NEW

0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

FH53 Series

Maximizes board space by utilizing its low profile,

and narrow pitch/depth

1 con

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

3.2

mm

m (4

tacts

)

0.2m

m

0.65mm

9.8 m

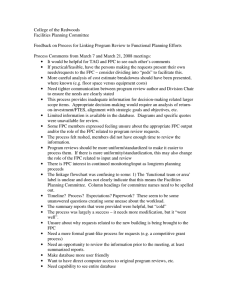

Fig. 1

QFeatures

1. Low-profile, top contact FPC connector

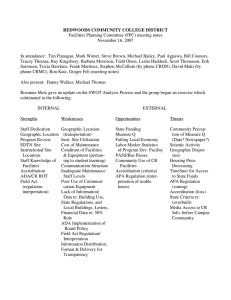

FH53 differential impedance

130ps rise time (20–80%)

Its super thin design produces a 0.65 mm

mounted height. (Fig. 1)

2. Maximizes board space

Its narrow pitch (0.2 mm) and depth (3.2 mm,

with the actuator in the locked position) combine

to maximize valuable board space. (Fig. 1)

3. Supports high-speed transmissions

By utilizing differential pairs of identical contacts

(even-even contacts or odd - odd contacts) these

connectors are able to provide superb transmission

characteristics and have achieved compliance with the

eDP (ver. 1.3), and MIPI (D-PHY) standards. (Fig. 2)

4. Multi-functional chucking metal

The chucking metal provides several functions all in

itself. It allows this connector to accept horizontal FPC

insertions; it generates a clear tactile click when the

FPC is inserted. It also provides increased retention

force on the FPC after insertion and prior to the lock

being engaged, because the metal was designed to

allow the FPC tabs to secure itself on it. (Fig. 3)

Fig. 2

Multi-functional chucking metal

[FPC in place]

5. Simplified FPC insertion

Large mating guides help to simplify the FPC

insertion process. These guides are located on

both sides of the housing. (Fig. 4)

Clear tactile click

by inserting FPC

[Locked]

6. Reduces assembly procedures

The actuator is delivered in the open position

and allows you to immediately insert the FPC.

7. Fully molded structure aids PCB layout

The bottom of this connector is enclosed by a fully

molded structure that protects the contacts and removes

any restrictions from PCB patterning and layout design.

8. Halogen-free

The connector does not contain chlorine and bromine

over the standard level.

All materials and substances used to produce this

product comply with Halogen-free standards.* Defined

in accordance with to 61249-2-21. Br: 900 ppm max,

Cl: 900 ppm max, Br+Cl: 1500 ppm max.

High FPC retention

force in locked state

Fig. 3

Smooth FPC insertion

The mating guides

are located on both

sides of the housing

9. Supports automatic pick-n-place mounting

Offered in tape and reel packaging that is compatible with

automatic machine mounting. (5,000 pieces per reel)

The standard packaging is 5,000 pieces per reel, but it is

also offered in a 500 pieces per reel. (The outer diameter of

the reel will be Ø180 mm in this case.)

The bottom of the opening is tapered to allow easier FPC insertion

Efficient use of space with no dead areas

The tapers are located in front of the SMT leads

Smooth FPC insertion

Fig. 4

2014.8

1

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

QProduct Specifications

Rating

Current rating 0.2 A (Note 1)

Voltage rating AC 30 Vms

Recommended

FPC SPC

t=0.12±0.02 Gold plated

Item

Specification

Conditions

1. Insulation Resistance

50 M1 min

100 V DC

2. Withstanding Voltage

No flashover or insulation breakdown

300 m1 Max.

*including FPC conductor resistance

Contact Resistance: 300 m1 Max.

No damages, cracks and looseness of parts

No electrical discontinuity to 1µ or longer

Contact Resistance: 300 m1 Max.

No damages, cracks and looseness of parts

No electrical discontinuity to 1µ or longer

Contact Resistance: 300 m1 Max.

No damages, cracks and looseness of parts

Contact Resistance: 300 m1 Max.

Insulation Resistance: 50M1 min

No damages, cracks and looseness of parts

Contact Resistance: 300 m1 Max.

