Device Under Test: Multiple Environmental Test: Thermal Shock

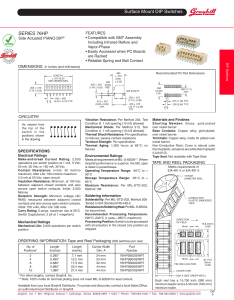

advertisement

Device Under Test: Multiple Environmental Test: Thermal Shock, Thermal Shock MIL, Salt Fog 48 Hrs, Salt Fog 96 Hrs Physical Test: Sinusoidal Vibration, Mechanical Shock, Rotational Life, Mounting Strength, Label Adhesion Test Report Number: SP03-128 Test Start Date: October 7, 2014 Test Completion Date: December 22, 2014 Test Facility: Grayhill Inc. La Grange, IL Facility Test Requested By: Troy Naumes Test Performed By: Greg Dombrowski Laboratory Technician Report Written By: Greg Dombrowski Laboratory Technician Report Approved By: Nicole Jachna Quality Lab Manager TABLE OF CONTENTS SUBJECT PAGE # 1.0 REVISION HISTORY ................................................................................................................................................... 4 2.0 SUMMARY ................................................................................................................................................................... 4 2.1. PURPOSE ................................................................................................................................................................ 4 2.2. REQUIREMENTS & METHODS .............................................................................................................................. 4 2.3. TEST SUMMARY ..................................................................................................................................................... 4 3.0 FLOW CHART ............................................................................................................................................................. 5 4.0 MOUNTING TORQUE ................................................................................................................................................. 6 4.1. PURPOSE ................................................................................................................................................................ 6 4.2. TEST SETUP DETAILS............................................................................................................................................ 6 4.3. TEST SETUP PHOTO .............................................................................................................................................. 7 4.4. ACCEPTANCE CRITERIA ....................................................................................................................................... 7 4.5. TEST RESULTS ....................................................................................................................................................... 7 5.0 SALT FOG (MIL-STD-810G, METHOD 509.4) ........................................................................................................... 8 5.1. PURPOSE ................................................................................................................................................................ 8 5.2. TEST SETUP DETAILS............................................................................................................................................ 8 5.3. TEST SETUP PHOTOS ........................................................................................................................................... 9 5.4. ACCEPTANCE CRITERIA ..................................................................................................................................... 10 5.5. TEST RESULTS ..................................................................................................................................................... 10 6.0 SALT FOG 96 Hrs (MIL-STD-810G, METHOD 509.4) ............................................................................................. 12 6.1. PURPOSE .............................................................................................................................................................. 12 6.2. TEST SETUP DETAILS.......................................................................................................................................... 12 6.3. TEST SETUP PHOTOS ......................................................................................................................................... 13 6.4. ACCEPTANCE CRITERIA ..................................................................................................................................... 14 6.5. TEST RESULTS ..................................................................................................................................................... 14 7.0 SINUSOIDAL VIBRATION TEST .............................................................................................................................. 