PDP System Review

advertisement

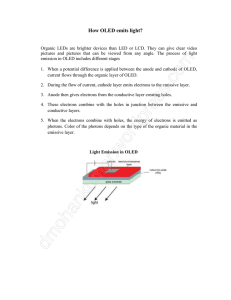

OSE-6820 Lecture 11: Introduction to Plasma Display Prof. Shin-Tson Wu College of Optics & Photonics University of Central Florida Email: swu@mail.ucf.edu Acknowledgment: Dr. Kung-Lang Chen of CPT UCF College of Optics & Photonics CREOL & FPCE Photonics & Display Group1 Outline • • • • • • • • • What is Plasma? PDP history Applications of PDP Discharge physics of PDP Process technology of PDP Driving technology of PDP Electronics system of PDP Performance improvement PDP vs. LCD & OLED 2 The fourth state of matter 3 PDP History 4 Early DC PDP TV at Bell System 5 The early AC PDP in UI: 1964 The monochrome plasma video display was coinvented in 1964 at the University of Illinois at Urbana-Champaign by Profs. Donald Bitzer, H. Gene Slottow, and graduate student Robert Willson for the PLATO Computer System. In 2007, SID established SlottowOwaki Prize, which is awarded for outstanding contributions to the education and training of students and professionals in the field of information display. 6 Recent Advances of PDP Samsung’s 102” PDP Pioneer 60” PDP Resolution: 1920x1080 Contrast ratio: 20,000:1 Brightness: 1000 Nits Surface reflection: 7.5% Large pixel size; burn-in? 7 Applications of PDP 8 Gas Discharge Physics MgO 95% Ne + 5% Xe 9 Gas Volume Reaction Main mechanism: 95% Ne + 5% Xe 10 Ne-Xe Energy Levels UV for excitation, near IR for inspection 11 Luminescence Mechanism Triode Electrodes: Surface discharge between top 2 electrodes (not phosphors) →Longer lifetime 12 Total Efficiency of PDP 95% Ne and 5% Xe Higher Xe → Higher V 13 Color PDP Structure Gas discharge→ UV → Phosphors →RGB lights 14 PDP: Cross-Section Scan Electrode Sustain Electrode Front Plate Plasma UV Light Barrier Rib Visible Light Back Plate Phosphor (R) Phosphor (G) Data Electrode Phosphor (B) 15 Color Formation Yellow R = 100% G = 100% B = 0% White R = 100% G = 100% B = 100% Purple R = 70% G = 30% B = 80% 16 Fabrication Process 17 AC-PDP Structure ITO (Ag; high conductivity) MgO meets these 3 conditions 18 ITO Process 19 Bus Electrode Process (Photo-polymer+ Ag particles) (Beta printing: Main stream approach) 20 Dielectric Process (Steel net) (Very thin dielectric) 21 MgO Protection Layer (Or electron beam: low I, high V) (Ion beam High I) Evaporation method 22 Address Electrode Process (Ag particles/binder) Bottom substrate 23 Dielectric Process Mesh: tension change after each use Resolution degradation 24 Rib Process: Early Days Rib height~150 μm: Each layer is ~15 μm; Needs 10 times Not practical! 25 New Rib Process (150 μm) New methods: Etching, printing, .. 26 Phosphor Process New methods: Dispensing, .. 27 Sealing Process 28 Panel Assembly Stainless steel clips: handled by robots 29 Sealing & Exhausting Ne+Xe Pressure: 450-500 torrs <1 ATM Thermal sealing 30 Block Diagram of PDP TV Set 31 Scanning Technique HDTV: n=1080 32 DC & AC Discharges Capacitor Simple grayscale control But resistors: 3M resolution → 6M contacts No resistors Mainstream approach: Grayscale: # of pulses 33 Memory Effect: AC-PDP If the 1st writing pulse is on, the remaining 3 are on If the 1st writing pulse is off, the remaining 3 are off. 34 Driving Waveforms Set-up: To erase memory; Address: determine which one ON These 3 periods repeat. Driving voltage ~ ±200 V for 95% N + 5% Xe 35 Gray Levels R and G: Kept at same width B: varies from 1, 2, 4, 8, 16, 32, 64, 128 Total gray levels: 256 36 Integration of weighted gray-level 37 PDP vs. LCD Plasma Emissive LCD Non-emissive Light Light Polarizer Front Plate (R) Electrode (G) Visible Light (B) Color Filter Electrodes UV Rear Plate Electrode Phosphors LCD Shutter Glass Plates Polarizer Backlight 38 Contrast Ratio Bright ambient (600 Lux) Dark Ambient (<1 lux) LCD ~800:1 ~2000:1 ~80:1 2000:1 PDP Surface reflection: LCD<2%; PDP~7.5% Reflection reduction: Film filter 40 PDP: Cost Structure Materials: 52%, Processing: 37%, Filter: 11% PDP cost: 70% driver & 30% panel 41 TV Market Forecast DisplaySearch: Q4, 2008 2009: LCD/PDP/CRT~73/15/12 42 Efficacy Improvement: Example 1 KW Whang et al, SID’05, p. 1130 43 Ex. 2: Volume vs. Surface Discharge • TFCS: thick film ceramic sheet T. Sato, et al., Proc. IDW, 1761 (2006) 44 Example 3: Phosphor Deposition TRANSMISSIVE REFLECTIVE HYBRID Fluorescent lamps use the hybrid type Homework 1. Read the following article and then compare/analyze the pros and cons between PDP, LED-lit LCD, and OLED TVs. 46 Recently, improvements in LCD TV has given substantial advantages to the consumer. One improvement is in the area of LED backlighting. This improvement alone yielded enhancement in image quality with respect to contrast and color gamut. Additional benefits of LED backlight is in the reduction in power consumption and reduction in thickness of TV. Plasma TV has been claiming higher contrast than LCD TV