Insulation Resistance: 50 M1 min

No damages, cracks and looseness of parts

No deformation of case of excessive looseness of

the terminal

90 Vrms AC/1 min

3. Contact Resistance

4. Durability

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Operating Temperature Range –55 to 85°C (Note 2)

Storage Temperature Range -10 to +50°C (Note 3)

Operating Humidity Range Relative humidity 90% MAX Storage Humidity Range Relative humidity 90% MAX

(condensation)

(condensation)

5. Vibration

6. Shock

7. Humidity

(Steady State)

8. Temperature Cycle

9. Resistance to soldering heat

1 mA

10 cycles

Frequency: 10 to 55 Hz, Half amplitude: 0.75 mm, for 10

cycles in 3 directions.

981 m/s2, Duration of pulse 6 ms at 3 times in 3 axial

directions.

96 hours at 40ç and humidity of 90 to 95%

Temperature:-55 / +15 to +35 / +85 / +15 to +35°C

30 / 2 to 3

/ 30 / 2 to 3 minutes

Time:

5 cycles with above conditions

Reflow: Recommended Temperature Profile

manual soldering: 350±10ç, 5 seconds

(Note 1) When electrifying rated current to all contacts, use 70% of rated current.

(Note 2) Including temperature rise caused by current flow.

(Note 3) The term “storage” refers to the long-term storage condition of unused products before PCB mounting.

For no-electrification state after PCB mounting, the operating temperature and humidity are applied.

QMaterials

Part

Material

Treatment

UL Regulation

Insulator

LCP

PA

Beige

Black

UL94V-0

UL94HB

Contact

Metal fitting

Phosphor bronze

Phosphor bronze

Nickel barrier gold plated

Pure tin reflow plated

___

___

QProduct Number Structure

Refor to this page when determining product specifications by model types. Please place orders with part numbers

listed in this catalog. The characteristics and specifications of the product described in this catalog are reference

values. Please make sure to check the latest delivery specifications at the time of product use.

FH 53 - 41S - 0.2 SHW (99)

q

w

e

qSeries Name: FH

wSeries No.: 53

eNo. of contacts: 41

rContact Pitch: 0.2mm

2

r

t

y

tTerminal Type

SHW…SMT horizontal staggered mounting type

ySpecifications

None: Regular (5000 per reel)

(99) : 500 per reel

0.65

HRS mark display

Cavity No.

1.53

display

**

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

(E)

a_a

(0.08)

0.4±0.1

(0.08)

A±0.15

B±0.15

)

0°

(9

Contact No.2

0.33±0.1

QConnector Dimensions

Contact

point

(0.25)

(FPC:t=0.12)

(1.1)

2.23±0.1

(0.45)

2.49±0.1

(0.36)

HRS mark display

Cavity No.

2.15±0.15

No. of contacts

display

**

(E)

21

−

31

41

(FPC:t=0.12)

FH53-51S-0.2SHW(**)

**

−

(0.36)

(0.25)

580-3401-7

0.3±0.1

FH53-31S-0.2SHW(**)

FH53-41S-0.2SHW(**)

−

((n–1)/2)×

0.02 X

(0.15)

B

C

D

3.6

4

4.8

0.2±0.02

7.8

9.8

5.6

7.6

C±0.02

6

11.8

9.6

F 10

5.8

X

0.4

8

0.4

X

Contact No.1

((n+1)/2)×

0.02 X

0.2±0.02

C±0.02

0.27±0.02

2×

F

Contact No.1

((n+1)/2)×

5.53

0.02 X

7.53

2×

9.53

10.8

11.53

0.02 X

QRecommended Stencil Pattern

推奨メタルマスク寸法図

(推奨メタルマスク厚:t=0.1)

Recommended

stencil thickness : t=01

B

0.4

0.18±0.01

((n–1)/2)×

0.02 Y

0.43±0.01

(0.26)

2.37±0.01

(Land pattern image)

0.44±0.01

(0.15)

(Connector Image)

E

6.8

8.8

0.27±0.02

Contact No.2

0.65±0.02

1.85±0.02

0.65±0.02

B

0.2±0.02

A

51

QRecommended

PCB Mounting Pattern

推奨ランド寸法図

0.4

0.65±0.02

point

FH53-21S-0.2SHW(**)

Unit: mm

Number of contacts

0.47±0.01

(1.03)

(1.38)

HRS

No.

Contact

1.85±0.02

8

Part number

2.23±0.1

2.15±0.15

(0.45)

(3.2: Actuator closed)

0.65±0.02

(0.08)

0.33±0.1

Notes 1 The dimension in parentheses are for reference.

2 Lead co-planarity including reinforced chucking metals shall be 0.1 max.

3 To be delivered with tape and reel packages.

推奨ランド寸法図

a_a

)

0° packaging specifications for details.

