 3-pole, 16 A 16 400 X BD01-AK1M1/A163 BVP:611318 1 unit 1.600 • 3-pole, 25 A 25 400 X BD01-AK1M1/A253 BVP:611319 1 unit 1.600 NSV0_00252 • 3-pole, 13 A Tap-off units, aluminum, size 2, with device installation unit NSV0_00315 With miniature circuit breaker, characteristic C • 3-pole, 40 A 40 400 X BD01-AK2HM2/A403 BVP:611320 1 unit 2.000 • 3-pole, 63 A 63 400 X BD01-AK2HM2/A633 BVP:611321 1 unit 2.000 • 2 × 1-pole, 16 A 16 230 X BD01-AK2M1/ 2T23-2A161 BVP:611310 1 unit 1.900 • 1 × 1-pole, 16 A, and 2-pole RCCB, 16 A/30 mA 16 230 X BD01-AK2M1/ 2T23-FI162-A161 BVP:611311 1 unit 2.100 With 3-pole miniature circuit breaker, 16 A, characteristic C 16 and 1 socket outlet type 25, 16 A, 5-pole 400 X BD01-AK2M1/T25-A163 BVP:611314 1 unit 2.000 NSV0_00316 NSV0_00272 With miniature circuit breaker, characteristic C and 2 socket outlets type 23, 16 A, 3-pole Use plastic cable glands with strain relief (not included in scope of supply). * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/25 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Tap-off units for Switzerland Version Rated current Rated operational voltage A V DT Type Order No. PS* Weight per unit approx. kg Tap-off units, aluminum, size 1, with device installation unit with ancillary equipment unit, aluminum, size 1 230 X BD01-AK1M1/GK1X/ 3T23-3A161 BVP:611312 1 unit 2.700 230 X BD01-AK2M2/GK1X/ 3T23-FI254-3A161 BVP:611313 1 unit 3.500 400 X BD01-AK2M2/GK1X/ T25-FI254-A163 BVP:611315 1 unit 3.500 400 X BD01-AK2HM2/GK1X/ CEE635-A633 BVP:611316 1 unit 2.500 NSV0_00317 With 3 × 1-pole miniature circuit breaker 16 A, characteristic C, 16 and 3 socket outlets type 23, 16 A, 3-pole Tap-off units, aluminum, size 2, with device installation unit with ancillary equipment unit, aluminum size 1 NSV0_00318 With 3 × 1-pole miniature circuit breaker 16 A, characteristic C, 16 and 4-pole RCCB 25 A/30 mA with 3 socket outlets type 23, 16 A, 3-pole NSV0_00319 With 3-pole miniature circuit breaker 16 A, characteristic C, 16 and 4-pole RCCB 25 A/30 mA with 1 socket outlet type 25, 16 A, 5-pole With 3-pole miniature circuit breaker 63 A, characteristic C, 63 and 1 CEE socket outlet 63 A, 5-pole NSV0_00320 4 Use plastic cable glands with strain relief (not included in scope of supply). 4/26 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Accessories ■ Selection and ordering data Version DT Type Order No. PS* Weight per unit approx. kg Optional equipment for degree of protection IP55 A BD01-FAS BVP:610363 5 units 0.100 A BD01-FS BVP:610362 5 units 0.150 A BD01-FES BVP:610364 1 unit 0.150 A BD01-KS BVP:611057 1 unit 0.030 Size 01 A BD01-AK01X-IP55 BVP:610365 1 unit 0.050 Size 02 A BD01-AK02X-IP55 BVP:610366 1 unit 0.050 Size 1 A BD01-AK1X-IP55 BVP:610367 1 unit 0.050 Size 2 A BD01-AK2X-IP55 BVP:610368 1 unit 0.050 For tap-off points NSV0_00978 For connection points NSV0_ 00979 For feeder units • Mounting position at the bottom NSV0_ 00980 • Mounting position at the side or top NSV0_00981 For tap-off units • Size 01X, 02X NSV0_ 00982 NSV0_00983 • Size 1X, 2X * You can order this quantity or a multiple thereof. Siemens LV 70 · 2009 4/27 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Accessories Rated current Ie DT Type Version Order No. PS* A Weight per unit approx. kg Fixing -- A BD01-B BVP:034262 1 unit 0.167 -- A BD01-BA BVP:081945 1 unit 0.167 -- A BD01-BAP BVP:203522 1 unit 0.576 -- A BD01-EF BVP:611071 1 unit 0.300 100 D BD01-100-KB BVP:201966 1 unit 0.350 160 D BD01-160-KB BVP:201967 1 unit 0.350 -- A BD01-K BVP:034263 10 units 0.010 -- A BD01-S90 BVP:611354 1 unit 1.500 -- A BD01-S90-ZUL-D BVP:611373 1 unit 0.200 NSV0_00275 Universal