Automotive coatings OEM Primer-surfacer, good stone chip

advertisement

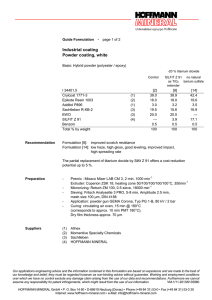

Guide Formulation - page 1 of 2 Automotive coatings OEM Primer-surfacer, good stone chip resistance, water dilutable Basis: Polyurethane Grinding stage A 14416.1 Setaqua B E 270 Deionized water Dimethylethanolamine, 10 % in water Surfynol 104 E Additol XW 395 Borchi Gen PP 100 Disperbyk-111 Special Black 4 Sachtleben R-FD-I Talkum IT extra SILLITIN Z 86 AKTISIL AM Aerosil R972 (11) (2) (3) (4) (5) (6) (7) (8) (9) (9) (10) [3] 4.23 16.00 0.60 0.52 0.52 0.47 --0.65 1.38 2.23 11.49 --0.36 [5] 4.23 16.00 0.60 0.52 0.52 0.47 --0.65 1.38 2.23 --11.49 0.36 [7] 4.23 16.00 0.60 0.52 0.52 --0.98 0.65 1.38 2.23 --19.44 0.36 42.81 7.06 5.23 0.96 0.80 95.31 42.81 7.06 5.23 0.96 0.80 95.31 42.81 7.06 5.23 0.96 0.80 103.77 Let-down stage Bayhytherm 3146 Bayhydrol U 241 Cymel 328 Byk-011 Dimethylethanolamine, 10 % in water Total parts by weight Recommendation Formulation [3]: PVC as usual for precipitated barium sulfate Formulation [5]: higher gloss and improved stone chip resistance Formulation [7]: increased solids content Remarks For getting a higher pH and herewith a better stability of formulation [7], it may be necessary to use a higher dosage of dimethylethanolamine. Preparation The preparation of the grinding stage was realized by dissolver with adapted bead mill (15 min, 7.2 m/s). Pre-mix raw materials of the completion in the a. m. order and incorporate to grinding stage. (1) (1) (3) (5) Our applications engineering advice and the information contained in this formulation are based on experience and are made to the best of our knowledge and belief, they must be regarded however as non-binding advice without guarantee. Working and employment conditions over which we have no control exclude any damage claim arising from the use of our data and recommendations. Furthermore we cannot assume any responsibility for patent infringements, which might result from the use of our information. VM-4/11.2013/6135980 HOFFMANN MINERAL GmbH • P. O. Box 14 60 • D-86619 Neuburg (Donau) • Phone (+49 84 31) 53-0 • Fax (+49 84 31) 53-3 30 Internet: www.hoffmann-mineral.com • e-Mail: info@hoffmann-mineral.com Guide Formulation - page 2 of 2 A 14416.1 Technical Data Fineness of grind Solids content (w/w) pH Flow time (4 mm flow cup, ISO 2431) µm % s [3] [5] [7] < 10 47.7 8.1 88 < 10 47.5 8.2 102 < 10 52.1 7.4 49 Adjust viscosity with deionized water to approx. 25 s (5 mm) or 30 s (4 mm) Properties Stoving conditions: primer-surfacer Dry film thickness Pendulum hardness (150 min after stoving) Gloss 60° (application 1d after completion) Gloss 60° (application 7d after completion) Stone chip tests Stoving: primer-surfacer on EDP + WBC + 2K-cc VDA test method (2 x 500g / 1.5 bar / 45°) Adhesion primer-surfacer / EDP Adhesion primer-surfacer / topcoat 10 min 23°C + 30 min 130°C µm s 31 104 51 --- 29 104 59 66 33 76 65 81 10 min 80°C + 20 min 140°C 10 min 80°C 10 min 23°C + 20 min 135°C 2-3 2-3* 1 2 1-2* 1 1-2 1 1 * = effect of talc BMW-test (-30°C) Suppliers (1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) --- Bayer MaterialScience Air Products Chemicals Allnex OMG Borchers Byk Chemie Orion Engineered Carbons Sachtleben Omya HOFFMANN MINERAL Evonik Industries Nuplex Resins Our applications engineering advice and the information contained in this formulation are based on experience and are made to the best of our knowledge and belief, they must be regarded however as non-binding advice without guarantee. Working and employment conditions over which we have no control exclude any damage claim arising from the use of our data and recommendations. Furthermore we cannot assume any responsibility for patent infringements, which might result from the use of our information. VM-4/11.2013/6135980 HOFFMANN MINERAL GmbH • P. O. Box 14 60 • D-86619 Neuburg (Donau) • Phone (+49 84 31) 53-0 • Fax (+49 84 31) 53-3 30 Internet: www.hoffmann-mineral.com • e-Mail: info@hoffmann-mineral.com