See attached

(9

4 Note that preventive hole for sink mark or slit could be added for improvement.

B

plastic.

5 The quality remains good, even with the dark spots, which could occasionally occur on molded

((n–1)/2)×

0.4

0.2±0.02 of these connectors.

6 The color of the plating may change after the reflow process, but it will not negatively affect performance

0.02 X

7 This product satisfies halogen free requirements defined as 900ppm maximum chlorine,

Contact No.2

900ppm maximum bromine, and 1500ppm maximum total of chlorine and bromine.

Contact

8 Shows hook part of the chucking

metal.

(Connector Image)

point

0.4

0.18±0.01

((n+1)/2)×

0.02 Y

C±0.02

Y

0.25±0.01

0.02 X

F

2×

0.02 Y

Notes 9. 'n' shows the number of contacts.

Unit: mm

0.47±0.01

推奨メタルマスク寸法図

Part number

FH53-21S-0.2SHW(**)B

FH53-31S-0.2SHW(**)

0.4

FH53-41S-0.2SHW(**)

FH53-51S-0.2SHW(**)

HRSタルマス

No. ク厚:t=0.1)Number

(推奨メ

0.18±0.01

−

−

((n–1)/2)×

0.02 Y

580-3401-7 **

− (Land pattern image)

of contacts

B

C

F

21

31

3.6

5.6

4

6

4.87

6.87

41

51

7.6

9.6

8

10

8.87

10.87

0.43±0.01

(0.26)

** Indicates a specification number of product. For detail, please refer to Page 2.

2.37±0.01

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

C±0.15

D±0.15

8

0.3±0.1

0.4±0.1

Contact

point

(1.03)

(0.12)

(3.2: Actuator closed)

Contact No.1

(0.08)

(1.38)

Production Lot No.

(0.2)

0.65±0.05

a

1.53±0.1 (Vacuum Pick up area)

Polarization

mark

2.69±0.1

a

3

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

(20

:

1)

PC寸法図

Recommended FPC 推奨F

Pattern

(FPC端末厚:t=0.12±0.02)

G±0.05

0.12± 0.02

H±0.05

Z

0.1±0.02

0.055±0.02

10 0.055±0.02

(0.05)

.15

±0

.1

R0

(0.1)

((n+1)/2)×

0.02 Z

Contact No.1

5)

13

0.0

(R

)

2)

0.

.05

(R (R0

0.2±0.02

10 0.1±0.02

R0

.1± 13

0.1

±0.1

R0.1

(0.05)

(2.73)

0.1

Contact No.2

R0

.1±

1

±0

.

.1

R0

1)

(0.1)

0.

2)

0.

11 P

0.63±0.1

1.21±0.1

1.31±0.1

10 0.1±0.02

0.07±0.1

0.65±0.1

1.2±0.05

0.8±0.05

10

0.75±0.05

(R

3.03±0.3 (Stiffener)

C±0.02

0.2

(R

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

1.63±0.3 (Exposed conductor)

0.75±0.05

(0.1)

0.15±0.02

0.195±0.02

0.1±0.02

0.1±0.02

((n–1)/2)×

0.02 Z

Notes

10

11

12

13

0.2±0.02

12

G±0.05

Shows recommended dimension when lead for plating is required.

Dimention P must be 1 mm minimum.

Indicated tolerance is applicable to the exposed conductor.

Both end side of contact pad on FPC can not be used for signal transmission.

Unit: mm

Part number

HRS No.

Number of contacts

C

G

H

FH53-21S-0.2SHW(**)

−

21

4

5.5

4.51

FH53-31S-0.2SHW(**)

FH53-41S-0.2SHW(**)

−

580-3401-7 **

31

41

6

8

7.5

9.5

6.51

8.51

FH53-51S-0.2SHW(**)

−

51

10

11.5

10.51

FPC部材構成

(FREE)

FPC Contruction Recommended Specifications

MATERIAL NAME

Cover film layer.