16 7.1. PURPOSE .............................................................................................................................................................. 16 7.2. TEST SETUP DETAILS.......................................................................................................................................... 16 7.3. TEST SETUP PHOTOS ......................................................................................................................................... 17 7.4. ..................................................................................................................................................................................... 18 7.5. ACCEPTANCE CRITERIA ..................................................................................................................................... 18 7.6. TEST RESULTS ..................................................................................................................................................... 18 8.0 MECHANICAL SHOCK ............................................................................................................................................. 19 8.1. PURPOSE .............................................................................................................................................................. 19 8.2. TEST SETUP DETAILS.......................................................................................................................................... 19 8.3. TEST SETUP PHOTOS ......................................................................................................................................... 20 8.4. ACCEPTANCE CRITERIA ..................................................................................................................................... 21 8.5. TEST RESULTS ..................................................................................................................................................... 21 9.0 THERMAL SHOCK (MIL-STD-202G, METHOD 107, TEST CONDITION A) ........................................................... 22 9.1. PURPOSE .............................................................................................................................................................. 22 9.2. TEST SETUP DETAILS.......................................................................................................................................... 22 9.3. TEST SETUP PHOTOS ......................................................................................................................................... 23 9.4. ACCEPTANCE CRITERIA ..................................................................................................................................... 23 9.5. TEST RESULTS ..................................................................................................................................................... 23 10.0 ROTATIONAL LIFE ............................................................................................................................................... 24 10.1. PURPOSE ........................................................................................................................................................... 24 10.2. TEST SETUP DETAILS ...................................................................................................................................... 24 10.3. TEST SETUP PHOTOS ...................................................................................................................................... 25 10.4. ACCEPTANCE CRITERIA .................................................................................................................................. 25 10.5. TEST RESULTS ................................................................................................................................................. 25 2 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 11.0 ROTATIONAL LIFE AT TEMPERATURE ............................................................................................................. 26 11.1. PURPOSE ........................................................................................................................................................... 26 11.2. TEST SETUP DETAILS ...................................................................................................................................... 26 11.3. ACCEPTANCE CRITERIA .................................................................................................................................. 