General-Purpose Failsafe Moulded Wirewound Resistors

advertisement

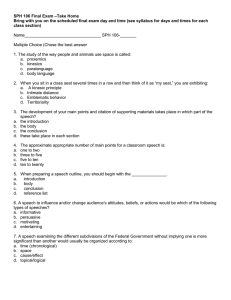

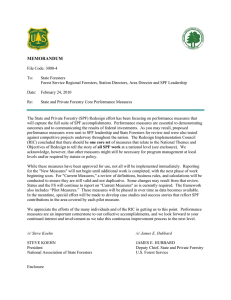

Resistors Purpose Failsafe General Molded Wirewound Resistor General-Purpose Failsafe Series Make Possible Moulded Wirewound Resistors General Purpose Failsafe SPH/SPF · SPF isSeries fusible · ±5%, tolerance Drop-in±10% replacement for BWH/BWF Molded Wirewound Resistor · 0.1 ohm to 2400 ohms SPH/SPF Series 3 1 2 watt rated with 1 watt dimensions Series · Weldable and solderable leads Series SPH/SPF ±5%, ±10% tolerance · ··· ·· · · · · · · 4 SPH/SPF 2 watt Series rated with 1 watt dimensions 0.1 ohm to 2400 ohms Drop-in replacement for BWH/BWF SPF TCR’sisasfusible low as ±150 ppm/°C standard Lead free, RoHS compliant construction available ±10% tolerance ±5%, (custom TCR’s asTC’s lowavailable) as ±150 ppm/°C standard 0.1 ohm to 2400 ohms (custom Weldable TC’s and solderable available)leads SPH/SPF Series Weldable and solderable leads 2 watt rated with 1 watt dimensions SPH/SPF Series Drop-in replacement for BWH/BWF SPH/SPF Series Lead free, RoHS compliant construction available · SPF is fusible TCR’s as low as ±150 ppm/°CSPH standard · ±5%, ±10% tolerance (custom TC’s available) Type SPH 1 3 (See notes below) 1 General Purpose Failsafe Molded Wirewound Resistor · · · · · · 3 2 4 2 (See notes below) All Pb-free parts comply with EU Directive 2011/65/EU (RoHS2) 4 1 3 2 (See notes below) 1. Resistive Element 3 1 1. Resistive Element 4 SPF 2 SPF 0.1 ohm to 2400 ohms (See notes below) SPH/SPF Series Weldable and solderable leads 44 Style EIA RS-344 Style MIL-R-11 Style Style Type Resistance - Std. e - Std. 4 Style 2 watt rated with 1 watt dimensions Drop-in replacement for BWH/BWF Lead free, RoHS compliant construction available SPF TCR’s as low asSPH ±150 ppm/°C standard SPH SPF (custom TC’s available) Ω Ω Tolerance EIA RS-344- Std. Style MIL-R-11 Style - Std. Type Power Rating Style Tolerance - Std. Min. Insulation MIL-R-11 Style Resistance Ω 1. Resistive Element 4 2 Ω Ω Ω SPH Ω Ω (See notes below) SPF Type Ω √ Ω Max. Working Voltage (RMS)Continuous Reduced Pressure ation Dry ting Tolerance - Std. Rating Min. Insulation Wet Power e Hotspot Temperature Rise Dry Ω √ 2. Termination 2. Termination 4. Encapsulation Marking 3. Ω Ω Ω Ω √ Working Voltage ctric ATM Typical Load Life Max. Continuous Min. Dielectric ATM Rating inuousPower Working Voltage √ Dry ding Volts Withstanding Volts Min. Insulation Wet Resistance Current Noise (RMS) Pressure Reduced Pressure ationReduced Dry Min. Dielectric ATM Max. Continuous Working Voltage √ Wet Withstanding e Volts Hotspot Temperature Rise (RMS) Reduced Pressure Min. Insulation emperature Rise Dry ctric Typical LoadATM Life √ Ω Ω Ω 3. Encapsulation Ω √ 3. Encapsulation 4. Marking 4. Marking √ √ Wet Rise Hotspot Temperature Resistance 3. Encapsulation Ω Wet Resistance 2.1. Termination Resistive Element Ω Dry MIL-R-11 Style Wet Tolerance - Std. 1. Resistive Element 3. Termination Encapsulation 2. SPF Ω - Std. Resistance - Std. Power Rating Min. Dielectric ATM inuous Working Voltage √ Resistance - Std. Withstanding Volts Ω 3 2 (See notes below) 2. Termination 2. Termination 1. Resistive Element SPH Resistance - Std. Continuous Voltage EIAMax. RS-344 Style Working EIA RS-344 Style e - Std. ting Ω 