fixing brackets NSV0_00276 Suspension brackets NSV0_00277 Hanger brackets • For suspension by cable or pendant chain • At the connection point Mounting parts NSV0_00985 End flanges NSV0_00984 Joint blocks Coding Coding sets • 4 coding positions NSV0_00278 Fire protection Fire protection kits for mounting by the customer with fire protection plates and fixing screws NSV0_01460 4 Fire protection approval kits (required only for Germany) 4/28 Siemens LV 70 · 2009 * You can order this quantity or a multiple thereof. © Siemens AG 2008 BD01 System — 40 ... 160 A Configuration information ■ Overview Specimen text for tenders Item Quantity Description ... m Busbar trunking system (see Appendix for diagram) • As type-tested low-voltage switchgear and controlgear combination (TTA) according to IEC/EN 60439-1 and -2 • Rated current, corresponds to thermal rated current at max. +40 °C and +35 °C on a 24 h average for indoor installation • Rated insulation voltage Ui = 400 V AC, 400 V DC; overvoltage category/degree of pollution III/3 • Operational voltage ... V, ... Hz • Rated peak withstand current of busbar trunking system, ... kA tested according to IEC/EN 60439-1 • Degree of protection IP54 with tap-off points at sides and bottom, otherwise IP50; increase to IP55 with optional equipment • 5-conductor system: L1, L2, L3, N, PE • Busbars: silver-plated Cu connection and pick-up contacts; Al or Cu conductors; supported by insulated busbar supports • Trunking units steel enclosed, galvanized and with paint finish; color: light gray, RAL 7035 • Halogen-free • Busbar connection via joint block with built-in expansion compensation • Tap-off points on one side, every 0.5 m or 1 m • Supplied ready for connection with all assembly parts • Made by Siemens • Type BD01-... Comprising: Unit price Amount 4 Siemens LV 70 · 2009 4/29 © Siemens AG 2008 BD01 System — 40 ... 160 A Configuration information ■ Design Fixing Wall or ceiling mounting with BD01-B 0,15 m 3m NSV0_00065 0,10 m 0,15 m NSV0_00066 4 4/30 Siemens LV 70 · 2009 © Siemens AG 2008 BD01 System — 40 ... 160 A Configuration information Pendent suspension using BD01-BAP (at connection point) NSV0_000 67 < =3m Mounting examples with BD01-B and BD01-BA NSV0_00068 4 1,5 m 3m NSV0_0006 9 Siemens LV 70 · 2009 4/31 © Siemens AG 2008 BD01 System — 40 ... 160 A Configuration information ■ Function Required details Short-circuit protection The following data must be considered when configuring the busbar lines: • Installation flat or upright, horizontal or vertical, quantity, type and approximate ratings of prospective loads, p.f. • Rated diversity factor D. • If data are not available, use only the rated diversity factor • Feeding transformers (short-circuit current) • Nature of the installation site (dimensions, construction of the building, transport paths, cellar) • Routing of supply lines from other power sources • Crane operation • Special requirements A system can be protected against short-circuit alone by fitting low-voltage LV HRC fuses (gL) into the incoming supply; the fuse size to be appropriate for the prospective short-circuit current at the place of installation. Operational current The operational current is calculated using the following formula: Pinst × D × b 冪3 × U × p.f. Due to their high response threshold (1.3 to 1.6 times rated current) and their long rupturing times at small overcurrents, fuses are not suitable for overload protection. Therefore we recommend the use of motor protectors or circuit breakers. The following can be used: System Overcurrent protective devices Icc = 15 kA1) Icc = 25 kA BD01-40 5SY4 340-6 3VL27 05 