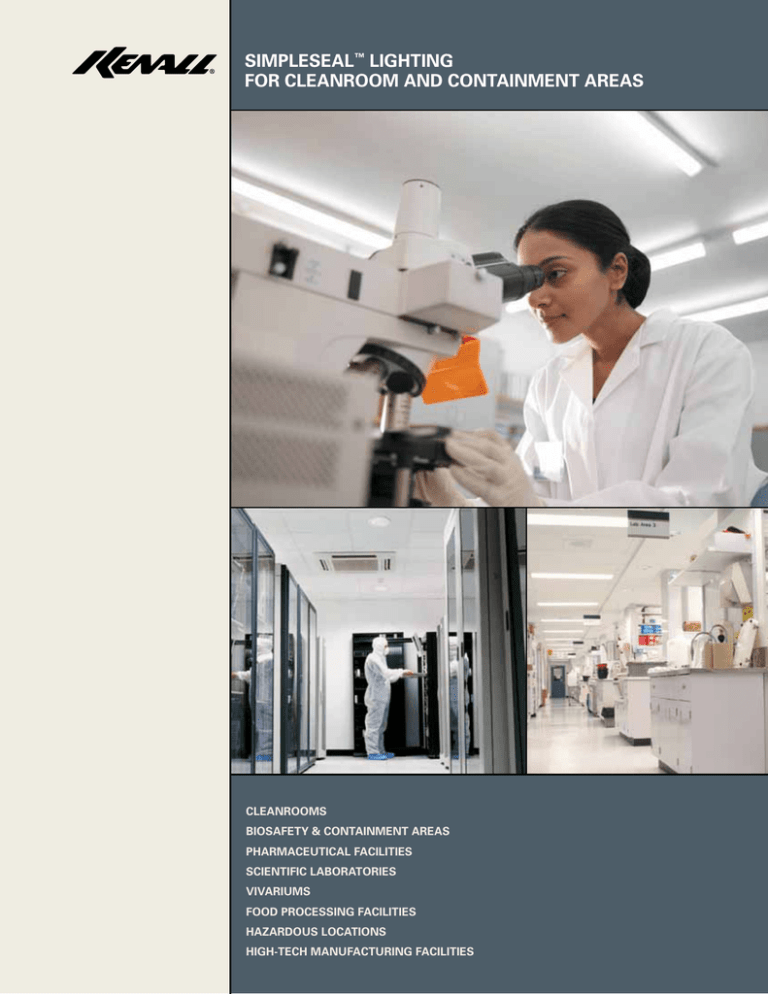

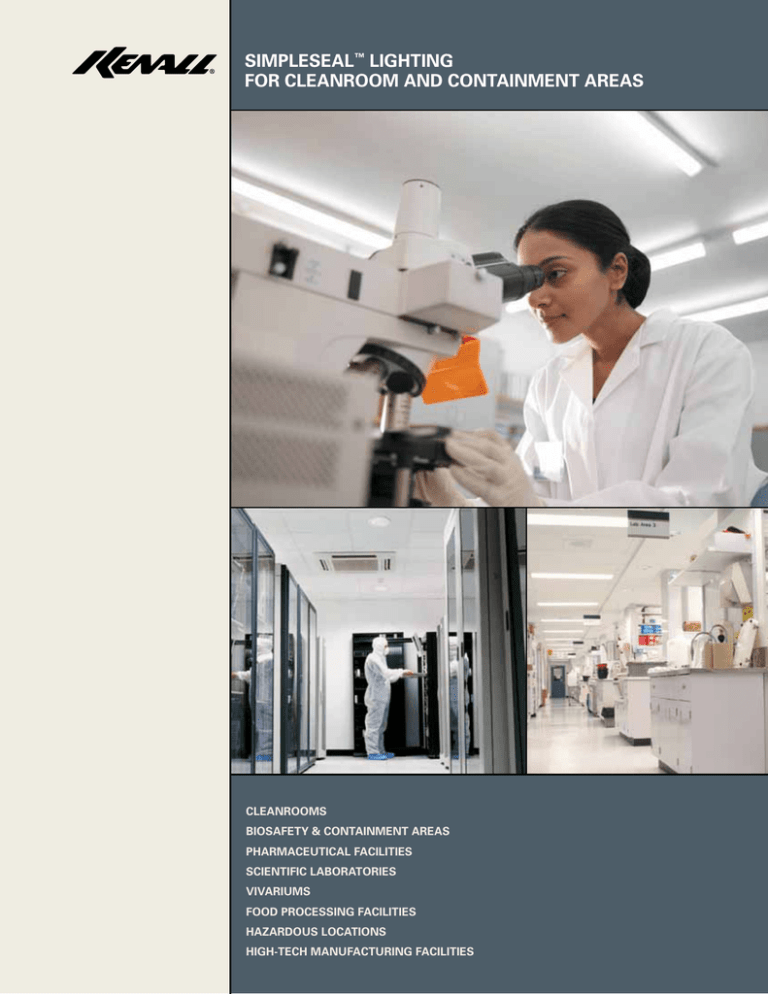

SIMPLESEAL™ LIGHTING

for cleanroom and containment areas

CLEANROOMs

BIOSAFETY & CONTAINMENT AREAS

PHARMACEUTICAL FACILITIES

SCIENTIFIC LABORATORIES

VIVARIUMS

FOOD PROCESSING FACILITIES

HAZARDOUS LOCATIONS

HIGH-TECH MANUFACTURING FACILITIES

Letter from the President

For over 20 years, Kenall has

developed industry-leading

expertise in Sealed Enclosure

lighting fixtures. Meeting the

needs of these specialized

installations, our luminaires

are designed to maintain the

particulate and contaminate

requirements of cleanroom and

containment areas while being

easy to install and inexpensive

to maintain. These critical

spaces require fixtures capable of satisfying a wide

range of demanding environmental and safety criteria,

while producing effective and efficient illumination with

superior optical and energy performance.

TABLE OF CONTENTS

SEALED ENCLOSURE LIGHTING BASICS .............................. 3

WHAT’S NEW.......................................................................... 5

SEALED ENCLOSURE LUMINAIRES

Our new Architectural Cleanroom Series creates

comfortable visual environments from attractive,

architecturally inspired fixtures, while our new

Overlapping Door Series now has an independently

verified total luminaire efficiency of over 83%!

We’ve also taken the most popular lighting fixture

styles, from wraparounds and downlights to exit signs,

and tailored them to meet or exceed the performance

requirements of even the most critical applications,

from hazardous locations, bio-safety labs and food

processing facilities to cleanrooms, research labs and

bio-containment areas. Examples include our new

EnviroSeal™ surface-mounted linear family that provides

high vertical footcandle levels while easily withstanding

the harshest cleaning protocols. We’re also introducing

the first sealed downlights and recessed cleanroom exit

signs in the industry. These innovative products have

been designed to meet all appropriate standards and

are certified to deliver the performance specifiers and

customers demand.

After all, we’ve been dedicated to your complete

satisfaction for environmentally challenging and critical

applications for over 40 years.

Extended Flange Series ............................ 20

This brochure provides an overview of our Sealed

Enclosure luminaires and a number of associated

supplementary lighting products. Included are Kenall’s

newest offerings with important new features and

performance benefits.

Whether your project requires luminaires that can

withstand the most rigorous cleaning protocols (NSF2

Splash Zone) or corrosive conditions, maintain critical

environmental barriers (UL/CUL IP65 and K230), or that

illuminate surgical suites or research areas without

interfering with sensitive electrical devices (MIL-STD461F – Air Force/Navy Fixed), you can trust Kenall to help

you reliably protect people, products and processes.

Overlapping Door Series ........................... 10

Inset Door Series ...................................... 28

Architectural Ambient Cleanroom Series.... 40

Research RFI Series.................................. 44

EnviroSeal™

Linear Fluorescent Series ......................... 48

Sealed Downlight Series............................ 52

Exit Signs................................................... 58

LISTINGS & CERTIFICATIONS:

Hosedown Ratings & Their Relation to IP Ratings................. 62

Ingress Protection Ratings..................................................... 63

National Sanitation Foundation NSF2 .................................... 64

Federal Standard 209E/Class 100........................................... 65

Hazardous Location Temperature Ratings ........................ 66-67

James Hawkins, President

Kenall K230 Standard ............................................................. 68

Kenall Manufacturing

EMI Testing/MIL-STD-461F.................................................... 69

www.kenall.com

2

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

Sealed Enclosure Lighting Basics

What is a Sealed Lighting

Enclosure?

