5 Limit switches - Electrocomponents

advertisement

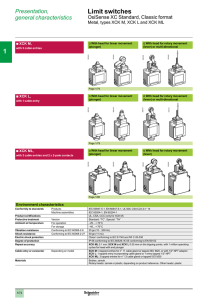

Presentation, general characteristics Limit switches 5 b XCK J 5 Osiswitch® Classic Metal, type XCK J Conforming to CENELEC EN 50041 v With head for linear movement (plunger) 561647 561646 fixed body with 1 cable entry Page 5/80 561650 561649 561648 v With head for rotary movement (lever) or multi-directional Page 5/80 b XCK J v With head for linear movement (plunger) 5 561652 561651 plug-in body with 1 cable entry Page 5/82 561655 561654 561653 v With head for rotary movement (lever) Page 5/82 Environment characteristics Conforming to standards Product certifications Protective treatment Ambient air temperature Vibration resistance Shock resistance Electric shock protection Degree of protection Repeat accuracy Cable entry or integral connector Materials 5/78 Products Machine assemblies Version Operation Storage Conforming to IEC 60068-2-6 Conforming to IEC 60068-2-27 Depending on model IEC 60947-5-1, EN 60947-5-1, UL 508, CSA C22-2 n° 14 IEC 60204-1, EN 60204-1 UL, CSA, CCC Standard “TC”, special "TH" - 25…+ 70 °C, special sub-assemblies available for extreme temperatures (-40 °C or +120 °C) - 40…+ 70 °C 25 gn (10…500 Hz) 50 gn (11 ms) Class I conforming to IEC 61140 and NF C 20-030 IP 66 conforming to IEC 60529; IK 07 conforming to EN 50 102 0.01 mm on the tripping points, with 1 million operating cycles for head with end plunger Tapped entry for n° 13 cable gland, or tapped ISO M20 x 1.5 or 1/2" NPT, or M12 connector Bodies and heads in zamak General characteristics Limit switches (continued) Osiswitch® Classic 5 5 Metal, type XCK J Conforming to CENELEC EN 50041 Contact block characteristics a AC-15; A300 (Ue = 240 V, Ie = 3 A); Ithe = 10 A c DC-13; Q300 (Ue = 250 V, Ie = 0.27 A), conforming to IEC 60947-5-1 appendix A, EN 60947-5-1 a AC-15; B300 (Ue = 240 V, Ie = 1.5 A); Ithe = 6 A c DC-13; R300 (Ue = 250 V, Ie = 0.1 A), conforming to IEC 60947-5-1 appendix A, EN 60947-5-1 Ui = 500 V degree of pollution 3 conforming to IEC 60947-1 Ui = 300 V conforming to UL 508, CSA C22-2 n° 14 Ui = 400 V degree of pollution 3 conforming to IEC 60947-1 Ui = 300 V conforming to UL 508, CSA C22-2 n° 14 XE2p P XE3p P XE2p P XE3p P Rated impulse withstand voltage XE2p P XE3p P U imp = 6 kV conforming to IEC 60947-1, IEC 60664 U imp = 4 kV conforming to IEC 60947-1, IEC 60664 Positive operation (depending on model) Resistance across terminals Short-circuit protection Cabling (screw clamp terminals) N/C contacts with positive opening operation conforming to IEC 60947-5-1 Appendix K, EN 60947-5-1 y 25 mΩ conforming to IEC 60255-7 category 3 10 A cartridge fuse type gG (gl) 6 A cartridge fuse type gG (gl) XE2p P XE3p P Clamping capacity, min: 1 x 0.34 mm2, max: 2 x 1.5 mm2 Clamping capacity, min: 1 x 0.5 mm2, max: 2 x 2.5 mm2 Clamping capacity, min: 1 x 0.75 mm2, max: 2 x 1.5 mm2 XE2S P21p1 XE2N P21p1 XCK J plug-in and XES P20p1 XE3N P and XE3S P Clamping capacity, min: 1 x 0.34 mm2, max: 1 x 1 mm2 or 2 x 0.75 mm2 Minimum actuation speed XE2S P21p1 and XE3S P: 0.01 m/minute XE2N P21p1 and XE3N P: 6 m/minute b Conforming to IEC 60947-5-1 Appendix C b Utilisation categories AC-15 and DC-13 b Maximum operating rate: 3600 operating cycles/hour b Load factor: 0.5 XE2N P21p1 XCK J plug-in, XES P20p1 Electrical durability Millions of operating cycles XE2S P21p1, XE2S P2141 a.c. supply a 50/60 Hz o inductive circuit 5 Ithe 1 110 V 0,5 24 V 230/400 V 48 V 0,1 0,5 1 2 3 4 5 5 4 3 Ithe 230 V 2 110 V 1 0,5 Ithe 12/24 V 2 1 230 V 48 V 0,5 0,1 0,5 10 1 2 3 4 5 10 Current in A 0,1 0,5 110 V 1 2 10 3 4 5 Current in A Ithe 5 1 0,5 110 V 230/400 V 24 V Millions of operating cycles Power broken in W for 5 million operating Power broken in W for 5 million operating Power broken in W for 5 million operating cycles. cycles. cycles. Voltage V 24 48 120 Voltage V 24 48 120 Voltage V 24 48 120 o W 10 7 4 o W 13 9 7 o W 10 7 4 For XE2S Pp151 on a or c, N/C and N/O contacts simultaneously loaded to the values shown with reverse polarity. XE3N Ppppp XE3S Ppppp Millions of operating cycles a.c. supply a 50/60 Hz o inductive circuit 5 4 3 5 0,2 Current in A d.c. supply c 12/24/48 V Millions of operating cycles Rated insulation voltage Millions of operating cycles Rated operational characteristics Ithe 5 4 3 2 230 V 1 12/24/48 V 110 V 0,5 0,2 48 V 0,1 0,5 d.c. supply c 1 2 10 3 4 5 Current in A Power broken in W for 5 million operating cycles. Voltage V 24 48 120 o W 3 2 1 0,1 0,5 1 2 3 4 5 10 Current in A Power broken in W for 5 million operating cycles. Voltage V 24 48 120 o W 4 3 2 5/79 Limit switches References, characteristics Type of head Type of operator 5 Osiswitch® Classic 5 Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, fixed body 1 ISO M20 x 1.5 cable entry Plunger (fixing by the body) Rotary (fixing by the body) (switches supplied for actuation from left AND right) Form A (1) Form B (1) Form C (1) Form D (1) Metal end plunger Steel roller plunger Thermoplastic roller lever (4) Steel roller lever (4) Variable length thermoplastic roller lever (4) Round thermoplastic rod lever, Ø 6 mm (4) (5) XCK J167H29 XCK J10511H29 XCK J10513H29 XCK J10541H29 XCK J10559H29 13 21 14 22 References (2) (3) 2-pole N/C + N/O XCK J161H29 snap action (XE2S P2151) 2 4,7(P) 21-22 13-14 21-22 13-14 0 21 22 21 22 13 11 12 14 0,9 6 mm 2-pole N/C + N/C ZCK J9H29 + snap action ZCK E61 (XE2S P2141) 2 21 22 0,9 11 23˚ 58˚(P) 23˚ 21-22 13-14 21-22 13-14 0 mm 4,7(P) 6 mm 2-pole N/C + N/C ZCK J7H29 + simultaneous, ZCK E61 slow break (XE2N P2141) 3,4(P) 90˚ 31 21 13 32 22 14 0 2 21 13 0 90˚ ZCK J7H29 + ZCK E05 + ZCK Y11 6 mm 0 mm 1,5 mm 0.430 0.455 contact closed contact open 90˚ ZCK J9H29 + ZCK E05 + ZCK Y13 23˚ 21-22 31-32 13-14 21-22 31-32 13-14 23˚ 21-22 13-14 0 33˚ 90˚ ZCK J9H29 + ZCK E05 + ZCK Y41 58˚(P) 0 0 90˚ ZCK J9H29 + ZCK E05 + ZCK Y59 23˚ 11-12 21-22 11-12 21-22 0 90˚ 0 90˚ 11˚ ZCK J7H29 + ZCK E05 + ZCK Y13 33˚ 23˚ 11-12 21-22 11-12 21-22 0 28˚ 90˚ ZCK JD39H29 + ZCK E05 + ZCK Y13 23˚ 90˚ 11˚ ZCK J7H29 + ZCK E05 + ZCK Y41 ZCK J7H29 + ZCK E05 + ZCK Y59 11-12 21-22 11-12 21-22 90˚ 0 28˚ 90˚ ZCK JD39H29 + ZCK E05 + ZCK Y41 