BD01-63 5SY4 363-6 3VL27 06 BD01-100 – 3VL27 10 BD01-125 – 3VL27 12 BD01-160 – 3VL27 16 × 103 with: 4 Busbar trunking systems must be protected against overload and short-circuits. Fuses and miniature circuit breakers must be selected so that the admissible current carrying capacity corresponding with the ambient conditions is not exceeded. IB = Operational current (A) Pinst = Installed power (kW) D = Rated diversity factor b = 1) Icf = rated conditional short-circuit current of the busbar trunking system and its outgoing feeders when protected by circuit breakers Supply factor b=1 = Single feeder unit b=½ = Double end feeder unit Ue = Rated operational voltage p.f. = Power factor (V) The prospective network short-circuit current and the let-through characteristic of the switches must be taken into account in each case. Temperature characteristic of BD01 systems If no data are available about the actual currents occurring simultaneously, the following values according to IEC/EN 60439-1 apply: Number of main circuits Rated diversity factor D 2 and 3 4 and 5 6 to 9 inclusive 10 and more 0.9 0.8 0.7 0.6 Rated current (%) NSV0_00071 IB = Overcurrent protection devices for overload and short-circuit protection 130 120 110 100 90 80 70 -5 +5 +15 +25 +35 +45 Ambient temperature °C (average over 24 hours) 4/32 Siemens LV 70 · 2009 +55 +65 © Siemens AG 2008 BD01 System — 40 ... 160 A Configuration information Voltage drop Fire protection Voltage drop at rated current General requirements (Load distribution factor a = 1) The German state building authorities demand that buildings are designed so that "spreading of fire and smoke is prevented, and that effective fire fighting and rescue of persons and domestic animals is facilitated". Fire or flue gas may not spread from one storey or fire area to another. 28 26 All BD01 busbar trunking systems can be equipped with fire protection and generally comply with the standards for buildings including high-rise buildings. 40 A The fire resistance class corresponds with S 90 according to DIN 4102 Part 9. The demands for verification of fire resistance duration at 90 min as specified by ISO 834 according to IEC/EN 60439-2 are fulfilled. 24 22 63 A 20 Configuration 125 A 160 A 18 100 A 16 14 NSV0_00070 12 10 0,4 0,5 0,6 0,7 0,8 0,9 To ensure fire protection according to S90, the following points must be observed when configuring and installing trunking units with fire protection: • The center of the fire protection in the trunking unit must be positioned in the center of the fire wall. • There are no tap-off points in the area covered by the fire protection. • The trunking units must be installed by an approved fire protection installation specialist. • Fire protection for installation in lightweight walls are available on request. NSV0_01462 U (V/100 m) 30 1 cos 1 Calculation of the voltage drop 4 For long busbar lines, it may be necessary to calculate the voltage drop. 'U = a × 冪3 × IB × l × (R × cos M + X × sin M) × 10–3 (V) with 'U IB l a R X cos M = = = = = = = Voltage drop Operational current Length Load distribution factor Ohmic resistance R20 Inductive resistance X20 Power factor (p. f.) (V) (A) (m) see Table (m:/m) (m:/m) 140 1 Packing Positioning in the fire wall Factor a used in the equation for calculating the voltage drop is dependent on the load distribution. Load distribution A B A B C D E B A C B D A E C Factor a Infeed at A, one outgoing feeder at B 1 Infeed at A, outgoing feeders at B, C, D, E 0.5 Infeed at A, outgoing feeders at B, C 0.25 Infeed at A, outgoing feeders at B, C, D, E 0.125 B Infeed at A, B, A C D E F outgoing feeders at C, D, E, F 650 Observe the following when installing the trunking units: • The space $ surrounding the busbar trunking unit within the component it passes through must be packed with mineral-based mortar or fire protection sealant. • The mortar or fire protection sealant must conform to the applicable regulations for establishing fire resistance rating or the construction of the wall or ceiling. • The installation must be carried out according to pertinent building regulations. The approval papers can be ordered separately. 