6up

advertisement

13/03/15

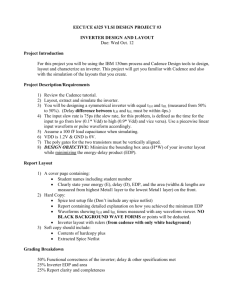

The CMOS Inverter – Static Model

Outline

First Glance

Digital Gate Characterization

Static Behavior (Robustness)

VTC

Switching Threshold

g

Noise Margins

CMOS INVERTER

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

1

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

The CMOS Inverter:

A First Glance

13/03/15

2

CMOS Inverters (1)

VDD

VDD

PMOS

1.2 m

= 2

Vin

Out

In

Vout

Metal1

CL

Polysilicon

NMOS

GND

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

3

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

0

4

Digital Gate Fundamental

Parameters

CMOS Inverter Operation Principle

1

13/03/15

1

0

Functionality

Reliability, Robustness

Area

Performance

Speed (delay)

p

Power Consumption

Energy

VOH = VDD VOL = 0

§ 5.2

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

5

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

6

1

13/03/15

The Ideal Inverter

Static CMOS Properties

Basic inverter belongs to class of static

circuits: output always connected to either

VDD or VSS. Not ideal but:

Rail to rail voltage swing

Vout

Ratio less design

Ri =

Ro = 0

Low output impedance

Vout

Extremely high input impedance

g = -

No static power dissipation

g = -

Good noise properties/margins

Vin

Vin

{TPS}: prioritize the list above

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

7

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

8

Load Line (Ckt Theory)

2.5

2.5V

ID [10-4 A]

VGS = 2.5V

B

2.0

Voltage Transfer Characteristic (VTC)

R

VGS

1.0

Vout

Vin

i

VGS = 2.0V

1.5

A

VGS = 1.5V

VGS = 1.0V

1 0V

05

0.5

0V

0

0.5

1.0

1.5

2.0

VDS [V]

2.5

Exercise:

The blue

load line A corresponds to R = 25k

The orange load line B corresponds to R = 12.5k

Vout = approx 1.6 V

With load line A and VGS = 1V,

Draw a graph Vout(Vin) for load line A and B

§ 5.2

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

9

PMOS Load Lines

Goal: Combine IDn and IDp in one graph

Kirchoff:

Vin = VDD + VGSp

IDn = - IDp

Voutt = VDD + VDSp

DS

-

VDSp

+

IDp

+

I n,p

Vout

IDn

IDn

Vin= 0

Vin=3

Vin=3

Vin= 3

VGSp=-2

VDSp

Vout

Vin= 4

VGSp=-5

Example: VDD=5V

Vin = VDD + VGSp

NMOS

Vin= 1

Vin=0

Vin= 5

PMOS

I Dn

Vin=0

VDSp

Vin= 5

Vin= 4

Vin= 2

Vin= 3

Vin= 3

Vin= 4

Vin= 2

Vin= 1

Vout = VDD + VDSp

13/03/15

Vin= 2

V =1

in

Vin= 0

Vout

IDn = - IDp

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

10

-

Vin

IDp

13/03/15

CMOS Inverter Load Characteristics

VDD

VGSp

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

11

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

12

2

13/03/15

Operating

Conditions

CMOS Inverter VTC

Need to know for proper dimensioning,

analysis of noise margin, etc.