58˚(P) 21-22 31-32 13-14 21-22 31-32 13-14 0 XCK J50559H29 62˚(P) 90˚ 23˚ 0 90˚ 0 11˚ 90˚ ZCK JD37H29 + ZCK E05 + ZCK Y41 23˚ 40˚(P) 23˚ 21-22 31-32 13-14 0.480 0.490 (A) = cam displacement (P) = positive opening point 28˚ 90˚ ZCK JD39H29 + ZCK E05 + ZCK Y59 0 90˚ 11˚ ZCK JD37H29 + ZCK E05 + ZCK Y13 0 0 21-22 31-32 13-14 21-22 31-32 13-14 21-22 31-32 13-14 21-22 31-32 13-14 11˚ 3-pole ZCK JD37H29 + ZCK JD37H29 + ZCK JD37H29 + N/C + N/C + N/O ZCK E61 ZCK E67 ZCK E05 + ZCK Y11 break before make, slow 3,2(A) 5,9(P) 2 3,4(P) 23˚ 40˚(P) 21-22 21-22 21-22 break 31-32 31-32 31-32 13-14 13-14 13-14 (XE3N P2141) 0 5,3 mm 0 3,2 6 0 33˚ 90˚ Weight (kg) Contact operation 33˚ 11-12 21-22 28˚ 90˚ 23˚ 21-22 13-14 0 0 11˚ XCK J50541H29 23˚ 40˚(P) 21-22 13-14 62˚(P) 0 90˚ 11˚ 11-12 21-22 mm 0 11˚ 11-12 21-22 11-12 21-22 5,9(P) 3,5(A) 90˚ XCK J50513H29 11˚ 21-22 31-32 13-14 21-22 31-32 13-14 0,9 14 mm 1,5 0 0 58˚(P) 3-pole ZCK JD39H29 + ZCK JD39H29 + ZCK JD39H29 + N/C + N/C + N/O ZCK E61 ZCK E67 ZCK E05 + ZCK Y11 snap action (XE3S P2141) 2 4,7(P) 3,2(A) 8,1(P) 23˚ 58˚(P) 0 22 0 11-12 21-22 6 mm 21-22 31-32 13-14 21-22 31-32 13-14 31 23˚ 11-12 21-22 11-12 21-22 23˚ 21-22 13-14 21-22 13-14 11˚ ZCK J9H29 + ZCK E05 + ZCK Y11 8,1(P) ZCK J7H29 + ZCK E67 11-12 21-22 32 3,2(A) 23˚ 21-22 13-14 21-22 13-14 11˚ ZCK J9H29 + ZCK E67 58˚(P) 21-22 13-14 21-22 13-14 0 1,5 11-12 21-22 11-12 21-22 0 12 8,1(P) 2-pole N/C + N/O XCK J561H29 XCK J567H29 XCK J50511H29 break before make, slow 3,2(A) 5,9(P) 23˚ 40˚(P) 2 3,4(P) 21-22 21-22 21-22 break 13-14 13-14 13-14 0 5,3 mm 0 33˚ 90˚ 0 3,2 6 (XE2N P2151) mm 11-12 21-22 11-12 21-22 5 3,2(A) 21-22 13-14 21-22 13-14 21-22 31-32 13-14 21-22 31-32 13-14 33˚ 90˚ 0 ZCK JD37H29 + ZCK E05 + ZCK Y59 33˚ 90˚ 0.485 0.485 N/C contact with positive opening operation Characteristics Switch actuation Type of actuation On end By 30° cam By any moving part Maximum actuation speed 0.5 m/s 1 m/s 1.5 m/s Mechanical durability (6) 30 25 30 (in millions of operating cycles) Minimum 20 N 16 N 0.25 N.m For tripping force or 50 N 40 N 0.50 N.m – For positive torque opening Cable entry (3) 1 entry tapped M20 x 1.5 mm for ISO cable gland, clamping capacity 9 to 12 mm (1) Form conforming to EN 50041, see page 5/185. (2) Switches with gold contacts or eyelet type connections: please consult your Regional Sales Office. (3) For an entry tapped for a Pg 13 cable gland, delete H29 from the end of the reference. Example: XCK J161H29 becomes XCK J161. For an entry tapped for 1/2" NPT (USAS B2-1) conduit, replace H29 at the end of the reference by H7. Example: XCK J161H29 becomes XCK J161H7. (4) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever or its mounting. (5) Value taken with actuation by moving part at 100 mm from the fixing. (6) Limited to 15 million operating cycles for switches with contacts XE3pP. 5/80 Dimensions 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, fixed body 1 ISO M20 x 1.5 cable entry XCK Jp61H29 ZCK Jp + ZCK E61 XCK Jp67H29 ZCK Jp + ZCK E67 XCK Jp051pH29 ZCK Jp + ZCK E05 + ZCK Y11 or Y13 57 17 5 41 5 41 50 60 60 120 (1) = 33,5 30 = (1) = 33,5 40 44 30 62 48 44 30 = 40 26,2 (4) (5) 5 60 60 (3) 132…177 40…85 62…107 (2) (1) (1) 33,5 = XCK Jp0559H29 ZCK Jp + ZCK E05 + ZCK Y59 52 60 33,5 = 40 44 XCK Jp0541H29 ZCK Jp + ZCK E05 + ZCK Y41 5,5 133 37 60 107 (1) 63 17 = 30 = 40 33,5 60 = 30 = 40 (1) 1 tapped entry for ISO M20 x 1.5 or Pg 13 cable gland or 1/2" NPT. (2) Ø 6 rod, length 200 mm. (3) 282 max. (4) 190 max. (5) 212 max. Ø: 2 elongated holes Ø 5.3 x 7.3. 5/81 Limit switches References, characteristics Type of head Type of operator 5 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, plug-in body ISO M20 x 1.5 cable entry Plunger (fixing by the body) Rotary (fixing by the body) (switches supplied for actuation from left AND right) Form A (1) Form B (1) Form C (1) Metal end plunger Steel roller plunger Thermoplastic roller lever (4) XCK J1161H29 XCK J1167H29 XCK J110511H29 XCK J110513H29 XCK J110541H29 XCK J110559H29 Steel roller lever (4) Variable length thermoplastic roller lever (4) Form D (1) Round thermoplastic rod lever, Ø 6 mm (4) (5) 13 11 14 12 References (2) (3) Single-pole C/O snap action 2 11-12 13-14 11-12 13-14 0 6mm 11-12 13-14 11-12 13-14 3,2(A) 0 0,9 Weight (kg) Contact operation 11-12 13-14 11-12 13-14 mm 0 11-12 13-14 11-12 13-14 0 11-12 13-14 11-12 13-14 0 11-12 13-14 11-12 13-14 0 1,5 0.430 contact closed 0.455 contact open Switch actuation Type of actuation On end By 30° cam Maximum actuation speed Mechanical durability (in millions of operating cycles) Minimum force or torque for tripping Cable entry (3) 0.5 m/s 30 1 m/s 25 0.480 0.490 0.485 (A) = cam displacement 0.485 Characteristics By any moving part 5 1.5 m/s 30 20 N 16 N 0.25 N.m 1 entry tapped M20 x 1.5 for ISO cable gland. Clamping capacity 7 to 13 mm (1) Form conforming to EN 50041, see page 5/185. (2) Switches with gold contacts: please consult your Regional Sales Office. (3) For an entry tapped for a n° 13 cable gland, delete H29 from the end of the reference. Example: XCK J1161H29 becomes XCK J1161. For an entry tapped for 1/2" NPT (USAS B2-1) conduit, replace H29 at the end of the reference by H7. Example: XCK J1161H29 becomes XCK J1161H7. (4) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever mounting or clamp. (5) Value taken with actuator operating at 100 mm from the fixing. 