0.25 Siemens LV 70 · 2009 4/33 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids ■ Dimensional drawings Trunking units BD01-... L 57,5 50 5,5 5,5 NSV0_00279 57 25 n × 125 4,5 77 90 125 250 a n× a L a Number of tap-off points 2000 500 1000 500 1000 4 2 6 3 3000 Junction units BD01(-160)-R1, BD01(-160)-R2 NSV0_00280 92 4 L1 57,5 50 L 316 NSV0_00281 L2 R 0 10 Type L L1 L2 BD01-...-R1 BD01-...-R2 500 1000 165 665 316 – 4/34 Siemens LV 70 · 2009 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Feeder units BD01-E 132 170 11 M32, M40, M50 9 45 27 34,5 53 104 90 Ø 5,3 NSV0_00282 150 158 260 BD01-160-E 260 20 1 4 130 M63 1 150 2 NSV0_00283 104 1 BD01-EF end flange 2 BD01-...-KB joint block Siemens LV 70 · 2009 4/35 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Tap-off units Tap-off units size 01 BD01-AK01X/ZS Tap-off units size 02 BD01-AK02X/ZS3 M25 66 77,5 77.5 100 116 100 116 200 NSV0_00284 NSV0_00285 100 Tap-off units size 02, with device installation unit BD01-AK02M0/A163 BD01-AK02M0/A323 BD01-AK02M0/F BD01-AK02M0/2SD163S14 BD01-AK02M0/2SD163A161 BD01-AK02M0/2SD163FIA161 70 200 14,5 200 100 116 100 116 NSV0_00286 NSV0_00287 4 26,7 BD01-AK02M0/CEE163S14 BD01-AK02M0/CEE163A161 26,5 BD01-AK02M0/CEE165A163 70 70 52 105 94 94 52 76 90 76 105 200 100 116 200 38,5 Dashed lines: free space for opening the flap Siemens LV 70 · 2009 100 116 NSV0_00289 NSV0_00288 38,5 4/36 M25 94 105 94 M25 118,2 14,5 76 76 70 102 77,5 66 M25 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids BD01-AK1X/2SD... BD01-AK1X/2BS... BD01-AK1X/2DKS... BD01-AK1X/2PC... 13 63 292 Tap-off units size 1 BD01-AK1X/S... BD01-AK1X/GB... BD01-AK1X/F 80 NSV0_00290 M25, 32, 40, 50 M25, 32, 40, 50 22,5 150 160 100 100 NSV0_00292 27 40 12 112 85 135 68 195 Tap-off units size 1, with device installation unit BD01-AK1M1/A... BD01-AK1M1/F BD01-AK1X/CEE163... 4 52 77 90 90 M25, 32, 40, 50 NSV0_00291 NSV0_00293 M25, 32, 40, 50 75,5 Dotted lines: usable component fitting space Dashed lines: free space for opening the flap Siemens LV 70 · 2009 4/37 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids 362 Tap-off units size 2 BD01-AK2X/F..., BD01-AK2HX/F... BD01-AK2X/S..., BD01-AK2HX/S... 27 NSV0_00294 112 85 205 12 40 80 M25, 32, 40, 50 22,5 150 160 100 200 265 Dotted lines: usable component fitting space Dashed lines: free space for opening the flap 4/38 Siemens LV 70 · 2009 62 52 105 72,5 NSV0_00299 72,5 68 NSV0_00301 130 BD01-AK2X/CEE325... 132 BD01-AK2X/CEE165... 13 63 BD01-AK2X/4SD... BD01-AK2X/4DKS.. BD01-AK2X/4PC... NSV0_00296 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Tap-off units size 2, with device installation unit BD01-AK2M2/F, BD01-AK2HM2/F BD01-AK2M1/BS... BD01-AK2HM2/A... BD01-AK2M1/2SD... BD01-AK2M1/2DKS... BD01-AK2M1/2PC... BD01-AK2M1/2T23... BD01-AK2M1/T25... NSV0_00297 NSV0_00298 52 13 77 77 NSV0_00295 68 BD01-AK2M1/CEE325... 77 90 90 105 160 BD01-AK2M1/CEE163..., BD01-AK2M1/CEE165... 72,5 BD01-AK2M2/CEE165... 