A sealed lighting fixture enclosure is

designed to separate its internal lighting

components from the surrounding

environment. One reason for this

separation is to protect the fixture’s

internal components from environmental

dirt, dust, moisture and other

performance-inhibiting elements.

A second, and in some cases critical,

reason is to protect the environment

from heat, sparking, arcing, dirt, dust,

contaminants, moisture, air pressure

leakage, Electromagnetic Interference

(EMI) and other conditions or events that

could adversely affect the safety of the

people or the integrity of the processes

being performed.

Overlapping Door Series

What are the Performance

Requirements of a Sealed

Lighting Enclosure?

There are four major challenges

to creating an effective sealed

lighting enclosure:

1.A housing that does not leak.

2.A doorframe that does not leak.

3.A doorframe-to-ceiling/housing

interface for recessed fixtures

that does not leak.

4.A housing-to-ceiling interface

that does not leak.

By reviewing the performance criteria,

design, listings, and certifications of

each SimpleSeal™ fixture, you will see

how Kenall has satisfied each of the

performance requirements listed above.

In addition to the leakage criteria, it is

critical that lighting equipment used in

research environments prevent EMI

emissions from interfering with the

performance of sensitive electronic

equipment.

EXTENDED FLANGE SERIES

Inset Door Series

The Overlapping Door Series is

designed for applications with the

highest cleanliness standards and most

stringent cleaning protocols, including

those that may involve caustic chemicals

and extreme abrasion.

The Extended Flange Series is designed

to prevent leakage between the fixture

and an imperfect ceiling through a

one-piece doorframe that mates to a

housing flange of similar material,

creating a predictable sealed surface.

The Overlapping Door Series is

comprised of a one-piece, seam-welded

hole-free housing, a one-piece doorframe

and a one-piece doorframe-to-housing

gasket. The doorframe’s fulcrum bracket

provides even, positive retention to the

ceiling surface.

The Extended Flange Series is comprised

of a one-piece, seam-welded housing,

a housing flange that is sealed to the

housing, and a one-piece housing-todoorframe gasket. The doorframe uses

a fulcrum repositioning leg for even,

positive retention.

These easy-to-clean fixtures are UL

certified IP65 for ingress protection and

have been tested for both positively and

negatively pressurized environments.

This ensures protection against

particulate contamination and the

integrity of pressurized plenums.

These easy-to-clean fixtures are UL

certified IP65 for ingress protection

and have been tested for both positively

and negatively pressurized environments.

This ensures protection against

particulate contamination and the

integrity of pressurized plenums.

www.kenall.com

P: 847-360-8200

The Inset Door Series is also designed for

applications with the highest cleanliness

standards, but with cleaning protocols

that do not involve caustic chemicals or

extreme abrasion.

The Inset Door Series is comprised of

a one-piece, seam-welded, hole-free

housing, a one-piece housing flange and

an inset doorframe.

The series offers an optional piano hinged

door that facilitates fixture maintenance in

less critical areas within the facility, such

as packaging or staging areas.

These easy-to-clean fixtures are UL

certified IP65 for ingress protection and

have been tested for both positively and

negatively pressurized environments. This

ensures protection against particulate

contamination and the integrity of

pressurized plenums.

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

3

SimpleSeal™ Application Universe

Cleanroom & Containment

Hazardous Locations

Luminaires used in cleanroom and containment areas must be

able to maintain their seal and withstand either negatively or

positively pressured environments. They must also be able to

stand up to some of the harshest, abrasive cleaning protocols.

Examples of these applications include biotechnology, research

labs, pharmaceutical research and development, vivariums and

biosafety labs. They must:

Luminaires used in Hazardous Location applications must

operate safely where environmental conditions and/or materials

exist that may cause personal injury or damage to facilities:

•

Resist leakage, from the room or the plenum, into the light

fixture (IP65 classification within IEC 60598).

•

Easily cleanable, manufactured with toxin-free materials

and corrosion resistant to minimize surface contamination

(NSF2 Splash Zone).

Resist leakage, from the room or the plenum, into the light fixture (IP65 classification within IEC 60598).

• The luminaire must be a hermetically sealed enclosure and

meet specific wiring methods and construction

requirements to prevent arching or sparking that could

ignite combustible gases (National Electric Code –

Class I-Div. 2) or combustible dust (National Electric Code –

Class II-Div. 2)

•

The operating temperature of any heat-producing component must be lower than the ignition temperature

of the hazardous material present.

Environmental Locations

Food Processing

Environmental applications, such as pharmaceutical research

facility corridors and gowning areas or hosedown applications,

call for slightly less performance criteria than traditional

cleanroom applications. Luminaires used in these applications

must still provide a superior level of environmental control

and cleanability. These luminaires are also ideal for corrosive

areas where fixture material selection and sealing are critical:

Food processing facilities require lighting fixtures that can

withstand rigorous cleaning protocols, contain no toxic

materials, and are highly resistant to corrosion:

•

Luminaires must prevent bacteria or other contaminants from compromising the area’s environmental integrity (IP65 classification within IEC 60598).

•

Resist leakage, from the room or the plenum, into the

lightfixture (IP65 classification within IEC 60598)

•

Fixtures will be free from gaps or holes that compromise comprehensive cleaning (NSF2 Food Zone and

Splash Zone)

•

Easily cleanable, manufactured with toxin-free materials

and corrosion resistant to minimize surface contamination

(NSF2 Splash Zone).

•

The fixture will be free of material toxicity and will be corrosion resistant (NSF2 Food Zone and Splash Zone)

•

Corrosion resistant components with choice of 304

and 316 stainless steel.

www.kenall.com

4

•

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

What’s New in Sealed Enclosure Lighting

SimpleSeal™ sealed Flush Lens Downlight

(pages 52-53)

Envela™ sealed regressed Lens Downlight

(pages 54-55)

A downlight suitable for effective and safe use in critical

applications where leakage, ease of cleanability and

electromagnetic interference are important concerns, has

long been requested by the specification community.

The high-performance LED Regressed Lens Downlight

Series features an optical system design that provides

exceptional performance, energy savings and serviceability.

This product is ideal for less critical environments, such as

administrative, packaging and staging areas, corridors and

other non-pressurized applications where aesthetics and

optical efficiencies are more important.

Kenall’s CDL Series successfully addresses these issues and

more. This lensed downlight features a completely sealed,

enclosed housing and a fully gasketed, overlapping trim ring.

A symmetric distribution pattern is available in either vertical

or horizontal compact fluorescent, incandescent, HID or

LED configurations. The 30-watt LED system provides 1285

lumen output with only 29.4-watts of consumed power at

44 lumens per watt and achieves a 1.1 s/mh.

The CDL Series is UL certified IP65 in compliance with

IEC60598 for dust- and water-tight assurance. These

luminaires have been tested to pressured plenum standards,

meet FED-STD-209E Class 100 (ISO 5 for protection from

plenum-based contaminants) and are NSF2 Food Zone/

Non-Contact Splash Zone listed to stand up to the most

rigorous cleaning protocols. Optionally available EMI

protection meets the stringent requirements of

MIL-STD-461F.

The fixture provides 1850 lumens from its 26-watt LED

source, available in either 3000K or 4000K, and achieves

a 1.4 s/mh. The Sealed Regressed Lens Downlight has an

equivalent light output to a 32-watt CFL, which results in

a 64 lumen per watt luminaire that is ideal for a wide range

of sealed environments.

The MRDL Regressed Lens Downlight is UL certified IP64

in compliance with IEC60598 for dust- and water-tight

assurance. It is also NSF2 Splash and Non-Food Zone listed

for corrosion resistance, cleanability and will not introduce

toxicity into the environment.

Optionally available EMI protection meets the stringent

requirements of MIL-STD-461F.

EnviroSeal™ Linear Fluorescent Series

(pages 48-49)

Kenall’s EnviroSeal linear fluorescent wraparounds are

designed for environmental performance in a variety of

applications. The family includes Environmental, Food

Processing and Hazardous Location versions.

Constructed of one-piece 20-gauge seam-welded, stainless

or cold-rolled steel housings and extruded UV-resistant

polycarbonate or acrylic lenses with internal prisms and

smooth exteriors, EnviroSeal is built to withstand extreme

cleaning protocols. A unique, slide-in-place and lock lens

makes installation and maintenance quick and easy.