5/82 Dimensions 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, plug-in body ISO M20 x 1.5 cable entry XCK J1611H29 XCK J1167H29 XCK J110511H29, XCK J110513H29 57 17 5 41 5 50 36 = = 30 25 62 = XCK J110541H29 (1) = 30 = 42,5 42,5 42,5 XCK J110559H29 52 5,5 60 60 127 140 37 60 114 = 30 (1) 25 (1) 25 36 41 63 17 48 26,2 44 (4) 60 60 25 60 (5) 5 (3) 139…184 40…85 62…107 (2) (1) = 30 (1) 25 = 60 42,5 = 30 = 42,5 (1) Tapped entry for ISO M20 x 1.5 or Pg 13 cable gland or 1/2" NPT conduit. (2) Ø 6 rod, length 200 mm. (3) 289 max. (4) 190 max. (5) 212 max. 5/83 Limit switches References, characteristics Type of head 5 Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, fixed body Integral M12 connector Plunger (fixing by the body) Type of operator 5 Osiswitch® Classic Rotary (fixing by the body) (switches supplied for actuation from left AND right) Form A (1) Form B (1) Form C (1) Form D (1) Metal end plunger Steel roller plunger Thermoplastic roller lever (2) Steel roller lever (2) Variable length thermoplastic roller lever (2) Round thermoplastic rod lever, Ø 6 mm (2) (3) XCK J161D XCK J167D XCK J10511D XCK J10513D XCK J10541D XCK J10559D 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 13 21 14 22 References (4) 2-pole N/C + N/O snap action (XE2S P2151) 2 3,2(A) 8,1(P) 4,7(P) 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 0 6mm 0 Weight (kg) Contact operation mm 0 0 0 0 1,5 0,9 0.430 0.455 contact closed contact open 0.480 0.490 (A) = cam displacement (P) = positive opening point 0.485 0.485 Characteristics Switch actuation On end By 30° cam By any moving part Type of actuation 5 0.5 m/s 1 m/s 1.5 m/s Maximum actuation speed 30 25 30 Mechanical durability (in millions of operating cycles) Minimum force or For tripping 20 N 16 N 0.25 N.m torque For positive opening 50 N 40 N 0.50 N.m – M12 5-pin connector, Ui = 60 V, Ie = 4 A (see suitable pre-wired female connectors below). Connection (1) Form conforming to EN 50041, see page 5/185. (2) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever or its mounting. (3) Value taken with actuation by moving part at 100 mm from the fixing. (4) Switches with gold contacts: please consult your Regional Sales Office. References of suitable pre-wired female connectors Type of connector With cable, Ø 5.8 mm (4 x 0.34 mm2 + 1 x 0.5 mm2) Weight (kg) 5/84 L=2m M12 straight, 5-pin, 4 A/24 V max. XZ CP1164L2 M12 elbowed, 5-pin, 4 A/24 V max. XZ CP1264L2 L=5m XZ CP1164L5 XZ CP1264L5 L = 10 m XZ CP1164L10 XZ CP1264L10 L=2m L=5m L = 10 m 0.115 0.270 0.520 – Limit switches Dimensions, connections 5 Osiswitch® Classic 5 Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, fixed body Integral M12 connector Dimensions XCK J161D XCK J167D XCK J1051pD 57 17 5 5 41 50 = XCK J10541D 30 = 33,5 40 44 = 12 33,5 = 12 30 40 44 60 60 120 133 37 60 107 = 12 33,5 41 63 17 XCK J10559D 30 = 40 62 XZ CP1164Lp 52 48 44 26,2 (3) (4) 42 5 XZ CP1264Lp 26 60 60 = 30 = 33,5 40 59 12 12 32 40 33,5 L (2) 132…177 40…85 62…107 (1) 20 5,5 = 30 L = 40 59 (1) Ø 6 rod, length 200 mm. (2) 282 max. (3) 190 max. (4) 212 max. Ø: 2 elongated holes Ø 5.3 x 7.3. L: Cable length 2, 5 or 10 m. Connections Limit switch XCK JppppD Pre-wired female connector XZ CP1p64Lp 2 2 1 3 1 3 1 2 3 4 5 = brown = white = blue = black = t yellow/green 4 13 21 14 22 4 1-2 = N/C 3-4 = N/O 5 =t 4 A / 24 V max. 5/85 Limit switches References, characteristics Type of head 5 Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, fixed body Integral 7/8" 16UN connector Plunger (fixing by the body) Type of operator 5 Osiswitch® Classic Rotary (fixing by the body) (switches supplied for actuation from left AND right) Form A (1) Form B (1) Form C (1) Form D (1) Metal end plunger Steel roller plunger Thermoplastic roller lever (2) Steel roller lever (2) Variable length thermoplastic roller lever (2) Round thermoplastic rod lever, Ø 6 mm (2) (3) XCK J161A XCK J167A XCK J10511A XCK J10513A XCK J10541A XCK J10559A 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 13 21 14 22 References (4) 2-pole N/C + N/O snap action (XE2S P2151) 2 3,2(A) 8,1(P) 4,7(P) 21-22 13-14 21-22 13-14 21-22 13-14 21-22 13-14 0 6mm 0 0 0 0 1,5 0,9 Weight (kg) Contact operation mm 0 0.430 0.455 contact closed contact open 0.480 0.490 (A) = cam displacement (P) = positive opening point 0.485 0.485 N/C contact with positive opening operation Characteristics Switch actuation Type of actuation On end By 30° cam By any moving part 5 Maximum actuation speed 0.5 m/s 1 m/s 1.5 m/s 30 25 30 Mechanical durability (in millions of operating cycles) Minimum force For tripping 20 N 16 N 0.25 N.m or torque For positive opening 50 N 40 N 0.50 N.m – – 7/8" 16UN 5-pin connector, Ui = 250 V; Ie = 6 A (see suitable pre-wired female connectors below). Connection (1) Form conforming to EN 50041, see page 5/185. (2) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever mounting or clamp. (3) Value taken with actuator operating at 100 mm from the fixing. (4) Switches with gold contacts: please consult your Regional Sales Office. References of suitable pre-wired female connectors Type of connector With cable, Ø 6.7 mm (5 x 0.5 mm2 ) Weight (kg) 5/86 L=2m 7/8" 16UN straight, 5-pin, 6 A/250 V max. XZ CP1771L2 L=5m XZ CP1771L5 L = 10 m XZ CP1771L10 L=2m L=5m L = 10 m 0.190 0.475 0.950 Limit switches Dimensions, connections 5 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Complete switches, fixed body Integral 7/8" 16UN connector Dimensions XCK J161A XCK J167A XCK J1051pA 57 17 5 41 5 50 60 60 120 133 37 17 17 60 107 17 = 33,5 30 = 33,5 = XCK J10541A 30 = XZ CP1771Lp 48 44 30 40 62 XCK J10559A 52 = 33,5 = 40 44 40 44 26,2 (1) 55 5 (2) 60 60 17 17 = 33,5 L (3) (4) 40…85 62…107 132…177 5,5 41 63 17 30 = = 33,5 40 59 30 = 40 59 (1) Ø 6 rod, length 200 mm. (2) 282 max. (3) 190 max. (4) 212 max. Ø: 2 elongated holes Ø 5.3 x 7.3. L: cable length 2, 5 or 10 m. Connections Limit switch XCK JppppA Pre-wired female connector XZ CP1771Lp 3 3 21 22 = 21 = 22 =t = 14 = 13 4 1 1 13 5 1 2 3 4 5 2 2 14 4 1 2 3 4 5 5 = black = blue = yellow/green t = brown = white 5/87 Presentation 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Variable composition: standard bodies Thermoplastic roller lever plunger, 1 direction of actuation Steel roller lever plunger, 1 direction of actuation ZCK E21 ZCK E23 Side metal plunger Side steel roller plunger, horizontal (1) Side steel roller plunger, vertical (1) ZCK E63 ZCK E64 ZCK E65 Spring rod “Cat’s whisker” ZCK E08 ZCK E06 5 End reinforced steel roller plunger End steel roller plunger with protective boot End steel roller plunger ZCK E67 ZCK E629 ZCK E62 End metal plunger End steel ball bearing plunger End metal plunger with protective boot ZCK E61 ZCK E66 ZCK E619 Body with 2-pole contact, fixed, 1 step, M12 connector (2) Body with contact, cable entry for Pg 13, fixed, 1 step (2) (3) ZCK J1D, J5D, J6D, J7D ZCK J8D ZCK JD3p, ZCK J1, J5, J6, J7, J9 Body with contact, cable entry for Pg 13, fixed, 1 step (2) (3) ZCK J2, J8 Body with contact, cable entry for Pg 13, fixed, 2 step (2) (3) ZCK J4 (1) Cannot be used with bodies ZCK J4 and ZCK J41. (2) For further details, see page 5/90. (3) For a cable entry tapped ISO M20 x 1.5, add H29 to the reference. Example: ZCK J1 becomes ZCK J1H29. For a cable entry tapped 1/2" NPT, add H7 to the reference. Example: ZCK J1 becomes ZCK J1H7. 