27 11.4. TEST RESULTS ................................................................................................................................................. 27 12.0 THERMAL SHOCK ................................................................................................................................................ 28 12.1. PURPOSE ........................................................................................................................................................... 28 12.2. TEST SETUP DETAILS ...................................................................................................................................... 28 12.3. TEST SETUP PHOTOS ...................................................................................................................................... 29 12.4. ACCEPTANCE CRITERIA .................................................................................................................................. 29 12.5. TEST RESULTS ................................................................................................................................................. 29 3 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 1.0 REVISION HISTORY Revision A Date 01/12/2015 Written By G. Dombrowski Description New 2.0 SUMMARY 2.1. PURPOSE Qualify sulfamate nickel testing 2.2. REQUIREMENTS & METHODS Tests to be performed to flow chart of report. 2.3. TEST SUMMARY Table 1 – Test Summary Test Description Group A Mounting Strength Group B 48 Hour Salt Fog 96 Hour Salt Fog Group C Sinusoidal Vibration Mechanical Shock Thermal Shock (MIL) Group D Life (Rotational) Basic Standard Test Results Test Date Test Location MIL-DTL-3786J 4.8.3.3 PASS 12/22/2014 Grayhill, Inc. MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-DTL-3786J 4.8.7 MIL-STD-202G 201A MIL-DTL-3786J 4.8.8 MIL-STD-202G 213B MIL-STD-202G 107 Test Condition A PASS PASS PASS PASS 10/07/2014 – 10/09/2014 10/07/2014 10/11/2014 11/12/2014 – 11/21/2014 11/24/2014 – 12/12/2014 Grayhill, Inc. Grayhill, Inc. Grayhill, Inc. Grayhill, Inc. PASS 12/19/2014 Grayhill, Inc. MIL-DTL-3786J 4.8.18 MIL-STD-202G 206 PASS 10/27/2014 – 12/11/2014 Grayhill, Inc. MIL-DTL-3786J 4.8.18 MIL-STD-202G 206 PASS 11/21/2014 – 12/08/2014 Grayhill, Inc. Grayhill Custom PASS 12/04/2014 – 12/18/2014 Grayhill, Inc. Group E Life at temperature (Rotational) Group F Thermal Shock (Grayhill) 4 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 3.0 FLOW CHART 5 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 4.0 MOUNTING TORQUE Test Specification Mounting Strength MIL-DTL-3786J 4.8.3.3 4.1. DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI 38-401-BLK DUT Serial Number Test Location Test Date 1-3 1-3 1-3 1-3 1-3 Grayhill Inc. 12/22/2014 1-3 1-3 1-3 1-3 PURPOSE The purpose for this test is to determine if the DUT can withstand the maximum torque directly applied to the nuts. 4.2. TEST SETUP DETAILS 1. 2. 3. 4. 5. 6. Mount DUT onto a metal brackets whose hole is the recommended size for the DUT. Use standard nut and lock washer for testing. Use torque wrench to tighten the nut to the maximum allowable torque. Inspect the DUT for any visible damage. Perform functional tests after mounting. Re-mount and torque nut until breakage or damage occurs and record FT-lbs. Table 2 - Equipment List Equipment ID GT-400 Equipment Type Torque Wrench Model Number CAL-36/4 Manufacturer Sturtvant Richmont Calibration Due Date 04/ 2015 Table 3 – Mounting Torque Test Conditions Test Condition Quantity Operational Mode Maximum Mounting Torque Units Parameters In-LB 57 Unpowered 15 6 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 4.3. TEST SETUP PHOTO Figure 1 – Mounting Torque test setup 4.4. ACCEPTANCE CRITERIA The DUT must have no part breakage and no disassembly of parts. The DUT must be functionally tested and operate as intended after test. 4.5. TEST RESULTS There was no sign of part breakage or disassembly of parts for Max torque of 15 FT-lbs. The DUT were mechanically and electrically operative. Table 4 – Test Results DUT 71A30-01-1-12N-C-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI 38-401-BLK Initial 15 FT-lbs PASS PASS PASS PASS PASS PASS PASS PASS Failed FT-lbs 34 36 36 34 34 34 36 30 7 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 5.0 SALT FOG (MIL-STD-810G, METHOD 509.4) Test Specification Salt Fog MIL-STD-810G Method 509.4 5.1. DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI 75AY23083-NI 38-401-BLK DUT Serial Number 9-13 9-13 9-13 9-13 9-13 9-13 9-13 9-13 9-13 9-13 Test Location Test Date Grayhill Inc. 10/07/2014 – 10/09/2014 PURPOSE The Salt Fog method is performed to determine the effectiveness of protective coatings and finished on materials. It may also be applied to determine the effects of salt deposits on the physical and electrical aspects of DUT. 5.2. TEST SETUP DETAILS 1. Prepare a 5 +/-1% solution by dissolving 5 parts by weight of salt in 95 parts by weight of water. 