PBSI Newsletter Pdf - Powder bulk solids india 2016

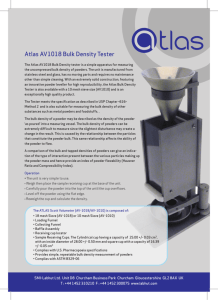

advertisement

ORGANIZER - EXHIBITION October 13 - 15, 2016 Bombay Convention & Exhibition Centre, Mumbai, India ORGANIZER - CONFERENCE & WORKSHOPS NEWSLETTER KNOWLEDGE PARTNER VOLUME 1 ONE STOP EVENT FOR THE POWDER AND BULK INDUSTRY across all the industries. B. V. Sambashivan (Chairman Conference Board - Powder and Bulk Solids India 2016) Powder and Bulk Solids India 2016 is an event which will provide a very effective platform for exhibitors and conference participants from the bulk solids industry to interact, network and get knowledge of the available technologies of ongoing research in various fields and also seek insight in to possible business oppor-tunities. The event will have a large participation considering the wide spectrum of topics and industries that will be covered "This industry has a big basket of its own industry segments covering the food, pharmaceuticals, infrastructure industries comprising mining, power, steel, fertilizers, cement, powder etc All these industries have their own growth patterns depending on various factors such as demand, availability, investments available etc. The food and the pharmaceuticals industries are continuing to grow well while some sluggishness is observed in the infra structure industries at the moment. However the infrastructure industry has to accelerate its growth considering the country's needs." "Whatever the industry status is at the moment, the event aims to provide a good opportunity for the participants in general to get a good view of various activities taking place in the industry. This event helps the industrial growth also since it gives opportunities for participants to understand the available efficient and cost effective technologies, interact with researchers and academicians which will prompt them to go for such technologies and implement them in their own segment industries. It is a platform where the top researchers and academicians of global repute interact and network with the industry." Many countries have shown a lot of interest in industrial growth in India in the last few decades and are continuing to do so. Therefore this event will give them also lot of opportunities to network with their Indian counterparts and showcase their expertise. The exhibitors and conference presenters get opportunities to present to visitors the developments they have made in their respective specialist areas. The conference presenters can be from research organisations, consultants, industry community etc. The visitors will gain good knowledge of the advances made in ongoing research, engineering, and manufacture and commissioning practices etc. This will help them to either implement them in their own plants if they are in the user industry or adopt such practices if they are in the technology developing industry. Overall the event experience will be exhilarating and visitors and participants will carry pleasant memories with them. Wishing a very happy experience. BLOCK YOUR DATES! October 13-15, 2016 Bombay Convention & Exhibition Centre, Mumbai, India For more information, please contact: Ms. Priya Sharma Ph.: 011-471 68830 E: priya.sharma@nm-india.com HOSOKAWA ALPINE AT POWDER AND BULK SOLIDS INDIA Mrs. V. Manjula Managing Director, Hosokawa Micron India Pvt. Ltd. Hosokawa Micron India a 100% subsidiary of Hosokawa Alpine Germany, a pioneer and world leader ( +120 year old company) in supplying of powder process equipments is supplying equipments ro the fast growing industry in India. They are the leading and well know technology providers in powder handling and processing technology. Like every year in 2016 Powder and Bulk Solids India too they are participating. Mrs. Manjula Managing Director of India, has also been appointed as the conference board member this year. In a conversation with Editor She shares her thoughts, “Powder and Bulk Solids India in general we consider as a technology platform for all industries / applications wherever Powders are handled. For us, it is a Powtech in India, and we will be focussing this year mainly for Pharma, Food, Chemical (speciality) and Plastic applications. We will be displaying products like Jet mills, Mechanical Impact mills, and classifier mills suitable for applications for Pharma- API milling, Food – Cryogenic grinding / Active Freeze Dryers, Chemicals– Organic Pigments, Toners, Metal Powders and PTFE processing. Minerals – Special value addition for Filler materials like Calcium Carbonate, Talc processing and so on, Recycling of Cables, Packaging Films''. “In general Indian industries have seen significant declines in exports, including commodity, engineering goods, and so on. However, not all segments of Indian exports have been so badly impacted. The Indian economy was expected to recover only gradually. Investment is yet to pick up significantly. The government has been pursuing a very positive policy of trying to attract global foreign direct investment into manufacturing in India through the 'Make in India' policy. This is expected to boost foreign investment