4 1 3. Encapsulation √ 4. Marking √ 4. Marking 4. Marking ding Volts oad LifeMin. Dielectric Current Noise Typical LoadATM Life Reduced Pressure Withstanding Volts oise (RMS) emperature Rise General Note General Note General Note Hotspot Temperature Rise TT Electronics reserves thechanges right to make changes in without product specification IRC reserves the right to make in product specification notice or liability. without notice or liability. oad Life oise Current Noise Reduced Pressure TT electronics reserves the right to make changes in product specification without notice or liability. All is subject to IRC’s and is considered accurate of going toaccurate print. Allinformation information is subject toown TT data Electronics’ own data and at is time considered at time of going to print. All information is subject to TT electronics’ own data and is considered accurate at time of going to print. Wire and Film Technologies Division • 4222 South Staples Street • Corpus Christi Texas 78411 USA Typical Load Telephone: 361 992 7900 plc •Life Facsimile: 361 992 3377 • Website: www.irctt.com © TT Electronics © TT electronics plc A subsidiary of www.ttelectronicsresistors.com TT electronics plc www.bitechnologies.com www.irctt.com www.welwyn-tt.com SPH/SPF Series Issue December 2008 Sheet 1 of 3 07.14 01.14 General Purpose Failsafe Molded Wirewound Resistor SPH/SPF SPH/SPFSeries Series General-Purpose General PurposeFailsafe Failsafe Moulded WirewoundResistor Resistors Molded Wirewound Make Possible Environmental Data Test SPH SPF 0.1Ω - 0.16Ω ± 1000 0.18Ω - 0.68Ω ± 800 0.75Ω - 2400Ω ± 400 0.10Ω ± 1700 0.11Ω - 0.16Ω ± 1000 0.18Ω - 0.68Ω ± 800 0.75Ω - 1000Ω ± 400 1000V 1000V Momentary Overload 5% 5% Low Temperature Operation 5% 5% Temperature Cycle 5% 5% Humidity 5% 5% Load Life 5% 5% Terminal Strength 5% 5% Resistance to Solder Heat 5% 5% No Failures No Failures Temperature Coefficient (ppm)* Dielectric Withstanding Voltage (RMS) Solderability Physical Data D A B C Dimensions (Inches and (mm)) Type SPH SPF A B C D 0.562 ± 0.010 (14.3 ± 0.25) 0.225 ± 0.008 0.032 ± 0.002 1.50 ± 0.126 (5.72 ± 0.20) (0.813 ± 0.05) (38.1 ± 3.2) 0.562 ± 0.010 (14.3 ± 0.25) 0.225 ± 0.008 0.032 ± 0.002 1.50 ± 0.126 (5.72 ± 0.20) (0.813 ± 0.05) (38.1 ± 3.2) Wire and Film Technologies Division • 4222 South Staples Street • Corpus Christi Texas 78411 USA Telephone: 361 992 7900 • Facsimile: 361 992 3377 • Website: www.irctt.com SPH/SPF Series Issue December 2008 Sheet 2 of 3 General GeneralNote Note TT to to make changes in product specification without noticenotice or liability. TT Electronics electronicsreserves reservesthe theright right make changes in product specification without or liability. All to to TTTT Electronics’ ownown datadata andand is considered accurate at time going to print. Allinformation informationis issubject subject electronics’ is considered accurate at of time of going to print. www.bitechnologies.com www.irctt.com www.welwyn-tt.com www.ttelectronicsresistors.com © plcplc © TT TTElectronics electronics 07.14 01.14 General Purpose Failsafe Molded Wirewound Resistor SPH/SPF Series SPH/SPF Series General-Purpose General PurposeFailsafe Failsafe Moulded WirewoundResistor Resistors Molded Wirewound SPF Power Derating Curve 2.5 2.5 2.0 2.0 Power (watts) Power (watts) SPH Power Derating