The Environmental (ES), Food Processing (FES) and

Hazardous (HES) Series are offered in 2', 3', 4', 6' and 8'

(tandem) lengths, and four widths for virtually any application:

•

•

•

•

3" wide – one lamp

5" wide – one or two lamps

8" wide – two lamps

12" wide – two, three or four lamps

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

5

What’s New in Sealed Enclosure Lighting

revit files available

Revit file downloads are available for Kenall’s SimpleSeal™,

EnviroSeal™, Sealed Downlights and Sealed Exit Signs at

www.kenall.com. Users can easily import the datacompressed .zip file into their workstation for use with their

lighting layout programs. Revit files allow the specifier to

identify location interference in plenum spaces, create fixture

schedules and access data on luminaire lamp type, ballast

type and voltage. The files also contain hyperlinks to the

product’s online specification sheet.

SPECINSTALLATION IES

SHEET

INSTRUCTIONS

DATA

REVIT

Top access – fluorescent and hid

(page 12)

Kenall’s Cleanroom fixtures are available with top access

for convenience in applications with walkable ceilings,

providing convenient access to the fixture interior for

easier maintenance. The top access products are sealed

against dust and particulates entering the fixture as well

as preventing contaminants from escaping the room. The

fixtures are customizable to virtually any manufacturer’s

ceiling system.

Fluorescent Top Access

HID Top Access

HERMETICALLY SEALED WIRING

Maintaining the integrity of a clean environment includes

preventing the leakage of contaminants from the plenum

into the fixture. Kenall’s hermetically sealed wiring option

increases leakage protection into the fixture by keeping

contaminants from entering the room during relamping or

maintenance procedures.

www.kenall.com

6

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

What’s New in Sealed Enclosure Lighting

SimpleSeal™ ARCHITECTURAL AMbient Cleanroom Series

(pages 40-41)

The new Architectural Ambient Cleanroom Inset Door Series

is ideal for general illumination in areas requiring less stringent

performance specifications and where aesthetics are important.

These sealed luminaires provide an alternative, architectural look

in areas ranging from corridors to research labs.

Available in four styles, the CSEA Series features

IEC60598 IP65 classification for ingress protection against dust

and moisture. These versatile luminaires also meet

pressurized plenum standards and FED-STD-209E/Class100

(ISO 5) Cleanrooms.

CSEAI Center perforated basket with acrylic overlay

CSEAI Dual side perforated baskets with acrylic overlay

CSEA3I Combination perforated basket and acrylic lens

CSEA4I Combination center and dual side lenses

High Efficiency Reflector Systems

(page 13)

Kenall’s already highly efficient Overlapping Door Series has

been enhanced with an optional reflector system that increases

luminaire efficiency to over 83%. The specular aluminum

reflector option is available on 1'× 4' and 2'× 4' flange-mount

fixtures and is ideal for applications where additional output or

better energy utilization is required, such as manufacturing and

assembly areas. OVERLAPPING DOOR Efficiency RATINGS

Size

1'×4' 2'×4' 2'×4' 2'×4' Lamp Quantity

2

2

3

4

Lamp Type

F32T8

F32T8

F32T8

F32T8

Efficiency Ratings

83.4%

85.3%

85.2%

83.5%

High Efficiency Reflector

Standard Swing-Out Mounting Brackets

Our recessed flange luminaires not only provide industry-leading

environmental protection and performance, but are now easier

than ever to install with standard swing-out mounting brackets.

These brackets replace traditional yoke-mount assemblies,

standard on competitive versions, and take significantly less

time to install, resulting in substantial labor cost savings. The

swing-out brackets also maintain greater fixture stability and

can be adjusted from within the fixture after installation to

maintain the integrity of the sealed room.

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

7

What’s New in Sealed Enclosure Lighting

SimpleSeal™ Recessed Exit Sign

(page 58)

The recessed SimpleSeal Exit Sign (CMEXR) resists leakage

and surface contamination more effectively than any other

exit sign on the market. Designed specifically for cleanroom,

containment and associated areas, it features a one-piece

overlapping doorframe with flush-mounted stainless steel

fasteners, a one-piece, seam welded cold-rolled steel housing

and one-piece lens. The bright face is evenly illuminated in

either green or red LEDs that are under-driven to provide

longer source life. The CMEXR is NSF2 Splash Zone listed,

UL certified IP65 in compliance with IEC 60598, meets

pressurized plenum standards and FED-STD-209E/Class 100

(ISO 5) Cleanrooms.

hazardous LOCATION SEALED ENCLOSURES

Kenall’s SimpleSeal Hazardous Series and the EnviroSeal™

HES Series are ideal for applications where storage of

chemicals and presence of dust and other volatile materials

can pose a danger of combustion.

In conjunction with the outstanding fixture performance in

a sealed environment, these luminaires meet the rigorous

requirements of the standard Hazardous Location Listing.

Both the Inset Door and Overlapping Door Series are Class I

Division 2, Groups A, B, C, D listed. The Overlapping

Door Series carries the additional listing of Class II

Division 2, Groups F, G (and Simultaneous Presence);

and Class III listings.

Kenall’s hazardous location products have the highest

Temperature Ratings (T-Ratings) amongst other fixtures

available of its type.

To ensure the SimpleSeal or EnviroSeal luminaire selected

will run cooler than the ignition temperature of the

surrounding atmosphere or material stored in a hazardous

location, please refer to the T-Rating charts published on

page 66-67.

SimpleSeal EXTENDED FLANGE Series:

The Perfect SOLUTION FOR IMPERFECT CEILINGS

(pages 24-25)

When there is a concern about an imperfect ceiling plane

affecting proper fixture installation, Kenall’s Extended Flange

series prevents leakage between fixture and ceiling. It

employs a doorframe that mates to the housing flange of

similar material to create a predictable sealed surface.

The doorframe/housing flange is available in cold-rolled

steel, extruded aluminum or stainless steel. Retractable

lanyards have been added to hinge the doorframe for easier

maintenance. Captive fasteners with sealing washers secure

the door to the housing. www.kenall.com

8

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

9

SimpleSeal™ OVERLAPPING DOOR SERIES

Linear Fluorescent

The Overlapping Door Series is designed for applications with the highest

cleanliness standards and most stringent cleaning protocols, including those

that may involve caustic chemicals and extreme abrasion.

These easy-to-clean fixtures meet IP65 Ingress Protection and pressurized plenum

standards, ensuring both protection against particulate contamination and the

integrity of pressurized plenums. The doorframe uses a fulcrum bracket for even,

positive retention to the ceiling surface.

4

2

3

1

8

5

2

ONE-PIECE Doorframe

Robotically TIG Welded

Eliminates inherent weakness of

lapped and spot-welded

construction.

Available in cold-rolled steel,

painted aluminum or stainless

steel (304 or 316).

Compression Set

PEM Studs

Subassemblies and electrical

components can be secured to

housing without compromising its

air-tight integrity.

3

Sealed Swing-Out Arms

Recessed flange housing can be

installed in ceilings more quickly

and securely.

4

Optional Hermetically Sealed

Wireway

Maintains seal integrity from

plenum and eliminates need

for caulk.

ONE-PIECE Doorframe GASKET

5

Frame with 60°

Beveled Edge

Assures protection against harsh

cleaning protocols. 60° beveled

edge is easier to clean than a

standard 90° return.

6

Patented Fulcrum

Repositioning Bracket

Reverse doorframe bowing to

assure consistent contact with

ceiling surface. Doorframe and

gasket mate to ceiling structure,

eliminating the need for caulk.

7

www.kenall.com

10

10

7

6

One-Piece Housing

1

9

8

Extruded Closed Cell

Customized shape with

continuous skin. No open cell

pockets to collect particulates

as in die-cut strip gaskets.

9

Vulcanized Corners

Sealed at corners.

No leakage.

10

Mechanically Secured to

Doorframe

Precise, secure and permanent

positioning of gasket.

Flush Mounted Fasteners

Stainless steel fasteners with

Teflon bushings ensures air-tight

integrity of the fixture and

provides ease of cleanability.