2. Adjust to and maintain the solution at a specific gravity by using the measured temperature and density of the salt solution. 3. Maintain the pH of the salt solution between 6.5 and 7.2. 4. Set the test chamber to 35C and condition the DUT for at least 2 hours before introducing the salt fog. 5. Atomize a salt solution into the test chamber for a period of 48 hours. 6. Dry the DUT at standard ambient temperatures and a relative humidity of 50% for 24 hours. 7. Perform physical and electrical. 8. Rinse or use a gentle wash the DUT in running water and conduct the corrosion examination. 9. Perform functional test. Table 5 – Equipment List Equipment ID Equipment Type Model Number GT-115 Salt Fog Chamber MX9204 GT-401 GT-110 NA NA Pressure Gauge PH Meter Gravity meters Graduated Cylinders 595-05 HI 98108 NA 100: 2ml Manufacturer Associated Environmental System Ashcroft PHEP+ NA Azcon Calibration Due Date 04/2015 04/2015 10/2015 NA NA 8 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 6 - Test Conditions Test Condition Quantity Duration Salt Solution Type of Water Duration pH Levels Temperature Volume of solution measured per hour 5.3. Units DUT Hours parts Parameters °C 100 48 5 ± 1 parts per 95 parts water by mass Distilled or De-ionized water 96 6.5 to 7.2 35 mL 1.0 to 2.0 mL hours TEST SETUP PHOTOS Figure 2– Salt Fog Test Setup 9 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Figure 3– DUT after 48 hours Salt Fog and 24 hours drying (STD plating on the left and NI plating on the right) 5.4. ACCEPTANCE CRITERIA The DUT shall satisfactorily withstand the salt fog conditions specified without physical damage. fully functional after the test. 5.5. The DUT shall be TEST RESULTS There was no visible corrosion, seal break down, or material breakdown on any DUT. The DUT exhibited normal posttest operation. 10 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 7 – Test Results DUT Test 71A30-01-1-12N-C-NI Salt Fog 48 Hrs 77P36-01-1-10N-NI Salt Fog 48 Hrs 51A30-01-1-10N-NI Salt Fog 48 Hrs 50A36-01-1-10N-NI Salt Fog 48 Hrs 26ASD22-01-1-AJS-NI Salt Fog 48 Hrs 56A36-01-1-10N-C-NI Salt Fog 48 Hrs 50YY50812-NI Salt Fog 48 Hrs 75BP36-01-1-10N-C-NI Salt Fog 48 Hrs 75AY23083-NI Salt Fog 48 Hrs 38-401-BLK Salt Fog 48 Hrs Specification MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 Pass Test Location PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. Test Date 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 10/07/2014 – 10/09/2014 11 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 6.0 SALT FOG 96 Hrs (MIL-STD-810G, METHOD 509.4) Test Specification Salt Fog MIL-STD-810G Method 509.4 6.1. DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI 75AY23083-NI 38-401-BLK DUT Serial Number 4-8 4-8 4-8 4-8 4-8 4-8 4-8 4-8 4-8 4-8 Test Location Test Date Grayhill Inc. 10/07/2014 – 10/11/2014 PURPOSE The Salt Fog method is performed to determine the effectiveness of protective coatings and finished on materials. It may also be applied to determine the effects of salt deposits on the physical and electrical aspects of DUT. 6.2. TEST SETUP DETAILS 1. Prepare a 5 +/-1% solution by dissolving 5 parts by weight of salt in 95 parts by weight of water. 2. Adjust to and maintain the solution at a specific gravity by using the measured temperature and density of the salt solution. 3. Maintain the pH of the salt solution between 6.5 and 7.2. 4. Set the test chamber to 35C and condition the DUT for at least 2 hours before introducing the salt fog. 5. Atomize a salt solution into the test chamber for a period of 96 hours. 6. Dry the DUT at standard ambient temperatures and a relative humidity of 50% for 24 hours. 7. Perform physical and electrical. 8. Rinse or use a gentle wash the DUT in running water and conduct the corrosion examination. 9. Perform functional test. Table 8 – Equipment List Equipment ID Equipment Type Model Number GT-115 GT-401 GT-110 NA NA Salt Fog Chamber Pressure Gauge PH Meter Gravity meters Graduated Cylinders MX9204 595-05 HI 98108 NA 100: 2ml Manufacturer Associated Environmental System Ashcroft PHEP+ NA Azcon Calibration Due Date 04/2015 04/2015 10/2015 NA NA 12 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 9 - Test Conditions Test Condition Quantity Duration Salt Solution Type of Water Duration pH Levels Temperature Volume of solution measured per hour 6.3. Units DUT Hours parts Parameters °C 100 96 5 ± 1 parts per 95 parts water by mass Distilled or De-ionized water 96 6.5 to 7.2 35 mL 1.0 to 2.0 mL hours TEST SETUP PHOTOS Figure 4– Salt Fog Test Setup 13 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Figure 5– DUT after 96 hours Salt Fog and 24 hours drying (STD plating on the left and NI plating on the right) 6.4. ACCEPTANCE CRITERIA The DUT shall satisfactorily withstand the salt fog conditions specified without physical damage. fully functional after the test. 6.5. The DUT shall be TEST RESULTS There was no visible corrosion, seal break down, or material breakdown on any DUT. The DUT exhibited normal posttest operation. 