Curve Make Possible 1.5 1.0 0.5 0 0 50 70 100 1.5 1.0 0.5 0 150 160 200 0 SPF Typical Fusing 150 200 SPH and SPF Temperature Rise Chart 25 150 0.1 ohm 1 ohm 15 10 ohm 10 100 ohm 1000 ohm 5 0 20 40 60 80 Temperature Rise (°C) 20 Power (watts) 100 Ambient Temperature (°C) Ambient Temperature (°C) 2 0 50 70 125 100 100 Time (seconds) 75 50 25 0 0 0.5 1.0 1.5 2.0 Power Input (watts) Wire and Film Technologies Division • 4222 South Staples Street • Corpus Christi Texas 78411 USA Telephone: 361 992 7900 • Facsimile: 361 992 3377 • Website: www.irctt.com SPH/SPF Series Issue December 2008 Sheet 3 of 3 General GeneralNote Note TT thethe right to make changes in product specification without notice notice or liability. TTElectronics electronicsreserves reserves right to make changes in product specification without or liability. All is subject to TT Electronics’ ownown datadata and is considered accurate at timeatoftime going print.to print. Allinformation information is subject to TT electronics’ and is considered accurate of to going www.ttelectronicsresistors.com www.bitechnologies.com www.irctt.com www.welwyn-tt.com ©©TT plc plc TTElectronics electronics 07.14 01.14 General-Purpose General PurposeFailsafe Failsafe Moulded WirewoundResistor Resistors Molded Wirewound Make Possible SPH/SPF SPH/SPFSeries Series Ordering Procedure This product has two valid part numbers: European (Welwyn) Part Number: SPH-150RJI (SPH, 150 ohms ±5%, Pb-free) S P H - 1 5 1 0 R 2 1 2 Type Value SPH SPF R = ohms K = kilohms J I 3 4 3 4 Tolerance Packing & Termination Finish J = ±5% K = ±10% I = Standard packing & Pb-free Tape pack 1250/reel USA (IRC) Part Number: SPH1500JLF (SPH, 150 ohms ±5%, Pb-free) S P H 1 5 1 0 0 J 2 L 3 F 4 1 2 3 4 Type Value Tolerance Termination Finish Standard Packing Omit for SnPb LF = Pb-free 1250/reel Tape pitch 0.375” (9.5mm) Tape to tape 2.875” (73mm) Leads untrimmed SPH 3 digits + multiplier J = ±5% SPF K = ±10% R = ohms for values <100 ohms General GeneralNote Note TT Electronics make changes in product specification without noticenotice or liability. electronicsreserves reservesthe theright righttoto make changes in product specification without or liability. All TTTT Electronics’ own data andand is considered accurate at time going to print. All information informationisissubject subjecttoto electronics’ own data is considered accurate at of time of going to print. www.bitechnologies.com www.irctt.com www.welwyn-tt.com www.ttelectronicsresistors.com © TT Electronics plcplc electronics 07.14 01.14 Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: TT Electronics: SPH33R0J SPHR240J SPHR200J SPF 47 5% SPH10R0J SPH4R70J SPH5100J SPHR270J SPH22R0J SPH2R00J SPF .3 5%TR SPH1000JTR SPH1001JTR SPH10R0JTR SPH1200JTR SPH1R00JTR SPH1R50J SPH2001JTR SPH2700JTR SPH3300J SPH33R0K SPH4700J SPH5R10JTR SPHR050JTR SPHR100JTR SPHR220JTR SPHR300J SPHR330J SPH2R20J SPH1R00J SPH20R0J SPF10R0J SPHR150J SPHR560J SPH82R0J SPHR510J SPF4700J SPH1001J SPH1000J SPH7500J SPH30R0J SPH 47 5% SPH56R0J SPH2000J SPH2001J SPH1500J SPHR470J SPHR390J SPHR100J SPH68R0J SPH8R00J SPHR910J SPHR180J SPH1501JTR SPH5R60KTR SPH10R0JLF SPH82R0JLF SPF2R00J SPH2400J SPF10R0JLFTR SPHR100JLF SPHR330JLF SPH1R00JLF SPH2R20JLF SPF1800JTR SPHR220JTRLF SPH1501J SPF2400JTR SPHR220JLFTR SPHR820JLF SPH3R30JLF SPHR200JLF