Vout

Vout

Vout = Vin - VTp

5

Vdd

NMOS

1 Vin = VGS < VTn off

I n,p

4

Vin = 5

Vin = 0

NMOS

Vout = Vin - VTn

3

PMOS

Vin = 1

Vin = 4

Vin = 3

Vin = 2

Vin = 3

- VTp

Vdd - |VTp|

2

Vin = 4

VTp

Vin = 2

V in = 1

Vin = 2

Vin = 3

Vdd Vin

VTn

PMOS

Vin = 0

Vin = 5

3 Vout < Vin - VTn resistive

1

Vin = 4

2 Vout > Vin - VTn

VDS > VGS - VTn

VGD < VTn

saturation

1

Vout

1

2

3

4

V in

5

2

6

3

5

4 Vin > VDD + VTp off

4

Exercise: check

results for PMOS

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

13

5 Vout < Vin - VTp saturation

6 Vout > Vin - VTp resistive

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

14

13/03/15

16

Operating Conditions

Vout

Vout = Vin - VTp

Vdd

Vout = Vin - VTn

- VTp

Vdd - |VTp|

Vout

Vdd Vin

NMOS sat

PMOS lin

5

4

NMOS sat

PMOS sat

NMOS lin

PMOS satNMOS lin

PMOS off

1

6

3

3

2

2

1

Inverter Static Behavior

Regeneration

Noise margins

Delay metrics

NMOS off

PMOS lin

4

VTn

5

VTp

NMOS 1 off

2 saturation

3 resistive

PMOS 4 off

5 saturation

6 resistive

1

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

2

3

4

5

§ 5.3

Vin

13/03/15

15

The Realistic Inverter

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

The Regenerative Property

Vout [V]

Vout

2.5

Ri =

2.0

Ro = 0

1.5

g = -

A chain of inverters

Regenerative

Propert ability

Property:

abilit to

regenerate (repair)

a weak signal in a

chain of gates

1.0

0.5

VIN [V]

Ideal Inverter

Vin

0

0.5

1.0

1.5

2.0

2.5

Realistic Inverter

Ex. 1.4

The regenerative property

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

17

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

18

3

13/03/15

The Regenerative Property (2)

The regenerative Property (3)

...

v1

v0

v2

v3

v5

v4

v6

Exercise: what is the output voltage of a chain of 4

inverters with a piece-wise linear VTC passing through (0,

) (3,7),

( ) ((7,1)) and ((10,0)) [[Volt],

] as the result of an input

p

10),

voltage of 6 [Volt].

(a) A chain of inverters.

v1, v3, ...

v1, v3, ...

finv(v)

f(v)

v0, v2, ...

(b) Regenerative gate

Exercise: discuss the behavior for an input of 5 [Volt]

f(v)

finv(v)

v0, v2, ...

(c) Non-regenerative gate

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

19

Inverter Switching Treshold

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Electrical Design Rule

Wp 2.5 Wn

See Figure 5.7

VM (V)

Point of Vin = Vout

Assumes Lp = Ln

Should be applied

y

consistently

Vout

Wp / Wn

Try to set Wn, Ln, Wp, Lp

so that VTC is symmetric

as this will improve noise

margins

optimize NMOS-PMOS ratio

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Symmetrical VTC Vm ½ VDD Wp/Wn 3.5

In practice: somewhat smaller

Why?

13/03/15

21

Save area with only slight asymmetry

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Inverter Switching Threshold

13/03/15

22

Inverter Switching Threshold

Analytical Derivation

Analytical Derivation (ctd)

VM is Vin such that Vin = Vout

ID kVDSAT VGS VT VDSAT / 2

IDSATn(VM) = - IDSATp(VM)

VDS = VGS VGD = 0 saturation

k nVDSATn VM VTn VDSATn / 2

k pVDSATP VM VDD VTp VDSATp / 2

Assume VDSAT < VM - VT

(velocity saturation)

Ignore channel length modulation

VM follows from

IDSATn(VM) = - IDSATp(VM)

VDSATn VM VTn

T VDSATn

DSAT / 2

kp

( W / L )p

kn

k

VDSATP VM VDD VTp VDSATp / 2

( W / L )n

k'n VDSATn VM VTn VDSATn / 2

' V

k p DSATP VM VDD VTp VDSATp

W '

k

L

/ 2

See Example 5.1:

(W/L)p = 3.5 (W/L)n for typical conditions and VM = ½ VDD

Usually: Ln = Lp

§ 5.3.1

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

20

Simulated Gate Switching Threshold

Not the device threshold Vm = f(Ronn, Ronp)