5/88 Body with contact, cable entry for Pg 13, plug-in, 1 or 2 step (2) (3) ZCK J11, J21, J41 Presentation (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Variable composition: standard bodies Square rod lever, steel, U 3 mm L = 125 mm (5) Round rod lever, steel, Ø 3 mm L = 125 mm (5) Round rod lever, glass fibre, Ø 3 mm L = 125 mm (5) Round rod lever, thermoplastic, Ø 6 mm L = 200 mm (5) ZCK Y51 ZCK Y53 ZCK Y52 ZCK Y59 Spring lever with thermoplastic end (4) Spring-rod lever, metal (4) ZCK Y81 ZCK Y91 Variable length thermoplastic roller lever (4) Variable length steel roller lever (4) ZCK Y41 ZCK Y43 Spring return, for actuation from left AND right or from left OR right ZCK E05 5 Thermoplastic roller lever (5) Steel roller lever (5) Steel ball bearing mounted roller lever (5) ZCK Y11 ZCK Y13 ZCK Y14 Body with double-pole 2 C/O staggered, snap action contact cable entry for Pg 13, fixed, 2 step (3) Body with double-pole 2 C/O staggered, snap action contact cable entry for Pg 13, plug-in, 2 step (3) ZCK J404 ZCK J4104 Stay put, for actuation from left AND right Forked arm with thermoplastic rollers, 1 track (5) Forked arm with thermoplastic rollers, 2 track (5) ZCK E09 ZCK Y71 ZCK Y61 : head assuring positive opening operation. (4) Adjustable throughout 360° in 5° steps, or in 90° steps by reversing the notched washer. (5) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever mounting. 5/89 References 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies: standard bodies Fixed bodies with 2-pole contact 23 21 22 21 21 13 14 22 24 13 22 11 12 14 13 14 13 14 21 23 24 21 22 11 12 22 13 21 2 C/O staggered, snap action (XES P2031) 23 2 step 22 5 – – 24 N/C + N/C snap action (XE2S P2141) 14 N/O + N/O simultaneous, slow break (XE2N P2131) 21 N/C + N/C simultaneous, slow break (XE2N P2141) 11 N/C + N/O make before make, slow break (XE2N P2161) 22 N/C + N/O break before make, slow break (XE2N P2151) ZCK J p 12 2 C/O simultaneous, snap action (XES P2021) 11 N/C + N/O snap action (XE2S P2151) Positive Cable entry operation (1) Pg 13 ISO M20 x 1.5 1/2" NPT 13 1 step Scheme 12 With contact block 14 Type – Reference Weight ZCK J1 ZCK J1H29 ZCK J1H7 kg 0.310 0.310 0.310 Pg 13 ZCK J2 ISO M20 x 1.5 ZCK J2H29 1/2" NPT ZCK J2H7 0.310 0.310 0.310 Pg 13 ZCK J5 ISO M20 x 1.5 ZCK J5H29 1/2" NPT ZCK J5H7 0.310 0.310 0.310 Pg 13 ZCK J6 ISO M20 x 1.5 ZCK J6H29 1/2" NPT ZCK J6H7 0.310 0.310 0.310 Pg 13 ZCK J7 ISO M20 x 1.5 ZCK J7H29 1/2" NPT ZCK J7H7 0.310 0.310 0.310 Pg 13 ZCK J8 ISO M20 x 1.5 ZCK J8H29 1/2" NPT ZCK J8H7 0.310 0.310 0.310 Pg 13 ZCK J9 ISO M20 x 1.5 ZCK J9H29 1/2" NPT ZCK J9H7 0.310 0.310 0.310 Pg 13 ZCK J4 ISO M20 x 1.5 ZCK J4H29 1/2" NPT ZCK J4H7 0.310 0.310 0.310 Fixed bodies with 3-pole contact (1) 5/90 : N/C contact with positive opening operation. 13 14 13 13 14 13 33 14 31 34 21 32 31 22 21 32 31 22 14 N/C + N/O + N/O break before make, slow break (XE3N P2151) 32 N/C + N/C + N/O break before make, slow break (XE3N P2141) 33 N/C + N/C + N/O snap action (XE3S P2141) 21 N/C + N/O + N/O snap action (XE3S P2151) Scheme 34 – With contact block 22 Type Positive Cable entry operation (1) Pg 13 ISO M20 x 1.5 1/2" NPT Reference Weight ZCK JD31 ZCK JD31H29 ZCK JD31H7 kg 0.310 0.310 0.310 Pg 13 ZCK JD39 ISO M20 x 1.5 ZCK JD39H29 1/2" NPT ZCK JD39H7 0.310 0.310 0.310 Pg 13 ZCK JD37 ISO M20 x 1.5 ZCK JD37H29 1/2" NPT ZCK JD37H7 0.310 0.310 0.310 Pg 13 ZCK JD35 ISO M20 x 1.5 ZCK JD35H29 1/2" NPT ZCK JD35H7 0.310 0.310 0.310 References (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies: standard bodies Plug-in bodies with contact 21 21 23 23 22 11 24 13 12 11 14 13 12 22 ZCK J p1 Double-pole 2 C/O staggered, snap action 24 2 step 14 Double-pole 2 C/O simultaneous, snap action 11 Single-pole C/O snap action Positive Cable entry operation (1) – Pg 13 ISO M20 x 1.5 1/2" NPT 13 1 step Scheme 12 With contact block 14 Type Reference Weight ZCK J11 ZCK J11H29 ZCK J11H7 kg 0.300 0.300 0.300 – Pg 13 ZCK J21 ISO M20 x 1.5 ZCK J21H29 1/2" NPT ZCK J21H7 0.300 0.300 0.300 – Pg 13 ZCK J41 ISO M20 x 1.5 ZCK J41H29 1/2" NPT ZCK J41H7 0.300 0.300 0.300 Bodies with contact, with rotary head (without operating lever) Type With contact block Scheme Positive Cable entry operation (1) Reference Weight kg 13 11 23 21 24 22 Double-pole 2 C/O staggered, snap action 12 2 step 1 from the left AND 1 from the right 14 Fixed body – Pg 13 ZCK J404 ISO M20 x 1.5 ZCK J404H29 1/2" NPT ZCK J404H7 0.455 0.455 0.455 – Pg 13 ZCK J4104 ISO M20 x 1.5 ZCK J4104H29 1/2" NPT ZCK J4104H7 0.465 0.465 0.465 13 11 23 21 24 22 Double-pole 2 C/O staggered, snap action 12 ZCK J404 14 Plug-in body 2 step 1 from the left AND 1 from the right 5 Plug-in housing only Description Single-pole 1 C/O with positive opening operation Double-pole 2 C/O simultaneous with positive opening operation Double-pole 1 C/O + 1 C/O staggered (1) For use with Contacts Reference ZCK J11 Silver ZCK J01 Weight kg 0.150 ZCK J21 Silver ZCK J02 0.160 ZCK J41 Silver ZCK J04 0.160 : N/C contact with positive opening operation. ZCK J0p 5/91 References 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies: bodies with indicator light module Fixed bodies with 2-pole contact Type With contact block Scheme Positive Cable entry operation (1) Reference Weight kg 21 21 13 22 Pg 13 ZCK J120 0.320 Pg 13 ZCK J520 0.320 21 21 13 22 22 N/C + N/O break before make, slow break (XE2N P2151) 13 N/C + N/O snap action (XE2S P2151) 14 With module comprising 2 LEDs, c 24 V 1 step 14 ZCK J ppp 22 N/C + N/O break before make, slow break (XE2N P2151) 13 N/C + N/O snap action (XE2S P2151) 14 1 step 14 With module comprising 1 LED, c 24 V Pg 13 ZCK J121 ISO M20 x 1.5 ZCK J121H29 0.320 0.320 Pg 13 ZCK J521 ISO M20 x 1.5 ZCK J521H29 0.320 0.320 Pg 13 ZCK J133 