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

STANDARDS & CERTIFICATIONS

Product Offerings

Installation

Housing

Type

Size

Cleanroom & Containment

Standard Luminaire

Surface

1'×4', 2'×2', 2'×4'

Grid

1'×4', 2'×2', 2'×4'

300mm×1200mm

600mm×600mm

600mm×1200mm

Flange

1'×4', 2'×2', 2'×4'

Low Profile Housing

Surface

1'×4', 2'×4'

Grid

1'×4', 2'×4'

300mm×1200mm

600mm×1200mm

Gasket Wrapped Doorframe

Flange

1'×4', 2'×4'

HEPA Flow-Thru

Grid

2'×4'

Gel T-Bar

Grid

2'×4'

300mm×1200mm

600mm×1200mm

Other

Corner

8"×48"

Teardrop

2', 3', 4', 8' Hazardous Location

Surface 1'×4', 2'×2', 2×4'

Grid 1'×4', 2'×2', 2'×4'

Flange

1'×4', 2'×2', 2'×4'

Corner 8"×48" Lamp

Type

Series

Prefix

Linear

Linear

CSESO

CSEGO

Linear

Linear

Linear CSEFO

CSESOL

CSEGOL

This series is ideal for applications requiring stainless steel

one-piece overlapping doorframe design. In addition, it meets the

following performance requirements:

Defined Performance

Standard Criteria

Testing

Facility

Water Jet Protection IEC 60598/IP65 UL 62-63

Dust-Tight IEC 60598/IP65 UL 62-63

No Toxicity NSF2 NSF 64

64

No Corrosion NSF2

NSF Easy to Clean NSF2 NSF 64

No Pressurized Leaks

K230

CRS

68

Flammable Gases/Vapors Present

Class I, Division 2 UL 62-63

Combustible Dust Present

Class II, Division 2 UL 62-63

Class III UL

62-63

Fed Std 209E, Class100

CRS

65

IES

ITL

Easily Ignitable Fibers Present

Linear

CSEFBO

Linear

CSEG24FT

Linear

CSEGO24G

Linear

Linear

CSECO

CSESTD

Linear

Linear

Linear

Linear

HSESO

HSEGO

HSEFO

HSECO

Reference

Page No.

Cleanliness Compatibility Efficiency

IP65

K230

HAZ

ISO 5

Class 100

CCEA

Approved

Recommended Applications

Cleanroom & Containment

•Laboratories

•Manufacturing Areas

•Semiconductor/Electronic/

Optics Assembly Areas

• Vivariums

• Pharmaceutical

• Research and Development Labs

• Biosafety

• Storage Facilities

• Packaging

• Anterooms

Hazardous Locations

•Laboratories

•Manufacturing Areas

•Processing Areas

•Storage and Dispensing Facilities

•Spray Finishing Areas

•Fuel Servicing Areas

www.kenall.com

Food Processing

•Research & Development Labs

•Food Processing

•Packaging Areas

•Storage Facilities

•Corridors

• Commercial Kitchens

(with FN option)

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

11

SimpleSeal™ OVERLAPPING DOOR SERIES

Top Access

Kenall’s Cleanroom and Hazardous Overlapping fixtures are available with a top

access option, providing convenient and easier maintenance in applications with

walkable ceilings. Kenall’s Top Access Overlapping Door luminaires are sealed

against dust and particulates from entering the fixture while preventing contaminants

from escaping the room. These fixtures are available in both linear fluorescent and

HID lamp sources.

1

4

2

3

1

Fabricated 16-gauge cold-rolled

steel with multiple returns for

strength. Doorframe is fully

sealed to housing with gasketing

to prevent leakage from plenum

into fixture.

2

Stainless steel rotary-action

latches; no tools required

for servicing.

3

TOP ACCESS HOUSING Product Offerings

Installation

Type

Housing

Size

Lamp

Type

Series

Prefix

Grid

2'×2'

Linear

CSEGRO22

Grid

2'×4'

Linear

CSEGRO24

Grid

2'×2'

HID

CSEGRO2424

Flange

1'×4'

Linear

CSEFRO14

Flange

2'×2'

Linear

CSEFRO22

Flange

2'×4'

Linear

CSEFRO24

Flange

2'×2'

HID

CSEFRO2424

One-piece doorframe provides

air-tight integrity of fixture.

Flanged and Grid fixtures are

accessible from both top access

and room side.

4

Continuous piano hinge enables

ease of handling and servicing.

Top Access – linear fluorescent and HID

Cleanroom & Containment

www.kenall.com

12

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

SimpleSeal™ OVERLAPPING DOOR SERIES

High Efficiency Reflector

Kenall’s already highly efficient Overlapping Door Flange Mount Series is

improved to over 83% when specified with the high efficiency reflector system.

The specular aluminum reflector is available on 1'× 4' and 2'×4' fixtures.

High performance specular aluminum reflector system with 95% reflectivity

HIGH EFFICIENCY REFLECTOR PRODUCT OFFERINGS

Installation

Type

Housing

Size

Lamp

Type

Series

Prefix

Luminaire

Efficiency

Flange

1'×4'

(2) F32T8

CSEFO14P232

83.4%

Flange

2'×4'

(2) F32T8

CSEFO24P232

85.3%

Flange

2'×4'

(3) F32T8

CSEFO24P332

85.2%

Flange

2'×4'

(4) F32T8

CSEFO24P432

83.5%

Cleanroom & Containment

ZONAL LUMEN SUMMARY

90˚

90°

75˚

75°

600

60˚

60°

1200

45˚

45°

1800

0˚

15˚

30˚

0°15°30°

LEGEND:

0-deg:

45-deg:

Legend

0-deg: 90-deg:

Legend 45-deg:

Legend 90-deg: ZONE LUMENS %LAMP%FIXTURE

0-30 1402

23.8 27.9

0-40 2301

39.0 45.7

0-60 4033

68.4 80.1

0-90 5033

85.3 100.0

90-180

0

0.0

0.0

0-180 5033

85.3 100.0

TOTAL LUMINAIRE EFFICIENCY = 85.3%

Test Report #ITL62999

Luminaire #CSEFO24P232

Lamp Type: F032/835 linear fluorescent

Total Input Watts: 54.9

Rated Lamp Lumens: 2950

www.kenall.com

SimpleSeal Overlapping luminaires with high efficiency

reflectors are ideal where additional light output is required,

such as manufacturing and assembly areas.

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

13

SimpleSeal™ OVERLAPPING DOOR SERIES Linear Fluorescent Lamp Options

Cleanroom & Containment

Lamp Type

Nominal Size 1'× 4' 1'× 4'

MountingSurfaceGrid

Series

CSESO14 CSEGO14

1'× 4'

Flange

CSEFO14

2'×2'

2'×2'

Surface Grid

CSESO22

CSEGO22

2'×2'

Flange

CSEFO22

2'×4'

2'×4'

2'× 4'

SurfaceGrid Flange

CSESO24

CSEGO24

CSEFO24

F17T8

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F31T8-1.625" U

2 or 3

2 or 3

2 or 3

F32T8

1, 2 or 3

1, 2 or 3

1, 2 or 3

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F40TT Biax

2, 3 or 4

2, 3 or 4

2, 3 or 4

F50TT Biax

2, 3 or 4

2, 3 or 4

2, 3 or 4

F48T8HO

1 or 2

1 or 2

1 or 2

2, 3 or 4

2, 3 or 4

2, 3 or 4

2F54T5HO

1 or 2

1 or 2

1 or 2

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

Top Access

Lamp Type

Nominal Size

Mounting

Series

1'× 4'

Flange

CSEFRO14

2'×2'

Grid CSEGRO22

2'×2'

Flange

CSEFRO22

F17T8

2, 3, 4 or 6

2, 3, 4 or 6

F31T8-1.625"U

2 or 3

2 or 3

F32T8

1, 2 or 3

2, 3, 4 or 6

2, 3, 4 or 6

F40TT Biax

2, 3 or 4

2, 3 or 4

F50TT Biax

2, 3 or 4

2, 3 or 4

F48T8HO

1 or 2

2, 3 or 4

2, 3 or 4

F54T5HO

1 or 2

2, 3 or 4

2, 3 or 4

Low Profile/

High Efficiency

Lamp Type

Nominal Size 1'× 4'

1'× 4'

MountingSurfaceGrid

Feature Low Profile Low Profile

Series

CSESOL14 CSEGOL14 1'× 4' Flange

High Eff.