4 52 NSV0_01476 105 132 77 62 NSV0_00300 72,5 77 160 90 72,5 440 Dotted lines: usable component fitting space Dashed lines: free space for opening the flap Siemens LV 70 · 2009 4/39 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids 77 13 63 Tap-off units size 1, with device installation unit with ancillary equipment unit size 1 BD01-AK1M1/GK1X/3T23... M25, 32, 40, 50 NSV0_00312 90 60,5 124,5 Tap-off units size 2, with device installation unit with ancillary equipment unit size 1 BD01-AK2M2/GK1X/T25... BD01-AK2M2/GK1X/3T23... BD01-AK2HM2/GK1X/CEE635... NSV0_00313 60,5 124,5 Dotted lines: usable component fitting space Dashed lines: free space for opening the flap 4/40 Siemens LV 70 · 2009 87,5 160 NSV0_00314 M25, 32, 40, 50 160 77 77 77 13 63 98 4 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Ancillary equipment units BD01-GK1X/4DKS103 BD01-GK1X/4PC163 BD01-GK1X/4SD163 BD01-GK1X/CEE163 BD01-GK1X/CEE165 52 105 M25, 32, 40, 50 NSV0_00304 150 160 100 135 175 60,5 124,5 NSV0_01477 NSV0_00302 13 63 Ancillary equipment units size 1 BD01-GK1X/F 87,5 Ancillary equipment units size 1, with device installation unit BD01-GK1M1/F BD01-GK1X/CEE325 77 62 132 90 87,5 NSV0_00303 NSV0_01478 4 Dotted lines: usable component fitting space Dashed lines: free space for opening the flap Siemens LV 70 · 2009 4/41 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Ancillary equipment units size 2 BD01-GK2X/F BD01-GK2X/CEE163CEE165 52 27 NSV0_00305 112 85 205 M25, 32, 40, 50 NSV0_00308 150 160 100 12 40 80 245 70 174 BD01-GK2X/2SD163CEE165 BD01-GK2X/2DKS103CEE165 Ancillary equipment units size 2, with device installation unit BD01-GK2M2/F BD01-GK2X/2SD163CEE325 77 52 63 105 62 63 132 142 112 13 13 NSV0_00306 150 160 84 179 84 179 Dotted lines: usable component fitting space Dashed lines: free space for opening the flap 4/42 NSV0_01479 NSV0_00307 12 4 Siemens LV 70 · 2009 245 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Protective covers according to IP55 For connection point BD01-FS 26 65 NSV0_00996 26 175 11,5 11,5 NSV0_00997 92 92 For tap-off point BD01-FAS 29 For feeder unit at bottom BD01-FES A 92 A-A 4 11,5 NSV0_00998 12 13 A 172 26 12 NSV0_00999 For feeder unit at side, top BD01-KS Siemens LV 70 · 2009 4/43 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids 11,5 11,5 92 For tap-off unit BD01-AK02X-IP55 92 For tap-off unit BD01-AK01X-IP55 26 26 12 12 13,5 NSV0_01001 NSV0_01000 13,5 11,5 11,5 4 26 26 12 NSV0_01002 13,5 4/44 Siemens LV 70 · 2009 13,5 NSV0_01003 12 92 For tap-off unit BD01-AK2X-IP55 92 For tap-off unit BD01-AK1X-IP55 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Fixing Universal fixing brackets BD01-B Suspension brackets BD01-BA Ø9 91 112 132 103 50 115 135 75 25 27,5 5,5 NSV0_00310a 4,5 15 10 NSV0_00309 10 10 27,5 27.5 49.5 49,5 52 59 Ø9 20 10 Ø6,6 15 30 Hanger brackets BD01-BAP 60 230 92 4 9 73 30 12 48 40 13 150 200 250 NSV0_00311 Siemens LV 70 · 2009 4/45 © Siemens AG 2008 BD01 System — 40 ... 160 A Project planning aids Fire protection Fire protection BD01-S90 Section A-A 134 90 A NSV0_01461 A 100 650 25 69 4 4/46 Siemens LV 70 · 2009 Siemens Industrial Automation & Drive Technologies Sir William Siemens House Princess Road Manchester M20 2UR Tel 0161 446 6400 Fax 0161 446 5789 www.siemens.co.uk/busbars The information provided in this catalog contains descriptions or characteristics of performance which in case of actual use do not always apply as described or which may change as a result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. Availability and technical specifications are subject to change without notice. All product designations may be trademarks or product names of Siemens AG or supplier companies whose use by third parties for their own purposes could violate the rights of the owners.