MATERIAL

polyimide

THICKNESS (µm)

25

1mil

25

Cover adhesive

Surface treatment

1µm to 6 µm nickel under plated

0.2 µm gold plated

Copper foil

Cu

(4)

1/3oz

Base adhesive

Heat-hardened adhesive

Base film

Polyimide

12

No adhesion material

1mil

Reinforcement material adhesive Heat-hardened adhesive

30

Stiffeder

50

Polyimide

2mil

Precautions

1. This specification is recommendation for the construction of the FH53 series FPC (t=0.12±0.02)

2. For details about the construction, please contact FPC manufactures.

4

25

1.75±0.1

Packaging Specifications

CL

OEmbossed Carrier Tape Dimensions

(Ø1

3)

Direction of unreeling

8±0.1

4±0.1

(2)

CL

リール状態寸法図

(FREE)

(Ø1

3)

(M: Reel inner width)

L±0.1

Direction of unreeling

(Ø380)

(Ø80)

J±0.2

(N: Reel outer width)

OLリeader,

Trailer Dimensions

ーダ部、

トレーラ部寸法図

(FREE)

400

mmMIN

(N: Reel

outer(Leader)

width)

Direction of unreeling

リーダ部、

トレーラ部寸法図

(FREE)

400 mmMIN (Leader)

Direction of unreeling

160 mmMIN

(trailer, empty components)

Embossed Carrier Tape

100 mmMIN

(empty components)

Top cover tape

リーダ部、

トレーラ部寸法図

(FREE)

160 mmMIN

(trailer, empty components)

Embossed Carrier Tape

100 mmMIN(Leader)

400 mmMIN

(empty components)

Top ofcover

tape

Direction

unreeling

Unit: mm

Part number

HRS No.

Number of contacts

J

FH53-21S-0.2SHW(**)

−

21

FH53-31S-0.2SHW(**)

−

Embossed Carrier Tape

FH53-41S-0.2SHW(**)

580-3401-7

**

160 mmMIN

100 mmMIN

(trailer, empty components)

FH53-51S-0.2SHW(**)

31

Top cover tape

41

(empty

− components)

51

Temperature Profile

MAX 250ç

250

230ç

Temperature

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

(M: Reel inner width)

Direction of unreeling

J±0.2

φ

1. +

5 0

0 .1

1.75±0.1

L±0.1

(1.25)

(0.3)

1.75±0.1

ール状態寸法図

(FREE)

OReel リ

Dimensions

コネクタ収納状態図

(5

:

1)

L±0.1

8±0.1

4±0.1

(2)

φ

1. +

5 0

0 .1

J±0.2

(1.25)

(0.3)

リール状態寸法

(Ø380)

(Ø80)

コネクタ収納状態図

(5

:

1)

Direction of unreeling

8±0.1

φ

1. +

4±0.1

5 0

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height,

Top

(2) Contact, Back Flip FPC Connector

0 .1

CL

Direction of unreeling

(1.25)

(0.3)

200

200ç

150

150ç

(ç)

L

M

N

16

7.5

17.4

21.4

24

24

11.5

11.5

25.4

25.4

29.4

29.4

24

11.5

25.4

29.4

Applicable Conditions

Reflow method

: IR/Hot air

Reflow environment : Room air

Solder

: Paste type Sn/3.0Ag/0.5Cu

(M705-GRN360-K2-V made by

Senju Metal Industry Co.)

Test PCB

: PCB material and size

Glass epoxy 25×50×0.8 mm

Land size 0.2×0.65, 0.2×0.65 mm

Stencil

: Thickness 0.1 mm

Opening size 0.18×0.47, 0.18×0.44 mm

100

50

25ç

0

(60 sec.)

90 to 120 seconds

Preheating time

Start

(60 sec.)

Soldering Time

This temperature profiles are based on the above

conditions.

It may vary depending on solder paste type,

manufacturer, PCB size and mounting materials.

Please use only after checking the mounting

conditions.

Time (sec)

5

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

Operation Methods of Connectors and Precautions

Operation Methods

This connector features small, thin and back flip design, requiring delicate and careful handling.

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

1. Initial condition

qActuator does not have to be operated before inserting

FPC, as the connector is delivered with the actuator

opened.

[Caution]

•Do not close the actuator before inserting FPC.

Closing the actuator without FPC could make the

contact gap smaller, which could increase the FPC

insertion force.

The actuator is in open state when embossed delivery.

2. How to insert FPC

qThis connector has contacts on the top. Insert the FPC with the exposed conductors face up.

[Caution]

•Insert the FPC with the actuator opened.

•Do not twist the FPC to up and down, right and left or an angle.

(It may cause a deformity of contact and contact failure.)

Conductor surface

Actuator (Close)

Actuator (Open)

FPC

FPC

PCB

PCB

_ Correct Operation _

_ Incorrect Operation _

3. FPC insertion check

Chucking metals guide the FPC tabs to the correct position.