ISO M20 x 1.5 ZCK J133H29 0.320 0.320 Pg 13 ZCK J533 ISO M20 x 1.5 ZCK J533H29 0.320 0.320 Pg 13 ZCK J134 ISO M20 x 1.5 ZCK J134H29 0.320 0.320 Pg 13 ZCK J534 ISO M20 x 1.5 ZCK J534H29 0.320 0.320 5 21 21 22 13 22 13 N/C + N/O break before make, slow break (XE2N P2151) 14 N/C + N/O snap action (XE2S P2151) 14 With module comprising 2 neon indicator lights, a 110/120 V 1 step 21 21 22 13 22 13 N/C + N/O break before make, slow break (XE2N P2151) 14 N/C + N/O snap action (XE2S P2151) 14 With module comprising 2 neon indicator lights, a 220/240 V 1 step Plug-in bodies with single-pole contact Type With contact block Scheme Positive Cable entry operation (1) Reference Weight kg 13 11 C/O snap action 12 1 step 14 With module comprising 2 LEDs, c 24 V – Pg 13 ZCK J1121 ISO M20 x 1.5 ZCK J1121H29 0.340 0.340 Pg 13 ZCK J1133 ISO M20 x 1.5 ZCK J1133H29 0.340 0.340 Pg 13 ZCK J1134 ISO M20 x 1.5 ZCK J1134H29 0.340 0.340 13 11 12 – (1) 13 11 C/O snap action 12 With module comprising 2 neon indicator lights, a 220/240 V 1 step 14 ZCK J1ppp C/O snap action 14 With module comprising 2 neon indicator lights, a 110/120 V 1 step – : N/C contact with positive opening operation. Indicator light module characteristics Type of indicator Rated insulation voltage Current consumption Rated operational voltage Voltage limits Service life Reverse polarity protection 5/92 1 LED or 2 LEDs c 50 V, conforming to IEC 60947-1 7 mA per LED c 24 V c 20…30 V (including ripple) 100 000 hours Yes 2 neon lights a 250 V, conforming to IEC 60947-1 2.5 mA per neon 5 mA per neon a 110/120 V a 220/240 V a 95…130 V a 190…260 V 20 000 hours 20 000 hours – References 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies: bodies with M12 connector Fixed bodies with 2-pole contact 13 21 22 13 14 21 22 14 13 14 21 22 23 21 24 N/O + N/O simultaneous, slow break (XE2N P2131) 11 N/C + N/C simultaneous, slow break (XE2N P2141) 22 ZCK J pD N/O + N/C make before make, slow break (XE2N P2161) 12 N/C + N/O break before make, slow break (XE2N P2151) Scheme 13 1 step With contact block N/C + N/O snap action (XE2S P2151) 14 Type Positive operation (1) – Reference ZCK J1D Weight kg 0.320 ZCK J5D 0.320 ZCK J6D 0.320 ZCK J7D 0.320 ZCK J8D 0.320 (1) N/C contact with positive opening operation. 5 5/93 References 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies: contact blocks Contact blocks Type of contact Scheme For bodies Positive operation (1) Reference Weight kg N/C + N/C snap action 13 21 23 21 21 22 23 22 13 14 24 24 21 22 13 22 11 14 13 12 11 12 14 13 14 21 21 22 22 11 12 23 5 24 N/O + N/O simultaneous, slow break 13 N/C + N/C simultaneous, slow break 14 XE2N P21p1 N/O + N/C make before break, slow break 21 2 C/O staggered, snap action 11 2 C/O simultaneous, snap action 22 N/C + N/O break before make, slow break 12 XE2S P21 p1 14 2-pole contact N/C + N/O snap action ZCK J1 ZCK J1D XE2S P2151 0.020 ZCK J5 ZCK J5D XE2N P2151 0.020 ZCK J2 – XES P2021 0.045 ZCK J4 – XES P2031 0.045 ZCK J6 ZCK J6D XE2N P2161 0.020 ZCK J7 ZCK J7D XE2N P2141 0.020 XE2N P2131 0.020 ZCK J9 XE2S P2141 0.020 ZCK JD31 XE3S P2151 0.035 ZCK JD39 XE3S P2141 0.035 ZCK JD37 XE3N P2141 0.035 ZCK JD35 XE3N P2151 0.035 ZCK J8 ZCK J8D – (1) 5/94 13 14 13 13 14 13 33 14 31 21 34 31 32 21 22 31 32 22 14 N/C + N/O + N/O break before make, slow break 33 XE3p P21p1 21 N/C + N/C + N/O break before make, slow break 34 N/C + N/C + N/O snap action 22 N/C + N/O + N/O snap action 32 3-pole contact XES P20p1 : N/C contact with positive opening operation. References 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies: add-ons Covers + indicator light module For use with Fixed body Number and type of indicators 1 LED Voltage Reference c 24 V ZCK Z020 Weight kg 0.060 2 LEDs c 24 V ZCK Z021 0.060 2 neon lights a 110/120 V ZCK Z033 0.060 a 220/240 V ZCK Z034 0.060 2 LEDs c 24 V ZCK J0121 0.200 2 neon lights a 110/120 V ZCK J0133 0.200 a 220/240 V ZCK J0134 0.200 ZCK Z0pp Plug-in body ZCK J01pp Indicator light modules For use with Number and type of indicators 1 LED Voltage Reference c 24 V ZCK J902 Weight kg 0.030 2 LEDs c 24 V ZCK J906 0.030 2 neon lights a 110/120 V ZCK J903 0.030 a 220/240 V ZCK J904 0.030 Resistor value Reference Fixed body (ZCK J1 only) 15 kΩ, 1/4 W ZCK J82A Weight kg 0.030 Other versions Covers + indicator light module for other supply voltages. Please consult your Regional Sales Office. Fixed body ZCK J90p Module with resistor for machine diagnostics For use with ZCK J82A 5/95 5 Operation 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies Function diagrams (positive operation assured only if the associated sub-assemblies are ) Heads ZCK E61, E619, E66 with body ZCK J1p 21-22 13-14 21-22 13-14 ZCK J2p 4,7(P) 2 0 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 0 6mm ZCK J8p 11-12 21-22 6mm 2 ZCK J9 3,4(P) 21-22 13-14 3,2 0 6mm ZCK J7p 3,2 4,6(P) 13-14 23-24 6mm 2 6mm 2 6mm 2 11-12 21-22 11-12 21-22 2 2 21-22 31-32 13-14 0 ZCK JD31 3,4(P) 2 ZCK JD35 3,2 6mm 3,4(P) 2 4,7(P) 21-22 33-34 13-14 21-22 33-34 13-14 21-22 33-34 13-14 6 mm 0,9 6mm 0,9 ZCK JD37 4,7(P) 4,7(P) 0 0,9 ZCK JD39 0 ZCK J6p 3,4(P) 2 21-22 13-14 0,9 21-22 31-32 13-14 21-22 31-32 13-14 ZCK J5p 2 0 0 3,2 6mm 6mm 0,9 Head ZCK E63 with body ZCK J1p 1,5 21-22 13-14 21-22 13-14 ZCK J2p 4(P) 0 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 5,5mm 0 5,5mm ZCK J8 2,9(P) 21-22 13-14 0 1,5 2,7 5,5mm 0 ZCK J7 2,7 4,1(P) 21-22 13-14 5,5mm 0 1,5 ZCK J9 21-22 13-14 0 1,5 5,5mm 5,5mm 11-12 21-22 11-12 21-22 1,5 0 1,5 ZCK JD37 4(P) ZCK JD31 1,5 2,9(P) 21-22 31-32 13-14 0 2,7 5,5mm 1,5 5,5mm 21-22 33-34 13-14 21-22 33-34 13-14 ZCK JD35 4(P) 1,5 2,9(P) 21-22 33-34 13-14 0 0 5,5mm 0,9 4(P) 0,9 0,9 ZCK JD39 0 ZCK J6 1,5 2,9(P) 21-22 13-14 0,9 21-22 31-32 13-14 21-22 31-32 13-14 ZCK J5p 1,5 2,7 5,5mm 5,5mm 0,9 Heads ZCK E64, E65 with body ZCK J1p ZCK J2p 2,6(A) 6,4(P) 21-22 13-14 21-22 13-14 0 mm 0 ZCK JD39 0 mm 1,5 2,6(A) mm 0 ZCK J9 21-22 13-14 0 2,6(A) mm 2,6(A) mm 2,6(A) 6,4(P) 11-12 21-22 11-12 21-22 mm 0 ZCK JD35 2,6(A) 6,4(P) 2,6(A) 4,7(P) 21-22 33-34 13-14 4,6 mm 0 0 mm 1,5 Heads ZCK E67, E629 with body ZCK J1p ZCK J2p 3,2(A) 8,1(P) 21-22 13-14 21-22 13-14 0 mm 1,5 