Vin

13/03/15

13/03/15

23

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

24

4

13/03/15

Gate Switching Threshold

w/o Velocity Saturation

Noise in Digital Integrated Circuits

Long channel approximation

Also applicable with low VDD

VDD

v(t)

i(t)

4.0

Exercise (Problem 5.1):

derive VM for longchannel approximation

as shown below

VM

3.0

2.0

(a) Inductive coupling (b) Capacitive coupling

(c) Power and ground

noise

1.00.1

VM

0.3

1.0

kp/kn

3.2

r ( VDD VTp VTn )

1 r

with

10.0

r

Study behavior of static CMOS Gates with noisy

signals

kp

kn

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

25

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Noise in Digital Circuits

13/03/15

26

Noise Margins

VDD

+

-

“0”

“1”

- +

Vnoise

VOH

VDD Drop

“X”

+

-

Ground Bounce

VOL

0

§ 1.3.2

§ 1.3.2

§ 5.3.2

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

27

Noise Margins

13/03/15

VIH

VDD

VOL = Output Low Voltage

VIL = Input Low Voltage

VOH, VIH = …

§ 5.3.2

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

28

Noise Margins

VOL = Output Low Voltage

VIL = Input Low Voltage

VOH, VIH = …

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

VIL

NMH = VOH - VIH = High Noise Margin

NML = VIL - VOL = Low Noise Margin

29

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

30

5

13/03/15

Noise Margin for Realistic Gates

Noise Margin Calculation

Piece-wise linear

approximation of

VTC

VIH VIL

VOL not well defined

Conveniently relate to slope s = -1

{TPS}: explain significance of slope = -1 for noise margin

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

31

2.5

1 r

2

r

Mostly determined by technology

VDD VM

g

13/03/15

32

k pVDSATp

k nVDSATn

1 r

VM VT VDSATp / 2 n p

Vin VM

0.2

0.15

1.5

Vout (V

V)

VM VT VDSATp / 2 n p

NML VIL

Vout(V)

NMH VDD VIH

dV in

k pVDSATP Vin VDD VTp VDSATp / 2 1 pVout pVDD 0

Vin VM

VIL VM

dV

consider g out

k nVDSAT n Vin VTn VDSATn / 2 1 nVout

dVout

dV in

g

Gain as a function of VDD

Approximate g as the slope in Vout vs. Vin at Vin = VM

g

g

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Noise Margin Calculation (2)

We know how

to compute VM

Next: how to

compute g

VOH VOL VDD

V

VM M

g

VIH

g = gain factor

(slope of VTC)

0.1

1

See example 5.2

0.05

0.5

Exercise: verify calculation

Exercise: explain why we add channel length

modulation to the ID expressions (we did not do

this to determine VM )

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

Gain=-1

0

0

0.5

1

1.5

2

2.5

Vin (V)

0

0

0.05

0.1

Vin (V)

0.15

0.2

Subthreshold!

33

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

34

Dynamic Noise Margin

CMOS INVERTER

dynamic behavior (performance)

Noise Pulse Amplitude

Previous definition was Static Noise Margin

Dynamic Noise Margin: how does noise energy

determine behavior

A short pulse may have higher amplitude than a

long pulse before problems occur.

p

may

y safely

y exceed Static Noise

Short spikes

Margin

Capacitances

(Dis)charge times

Delay

§ 5.4

Error free

Noise Pulse Duration

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

35

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

36

6

13/03/15

Reducing tp

t pHL 0.69

Before: propagation delay analysis

3 VDD 5

t p 0.69

1 - VDD CL

4 IDSAT 6

IDSAT k '

3 VDD 5

1 - VDD CL

4 IDSATn 6

=0

W

2

VGS VT VDSAT 1VDSAT

2

L

The Transistor as a Switch

N

Next:

t propagation

ti

d

delay

l

from a design perspective

inverter sizing

VGS VT

t pHL 0.52

Ron

S

D ID

V GS = VD D

Rmid

{TPS}: How can you reduce propagation delay?