CSEFO14P 2'×4'

2'×4'

SurfaceGrid

Low Profile Low Profile

CSESOL24

CSEGOL24

2'× 4'

Flange

High Eff.

CSEFO24P

F32T8

2

2, 3 or 4

F28T5

2

2

4

4

F54T5HO

2

2

4

4

Specialty

Lamp Type

Nominal Size

Mounting

Feature

Series

8"× 48"

Corner

Teardrop

CSECO14

1'× 4'

2'×2'/3'/4'/8'

Flange

Surface

Gasket Wrapped

Teardrop

Doorframe

CSEFBO14

CSESTD

F17T8

1 (2' only)

F25T8

1 (3' only)

F32T8

1, 2 or 3

1, 2 or 3 1 (4' only), 2 (8' only)

F40TT Biax

2 (4' only), 4 (8' only)

F48T8HO

1 or 2

1 or 2 F54T5HO

1 or 2

1 or 2

2'×4'

2'× 4'

Grid

Flange

CSEGRO24 CSEFRO24

2'×4'

2'×4'

Grid

Grid

HEPA

Gel T-Bar

Flow-Thru

CSEG24FT

CSEGO24G

2'× 4'

Flange

Gasketed

Doorframe

CSEFBO24

2, 3 or 4

2, 3, 4 or 6

2, 3, 4 or 6

2, 3 or 4

2, 3 or 4

2, 3 or 4

2, 3 or 4

2'×4'

Grid

HSEGO24

2'× 4'

Flange

HSEFO24

2, 3, 4 or 6

2, 3, 4 or 6

Hazardous Locations

Lamp Type

Nominal Size

Mounting

Series

1'× 4' Surface

HSESO14

1'× 4'

Grid

HSEGO14

1'× 4'

Flange

HSEFO14

2'×2'

Surface

HSESO22

2'×2'

Grid

HSEGO22

2'×2'

Flange

HSEFO22

2'×4'

Surface

HSESO24

F17T8

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F31T8-1.625" U

2 or 3

2 or 3

2 or 3

F32T8

1, 2 or 3

1, 2 or 3

1, 2 or 3

F40TT Biax

2, 3 or 4

2, 3 or 4

2, 3 or 4

Corner Mount

Lamp Type

Nominal Size

Mounting

Series

8"× 48"

Corner

HSECO14

F32T8

1, 2 or 3

www.kenall.com

14

P: 847-360-8200

F: 847-360-1781

2, 3, 4 or 6

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

SimpleSeal™ OVERLAPPING DOOR SERIES Metric Options

Metric Sizes

Nominal Size

300mm×1200mm 600mm×600mm

600mm×1200mm

300mm×1200mm

600mm×1200mm

Mounting

GridGridGridGridGrid

Lamp Type

Series

CSEGO312 CSEGO66

CSEGO612

CSEGOL312

CSEGOL612

Low Profile

Low Profile

F28T5

F17T8

2, 3, 4 or 6

F31T8-1.625" U

2 or 3

F32T8

1, 2 or 3

F40TT

2, 3 or 4

F50TT

2, 3 or 4

F54T5HO

L36W21-840 Plus

1, 2 or 3

2, 3, 4 or 6

2

4

2

4

2, 3, 4 or 6

SimpleSeal Linear Fluorescent Ordering Nomenclature

Example: C - SE - S - O - 24 - 4 - 32 - RS - 2 - 277 - 5F - 5H - U - EL - FN

Location Series Mounting Door

Size

Lamp

Lamp Ballast Ballast Voltage Doorframe Housing Lens Electrical Other

Quantity

Type

Type

Quantity

Options

Options

C

SE

Location

C Cleanroom

Series

SE Sealed Enclosure

Mounting

S Surface

Door Style

O Overlapping

Size

24 2'x4'

S

O

24

4

32

Lamp Quantity

2 Two

3 Three

4 Four

6 Six

Lamp Type

32 F32T8

44 F48T8HO (4 lamp max.)

54 F54T5HO

Ballast Type

IS Instant Start Electronic <10% THD

RS Rapid Start Electronic <10% THD

SB Specified Ballast

Ballast Quantity

1 One

2 Two

T Tandem Wiring

RS

2

277

5F

Voltage

120 120 Volts

277 277 Volts

347 347 Volts

Doorframe

2F 20 Ga CRS

5F 20 Ga Type 304 SS (STD)

XF 20 Ga Type 316 SS

PAF 063" Painted Fabricated

Aluminum

5H

U

EL

FN

Electrical Options

DLN LED Night Light w/Light Level Control

TN PL Night Light – 5/7/9 Watt

(Lamp supplied by other)

(120/277V only)

EL* Standard Lumen One-Lamp EL Pack

PEL*High Lumen One-Lamp EL Pack

SEL*Specified EL Pack

FS HLR/GLR Single Fuse & Holder

HJ Hermetically Sealed Wireway

RF Radio Frequency Filter

*Not available w/six F54T5HO lamps

Housing

2H 20 Ga CRS

5H 20 Ga Type 304 SS (STD)

XH 20 Ga Type 316 SS

PAH .050" Painted Aluminum

Lens

Acrylic

T .125" Clear

U .125" #12 Prismatic High Impact

UV UV Filtering (specify)

Polycarbonate

2 .125" #12 Prismatic

G .125" Clear

Tempered Glass

R .156" C73

Specified Lens

SL Specified Lens

Other Options

FN Food Zone Non-Contact

PM Pendant Mounting Holes

(pendant by others)

Please refer to www.kenall.com for the most current detailed specification sheets for each luminaire.

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

15

SimpleSeal™ OVERLAPPING DOOR SERIES

HID, Incandescent & Compact Fluorescent

SimpleSeal Overlapping Door luminaires are also available for those applications that call

for an HID, incandescent or compact fluorescent light source. The design of these fixtures

is also appropriate for applications with the highest cleanliness standards and most

stringent cleaning protocols that may involve caustic chemicals and extreme abrasion.

These easy-to-clean fixtures meet IP65 Ingress Protection and pressurized plenum

standards, ensuring both protection against particulate contamination and the integrity

of pressurized plenums. The doorframe uses a fulcrum bracket for even, positive

retention to the ceiling surface.

3

2

1

4

5

6

One-Piece Housing

ONE-PIECE Doorframe

1

Robotically TIG Welded

Eliminates inherent weakness

of lapped and spot-welded

construction. Available in

20-gauge cold-rolled steel or

stainless steel (304 or 316).

2

Compression Set

PEM Studs

Subassemblies and electrical

components can be secured to

housing without compromising its

air-tight integrity.

3

4

Optional Hermetically Sealed

Wireway

Maintains seal integrity from

plenum and eliminates need

for caulk.

5

6

www.kenall.com

16

7

8

9

ONE-PIECE Doorframe GASKET

Frame with 60° Beveled Edge

Assures protection against harsh

cleaning protocols. 60° beveled

edge is easier to clean than a

standard 90° return.

7

Extruded Closed Cell

Customized shape with

continuous skin. No open cell

pockets to collect particulates

as in die-strip gaskets.

Patented Fulcrum

Repositioning Bracket

Reverse doorframe bowing to

assure consistent contact with

ceiling surface. Doorframe and

gasket mate to ceiling structure,

eliminating the need for caulk.

8

Vulcanized Corners

Sealed at corners.

No leakage.

9

Mechanically Secured to

Doorframe

Precise, secure and permanent

positioning of gasket.

Flush Mounted Fasteners

Stainless steel fasteners with

Teflon bushings ensures air-tight

integrity of the fixture and

provides ease of cleanability.

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

STANDARDS & CERTIFICATIONS

Product Offerings

Installation

Housing

Lamp

Type

Size

Type

Cleanroom & Containment

Surface

16"×16", 24"×24"

HID

Grid

24"×24"

HID

Flange

12"×12"

HID, Incandescent, CFL Flange

16"×16", 24"×24"

HID Hazardous Location

Surface Grid

Flange

16"×16", 24"×24" 24"×24"

16"×16", 24"×24"

HID

HID

HID

Series

Prefix

This series is ideal for applications requiring stainless steel

one-piece overlapping doorframe design. In addition, it meets the

following performance requirements:

CSESO

CSEGO

CSEFO

CSEFO

Defined Performance

HSESO

HSEGO

HSEFO

Standard Criteria

Testing Facility

Reference

Page No.