14 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 10 – Test Results DUT Test 71A30-01-1-12N-C-NI Salt Fog 96 Hrs 77P36-01-1-10N-NI Salt Fog 96 Hrs 51A30-01-1-10N-NI Salt Fog 96 Hrs 50A36-01-1-10N-NI Salt Fog 96 Hrs 26ASD22-01-1-AJS-NI Salt Fog 96 Hrs 56A36-01-1-10N-C-NI Salt Fog 96 Hrs 50YY50812-NI Salt Fog 96 Hrs 75BP36-01-1-10N-C-NI Salt Fog 96 Hrs 75AY23083-NI Salt Fog 96 Hrs 38-401-BLK Salt Fog 96 Hrs Specification MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 MIL-STD-810G Method 509.4 Pass Test Location PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. Test Date 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 10/07/2014 – 10/11/2014 15 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 7.0 SINUSOIDAL VIBRATION TEST Test Specification Sinusoidal Vibration MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A 7.1. DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 5050YY50812-NI 75BP36-01-1-10N-C-NI DUT Serial Number 14-23 14-23 14-23 14-23 14-23 14-23 14-23 14-23 Test Location Test Date Grayhill Inc. 11/12/2014 11/21/2014 PURPOSE The purpose of this test is to evaluate the DUT of its ability to withstand sinusoidal vibration. The potential product failure modes and effects detected in this test are: • • • • • Cracked housing/components Broken product/components Open solder joints Dislodged parts Loose mounting interfaces. 7.2. TEST SETUP DETAILS Test Profile and Setup Details: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Visual Inspection of the DUT is to be performed before and after testing Attach characterization sample(s) to the test fixture on the test table in specified orientation. Characterize set-up conditions. Attach DUT in specified orientation. Attach connector(s) and tie down wire harness(es) at appropriate lengths, if required. Power and monitor DUT output. Apply vibration, temperature and voltage per specified levels and verify operation, if required. Vibrate the DUT for specified duration. Subject DUT to conditions in Test Checkpoint Table. Repeat steps D thru I until all DUT have been tested for their total duration. Perform the Visual Examination and Functional Check after the test. Table 11 – Equipment List Equipment ID Equipment Type Model Number Manufacturer Calibration Due Date GT-353 Shaker Table Shaker Table Amplifier Shaker Table Controller Shear Accelerometer DS-11000VH/1.7-50 Dynamic Solutions Calibration Not Required SA-50 Dynamic Solutions Calibration Not Required DVC-8 Vibration World 05/2015 JTLD352C04 PCB Piezotronics 10/2015 GT-354 GT-355 GT-535 16 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 12 - Test Condition Test Condition Units Parameters Quantity Duration Operational Mode Applicable Axes Temperature Lower Limit Frequency Upper Limit Frequency Sweep Rate Pass/Fail Criteria DUT Hours Volts 3 C Hz Hz Min./Cycle 170 2 per axis Monitored with Chatterbox Longitudinal, Transverse, and Vertical Ambient 10 55 1 See below Table 13 – Profile Break Points Frequency (Hz) Displacement (th) 10 55 60 60 7.3. TEST SETUP PHOTOS Figure 6 – Sinusoidal Vibration for DUT being monitored. 17 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Figure 7 – Sample of finished test profile 7.4. 7.5. ACCEPTANCE CRITERIA Upon completion of the Sinusoidal Vibration test, the DUT must be functionally tested and operate as intended. There shall not be any visible damage such as broken, loose, deformed or displaced parts. There shall be no change in the shaft position. All DUT shall be monitored and show no evidence of false activation. 7.6. TEST RESULTS All DUT passed the functional testing and showed no evidence of damage. All DUT were powered and monitored by use of a chatter box to insure no impaired function during and after the test. All mounting hardware was intact. Table 14– Test Results DUT Test 71A30-01-1-12N-C-NI Sinusoidal Vibration 77P36-01-1-10N-NI Sinusoidal Vibration 51A30-01-1-10N-NI Sinusoidal Vibration 50A36-01-1-10N-NI Sinusoidal Vibration 26ASD22-01-1-AJS-NI Sinusoidal Vibration 56A36-01-1-10N-C-NI Sinusoidal Vibration 50YY50812-NI Sinusoidal Vibration 75BP36-01-1-10N-C-NI Sinusoidal Vibration Specification MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A MIL-DTL-3786J 4.8.7 MIL-STD0202G 201A Pass Test Location PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. Test Date 11/12/2014 11/21/2014 11/12/2014 11/21/2014 11/12/2014 11/21/2014 11/12/2014 11/21/2014 11/12/2014 11/21/2014 11/12/2014 11/21/2014 