R0

V DS

Ex. 3.8

VDD/2

§ 5.4.1

CLVDD

(W / L)n k n' VDSATn (VDD VTn VDSATn / 2)

TUD/EE ET4293 - Dig. IC - 1112 - © NvdM - 01 Devices

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

VDD

12/03/05

13/03/15

39

37

Propagation Delay tp can be reduced by

Increasing VDD (until VDD >> VT + VDSAT/2)

Increasing W

Reducing CL

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Delay as a function of VDD

Propagation Delay tp can be reduced by

Increasing VDD (until VDD >> VT + VDSAT/2)

Increasing W

Reducing CL

5

tp (Normalized)

4.5

t pHL 0.52

CLVDD

(W / L)n k n' VDSATn (VDD VTn VDSATn / 2)

3.5

t pHL 0.52

3

CL

W

CL can be reduced by good layout design

But part of CL depends on W!

2

1.5

1

CLVDD

(W / L) n k n' VDSATn (VDD VTn VDSATn / 2)

Spice

2.5

Fg.5.17

38

Sizing

5.5

4

13/03/15

0.8

1

1.2 1.4 1.6 1.8

2

2.2 2.4

VDD (V)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

39

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

41

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

40

tp as a function of Wp/Wn

x 10-11

5

tp(sec)

Ipd tpHL

tpLH

4.5

Wn

tpHL

CD tpLH

4

(tpHL + tpLH)/2

3.5

…

…

Wp

3

1

1.5

2

2.5

3

3.5

4

4.5

5

Wp/Wn

Min tp in general not when tpLH = tpHL

Save area, time at expense of robustness

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

07 inductance 42

7

13/03/15

Isolated Inverter Sizing

Intrinsic vs Extrinsic vs Parasitic Load Cap

VDD

CGS4

M2

R0:

resistance of minimum size inverter

(assume proper = Wp / Wn ratio)

C0:

intrinsic load (output, drain) cap of min. size inverter

tp0 = 0.69 R0C0:

intrinsic or unloaded delay

basic time constant for technology

minimum delay possible in technology given VDD

S:

sizing factor for Wn, Wp of driving inverter

Wn = S Wmin, Wp = S Wmin

M4

CDB2

Vout

Vin

Vout2

CDB1

CGS3

CGD1+ CGD2

M1

M3

CW

Cint = CDB1 + CDB2 + 2(CGD1 + CGD2)

Cext = CGS3 + CGS4 + CGD3 + CGD4

Cpar = Cw

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Intrinsic load

Extrinsic / fan-out load

Parasitic load

13/03/15

43

Req = R0 /S

Cint = SC0

C

t p t p 0 1 ext

SC0

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Isolated Inverter Sizing

C

t p t p0 1 ext

SC0

Assume Cpar can be

ignored or its effect can

be absorbed in other C

C

t p 0.69Req (Cint Cext ) 0.69Req Cint 1 ext

Cint

VDD

13/03/15

44

Inverter Chain

Assume size of inverter 1 is fixed.

Increasing S of inverter 2 reduces tp of inverter 2

But it increases tp of inverter 1 (higher load cap)

Expect an optimum!

Increasing S reduces delay until SC0 >> Cext

In

2

1

Out

CL

tp

S

{TPS} If CL is given and knowing properties of input source:

- How many stages are needed to minimize the delay?

- How to size the inverters?

tp0

Cext

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

45

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Delay Formula

C

t p t p0 1 ext

SC0

f

t p0 1

In

Out

2

N

input gate capacitance

CL

= Cint/Cgin = SC0 /Cgin

self

lf loading

l di coefficient

ffi i t

tp = tp,1 + tp,2 + …+ tp,N

property of technology, typically 1

fj

t p, j t p0 1

f = Cext /Cgin effective fanout

f

Cgin

C

ext x

Cgin SC0

C

t p0 1 gin, j 1

Cgin, j

N

N

Cgin, j 1

, C

t p t p, j t p0 1

CL

Cgin, j gin,N 1

j 1

j 1

[ tp = tp0(1+f/)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

46

Apply to Inverter Chain

1

Cgin

13/03/15

13/03/15

47

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

f = Cext /Cgin effective fanout ]