Water Jet Protection IEC 60598/IP65 UL 62-63

Dust-Tight IEC 60598/IP65 UL 62-63

No Toxicity NSF2 NSF 64

No Corrosion NSF2

NSF 64

Easy to Clean NSF2 NSF 64

No Pressurized Leaks

K230

CRS

68

Flammable Gases/Vapors Present

Class I, Division 2 UL 62-63

Combustible Dust Present

Class II, Division 2 UL 62-63

Easily Ignitable Fibers Present

Cleanliness Compatibility Class III UL

62-63

Fed Std 209E, Class100

CRS

65

IES

ITL

Efficiency

IP65

K230

HAZ

ISO 5

Class 100

CCEA

Approved

Recommended Applications

Cleanroom & Containment

•Laboratories

•Manufacturing Areas

•Semiconductor/Electronic/

Optics Assembly Areas

•Vivariums

•Pharmaceutical

•Research and

Development Labs

•Biosafety

•Storage Facilities

•Packaging

•Anterooms

Hazardous Locations

•Laboratories

•Manufacturing Areas

•Processing Areas

•Storage and

Dispensing Facilities

•Spray Finishing Areas

•Fuel Servicing Areas

www.kenall.com

Food Processing

•Research and

Development Labs

•Food Processing

•Packaging Areas

•Storage Facilities

•Corridors

• Commercial Kitchens

(with FN option)

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

17

SimpleSeal™ OVERLAPPING DOOR SERIES HID, Incandescent & Compact Fluorescent

Cleanroom & Containment

Lamp Type

Nominal Size

12"×12" 16"×16"

16"×16"

24"×24"

24"×24"

24"×24"

24"×24" 24"× 24"

Mounting Flange

SurfaceFlange SurfaceGrid Flange Grid Flange

FeatureTop Access

Top Access

Series

CSEFO1212 CSESO1616

CSEFO1616

CSESO2424

CSEGO2424

CSEFO2424

CSEGRO2424 CSEFRO2424

50W HPS or 50W MH

1

1

1

70W HPS or 70W MH

1

1

1

100W HPS or 100W MH

1

1

150W HPS

1

1

1

1

1

1

1

250 W HPS or 250W MH

1

1

1

1

1

400W HPS or 400W MH 1

1

1

1

1

25W/40W/60W/75W/100W Incandescent A-19

1 or 2

13W (4) Pin Twin

1 or 2

13W Quad or 26W Quad

1 or 2

Induction lamps also available – consult factory.

Hazardous Locations

Lamp Type

Nominal Size

Mounting

Series

16"×16"16"×16"24"×24"24"×24"24"×24"

SurfaceFlange SurfaceGrid Flange

HSESO1616 HSEFO1616

HSESO2424

HSEGO2424

HSEFO2424

50W HPS or 50W MH

1

1

70W HPS or 70W MH

1

1

100W HPS or 100W MH

1

150W HPS

1

250W HPS or 250W MH

400W HPS or 400W MH 1

1

1

1

1

1

1

1

1

1

1

Induction lamps also available — consult factory.

SimpleSeal HID, Incandescent and Compact Fluorescent Ordering Nomenclature

Example: C - SE - F - O - 2424 - 1 - 250M - 1- 120 - 5F - 2H - R - FS - FN

Location Series Mounting

C

SE

F

Door

Size

Style

O

Lamp

Type

2424

1

Lamp

Quantity

250M

Ballast Voltage Doorframe Housing Lens Electrical Other

Quantity

Options Options Options

1

120

5F

Location

CCleanroom

Size

2424

Series

SE Sealed Enclosure

Lamp Quantity

1One

Voltage

120 120 Volts

277 277 Volts

347 347 Volts

DT 120/277 Volts

Mounting

F Recessed Flange

Lamp Type

150S 150 Watt HPS

250S 250 Watt HPS

250M 250 Watt MH

400S 400 Watt HPS

400M 400 Watt MH

Doorframe

5F 20 Ga Type 304 SS (STD)

2F 20 Ga CRS

XF 20 Ga Type 316 SS

PAF 063" Painted Fabricate

Aluminum

Ballast Quantity

1 One

Housing

2H 20 Ga CRS (STD)

5H 20 Ga Type 304 SS

XH 20 Ga Type 316 SS

Door Style

OOverlapping

24"×24"

2H

R

FS

FN

Electrical Options

FS Single Fuse & Holder

HJ Hermetically Sealed Wireway

QR Quartz Restrike System

for 100W HID max.

QS Quartz Socket only

SB Specified Ballast

Other Options

FN Food Zone Non-Contact

Lens

Acrylic

T.125" Clear

UV UV Filtering (specify)

Polycarbonate

G .125" Clear

Tempered Glass

R.156" C73

Specified Lens

SL Specified Lens

Please refer to www.kenall.com for the most current detailed specification sheets for each luminaire.

www.kenall.com

18

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

19

SimpleSeal™ extended flange SERIES

Linear Fluorescent

The SimpleSeal Extended Flange Series is designed to prevent leakage between the

fixture and an imperfect ceiling through a doorframe that mates to a housing flange of

similar material, creating a predictable sealed surface. The doorframe uses a fulcrum

repositioning leg for even, positive retention to the integral, consistent flange surface.

The Extended Flange Series is designed for applications with the highest cleanliness

standards, with cleaning protocols that might involve caustic chemicals or extreme

abrasion. This clean design provides a high level of performance that can be

defined, measured to universally accepted standards and certified by an independent

testing facility.

4

2

3

1

6

8

5

9

7

One-Piece Housing

1

2

ONE-PIECE Doorframe

Robotically TIG Welded

Eliminates inherent weakness

of lapped and spot-welded

construction.

Available in cold-rolled steel,

painted aluminum or stainless

steel (304 or 316).

Compression Set

PEM Studs

Subassemblies and electrical

components can be secured to

housing without compromising

its air-tight integrity.

3

Sealed Swing-Out Arms

Recessed flange housing can be

installed in ceilings more quickly

and securely.

4

Optional Hermetically

Sealed Wireway

Maintains seal integrity from

plenum and eliminates need

for caulk.

5

Frame with 60° Beveled Edge

Assures protection against harsh

cleaning protocols. 60° beveled

edge is easier to clean than a

standard 90° return.

6

Patented Fulcrum

Repositioning Bracket

Doorframe mates consistently to

housing flange for uniform seal.

7

Flush Mounted Fasteners

Stainless steel fasteners with

Teflon bushings ensures air-tight

integrity of the fixture and

provides ease of cleanability.

www.kenall.com

20

ONE-PIECE Doorframe GASKET

P: 847-360-8200

F: 847-360-1781

8

Extruded Closed Cell

Customized shape with

continuous skin. No open cell

pockets to collect particulates

as in die-strip gaskets.

9

Vulcanized Corners

Sealed at corners.

No leakage.

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

STANDARDS & CERTIFICATIONS

Product Offerings

Installation

Housing

Type

Size

Cleanroom & Containment

Surface

1'×4', 2×2', 2'×4'

Grid

1'×4', 2'×2', 2'×4'

Flange

1'×4', 2'×2', 2'×4'

Corner

8"×48"

Lamp

Type

Series

Prefix

Linear

Linear

Linear

Linear

CSESL

CSEGL

CSEFL

CSECL

This series is ideal for applications requiring an extended flange

doorframe design to create a predictable sealed surface. In

addition, it also meets the following requirements:

Defined Performance

Standard Criteria

Testing Facility

Reference

Page No.