11/12/2014 11/21/2014 11/12/2014 11/21/2014 18 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 8.0 MECHANICAL SHOCK Test Specification MIL-DTL-3786J 4.8.8 Mechanical Shock MIL-STD0202G 213B 8.1. DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI DUT Serial Number Test Location Test Date 14-23 14-23 14-23 14-23 11/24/2014 Grayhill Inc. 14-23 12/12/2014 14-23 14-23 14-23 PURPOSE The purpose of this test is to validate the manufacturing process in its ability to produce a product capable of withstanding the effects of shipping, handling, installation, and operational shock. The potential product issue modes and effects detected in this test are: • • • Housing cracks Product/component breakage Inadvertent activation 8.2. TEST SETUP DETAILS 1. 2. 3. 4. 5. 6. 7. 8. Visual Inspection of the DUT is to be performed before and after testing. Verify specified test conditions table with test fixture on test table. Place product in a holding fixture in specified orientation. Attach connector(s) and tie down wire harness at appropriate lengths, if required. Monitor DUT outputs, if required. Test product for specified shocks/axis. Repeat until all DUT have completed their total shocks/unit. Perform the Visual Examination and Functional Check after the test. Table 15 – Equipment List Equipment ID GT-535 Equipment Type Accelerometer Model Number JTLD352C04 Manufacturer PCB Piezotronics GT-141 Mechanical Shock Table M-RAD 1616(100)PA-MP MRAD Calibration Due Date 10/2015 verified by controller’s software & Accelerometer GT-532 19 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 16 - Test Conditions Test Condition Quantity Operational Mode Pulse Type Acceleration Pulse duration Drops Direction 8.3. Units DUT G ‘msec. per/axis Parameters 170 Unpowered / Chatter Box Saw Tooth 100 6 3 3 in each of +/-X, +/-Y, +/-Z (18 shocks total) TEST SETUP PHOTOS Figure 8– Mechanical Shock Test Setup Figure 9 – Mechanical Shock Test Monitoring 20 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Figure 10 – Mechanical Shock Wave Form 8.4. ACCEPTANCE CRITERIA As MIL-DTL-3786J states, any pair of mating switch section contacts shall not open for a period of time longer than 10 µs unless otherwise specified. After the test, there shall be no change in shaft position, or evidence of broken, loose, deformed, or displaced parts. 8.5. TEST RESULTS Functional status was verified by monitoring DUT with a Chatter Box during testing. After testing there was no change in shaft position, no evidence of broken, loose, deformed or displaced parts. All DUT passed the functional testing. Table 17 – Test Results DUT Test 71A30-01-1-12N-C-NI Mechanical Shock 77P36-01-1-10N-NI Mechanical Shock 50A36-01-1-10N-NI Mechanical Shock 26ASD22-01-1-AJS-NI Mechanical Shock 56A36-01-1-10N-C-NI Mechanical Shock 50YY50812-NI Mechanical Shock 75BP36-01-1-10N-C-NI Mechanical Shock Specification MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B MIL-DTL-3786J 4.8.8 MIL-STD0202G 213B Pass Test Location PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. PASS Grayhill Inc. Test Date 11/24/2014 12/12/2014 11/24/2014 12/12/2014 11/24/2014 12/12/2014 11/24/2014 12/12/2014 11/24/2014 12/12/2014 11/24/2014 12/12/2014 11/24/2014 12/12/2014 21 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 9.0 THERMAL SHOCK (MIL-STD-202G, METHOD 107, TEST CONDITION A) Test Specification DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI MIL-STD-202G, METHOD 107, Thermal Shock TEST CONDITION A 9.1. DUT Serial Number 39-43 39-43 39-43 39-43 39-43 39-43 39-43 39-43 Test Location Test Date Grayhill Inc. 12/19/2014 PURPOSE This test was conducted for the purpose of determining the resistance of DUT from sudden changes in the temperature of the surrounding atmosphere without experiencing physical, mechanical, and electrical damage or deterioration in performance. 9.2. TEST SETUP DETAILS 1. Visual examination of the test item with special attention to stress areas such as corners of molded housing and document the results. 2. Take picture of the test item. 3. Set Temperature Chamber as specified in the test plan for thermal shock. 4. Maintain the thermal shock temperature for a period as specified in the test plan. 5. Adjust Temperature Chamber to standard ambient and maintain until the test item has achieved temperature stabilization. 6. Conduct a complete visual examination of the test item and document the results. 7. Compare these data with the initial visual examination. 