ZCK JD39 3,2 21-22 31-32 13-14 21-22 31-32 13-14 ZCK J5p 3,2(A) 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 mm 1,5 0 ZCK J8 3,2(A) ZCK J9 5,9(P) 13-14 23-24 3,2(A) mm mm 3,2(A) mm 11-12 21-22 11-12 21-22 3,2 (A) 8,1(P) 0 mm 5,3 mm ZCK JD35 3,2(A) 8,1(P) 21-22 33-34 13-14 21-22 33-34 13-14 mm 1,5 ZCK J7 8(P) 11-12 21-22 5,3 mm ZCK JD31 3,2 5,9(P) 0 5,3(A) 21-22 13-14 1,5 ZCK JD37 8,1(P) ZCK J6 3,2(A) 5,9(P) 21-22 13-14 0 21-22 31-32 13-14 0 3,2(A) 5,9(P) 21-22 33-34 13-14 0 0 5,3 mm mm 1,5 Heads ZCK E21, E23 with body ZCK J1p ZCK J2p 5(A) 11,5(P) 21-22 13-14 21-22 13-14 0 mm ZCK JD39 5(A) 21-22 31-32 13-14 21-22 31-32 13-14 8 0 0 mm 5(A) ZCK J8 ZCK J9 8,5(P) 21-22 13-14 5(A) mm 21-22 13-14 0 mm 5(A) ZCK JD31 mm 5(A) 11,5(P) 11-12 21-22 11-12 21-22 0 5(A) 8,5(P) 0 mm ZCK J7 8,(A) 11,5(P) 21-22 13-14 mm 2,2 mm 2,2 8 0 ZCK JD37 11,5(P) ZCK J6 5(A) 8,5(P) 21-22 13-14 0 21-22 31-32 13-14 0 ZCK J5p 5(A) 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 2,2 5(A) 21-22 33-34 13-14 21-22 33-34 13-14 2,2 2,2 ZCK JD35 11,5(P) 5(A) 8,5(P) 21-22 33-34 13-14 mm 8 0 0 mm Heads ZCK E06, E08 with body ZCK J1p ZCK J2p 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 0 ZCK JD39 21-22 31-32 13-14 0 0 ZCK JD31 21-22 33-34 13-14 21-22 33-34 13-14 ZCK J7 21-22 13-14 0 ZCK J8 ZCK J9 11-12 21-22 11-12 21-22 21-22 13-14 0 0 0 ZCK JD35 21-22 33-34 13-14 0 0 (A) = cam displacement (P) = positive opening point 21 22 3,5 11 23 12 24 13 21 22 2 11 23 12 22 5/96 G contact closed H contact open 2nd step 24 21 24 Contact operation 13 11 23 12 1st step 14 ZCK J4p Unactuated 13 ZCK J6 21-22 13-14 0 0 ZCK JD37 21-22 31-32 13-14 21-22 31-32 13-14 ZCK J5p 21-22 13-14 14 21-22 13-14 21-22 13-14 14 5 ZCK JD31 21-22 33-34 13-14 21-22 33-34 13-14 4,6 mm 0 ZCK J8 4,7(P) 21-22 13-14 1,5 2,6(A) 4,7(P) 21-22 31-32 13-14 0 4,6 mm ZCK J7 3,7 5,8(P) 21-22 13-14 mm 1,5 ZCK JD37 2,6(A) 6,4(P) ZCK J6 2,6(A) 4,7(P) 21-22 13-14 0 1,5 21-22 31-32 13-14 21-22 31-32 13-14 ZCK J5p 2,6(A) 11-12/21-22 13-14/23-24 11-12/21-22 13-24/23-24 mm Limit switches Operation, schemes 5 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies Function diagrams (positive operation assured only if the associated sub-assemblies are ) Head ZCK E05 with body ZCK J1p ZCK J2p 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 21-22 13-14 21-22 13-14 0 ZCK JD39 ZCK J5p 21-22 13-14 ZCK J7 21-22 13-14 11-12 21-22 0 0 ZCK JD37 21-22 31-32 13-14 21-22 31-32 13-14 ZCK J6 ZCK JD39 21-22 31-32 13-14 ZCK J9 11-12 21-22 11-12 21-22 13-14 23-24 0 ZCK JD31 21-22 33-34 13-14 21-22 33-34 13-14 21-22 33-34 13-14 0 ZCK J8 0 0 0 ZCK J4p 21 22 11 13 14 23 21 22 12 23 24 24 11 13 21 22 14 11 23 12 24 13 14 2nd step, actuated from left or right 12 1st step, actuated from left or right Unactuated Head ZCK E09 with body ZCK J1p ZCK J2p 0 ZCK JD31 0 21-22 13-14 21-22 13-14 0 0 ZCK JD39 21-22 31-32 13-14 21-22 31-32 13-14 21-22 33-34 13-14 21-22 33-34 13-14 11-12/21-22 13-14/23-24 11-12/21-22 13-14/23-24 0 0 ZCK J404, J4104 (body with head) G contact closed H contact open 21 22 13 14 11 21 22 23 23 24 12 11 24 13 12 21 22 Contact operation Actuated from right 14 11 23 12 Actuated from left 24 13 14 Unactuated 5 (P) = positive opening point Wiring schemes Indicator light modules 1 LED, c 24 V Module with resistor 2 LEDs, c 24 V 2 neon lights, a 110/120 or 220/240 V (2) 14 X2 X3 X2 X3 (1) 15 kΩ 1/4 W (1) (2) – – X1 X1 X1 (1) 13 13 14 13 14 13 14 + X3 21 22 + (1) Orange indicator (2) Green indicator ZCK JpD 2 1 3 13 21 22 1 - 2 = N/C 3 - 4 = N/O 5 = t 4 A / 24 V max. 14 4 5/97 Dimensions 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies Bodies 6,5 5 60 76,5 60 60 83,5 6,5 5 76,5 ZCK J1D, J5D, J6D, J7D, J8D 6,5 ZCK J11, J21, J41, J11pp ZCK J11H29, J21H29, J41H29, J11ppH29 ZCK J11H7, J21H7, J41H7, J11ppH7 5 ZCK J1, J2, J5, J4, Jp2p, Jp3p, J6, J7, J8, J9 ZCK J1H29, J2H29, J5H29, J4H29, Jp2pH29, Jp3pH29, J6H29, J7H29, J8H29, J9H29 ZCK J1H7, J2H7, J5H7, J4H7, Jp2pH7, Jp3pH7, J6H7, J7H7, J8H7, J9H7 33,5 30 = 44 = (1) 40 30 = 36 12 (1) = 33,5 42,5 44 = 30 = 40 Bodies with rotary head mounted 10 M6 60 109 60 102 22 10 M6 ZCK J4104, ZCK J4104H29, ZCK J4104H7 22 ZCK J404, ZCK J404H29, ZCK J404H7 (1) 5 33,5 = 44 30 = (1) 40 36 60 = 30 = 42,5 60 Plunger heads ZCK E619 17 ZCK E63 52,3 ZCK E65 20 17 63,6 10 63,6 ZCK E66 20 20 41 5 5 10 ZCK E64 49,5 37 17 10 ZCK E61 ZCK E629 17 17 17 7 (1) 1 tapped entry for ISO M20 x 1.5 or Pg 13 cable gland or tapped 1/2" NPT. Ø: 2 elongated holes Ø 5.3 x 7.3. 50 5 50 5 5/98 ZCK E21, E23 19 61 ZCK E62, ZCK E67 Dimensions (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies Rotary head ZCK E05 with operating lever ZCK Y11, Y13, Y14 ZCK Y41, Y43 62 57 59 57 52 J1 J K ZCK Y91 157 53 114 92 5 J1 20 20 20 26.2 49 49 49 48 K max. 137 137 137 212 K1 Ø 123 125 125 200 U3 Ø3 Ø3 Ø6 179 53 ZCK Y51 ZCK Y52 ZCK Y53 ZCK Y59 J K1 62…107 41 5,5 63 ZCK Y81 40…85 44 41 5 5 ZCK Y51, Y52, Y53, Y59 Rotary head ZCK E09 with operating lever ZCK Y61 68 5 ZCK Y71 68 56 15 56 56 15 5 63 63 5 Multi-directional heads ZCK E06 ZCK E08 155 141 17 17 Note: operating lever spindle threaded M6. 5/99 References 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies for low temperature applications (- 40 °C) Body with contacts For plunger or rotary head Type Contact block Scheme Positive Cable entry operation (1) Reference Weight kg 21 22 21 23 24 13 22 11 12 21 13 21 23 24 22 14 22 13 14 13 14 21 22 11 12 23 21 22 Double-pole 2 C/O staggered snap action (XES P2031) 24 2 step 21 5 22 2-pole 1 N/C + 1 N/C snap action (XE2S P2141) 11 ZCK J11 Pg 13 ZCK J1 ISO M20 x 1.5 ZCK J1H29 1/2" NPT ZCK J1H7 0.310 0.310 0.310 Pg 13 ZCK J2 ISO M20 x 1.5 ZCK J2H29 1/2" NPT ZCK J2H7 0.310 0.310 0.310 Pg 13 ZCK J5 ISO M20 x 1.5 ZCK J5H29 1/2" NPT ZCK J5H7 0.310 0.310 0.310 Pg 13 ZCK J6 ISO M20 x 1.5 ZCK J6H29 1/2" NPT ZCK J6H7 0.310 0.310 0.310 Pg 13 ZCK J7 ISO M20 x 1.5 ZCK J7H29 1/2" NPT ZCK J7H7 0.310 0.310 0.310 Pg 13 ZCK J8 ISO M20 x 1.5 ZCK J8H29 1/2" NPT ZCK J8H7 0.310 0.310 0.310 Pg 13 ZCK J9 ISO M20 x 1.5 ZCK J9H29 1/2" NPT ZCK J9H7 0.310 0.310 0.310 – Pg 13 ZCK J4 ISO M20 x 1.5 ZCK J4H29 1/2" NPT ZCK J4H7 0.310 0.310 0.310 – Pg 13 ZCK J11 ISO M20 x 1.5 