Water Jet Protection IEC 60598/IP65 UL 62-63

Dust-Tight IEC 60598/IP65 UL 62-63

No Toxicity NSF2 NSF 64

64

No Corrosion NSF2

NSF Easy to Clean NSF2 NSF 64

No Pressurized Leaks

K230

CRS

68

Fed Std 209E, Class100

CRS

65

IES

ITL

Cleanliness Compatibility Efficiency

IP65

K230

ISO 5

Class 100

CCEA

Approved

RECOMMENDED APPLICATIONS

Cleanroom & Containment

•Laboratories

•Manufacturing Areas

•Semiconductor/Electronic/

Optics Assembly Areas

•Vivariums

•Pharmaceutical

•Research and

Development Labs

•Biosafety

•Storage Facilities

•Packaging

•Anterooms

Hazardous Locations

•Laboratories

•Manufacturing Areas

•Processing Areas

•Storage and Dispensing Facilities

•Spray Finishing Areas

•Fuel Servicing Areas

www.kenall.com

Food Processing

•Research and

Development Labs

•Food Processing

•Packaging Areas

•Storage Facilities

•Corridors

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

21

SimpleSeal™ Extended Flange Series Linear Fluorescent

Cleanroom & Containment

Lamp Type

Nominal Size

Mounting

Series

1'× 4' 1'×4'

SurfaceGrid

CSESL14 CSEGL14

1'×4'

Flange

CSEFL14

2'×2'

2'×2'

SurfaceGrid

CSESL22 CSEGL22

2'×2'

Flange

CSEFL22

2'×4'

2'×4'

2'× 4'

SurfaceGrid Flange

CSESL24

CSEGL24 CSEFL24

F17T8

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F31T8-1.625" U

2 or 3

2 or 3

2 or 3

F32T8

1, 2 or 3

1, 2 or 3

1, 2 or 3

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F48T8HO

1 or 2

1 or 2

1 or 2

2, 3 or 4

2, 3 or 4

2, 3 or 4

2F54T5HO

1 or 2

1 or 2

1 or 2

2, 3 or 4

2, 3 or 4

2, 3 or 4

F40TT Biax

2, 3 or 4 2, 3 or 4

2, 3 or 4

F50TT Biax

2, 3 or 4 2, 3 or 4

2, 3 or 4

Corner Mount

Nominal Size

Mounting

Series

8"× 48" Corner

CSECL

F32T8

1, 2 or 3

F48T8HO

1 or 2

F54T5HO

1 or 2

SimpleSeal Extended Flange Linear Fluorescent Ordering Nomenclature

Example Luminaire: C - SE - S - L - 24 - 4 - 32 - RS - 1 - 120 - AF - 2H - U - EL - TH

Location Series Mounting Door

Size

C

SE

S

L

Lamp

Lamp Ballast Ballast

Voltage Doorframe Housing Lens

QuantityType TypeQuantity

24

4

Location

C Cleanroom

Size

242'x4'

Series

SE Sealed Enclosure

Lamp Quantity

2 Two

3Three

4 Four

6Six

Mounting

S Surface

Door Style

L Extended Flange

32

Lamp Type

32 F32T8

44 F48T8HO (4 Lamp Max.)

54 F54T5HO (4 Lamp Max.)

Ballast Type

IS Instant Start Electronic <10%THD

RS Rapid Start Electronic <10% THD

Ballast Quantity

1One

2Two

T Tandem Wiring

RS

1

120

AF

Voltage

120 120 Volts

277 277 Volts

347 347 Volts

Doorframe

AF Anodized Aluminum (STD)

PAF Painted Fabricated

Aluminum

Housing

2H 20 Ga CRS (STD)

5H 20 Ga Type 304 SS

XH 20 Ga Type 316 SS

PAH .050" Painted Aluminum

Lens

Acrylic

T .125" Clear

U .125" #12 Prismatic

High Impact

UV UV Filtering (specify)

Polycarbonate

2 .125" #12 Prismatic

G .125" Clear

Tempered Glass

R .156" C73

Specified Lens

SL Specified Lens

2H

U

Electrical Other

OptionsOptions

EL

TH

Electrical Options

EL Standard Lumen One-Lamp EL Pack

FS HLR/GLR Single Fuse & Holder

HJ Hermetically Sealed

Wireway

RF Radio Frequency Filter

TN PL Night Light – 5/7/9 Watt

(Lamp supplied by other)

(120/277V only)

Other Options

PM Pendant Mounting Holes

(pendant by others)

TH 1/2" Trade Size

Threaded Hub

Please refer to www.kenall.com for the most current detailed specification sheets for each luminaire.

www.kenall.com

22

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

23

SimpleSeal™ extended flange SERIES

HID, Incandescent & Compact Fluorescent

The SimpleSeal Extended Flange Series is also available for those applications that call for

an HID, incandescent or compact fluorescent source. The luminaires are designed to prevent

leakage between the fixture and an imperfect ceiling through a doorframe that mates to

a housing flange of similar material, creating a predictable sealed surface. The doorframe

uses a fulcrum repositioning leg for even, positive retention to the integral, consistent

flange surface.

The Extended Flange Series is designed for applications with the highest cleanliness

standards, with cleaning protocols that may involve caustic chemicals or extreme

abrasion. This clean design provides a high level of performance that can be defined,

measured to universally accepted standards and certified by an independent testing facility.

4

2

1

3

8

5

6

One-Piece Housing

1

2

ONE-PIECE Doorframe

Robotically TIG Welded

Eliminates inherent weakness

of lapped and spot-welded

construction.

Available in cold-rolled steel,

painted aluminum or stainless

steel (304 or 316).

5

6

Compression Set

PEM Studs

Subassemblies and electrical

components can be secured to

housing without compromising

its air-tight integrity.

7

3

Sealed Swing-Out Arms

Recessed flange housing can be

installed in ceilings more quickly

and securely.

4

Optional Hermetically

Sealed Wireway

Maintains seal integrity from

plenum and eliminates need

for caulk.

www.kenall.com

24

9

7

ONE-PIECE Doorframe GASKET

Frame with 60° Beveled Edge

Assures protection against harsh

cleaning protocols. 60° beveled

edge is easier to clean than a

standard 90° return.

8

Extruded Closed Cell

Customized shape with

continuous skin. No open cell

pockets to collect particulates

as in die-strip gaskets.

Patented Fulcrum

Repositioning Bracket

Doorframe mates consistently to

housing flange for uniform seal.

9

Vulcanized Corners

Sealed at corners.

No leakage.

Flush Mounted Fasteners

Stainless steel fasteners with

Teflon bushings ensures air-tight

integrity of the fixture and

provides ease of cleanability.

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

Product Offerings

STANDARDS & CERTIFICATIONS

Installation

Housing

Lamp

Type

Size

Type

Cleanroom & Containment

Surface

12"×12"

HID, Incandescent, CFL

Surface

16"×16", 24"×24"

HID

Grid

24"×24"

HID

Flange

12"×12"

HID, Incandescent, CFL

Flange

16"×16", 24"×24"

HID

Series

Prefix

CSESL

CSESL

CSEGL

CSEFL

CSEFL

This series is ideal for applications requiring an extended flange

doorframe design to create a predictable sealed surface. In

addition, it also meets the following requirements:

Defined Performance

Standard Criteria

Testing Facility

Reference

Page No.

Water Jet Protection IEC 60598/IP65 UL 62-63

Dust-Tight IEC 60598/IP65 UL 62-63

No Toxicity NSF2 NSF 64

No Corrosion NSF2

NSF 64

Easy to Clean NSF2 NSF 64

No Pressurized Leaks

K230

CRS

68

Fed Std 209E, Class100

CRS

65

IES

ITL

Cleanliness Compatibility Efficiency

IP65

K230

ISO 5

Class 100

CCEA

Approved

RECOMMENDED APPLICATIONS

Cleanroom & Containment

•Laboratories

•Manufacturing Areas

•Semiconductor/Electronic/

Optics Assembly Areas

•Vivariums

•Pharmaceutical

•Research and

Development Labs

•Biosafety

•Storage Facilities

•Packaging

•Anterooms

Hazardous Locations

•Laboratories

•Manufacturing Areas

•Processing Areas

•Storage and

Dispensing Facilities

•Spray Finishing Areas

•Fuel Servicing Areas

www.kenall.com

Food Processing

•Research and

Development Labs

•Food Processing

•Packaging Areas

•Storage Facilities

•Corridors

• Commercial Kitchens

(with FN option)

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

25

SimpleSeal™ Extended Flange Series HID, Incandescent & Compact Fluorescent

Cleanroom & Containment

Nominal Size

Mounting

Series

Lamp Type

12"×12" Surface

CSESL1212 12"×12"

Flange

CSEFL1212

16"×16"

Surface

CSESL1616

16"×16"

Flange

CSEFL1616

24"×24"

Surface

CSESL2424

13 Twin

1, 2 or 3

13W (4) Pin Twin

1 or 2

1 or 2 13W Quad or 26W Quad

1

1 or 2

28W 2D or 38W 2D

1

24"×24"

Grid

CSEGL2424

24"×24"

Flange

CSEFL2424

25W/40W/60W/75W/100W Incandescent A-19

1

1

50W HPS or 50W MH

1

1

1

70W HPS or 70W MH

1

1

1

100W HPS or 100W MH

1

1

1

150W HPS

1

1

1

1

1

175W MH

1

1

1

1

250W HPS or 250W MH

1

1

1

400W HPS or 400W MH 1

1

1

Induction lamps also available – consult factory.