13/03/15

48

8

13/03/15

Apply to Inverter Chain

Optimal Tapering for Given N

Optimal size of each stage is geometric mean of 2 neighbors:

Delay equation has N-1 unknows, Cgin,2 … Cgin,N

N

Cgin, j 1

, C

t p t p , j t p0 1

CL

Cgin, j gin,N 1

j 1

j 1

N

Cgin, j Cgin, j 1 Cgin, j 1 ,

2

Cgin

, j Cgin, j 1 Cgin, j 1

Make N-1 partial derivatives for Cgin,j zero for minimization:

t p

Cgin, j

Cgin, j 1

1

t p0

0,

Cgin, j 1 C

2

gin, j

Cgin, j

j 2N 1

Cgin, j 1

1 b

c ab

a c2

fj

Optimal size of each stage is geometric mean of 2 neighbors:

Cgin, j Cgin, j 1 Cgin, j 1 ,

13/03/15

Cgin, j 1

Cgin, j 1

Cgin, j

49

CL

NF

Cgin,1

N

F = CL/Cgin,1: path fan-out.

Same fan-out, same delay for

each stage.

NF

C

t p0 1 gin, j 1 t p0 1

Cgin, j

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Optimal Tapering for Fixed-N

Summary

In

Load cap / input cap ratio

same for each stage

Cgin, j

fj

t p, j t p0 1

j 2N 1

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

j 2 N 1

13/03/15

50

Example

Out

In

1

f

C1 = Cgin,1

1

C1 = Cgin,1

i 1

Delay per stage and total Path Delay

fj

t p, j t p0 1

Out

CL

f2

NF

C

t p0 1 gin, j 1 t p0 1

Cgin, j

f1 = f2 = f3 = ... = F1/N

f1 x f2 x f3 x … = F

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

fj

t p Ntp0 1

f

CL/C1 has to be evenly distributed across N = 3 stages:

38

9t p0

t p 3t p0 1

f 38 2

F = CL/Cgin,1

13/03/15

51

Optimum Number of Stages

CL= 8 C1

f2

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

for 1

13/03/15

52

Optimum Effective Fanout f

Optimum f for given process defined by

For a given load, CL and given input capacitance Cin

find optimal f if N is free (and possibly non-integer)

CL F Cin f N Cin with N

f exp 1

f

ln F

ln f

f

=1

fopt

e=2.72

3.6

Nopt

lnF

0.78lnF

f

f exp 1

f

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

=0

t p0 ln F f ln f 1

0

ln2 f

ln f 1

ln F

ln f

(In practice, N must be rounded

up or down to integer value)

f

f t p0 ln F

t p Nt p0 1

ln f ln f

t p

N

Closed-form solution

only for = 0

13/03/15

53

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

54

9

13/03/15

Normalized delay function of F

Normalized tp vs. f

With Self-Loading =1,

fopt = 3.6

Slight increase of tp for

f > fopt

Choosing too few

stages (f > fopt) is

relatively harmless for

delay and saves area

oo many

a y stages is

s

Too

expensive in terms of

delay

NF

t p Nt p0 1

F

(= 1)

Inverter

Chain

Unbuffered

Two Stage

10

11

83

8.3

83

8.3

100

101

22

16.5

1000

1001

65

24.8

10,000

10,001

202

33.1

Fan-out of 4 (FO4) is safe common practice

http://en.wikipedia.org/wiki/FO4

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

55

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

56

Buffer Design

Power

(= 1)

1

N

f

tp

1

64

65

2

8

18

64

3

4

15

64

4

2.8

15.3

64

1

8

1

4

16

2.8

8

64

Dynamic Power

Static Power

Metrics

www.quietpc.com

1

22.6

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

57

CMOS Power Dissipation

13/03/15

58

Estimate

Furnace: 2000 Watt, r=10cm

P 6Watt/cm2

Processor chip: 100 Watt, 3cm2 P 33Watt/cm2

§ 5.5

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Power Density

Power dissipation is a very important circuit

characteristic

CMOS has relatively low static dissipation

Power dissipation was the reason that CMOS

technology won over bipolar and NMOS

technology for digital IC’s

(Extremely) high clock frequencies increase

dynamic dissipation

Low VT increases leakage

Advanced IC design is a continuous struggle to

contain the power requirements!