in dark environment. With the use of LED backlight with image adaptive dimming, this advantage is gradually being lost. The color gamut of RGB-LED- lit LCD TV is the highest of all types of TV including OLED TV. OLED panels are supposed to be thin because there is no backlight involved. The 11" OLED TV on the market is cautiously quoted to be 3mm at the "thinnest point of TV". Here is a quote from Samsung that appeared in December of 2008- "Even if the OLED panel is only 3mm thick, the TV will need to be 25mm or so – we are getting close to that with LCD technology." (In fact the thickness of recent models of LCD TVs is likely to be far less than 25 mm). This is true for LED-lit LCD TV as long as the backlight is fabricated in the 'edge-lit' mode. But the edge-lit mode will not be giving the advantage of high color gamut. In the 'direct-lit' mode of LED backlight, OLED TV has the advantage of slimness but has to face a stiff competition in power consumption because of the 'image adaptive dimming' employed in 'direct-lit' mode. Having said this. the competition in power consumption that OLED TV has to face is not that simple even with 'edge-lit' mode of LCD TV because of the impressive efficacy of white LEDs employed in 'edge-lit' mode. Plasma TV will also face the stiff competition in terms of power consumption. In December of 2008, 11" OLED TV by Sony consumed a power of around 45W. Recent development on 46" LCD TV employing 'image adaptive dimming‘ has demonstrated power consumption of 50W. So with the introduction of LED-lit LCD TV, the power consumption has been substantially dropping. 'White pixel‘ approach is another route available for both OLED technology and LCD technology to decrease the power further. What is significant here is that OLED technology has the inherent advantage of the 'absence' of backlight. Under this condition one would normally expect a significant drop in power consumption and low price. But it is not happening in the real world. (With 'but' and 'if' condition an extrapolation of OLED power and life can be arrived at). Any new technology will take time to reveal its full potential in the market place. OLED technology has the potential of low power consumption through its well demonstrated 'harvesting of triplet states'. The materials developed in the phosphorescent OLED family have demonstrated even 200,000 hours at lab level except for blue-emitting material. Blue is till a problem even at lab level. In terms of low cost of manufacturing, solution-based processes and 'roll-to-roll' manufacturing processes hold the key in OLED technology. None of 47 these are validated at the commercial product level in mass manufacturing. Substantial generation of learning curve in large area OLED mass manufacturing will start with the introduction of >32" OLED TV. Establishing infrastructure similar to LCD is capital intensive. In addition to all these barriers, LED backlight is imposing another barrier. Both OLED and LED have potential application in TV and Lighting. The R&D and manufacturing activity in LED is far higher than OLED. Big giants like, GE, Osram, Philips are taking the lead in LED lighting. The price of LED is coming down substantially. Efforts are underway to introduce 6" wafer in mass manufacturing and low cost substrates including glass are being experimented. Low power white LEDs in mass manufacturing have shown efficacy as high as 150 lm/w and lab level demonstration for white has revealed 247 lm/w. Medium power white LEDs have shown mass manufacturing level efficacy of 110 lm/w. What is important is that the efficacy of LEDs quoted is in higher range of brightness compared to OLED. OLEDs have also demonstrated 100 lm/w at lab level (1000 nits) but not yet at manufacturing level. Correlated color temperature for white is another question that needs to be looked in to precisely for comparison. It appears that LED efficacies are not saturating and is galloping. This is likely to keep pressure on OLED TV and plasma TV. Samsung, AUO, ChiMei, LG Display, Sony, Sharp, Panasonic are all in LCD/LCD TV activity and are exploiting LED backlight for low power consumption and enhancement in image quality. Sony and Samsung are leading in OLED manufacturing with Sony leading in OLED TV but Samsung delaying the introduction of large size OLED TV. All other things being equal (with LCD), theoretically OLED technology should be advantageous both from the price angle and power angle. This advantage is delayed due to various factors and one of the recent factors is the pressure from LED backlight. One area that OLED holds the key is in its potential to have 'roll-to-roll‘ manufacturing resulting in a dominant advantage of flexibility, slimness and low weight. In this aspect there will not be any threat from LCD TV or plasma TV. But in the next 10 years this is not likely to happen. 48