ZCK J11H29 1/2" NPT ZCK J11H7 0.300 0.300 0.300 – Pg 13 ZCK J21 ISO M20 x 1.5 ZCK J21H29 1/2" NPT ZCK J21H7 0.300 0.300 0.300 – Pg 13 ZCK J41 ISO M20 x 1.5 ZCK J41H29 1/2" NPT ZCK J41H7 0.300 0.300 0.300 – – 12 2-pole 1 N/O + 1 N/O simultaneous slow break (XE2N P2131) 13 2-pole 1 N/C + 1 N/C simultaneous slow break (XE2N P2141) 14 2-pole 1 N/O + 1 N/C make before break slow break (XE2N P2161) 11 2-pole 1 N/C + 1 N/O break before make slow break (XE2N P2151) 12 ZCK J1 13 Double-pole 2 C/O simultaneous snap action (XES P2021) 14 2-pole 1 N/C + 1 N/O snap action (XE2S P2151) 14 Fixed body 1 step 21 22 21 22 23 23 24 24 11 12 11 12 13 13 14 11 Double-pole 2 C/O staggered snap action 12 2 step 13 Double-pole 2 C/O simultaneous snap action 14 Single-pole 1 C/O snap action 14 Plug-in body 1 step Body with contacts With spring return rotary head (without operating lever) Type Contact block Scheme Positive Cable entry operation (1) Reference Weight kg 13 11 23 21 12 24 22 Double-pole 2 C/O staggered snap action 14 Fixed body 2 step 1 from the left and 1 from the right – Pg 13 ZCK J4046 ISO M20 x 1.5 ZCK J4046H29 1/2" NPT ZCK J4046H7 0.455 0.455 0.455 – Pg 13 ZCK J41046 ISO M20 x 1.5 ZCK J41046H29 1/2" NPT ZCK J41046H7 0.465 0.465 0.465 13 11 23 21 12 24 22 Double-pole 2 C/O staggered snap action 14 Plug-in body 2 step 1 from the left and 1 from the right ZCK J4046 (1) Setting-up: pages 5/96 and 5/97 5/100 : operating head able to guarantee positive opening operation. Dimensions: pages 5/98 and 5/99 References (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies for low temperature applications (- 40 °C) Plunger heads Type of operator Compatible Max. Positive Reference bodies actuation operation speed (1) Weight kg For actuation on end ZCK E616 ZCK E636 End plunger metal ZCK Jp, ZCK Jpp 0.5 m/s ZCK E616 0.140 Side plunger metal ZCK Jp, 0.5 m/s ZCK Jpp, except ZCK J4 and J41 ZCK E636 0.200 ZCK Jp, ZCK Jpp 1 m/s ZCK E626 0.155 End reinforced roller plunger ZCK Jp, steel ZCK Jpp 1 m/s ZCK E676 0.155 ZCK Jp, 0.6 m/s ZCK Jpp, except ZCK J4 and J41 ZCK Jp, 0.6 m/s ZCK Jpp, except ZCK J4 and J41 ZCK Jp, 1.5 m/s ZCK Jpp ZCK E646 0.205 ZCK E656 0.205 ZCK E216 0.185 ZCK Jp, ZCK Jpp ZCK E236 0.195 For actuation by 30° cam ZCK E626 ZCK E646 ZCK E676 ZCK E656 End roller plunger steel Side roller plunger steel Horizontal Vertical ZCK E216 ZCK E236 Roller lever Thermoplastic plunger (1 direction of actuation) Steel 1.5 m/s Rotary heads (without operating lever) Type ZCK E056 ZCK E096 Compatible Max. Positive Reference bodies actuation operation speed (1) Spring return, ZCK Jp, 1.5 m/s by ZCK E056 actuation from left AND right or ZCK Jpp 30° cam from left OR right (see page 5/184) Stay put, ZCK J1, J11 1.5 m/s – ZCK E096 actuation from left AND right ZCK J2, J21 (see page 5/184) Weight kg 0.165 0.190 Multi-directional heads Type of operator ZCK E066 ZCK E086 Compatible Max. Positive Reference bodies actuation operation speed (1) kg For actuation by any moving part “Cat's whisker” ZCK Jp, 1 m/s – ZCK E066 ZCK Jpp, in any except direction ZCK J4 and ZCK J41 Spring rod lever ZCK Jp, 0.5 m/s – ZCK E086 ZCK Jpp, in any except direction ZCK J4 and ZCK J41 (1) : operating head able to guarantee positive opening operation. Setting-up: pages 5/96 and 5/97 Weight 0.115 0.125 Dimensions: pages 5/98 and 5/99 5/101 5 References (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies for low temperature applications (- 40 °C) Operating levers for rotary heads Description Positive operation (1) Reference Weight kg For actuation by 30° cam Roller lever (2) ZCK Y1p Variable length roller lever (3) Thermoplastic ZCK Y11 0.025 Steel ZCK Y13 0.035 Steel, ball bearing mounted ZCK Y14 0.030 Thermoplastic – ZCK Y41 0.030 Steel – ZCK Y43 0.040 For actuation by any moving part ZCK Y4p ZCKY51 ZCKY5p ZCK Y59 Square rod (2) U 3 mm steel, L = 125 mm – ZCK Y51 0.025 Round rod (2) Ø 3 mm steel, L = 125 mm – ZCK Y53 0.025 Ø 3 mm glass fibre, L = 125 mm – ZCK Y52 0.020 Ø 6 mm thermoplastic, L = 200 mm – ZCK Y59 0.030 Spring lever (3) – ZCK Y81 0.020 Spring metal rod lever (3) – ZCK Y91 0.025 For actuation by specific cam (for operation with ZCK-E096 head) Forked arm and rollers (2) thermoplastic 5 1 track – ZCK Y71 0.035 2 track – ZCK Y61 0.035 Positive operation (1) Reference 2- or double-pole contact blocks 1 N/C + 1 N/C snap action (1) 21 22 21 21 22 22 21 23 23 13 21 22 14 24 24 22 13 14 13 11 14 13 11 12 13 12 14 For body type 14 23 1 N/O + 1 N/O simultaneous slow break 24 XES P20p1 21 XE2N P21p1 22 XE2S P21p1 1 N/C + 1 N/C simultaneous slow break 21 1 N/O + 1 N/C make before break slow break 22 2 C/O staggered snap action ZCK Y61 11 ZCK Y71 12 2 C/O simultaneous snap action 13 1 N/C + 1 N/O break before make slow break ZCK Y91 14 ZCK Y81 11 1 N/C + 1 N/O snap action Scheme 12 Type Weight kg ZCK J1 XE2S P2151 0.020 ZCK J5 XE2N P2151 0.020 ZCK J2 – XES P2021 0.045 ZCK J4 – XES P2031 0.045 ZCK J6 XE2N P2161 0.020 ZCK J7 XE2N P2141 0.020 XE2N P2131 0.020 XE2S P2141 0.020 ZCK J8 ZCK J9 – : operating lever able to guarantee positive opening operation or N/C contact with positive opening operation. (2) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever mounting or clamp. (3) Adjustable throughout 360° in 5° steps. Setting-up: pages 5/96 and 5/97 5/102 Dimensions: pages 5/98 and 5/99 References (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies for high temperature applications (+ 120 °C) Body with contacts For plunger or rotary head Type Contact block Scheme Positive Cable entry operation (1) Reference Weight kg 21 22 21 23 24 13 22 11 12 21 13 21 23 21 22 21 24 22 14 22 13 14 13 14 21 22 11 12 23 Double-pole 2 C/O break before make snap action (XES P20315) 24 2 step 22 2-pole 1 N/C + 1 N/C snap action (XE2S P2141) 11 ZCK Jp15 Pg 13 ZCK J1 ISO M20 x 1.5 ZCK J1H29 1/2" NPT ZCK J1H7 0.310 0.310 0.310 Pg 13 ZCK J25 ISO M20 x 1.5 ZCK J25H29 1/2" NPT ZCK J25H7 0.310 0.310 0.310 Pg 13 ZCK J5 ISO M20 x 1.5 ZCK J5H29 1/2" NPT ZCK J5H7 0.310 0.310 0.310 Pg 13 ZCK J6 ISO M20 x 1.5 ZCK J6H29 1/2" NPT ZCK J6H7 0.310 0.310 0.310 Pg 13 ZCK J7 ISO M20 x 1.5 ZCK J7H29 1/2" NPT ZCK J7H7 0.310 0.310 0.310 Pg 13 ZCK J8 