SimpleSeal Extended Flange Series HID, Incandescent & Compact Fluorescent Ordering Nomenclature

Example Luminaire: C - SE - S - L - 1212 - 1 - 26Q - RS - 1 - 120 - AF - 2H - U - TN - TH

Location Series Mounting

C

SE

Location

C Cleanroom

Series

SE Sealed Enclosure

Mounting

S Surface

Door Style

L Extended Flange

Size

1212 12"x12"

Lamp Quantity

1 One

2 Two

3 Three (13-watt twin only)

S

Door

Size

Lamp

Lamp Ballast Ballast Voltage Doorframe H

ousing Lens Electrical Other

Style QuantityType TypeQuantity OptionsOptions

L

1212

1

26Q

Lamp Type

13 13 Watt Twin

13E 13 Watt (4) Pin Twin

13Q 13 Watt Quad

26Q 26 Watt Quad

28D 28 Watt 2D

38D 38 Watt 2D

25I 25 Watt Incandescent (A-19)

40I 40 Watt Incandescent (A-19)

60I 60 Watt Incandescent (A-19)

75I 75 Watt Incandescent (A-19)

100I 100 Watt Incandescent (A-19)

50S 50 Watt HPS

70S 70 Watt HPS

50M 50 Watt MH

70M 70 Watt MH

Ballast Type

IS Instant Start Electronic <10% THD

MB Magnetic ES (13 Watt Twin Only)

RS Rapid Start Electronic <10% THD (STD)

SB Specified Ballast

Ballast Quantity

1One

2Two

T Tandem Wiring

RS

1

120

AF

Voltage

120 120 Volts

277 277 Volts

347 347 Volts

Doorframe

AF Anodized Aluminum (STD)

PAF Painted Fabricated

Aluminum

Housing

2H 20 Ga CRS (STD)

5H 20 Ga Type 304 SS

XH 20 Ga Type 316 SS

PAH .050" Painted Aluminum

2H

U

TN

Electrical Options

EL* Standard Lumen One-Lamp EL Pack

FS HLR/GLR Single Fuse & Holder

HJ Hermetically Sealed

Wireway

RF* Radio Frequency Filter

TN* PL Night Light – 5/7/9 Watt

(Lamp supplied by other)

(120/277V only)

*Fluorescent only

Other Options

TH 1/2" Trade Size Threaded Hub

Lens

Acrylic

T .125" Clear

U .125" #12 Prismatic

High Impact

UV UV Filtering (specify)

Polycarbonate

2 .125" #12 Prismatic

G .125" Clear

Tempered Glass

R .156" C73

Specified Lens

SL Specified Lens

Please refer to www.kenall.com for the most current detailed specification sheets for each luminaire.

www.kenall.com

26

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

TH

www.kenall.com

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

27

SimpleSeal™ Inset Door Series

Linear Fluorescent

The Inset Door Series is designed for applications where cleaning and clamping protocols

are less important, providing an economical alternative for less inclusive performance

requirements. This series meets IP65 Ingress Protection and pressurized plenum standards

for prevention of particulate contamination and pressure leakage.

The Inset Door series is comprised of a one-piece, seam welded and hole-free housing,

a one-piece housing flange, a doorframe in either aluminum, cold-rolled or stainless steel,

and a housing-to-doorframe gasket. This clean design provides excellent performance that

has been defined, measured to the highest available standards and certified by an

independent testing laboratory.

1

4

2

3

6

5

7

One-Piece Housing

1

2

Doorframe

Robotically TIG Welded

Eliminates inherent weakness

of lapped and spot-welded

construction. Available in

cold-rolled steel, painted

aluminum or stainless steel

(304 or 316).

Compression Set

PEM Studs

Subassemblies and electrical

components can be secured to

housing without compromising

its air-tight integrity.

3

Sealed Swing-Out Arms

Recessed flange housing can be

installed in ceilings more quickly

and securely.

4

Optional Hermetically

Sealed Wireway

Maintains seal integrity

from plenum.

Doorframe GASKET

5

Available in cold-rolled steel,

aluminum or brushed 304

stainless steel.

6

Doorframe secured by

retractable aircraft cables and

stainless steel fasteners.

7

Flush Mounted Fasteners

Stainless steel fasteners with

Teflon bushings ensures air-tight

integrity of the fixture and

provides ease of cleanability.

www.kenall.com

28

8

P: 847-360-8200

F: 847-360-1781

8

Extruded Closed Cell

Customized shape with

continuous skin. No open cell

pockets to collect particulates

as in die-strip gaskets.

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

Product Offerings

STANDARDS & CERTIFICATIONS

Installation

Housing

Type

Size

Cleanroom & Containment

Surface

1'×4', 2'×2', 2'×4'

Grid

1'×4', 2'×2', 2'×4'

Flange

1'×4', 2'×2', 2'×4'

Corner

8"×48" Hazardous Locations

Surface

Grid

Flange

Corner

1'×4', 2'×2', 2'×4' 1'×4', 2'×2', 2'×4'

1'×4', 2'×2', 2'×4'

8"×48"

Lamp

Type

Series

Prefix

Linear

Linear

Linear

Linear

CSESI

CSEGI

CSEFI

CSECI

Linear

Linear

Linear

Linear

HSESI

HSEGI

HSEFI

HSECI

This series is ideal for applications requiring easy installation

and access to electrical components. In addition, it meets the

following performance requirements:

Defined Performance

Standard Criteria

Testing Facility

Water Jet Protection IEC 60598/IP65 UL 62-63

Dust-Tight IEC 60598/IP65 UL 62-63

No Toxicity NSF2 NSF 64

No Corrosion NSF2

NSF 64

Easy to Clean NSF2 NSF 64

No Pressurized Leaks

K230

CRS

68

Class I, Division 2 UL 62-63

Fed Std 209E, Class100

CRS

65

IES

ITL

Flammable Gases/Vapors Present

Cleanliness Compatibility Reference

Page No.

Efficiency

IP65

K230

HAZ

ISO 5

Class 100

RECOMMENDED APPLICATIONS

Cleanroom & Containment

•Corridors

•Stairwells

•Anterooms

•Research and

Development Labs

•Storage Facilities

•Packaging Areas

Hazardous Locations

• Laboratories

• Storage and

Dispensing Facilities

• Spray Finishing Areas

• Fuel Servicing Areas

• Corridors

• Stairwells

www.kenall.com

Environmental

• Exteriors

• Entryways

• Corridors

• Stairwells

• Restrooms

• Parking Structures

P: 847-360-8200

F: 847-360-1781

1020 Lakeside Drive Gurnee, Illinois 60031

The Kenall product shown on this page is manufactured in the USA with components purchased from US suppliers, and meets the Buy American requirements under the ARRA.

Kenall has not determined the origin of its domestically purchased components or the subcomponents thereof.

29

SimpleSeal™ Inset Door Series Linear Fluorescent

Cleanroom & Containment

Lamp Type

Nominal Size

Mounting

Series

1'×4' Surface

CSESI14 1'×4'

Grid

CSEGI14

1'×4'

Flange

CSEFI14

8"×48"

Corner

CSECI14

2'×2'

Surface

CSESI22

2'×2'

Grid

CSEGI22

2'×2'

Flange

CSEFI22

2'×4'

Surface

CSESI24

2'×4'

Grid

CSEGI24

2'×4'

Flange

CSEFI24

F17T8

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F31T8-1.625" U

2 or 3

2 or 3

2 or 3

F32T8

1, 2 or 3

1, 2 or 3

1, 2 or 3

1, 2 or 3

F28T5

1, 2 or 3

1, 2 or 3

1, 2 or 3

1, 2 or 3

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F24T5HO

2, 3 or 4 2, 3 or 4

2, 3 or 4

2, 3, 4 or 6

F54T5HO

1, 2 or 3

1, 2 or 3

1, 2 or 3

1, 2 or 3

F40TT Biax

2, 3 or 4

2, 3 or 4

2, 3 or 4

2, 3, 4 or 6

2, 3, 4 or 6

2, 3, 4 or 6

F50TT Biax