8. Perform functional check on the test item. Table 18 – Equipment List Equipment ID Equipment Type Model Number Manufacturer Calibration Due Date GT- 1008 Thermal Shock VTS-3-6-6-SC/WC Cincinnati Sub Zero 10/2015 GT-542 Thermometer EasyView 15 Extech 08/2015 Table 19 - Test Conditions Test Condition Quantity Duration Dwell Time Transfer time Operational Mode Minimum Temperature Maximum Temperature Units DUT Cycles Hours Or Minute Minute C C Parameters 170 5 1 Hour 1 Unpowered -65 85 22 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 9.3. TEST SETUP PHOTOS Figure 11 – Thermal Shock Test Setup 9.4. ACCEPTANCE CRITERIA Upon completion of the Thermal Shock Test, DUT contact resistance shall not exceed 500 milliohms, and there shall be no mechanical or electrical damage, loosing of rivets, or other fastening devices. 9.5. TEST RESULTS DUT contact resistance did not exceed 500 milliohms. There was not any evidence of damage to DUT housing and shaft. Table 20 – Test Results DUT Test 71A30-01-1-12N-C-NI Thermal Shock 77P36-01-1-10N-NI Thermal Shock 51A30-01-1-10N-NI Thermal Shock 50A36-01-1-10N-NI Thermal Shock 26ASD22-01-1-AJS-NI Thermal Shock 56A36-01-1-10N-C-NI Thermal Shock 50YY50812-NI Thermal Shock 75BP36-01-1-10N-C-NI Thermal Shock Specification MIL-STD-202G 107G MIL-STD-202G 107G MIL-STD-202G 107G MIL-STD-202G 107G MIL-STD-202G 107G MIL-STD-202G 107G MIL-STD-202G 107G MIL-STD-202G 107G Pass Test Location Test Date PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 PASS Grayhill Inc. 12/19/2014 23 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 10.0 ROTATIONAL LIFE Test Specification Rotational Life MIL-DTL-3786J DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI DUT Test Location Test Date 24 To 33 Grayhill Inc. 10/27/2014 – 12/11/2014 10.1. PURPOSE The purpose of this test is to determine the ability of DUT to operate satisfactorily under simultaneously applied varying conditions of high / low temperature. 10.2. TEST SETUP DETAILS 1. 2. 3. 4. 5. 6. Visual Inspection of the DUT is to be performed before and after testing Measure and record the Initial torque values. Program the Rotational Life Tester at 20RPM for 25000 cycles. The cycle rate was approximately 10 cycles per minute. Mount DUT onto Rotational Life Tester. After 25000 cycles, measure and record Torque. Table 21 – Equipment List Equipment ID GT-143 PAL-7 RLS-46 RLS-83 RLS-84 RLS-85 RLS-64 Equipment Type Hygrometer Torque Force Reader Smart Motor Rotational Life Smart Motor Rotational Life Smart Motor Rotational Life Smart Motor Rotational Life Smart Motor Rotational Life Model Number MDM25 Manufacturer Mitchell Instrument Calibration Due Date 06/2014 BGI Mark-10 09/2015 SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA 24 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 22 - Test Conditions Test Condition Units Parameters Quantity Operational Mode Test Temperature Humidity Cycle Rate Assemblies 170 Unpowered 24.6 26.1 20 °C %Rh RPM 10.3. TEST SETUP PHOTOS Figure 12 – Rotational Life Test Setup 10.4. ACCEPTANCE CRITERIA The DUT must function normally before, during, and after the Rotational Life Tests. There shall be no mechanical damage, loosening of rivets or other fastening devices. The rotational torque shall be in between 0.5 in-lbs and 1.5 in-lbs. 10.5. TEST RESULTS There was no evidence of any electrical, physical, or mechanical damage. All DUT were function normally after the Rotational Life Tests. Table 23 – Test Results DUT Test Specification Pass Test Location 71A30-01-1-12N-C-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 77P36-01-1-10N-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 50A36-01-1-10N-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 26ASD22-01-1-AJS-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 56A36-01-1-10N-C-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 50YY50812-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 75BP36-01-1-10N-C-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. Test Date 10/27/2014 – 12/11/2014 10/27/2014 – 12/11/2014 10/27/2014 – 12/11/2014 10/27/2014 – 12/11/2014 10/27/2014 – 12/11/2014 10/27/2014 – 12/11/2014 10/27/2014 – 12/11/2014 25 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 11.0 ROTATIONAL LIFE AT TEMPERATURE Test Specification Rotational Life at Temperature MIL-DTL-3786J 4.8.19 MIL-STD-202G 108A DUT Part Number 26ASD22-01-1-AJS (NI,STD) 50A36-01-1-10N (NI, STD) 50YY50812 (NI, STD) 51A30-01-1-10N (NI, STD) 71A30-01-1-12N-C (NI, STD) 75BP36-01-1-10H-C (NI, STD) 75YY50033 STD 77P36-01-10N (NI, STD) DUT Test Location Test Date 34 - 38 Grayhill Inc. 11/21/14 – 12/08/14 11.1. PURPOSE The purpose of this test is to determine the ability of DUT to operate satisfactorily under simultaneously applied varying conditions of high / low temperature. 11.2. TEST SETUP DETAILS 1. 2. 3. 4. 5. 