§ 1.3.4

24 hours audio

playback time

§ 5.5

Power-aware design, design for low power, is

blossoming subfield of VLSI Design

13/03/15

59

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

60

10

13/03/15

Power Evolution over Technology Generations

14

© ASME 2004

{TPS}: what is the difference in power between Bipolar and

CMOS technologies?

Module Heat Flux(watts/cm2)

A: 10 years

CMOS

IBM ES9000

Prescott

Jayhawk(dual)

12

Bipolar

10

T-Rex

Mckinley

Squadrons

Fujitsu VP2000

8

IBM GP

IBM 3090S

NTT

IBM RY5

6

Pentium 4

IBM RY7

Fujitsu M-780

Pulsar

4

IBM 3090

Start of

Water Cooling

2

Vacuum

0

1950

IBM 370

IBM 360

CDC Cyber 205

IBM 4381

IBM 3081

Fujitsu M380

IBM 3033

IBM RY6

IBM RY4

Apache

Merced

Pentium II(DSIP)

1960

1970

1980

1990

2000

2010

Year of Announcement

Introduction of CMOS over bipolar bought industry 10 years

(example: IBM mainframe processors)

[From: Jan Rabaey, Low Power Design Essential, Ref: R. Chu, JEP’04]

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

61

Low Power Design Essentials

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

62

Where Does Power Go in CMOS

Dynamic Power Consumption

Charging and discharging capacitors

Short Circuit Currents

Short circuit path between supply rails during

switching (NMOS and PMOS on together)

Leakage

Leaking diodes and transistors

May be important for battery-operated equipment

Recommended reading

(available online via University Library and site (?) of book)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

63

Dynamic Power

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

vDD

Equivalent circuit for lowto-high transition

i(t)

v0(t)

C

1

Ei

T i

EC - Energy stored on C

Ei = Power-Delay-Product P-D

important quality measure

EC iv 0dt

0

Cv0

Energy-Delay-Product E-D

combines powerspeed performance

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

64

Low-to-High Transition Energy

Dynamic Power

Ei = energy of switching event i

independent of switching speed

depends on process, layout

Power = Energy/Time

P

13/03/15

13/03/15

0

v 0 = v 0 (t )

i i (t ) C

dv 0

dt

dv0

dt

dt

V

VDD

DD

1

1

2

CVDD

Cv 0dv 0 Cv 02

2

2

0

0

65

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

66

11

13/03/15

Low-to-High Transition Energy

Low-to-High Transition Energy

vDD

i(t)

i(t)

vDD

v0(t)

v0(t)

C

EVDD

C

Energy delivered by supply

E diss

dv

2

EVDD i t VDDdt CVDD 0 dt CVDD

dt

0

0

1

2

2

EVDD CVDD

Ec CVDD

2

Where is the rest?

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Ediss i VDD v 0 dt

0

0

0

iVDDdt iv 0dt

EVDD Ec

Dissipated in transistor

13/03/15

Energy dissipated in transistor

VDD

67

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

High-to-Low Transition Energy

C

68

Compare Charging Strategies

Constant voltage

i

13/03/15

Equivalent circuit

+

V

i C

dVC

dT

Constant current

R

CV

T

R

I

C

-

dV

ER VR idt V VC C C dt

dt

0

0

Exercise: Show that the energy that is dissipated

in the transistor upon discharging C from VDD to

0 equals Ediss = ½CVDD2

I

V

1

V Vc CdVC CV 2

2

0

C

T

ER I RI dt I RI dt RI 2T

0

0

RC

CV 2

T

Reduced dissipation if T > 2RC = t76%

Difficult to reap benefits in practice

See ‘Adiabatic Logic’

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

69

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

CMOS Dynamic Power Dissipation

CLoad

2

CVDD

f

input

waveform

Can only reduce C, VDD or f to reduce dynamic

power

(NMOS current is used for

discharging)

VTn

NMOS

turns on

71

Shaded area is where both pull-up

and pull-down transistors are on

(this is when short-circuit current

can exist). This region is determined

by crossings of input waveform with

VTn and VDD-|VTp|.