into building production facilities in India, including for export. It is highly beneficial if the implementation is done in full force” “Powder and Bulk Solids India conference and exhibition is focusing mainly on visitors and exhibitors issues of interest. They offer high level panel of speakers which include repre- sentatives from the operational side, industry, media, experts and leading professors from renowned Institutes. It will be covering all aspects of particle, powder technology and bulk handling. It will help the industries related with the field to get the technical updation at one place” “Since Powder and Bulk Solids India 2016 will be now planned with a quality inter-national workshops and panel discussions on dedicated topics, technology advancement and experiences of Managers learned from operations of the systems/ technologies, it is highly beneficial to participants who will attend this time. My recommendation is CEOs, Head of Depts from Project, Quality Control, and Regulatory Affairs, Production and Maintenance officials should participate from companies in the sector of Minerals and Metals, Pharma, Food, Chemicals and so on” ACHIEVING HIGH PERFORMANCE FOR POWDER AND BULK SOLIDS IN RESONANCE WITH NATURE TOPICS TO BE COVERED l l l l l Achieve high performance of Powder/Bulk Material Handling Systems Efficient & clean technology needs drive Design & R&D processes Industry & social needs drive handling technology growth Are technologies of bulk material handling systems in resonance with their nature Powder /Bulk Material Handling Systems for meeting all needs ADVISORY BOARD MEMBERS FOR POWDER AND BULK SOLIDS INDIA 2016 Mr. B.N.Sambashivan Retired from Tata Consulting Engineers Prof. Dr. V.K.Agarwal Indian Institute of Technology, Delhi Prof. Dr. Mark Jones The University of Newcastle, Australia REGISTER NOW! Prof. Yutaka Tsuji Prof. Dr. Craig Wheeler Professor Emeritus at The University of Osaka University, Japan Newcastle, Australia Early bird discount of 10% on registration fee till 30 July 2016 Mrs. V. Manjula Managing Director, Hosokawa Micron India Pvt. Ltd. For more information, please contact: Ms. Priya Sharma, Ph.: 011-471 68830 E: priya.sharma@nm-india.com ROLOLOK VALVES AT POWDER AND BULK SOLIDS INDIA 2016 Rololok Valves is pleased to participate at the Powder and Bulk Solids India 2016 going to be held at Mumbai. Rotolok has been almost in the global market for more than 40 years & offered a correct solution for handling bulk solids for flow control. We are going to display flow control products for handling bulk solids. We will be giving Rotary Airlock valve for all application starting from normal conveying to pressure conveying and its focus on industries like cement, power, steel, minerals, process and food industries. The industry is slowly picking up and in coming year there will be an opportunity for supplying bulk solid handling equip- ment's to the industry. There are many manufacturer of rotary airlock which they are manufacturing without knowing the proper application, here we stand out with large experience and expertise in this flied. Mr. Prasanna Veraraghavan Director, Rololok Valves ROTARY & ROUNDHEAD VALVES Rotolok valves have several features that need to be considered when comparing our valves to the competition. Construction of valves is of robust cast bodies and end covers. Bodies, end covers and rotor are precisely machined on CNC machines. Spigot Located End Covers – ensures concentricity and tight clearances. All bodies can be drilled and tapped for body vents. All end covers can be drilled and tapped for air purge shaft seals. Rotors are available with open or closed ends. Fixed bladed rotors are standard (beveled blades optional) which have less drag and have less product degradation. Larger rotor shafts – ensures rotor does not deflect under product and/or pressure loading. Bearings are sealed for life ball type rigged outboard and for high temperature above 250° C, ZZ bearings with kluber grease are fitted. Gland type shaft seals – eliminates leakage and allows adjustment and various types of packing material. Gland follower will withdraw sufficiently to allow the packing to be changed without disassembling entire valve. All threads and fasteners are metric. CHAIN-VEY CONVEYOR Modern Process Equipment, in India know as Bectochem Consultants and Engineers manufactures the Chain-Vey, a tubular drag conveyor that is specifically designed for the transport of food, chemical and other bulk powder products without product degradation or declassification. It has a totally enclosed design that eliminates dust hazards and the need for pneumatics - low power consumption in terms of per kg of material conveyed hence making most economical and most efficient conveying system. System can be configured to accept heated air to maintain product temperature and moisture levels , Flexible system configurations , Gentle conveying eliminates SAP declassification during transport , Low maintenance operation NOVEL WAY CHAIN VEY: New way of conveying with reduced power consumption per kg of product conveyed, virtually the application