6. Visual Inspection of the DUT is to be performed before and after testing Measure and record the Initial torque values. Program the Rotational Life Tester at 20RPM for 25000 cycles. The cycle rate was approximately 10 cycles per minute. Mount DUT onto Rotational Life Tester. After 25000 cycles, measure and record Torque. Table 24 – Equipment List Equipment ID GT-143 PAL-7 GT-1003 RLS-46 RLS-83 RLS-84 RLS-85 RLS-64 Equipment Type Hygrometer Torque Force Reader Temperature and Humidity Chamber Smart Motor Rotational Life Smart Motor Rotational Life Smart Motor Rotational Life Smart Motor Rotational Life Smart Motor Rotational Life Model Number MDM25 Manufacturer Mitchell Instrument Calibration Due Date 06/2015 BGI Mark-10 09/2015 SM-8-3800 Thermotron 03/2015 SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA SM3416D-PLS2 Animatics NA 26 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A Table 25 - Test Conditions Test Condition Units Parameters Quantity Operational Mode Test Temperature Duration Cycle Rate Assemblies 85 Unpowered 85 25,000 20 °C Cycles RPM 11.3. ACCEPTANCE CRITERIA The DUT must function normally before, during, and after the Rotational Life Tests. There shall be no mechanical damage, loosening of rivets or other fastening devices. The rotational torque shall be in between 0.5 in-oz and 1.5 inoz. 11.4. TEST RESULTS There was no evidence of any electrical, physical, or mechanical damage. DUT function normally after the Rotational Life Tests Table 26 – Test Results DUT Test Specification Pass Test Location 71A30-01-1-12N-C-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 77P36-01-1-10N-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 50A36-01-1-10N-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 26ASD22-01-1-AJS-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 56A36-01-1-10N-C-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 50YY50812-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. 75BP36-01-1-10N-C-NI Rotational Life MIL-DTL-3786J PASS Grayhill Inc. Test Date 11/21/14 – 12/08/14 11/21/14 – 12/08/14 11/21/14 – 12/08/14 11/21/14 – 12/08/14 11/21/14 – 12/08/14 11/21/14 – 12/08/14 11/21/14 – 12/08/14 27 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 12.0 THERMAL SHOCK Test Specification Thermal Shock LREQ-SP03-128 DUT Part Number 71A30-01-1-12N-C-NI 77P36-01-1-10N-NI 51A30-01-1-10N-NI 50A36-01-1-10N-NI 26ASD22-01-1-AJS-NI 56A36-01-1-10N-C-NI 50YY50812-NI 75BP36-01-1-10N-C-NI 75AY23083-NI 38-401-BLK DUT Serial Number 39-43 39-43 39-43 39-43 39-43 39-43 39-43 39-43 39-43 39-43 Test Location Test Date Grayhill Inc. 12/04/2014 – 12/18/2014 12.1. PURPOSE This test was performed to determine if DUT would maintain the structural integrity after being subjected to a rapid change in temperature multiple times. 12.2. TEST SETUP DETAILS 1. Visual examination of the test item with special attention to stress areas such as corners of molded housing and document the results. 2. Take picture of the test item. 3. Set Temperature Chamber as specified in the test plan for thermal shock. 4. Maintain the thermal shock temperature for a period as specified in the test plan. 5. Adjust Temperature Chamber to standard ambient and maintain until the test item has achieved temperature stabilization. 6. Conduct a complete visual examination of the test item and document the results. 7. Compare these data with the initial visual examination. Table 27 – Equipment Equipment ID Equipment Type Model Number Manufacturer Calibration Due Date GT- 1008 Thermal Shock VTS-3-6-6-SC/WC Cincinnati Sub Zero 10/2015 GT-542 Thermometer EasyView 15 Extech 08/2015 Table 28 – Test Condition Test Condition Quantity Test Duration Operational Mode Dwell Duration Transfer Time Minimum Temperature Maximum Temperature Units Assemblies Cycles min min C C Parameters 100 1000 Unpowered 10 1 -40 85 28 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A 12.3. TEST SETUP PHOTOS Figure 13 – Thermal Shock Setup 12.4. ACCEPTANCE CRITERIA Upon completion of the Thermal Shock Test, there shall not be any visible damage or tin whiskers to DUT. 12.5. TEST RESULTS There was no physical damage to the NI plated DUT after completing the test. Table 29 – Test Results DUT Test Specification Pass Test Location 71A30-01-1-12N-C-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 77P36-01-1-10N-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 51A30-01-1-10N-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 50A36-01-1-10N-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 26ASD22-01-1-AJS-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 56A36-01-1-10N-C-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 50YY50812-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 75BP36-01-1-10N-C-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 75AY23083-NI Thermal Shock Grayhill Custom PASS Grayhill Inc. 38-401-BLK Thermal Shock Grayhill Custom PASS Grayhill Inc. Test Date 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 12/04/2014 12/18/2014 29 of 29 OPS Form #333, Rev A 11/12/12 Report SP03-128 Rev. A