ISO M20 x 1.5 ZCK J8H29 1/2" NPT ZCK J8H7 0.310 0.310 0.310 Pg 13 ZCK J9 ISO M20 x 1.5 ZCK J9H29 1/2" NPT ZCK J9H7 0.310 0.310 0.310 – Pg 13 ZCK J45 ISO M20 x 1.5 ZCK J45H29 1/2" NPT ZCK J45H7 0.310 0.310 0.310 – Pg 13 ZCK J115 ISO M20 x 1.5 ZCK J115H29 1/2" NPT ZCK J115H7 0.300 0.300 0.300 – Pg 13 ZCK J215 ISO M20 x 1.5 ZCK J215H29 1/2" NPT ZCK J215H7 0.300 0.300 0.300 – Pg 13 ZCK J415 ISO M20 x 1.5 ZCK J415H29 1/2" NPT ZCK J415H7 0.300 0.300 0.300 – – 12 2-pole 1 N/O + 1 N/O simultaneous slow break (XE2N P2131) 13 2-pole 1 N/C + 1 N/C simultaneous slow break (XE2N P2141) 14 2-pole 1 N/O + 1 N/C make before break slow break (XE2N P2161) 11 2-pole 1 N/C + 1 N/O break before make slow break (XE2N P2151) 12 ZCK Jp 13 Double-pole 2 C/O simultaneous snap action (XES P20215) 14 2-pole 1 N/C + 1 N/O snap action (XE2S P2151) 14 Fixed body 1 step 21 22 21 22 23 23 24 24 11 12 11 12 13 13 14 11 Double-pole 2 C/O break before make snap action 12 2 step 13 Double-pole 2 C/O simultaneous snap action 14 Single-pole 1 C/O snap action 14 Plug-in body 1 step Body with contacts With spring return rotary head (without operating lever) Type Contact block Scheme Positive Cable entry operation (1) Reference Weight kg 13 11 23 21 12 24 22 Double-pole 2 C/O break before make snap action 14 Fixed body 2 step 1 from the left AND 1 from the right – Pg 13 ZCK J4045 ISO M20 x 1.5 ZCK J4045H29 1/2" NPT ZCK J4045H7 0.455 0.455 0.455 – Pg 13 ZCK J41045 ISO M20 x 1.5 ZCK J41045H29 1/2" NPT ZCK J41045H7 0.465 0.465 0.465 13 11 23 21 12 24 22 Double-pole 2 C/O break before make snap action 14 Plug-in body 2 step 1 from the left AND 1 from the right ZCK J4045 (1) Setting-up: pages 5/96 and 5/97 : operating head able to guarantee positive opening operation. Dimensions: pages 5/98 and 5/99 5/103 5 References (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies for high temperature applications (+ 120 °C) Plunger heads Type of operator Compatible bodies Max. actuation speed Positive Reference operation (1) Weight kg For actuation on end ZCK E615 End plunger Metal Side plunger Metal ZCK E635 ZCK J1, J2, J4, 0.5 m/s ZCK J115, J215, J415, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, 0.5 m/s ZCK J115, J215, ZCK J5, J6, J7, J8, J9 ZCK E615 0.140 ZCK E635 0.200 ZCK J1, J2, J4, ZCK J115, J215, J415, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, J4, ZCK J115, J215, J415, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, J4, ZCK J115, J215, J415, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, ZCK J115, J215, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, ZCK J115, J215, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, J4, ZCK J115, J215, J415, ZCK J5, J6, J7, J8, J9 ZCK J1, J2, J4, ZCK J115, J215, J415, ZCK J5, J6, J7, J8, J9 0.1 m/s ZCK E665 0.150 1 m/s ZCK E625 0.155 1 m/s ZCK E675 0.155 0.6 m/s ZCK E645 0.205 0.6 m/s ZCK E655 0.205 1.5 m/s ZCK E235 0.195 1.5 m/s ZCK E215 0.185 Compatible bodies Max. actuation speed 1.5 m/s by 30° cam Positive Reference operation (1) ZCK E055 For actuation by 30° cam ZCK E665 End ball bearing plunger Steel End roller plunger Steel ZCK E625 End reinforced roller plunger Steel Side roller plunger ZCK E675 Steel Horizontal Steel Vertical ZCK E645 Roller lever plunger (1 direction of actuation) Steel Thermoplastic 5 Rotary heads (without operating lever) Type ZCK E655 ZCK E055 ZCK E235 ZCK E095 Spring return, actuation from left AND right or from left OR right (see page 5/184) ZCK J1, J2, J4, ZCK J115, J215, ZCK J415, ZCK J5, J6, J7, J8, J9 Stay put, actuation from left AND right (see page 5/184 ) ZCK J1, J2, ZCK J115, J215 0.5 m/s – Compatible bodies Max. actuation speed Positive Reference operation (1) ZCK E095 Weight kg 0.165 0.190 Multi-directional heads Type of operator Weight kg For actuation by any moving part ZCK E065 “Cat's whisker” ZCK J1, J2, 1 m/s in any ZCK J115, J215, direction ZCK J5, J6, J7, J8, J9 – ZCK E065 0.115 Spring rod lever ZCK J1, J2, 0.5 m/s in any – ZCK J115, J215, direction ZCK J5, J6, J7, J8, J9 ZCK E085 0.125 ZCK E085 (1) Setting-up: pages 5/96 and 5/97 5/104 : operating head able to guarantee positive opening operation. Dimensions: pages 5/98 and 5/99 References (continued) 5 Limit switches 5 Osiswitch® Classic Metal, conforming to CENELEC EN 50041, type XCK J Fixed or plug-in body Adaptable sub-assemblies for high temperature applications (+ 120 °C) Operating levers for rotary heads Description Positive Reference operation (1) Weight kg For actuation by 30° cam Roller lever (2) ZCK Y1p Variable length roller lever (3) Thermoplastic ZCK Y115 0.025 Steel ZCK Y13 0.035 Steel, ball bearing mounted ZCK Y14 0.030 Thermoplastic – ZCK Y415 0.030 Steel – ZCK Y43 0.040 For actuation by any moving part Square rod (2) U 3 mm Steel, L = 125 mm – ZCK Y51 0.025 Round rod (2) Ø 3 mm steel, L = 125 mm – ZCK Y53 0.025 Ø 3 mm glass fibre, L = 125 mm – ZCK Y52 0.020 ZCK Y43 For actuation by specific cam (for operation with ZCK-E095 head only) Forked arm and rollers (2) thermoplastiic 1 track – ZCK Y715 0.035 2 track – ZCK Y615 0.035 2- or double-pole contact blocks 1 N/O + 1 N/O simultaneous slow break 1 N/C + 1 N/C snap action 13 21 22 21 22 21 22 23 23 24 24 21 14 13 11 13 11 14 13 13 ZCK J5 12 21 Positive Reference operation (1) XE2S P2151 Weight kg 0.020 5 12 22 ZCK J1 14 14 For body type 14 22 1 N/C + 1 N/C simultaneous slow break 23 XES P20p15 24 XE2N P21p1 21 XE2S P21p1 22 1 N/O + 1 N/C make before break slow break 21 2 C/O staggered snap action 22 ZCK Y615 11 ZCK Y715 2 C/O simultaneous snap action 12 1 N/C + 1 N/O break before make slow break 13 1 N/C + 1 N/O snap action Scheme 14 Type of operator 11 ZCK Y5p 12 ZCK Y51 XE2N P2151 0.020 ZCK J25 – XES P20215 0.045 ZCK J45 – XES P20315 0.045 ZCK J6 XE2N P2161 0.020 ZCK J7 XE2N P2141 0.020 XE2N P2131 0.020 XE2S P2141 0.020 ZCK J8 ZCK J9 – (1) : operating lever able to guarantee positive opening operation or N/C contact with positive opening operation. (2) Adjustable throughout 360° in 5° steps, or in 45° steps by reversing the lever mounting or clamp. (3) Adjustable throughout 360° in 5° steps. Setting-up: pages 5/96 and 5/97 Dimensions: pages 5/98 and 5/99 5/105