Short circuit current for output

going low is the current delivered by

the PMOS

|VTp|

Independent of transistor on-resistances

13/03/15

70

Short Circuit Current

Energy

Energy

# transitions

Power

Time

transition

time

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

PMOS

turns off

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

{TPS} Discuss the influence of CLoad

on the amount of short circuit

dissipation

higher CLOAD higher dissipation?

or not?

13/03/15

72

12

13/03/15

Short Circuit Current

|VDSp|

|VTp|

input

waveform

VTn

|VTp|

VTn

NMOS

turns on

Short Circuit Current

Input and output waveforms of

inverter loaded with a large

capacitance (top) and with a small

capacitance (bottom).

output for

large CL

Short-circuit current increases with

|VDSp|. This is clearly much larger

on average for small CL compared

to large CL.

Similarly, short-circuit current can

exist for low-to-high transition at

output.

|VDSp|

Pull-up turns off

before VDSp becomes

significant

output for

small CL

Best to maintain approximately equal input/output slopes

PMOS

turns off

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

73

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

74

Sub-Threshold

Current

Leakage

Leakage current of reverse biased S/D junctions

Sub-threshold current of MOS devices

no channel parasitic bipolar device:

n+ (source) – p (bulk) – n+ (drain)

10-2

Important source of leakage

Rapidly becomes

bottleneck with lowering

threshold voltages

Modern technologies offer

low-Vt and hi-Vt devices

Balance speed and power

Linear

10-4

10-6

Quadratic

ID(A)

§3.3

10-8

10-10

qVGS

I D I 0e nkT

qVDS

kT

1 e

10-120

1 VDS

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Exponential

VT

0.5

1

1.5

2

Y. Taur, CMOS design near the limit

of scaling, IBMJRD, Volume 46,

Numbers 2/3, 2002

2.5

VGS (V)

13/03/15

75

Sub-Threshold Current

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

In

Out

C G1

Linear

10-4

ID(A)

Quadratic

10-8

10-120

Exponential

VT

0.5

1

1.5

2

Ex.

5.13

2.5

VGS (V)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

1

f

CL= FCG1

Goal:

Goal Minimize

Minimi e Energy

Energ of whole

hole circuit

circ it

C VDD

t pHL

0.52 parameters: f andLVDD

Design

'

VVTn =VVDSATn / 2)

)n k nVDSATn

tp tpref(Wof/ Lcircuit

with f =(V1DD

and

DD

ref

10-2

10-10

76

Transistor Sizing for Minimum Energy

Rapidly becomes bottleneck with lowering threshold

voltages

Modern technologies offer low-Vt and hi-Vt devices

Balance speed and power

10-6

13/03/15

77

f

F

t p t p0 1 1

f

VDD

See Eq. 5.21

t p0

VDD VTE

VTE = VT + ½VDSAT : Effective VT

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

78

13

13/03/15

Transistor Sizing (2)

f

F

t p t p0 1 1

f

t pref

VDD

VDD VTE

4

3.5

F

2f

t p 0

f VDD Vref VTE

t p 0ref 3 F

Vref VDD VTE

F

2 f

f

3 F

2

2.5

5

2

1.5

VTE: technology (0.5 V), Vref: standard supply (2.5 V)

F: fanout

VDD, f: design parameters

VDD is a function of f, given a fixed performance

VDD

Supply voltage needed

as a function of f to

maintain reference

performance

Lowest supply voltage

needed for f = F 0.5

F=1

3

vdd (V)

v

tp

t p0

(with = 1, tpref f=1):

Performance Constraint

1

Transistor Sizing (3)

