Maintenance Manual - Great Dane Trailers

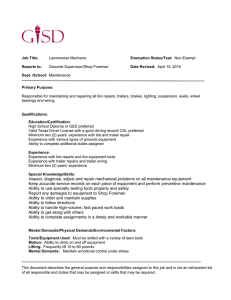

advertisement