list is endless be it powder or any difficult application it can convey pellets, powders, peanuts, oats, soap noodles etc. We have conducted numerous trials on various products, where we have demonstrated the new way of conveying using chains and specially engineered Plastic UHMW. Slide fiction of the UHMW is very low with the Stainless steel hence the close gap between the two ensures maximum product conveying with less spillage and Source: Bectochem Consultants and Engineers Pvt. Ltd. added extra wiper disc ensures cleaning of the pipe internally all the time making ideal choice for the production people. Eliminates Product Declassification and Degradation with a dust-tight enclosed design. It features clean-in-place capabilities with automated wash cycles for sanitary conveying needs. The Chain Vey design uses less than 20% of the energy usage of pneumatic conveying systems and can convey distances of up to 200 feet (60 meters). These flexible designs also enable multiple inlets and discharge points, enabling our customers to design and build conveying systems that fit their unique processing needs. It is the most robust and reliable tubular drag conveyor on the market, requiring zero unscheduled maintenance per year, and less than 1% of scheduled maintenance time. It requires very few consumable parts, typically less than $100 per year. www.chainvey.com or contact MPE at solutions@mpechicago.com WORKSHOPS CONDUCTED BY INTERNATIONAL EXPERTS ON BELOW TOPICS Source: Rololok Valves Pneumatic Conveying Systems Hopper / Silo Geometry for flow of fine powders Prof. Dr. V.K.Agarwal Indian Institute of Technology, Delhi Prof. Dr. Mark Jones The University of Newcastle, Australia Guidelines for Energy Efficient Belt Conveyor Design Explotion Protection Prof. Dr. Craig Wheeler The University of Newcastle, Australia Mr. Stefan Penno INDEX INDIAN POWER SECTOR India has seen lot of changes in past few months . It has been in spotlight since the it crossed china's GDP rate . There is lot of work happening from Industry and government side. New opportunities are opening up. To give some facts of the industry I present to you some key figures. SECTOR l Indian power sector grew by 8.4% YoY due to l Availability of coal stock l Increase in the installed power capacity l India has added cumulative The Chemical & Pharmaceutical Industry :It is the 3rd largest producer in Asia and 12 largest in terms of volume .It accounts for 7% of world production of dye stuff and intermediaries .India is a key manufacturer for generics and drug intermediaries. This industry likely to grow at 12% over the next five years. The Food Processing Sector : The Indian food industry is expected to grow at a rate of 11 per cent to touch (US$ 64.31 billion) by 2018.Share of Food processing sector in GDP of manufacturing sector was around 10 -11% in 2014 CURRENT SCENARIO IN POWER power capacity of 61,014 MW upto March 2015 l Thermal segment has achieved ~80% of the targeted capacity addition, followed by Hydro (~21%) and balance by nuclear segment with ~19% GROWTH DRIVERS IN POWER SECTOR l Reallocation of coal blocks through e-auction process l New gas pooling mechanism to bailout 14,000 MW of stranded power plants l New Ultra Mega Power Project (UMPP) policy to approach plug and play model l Rising focus on renewable energy sector l Capex for power generation to boost the focus on the T&D space Our study helps us to share our findings to the industry. Power sector shall have moderate growth for the next fiscal as the plant load factor of plants is expected to remain low along with marginal growth in electricity demand.It is expected that power demand shall have moderate growth of ~4-5% whereas power generation is expected to grow at 5-6% in FY 2016-17, with deficits remaining low at 3-4%.The PLFs of the thermal power plants are likely to remain low as demand growth is marginal. Also, as the renewable energy share increases, it could exert additional pressure on the PLFs of coal-based plants. large coal importers Against the backdrop of limited possibility of tariff hikes, discoms will be forced to improve their operational efficiency by lowering of aggregate technical & commercial (AT&C) losses, power purchase cost rationalisation and lowering of interest costs. Despite the odds, the outlook could be revised to 'stable' on directional movement towards improvement in the financial health of discoms, better visibility on demand growth for electricity leading to improvements in PLFs. The coal output to increase by 10% in the next fiscal to reach 594 metric tonnes, given the government's focus on achieving the targeted one billion metric tonnes by 2020 and on the back of the strong performance this financial year. Higher output will come from ramping up output from existing and new mines and better efficiency. The increase in domestic coal output, coal imports into India could decline by 10-15 per cent, which is likely to exert pressure on volumes of Manish Kulkarni Director- Strategy & Business Development BDB India Private Limited Source for all images is BDB India Source: BDB India www.powderbulksolidsindia.com