VDD=f(f)

10

1

20

0.5

0

1

2

3

4

5

6

VDD

f 15 5F

14f 8f 2 8F 10fF

7

f

f 15 5F

14f 8f 2 8F 10fF

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

79

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

Transistor Sizing (4)

13/03/15

80

Transistor Sizing (5)

E/Eref=f(f)

2 C 1 1 f F

E VDD

g1

CL= FCG1

2

V

2 2f F

DD

E ref Vref 4 F

E

normalized energy

Energy for single Transition:

1.5

Size of 1st +

2nd inverter

Cg1 + Cint

F=1

V

2 2 2f F

E

DD

E ref Vref 4 F

2

1

5

10

0.5

F=20

VDD

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

f 15 5F

14f 8f 2 8F 10fF

13/03/15

0

1

6 7

f

Device sizing is effective

Oversizing is expensive for power

Optimal sizing for energy slightly different from sizing for performance

81

2

3

4

5

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

4004

13/03/15

82

Moore’s Law

The number of transistors

that can be integrated on a

single chip will double

every 18 months

Technology Scaling

Gordon Moore, co-founder of Intel

[El t

[Electronics,

i

Vol

V l 38,

38 No.

N 8,

8 1965]

Also see: IBM JRD, Vol 46, no 2/3, 2002

Scaling CMOS to the limit

http://www.research.ibm.com/journal/rd46-23.html

§ 5.6

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

83

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

84

14

13/03/15

IC Technology Scaling

Why Scaling

Scaling improves density and performance

Reduce price per function:

Want to sell more functions (transistors) per

chip for the same money better products

Build same products cheaper, sell the same

part for less money larger market

Price of a transistor has to be reduced

But also want to be faster, smaller, lower power

First order scaling theory

dimensions,

voltages

intrinsic delay

power per transistor

1982

S5

85

Scaling Models

2008

S150

2010

S200

(65nm)

first proc

13/03/15

2008 / 1971

0.007

0.007

0.007

0 00004

0.00004

Scaling trend

1971

S=1 (10m)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

1/S

1/S

1/S

1/S2

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

86

Scaling for Velocity Saturated Devices

Constant Field Scaling: S = U

Parameter

Fixed Voltage Scaling

most common model until 1990’s

only dimensions scale, voltages remain constant

Full Scaling (Constant Electrical Field)

ideal model — dimensions and voltage

g scale together

g

by

y

the same factor S

General Scaling

most realistic for today’s situation

Two scaling factors:

dimensions scale with S

voltages scale with U

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

Relation

General Scaling

W, L, tox

1/S

VDD, VT

1/U

NSUB

V / Wdepl2

S2/U

Area / Device

WL

1/S2

Cox

1/tox

S

Cgate

Cox W L

1/S

kn, kp

Cox W / L

S

Isat

Cox W V

1/U

Current Density

Isat / Area

S2/U

Ron

V / Isat

1

Intrinsic Delay

Ron Cgate

1/S

Power / Device

Isat V

1/U2

Power Density

P / Area

S2/U2

87

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

88

89

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

90

Technology Practice & ITRS

Scaling – Technology Generations

S 1.4 20.5 per generation

… – 250 – 180 – 130 – 90 – 65 – 45 – 35 – 22 – … nm

ITRS: International Technology Roadmap for Semiconductors

Industry-wide organization for forecasting technology

developments – and (planning) requirements

http://www.itrs.net/home.html

Not really – it is more like science

(and a self-fulfilling prophecy at the same time)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

15

13/03/15

Summary

Digital Gate Characterization (§ 1.3)

Static Behavior (Robustness) (§ 5.3)

VTC

Switching Threshold

Noise Margins

Dynamic Behavior (Performance) (§ 5.4)

Capacitances

Delay

Power (§ 5.5)

Dynamic Power, Static Power, Metrics

Scaling (§ 5.6)

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

91

TUD/EE ET4293 - DigIC - 12/13 - © NvdM - 03 Inverter

13/03/15

92

16