Make sure that the FPC tabs are located in proper position as shown in the figure below after FPC insertion.

Incomplete FPC insertion

NG

Through the FPC cutout, PCB is visible

6

Correct FPC insertion

FPC cutout

OK

The FPC cutout is hidden by

the connector housing and

PCB is not visible from the cutout

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

Operation Methods

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

4. How to lock

qApply load to rotate the actuator by 90 degree after inserting the FPC.

•Operate the actuator by hand without using sharp tool such as Tweezers.

•To close the actuator, operate at the center of the actuator.

•To close the actuator, do not operate the actuator at one end only.

•Do not apply excess force to the housing during the operation.

Rotate

Close the actuator at the center

Do not apply excess force to the

housing during the operation

Do not operate the actuator

at one end only

5. How to remove FPC (How to unlock FPC)

qSlowly flip up the actuator to release the lock. After rotating the actuator to the fully opened position

carefully withdraw the FPC.

wTo open the actuator, operate at the center of the actuator.

(Do not lift up only one side of the actuator. The actuator can be twisted causing damage.)

*The actuator is opened up to the movable limit 90 degree.

Do not open the actuator beyond the specified degree or apply excess force to the actuator.

Rotate

Open the actuator at the center

Do not apply force to the direction as shown in the

figure and / or try to open more than 90°

Do not operate the actuator

at one end only

*This connector utilizes a back flip system; the actuator is placed on the side opposite of the FPC insertion

opening. Do not attempt to open the actuator from the FPC insertion side.

7

FH53 SeriesO0.2 mm Pitch, 0.65 mm Height, Top Contact, Back Flip FPC Connector

Operation Methods

Oct.1.2016 Copyright 2016 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

6. FPC routing after connection

qDepending on a FPC rounding, a load is applied to connector, and a contact failure may occur.

To prevent a failure, take the following notes into a consideration during mechanism design.

[Caution]

•Make sure that FPC and stiffener do not contact chassis.

•Avoid applying forces to FPC in vertical or horizontal directions.

In addition, avoid pulling up and down on the FPC.

•When fixing FPC after FPC cabling, avoid pulling FPC, and route the wire FPC with slack.

FPC

In this regard, the stiffener is parallel to the PCB.

•Do not mount other components touching to the FPC underneath the FPC stiffener. Stiffener

FPC

FPC

Powered by TCPDF (www.tcpdf.org)

PCB

FPC

Stiffener

Stiffener

Stiffener

Stiffener

FPC

FPC

Stiffener

FPC

FPC

Component part

PCB

PCB

PCB

PCB

PCB

Stiffener

Stiffener

FPC

FPC

PCB

PCB

FPC

Stiffener

FPC

Stiffener Stiffener

Component part

Component part

Component part

PCB

PCB

PCB

Cautions when Mounting PCB

SWarp of PCB

Minimize warp of the PCB as much as possible.

Lead co-planarity including reinforced metals is 0.1 mm or less.

Too much wrap of the PCB may result in a soldering failure.

SFlexible board design

Please make sure to put a stiffener on the backside of the flexible board.

We recommend a glass epoxy material with the thickness of 0.3 mm MIN.

SLoad to Connector

Do not add 0.5N or greater external force when unreel or pick and place the connector etc,

or it may get broken.

In addition, do not insert the FPC or operate the connector before mounting.

SLoad to PCB

•Splitting a large PCB into several pieces

•Screwing the PCB

Avoid the handling described above so that no force is

exerted on the PCB during the assembly process.

Otherwise, the connector may become defective.

Connector

FPC

(For connector mounting)

SInstructions on manuel soldering

Follow the instructions shown below when soldering the

connector manually during repair work, etc.

qDo not perform manual soldering with the FPC inserted into the connector.

wDo not heat the connector excessively. Be very careful not to let the soldering iron contact any parts other

than connector leads. Otherwise, the connector may be deformed or melt.

eDo not supply excessive solder (or flux).

If excessive solder (or flux) is supplied on the terminals, solder or flux may adhere to the contacts or

rotating parts of the actuator, resulting in poor contact or a rotation failure of the actuator.

Supplying excessive solder to the chucking metals may hinder actuator rotation, resulting in breakage of

the connector.

8

The contents of this catalog are current as of date of 8/2014. Contents are subject to change without notice for the purpose of improvements.