Slip-Resistant Footwear

advertisement

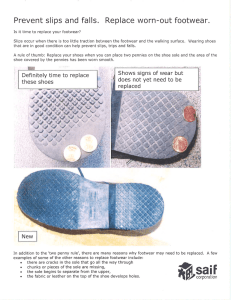

Preventing Slips and Falls: Slip-Resistant Footwear Risk Control Services FOR SAFER OPERATIONS Highlights: ■■ Slip-resistant soles and testing ■■ Tread design and material ■■ Implementing a slip-resistant footwear program This reference note provides guidelines on characteristics of slipresistant soles, guidelines for selecting slip-resistant footwear, and guidelines for implementing a slip-resistant footwear program. Slips, trips, and falls (STF) are a leading cause of workplace injuries. According to the 2013 Liberty Mutual Workplace Safety Index (WSI), the direct cost of same-level, fall-related injuries in the U.S. in 2011 was $8.6 billion. Slips and falls are the leading cause of injury among restaurant workers, and footwear labeled “slip resistant” seems to be effective in reducing slip risk in the restaurant industry.1 In most industry groups, slips and falls represent the highest or second-highest type of workers compensation claim.2 In addition, 11 percent of low back pain-related claims and 12 percent of low back pain-related claims costs are attributed to slips and falls.3 Proper housekeeping and the installation of quality slip-resistant floor surfaces is the foundation of any slip/fall prevention program. Using slip-resistant footwear is an additional intervention strategy for reducing the likelihood of slips and falls. A slip-resistant footwear program needs to consider the entire working environment, including the selection of proper footwear. Considering the floor condition, such as whether floors are wet or greasy, and whether the worker will be indoors or outdoors, has a bearing on footwear selection. Slip-Resistant Soles and Testing “Slip resistant” is a specific term given to footwear that reduces the likelihood of slipping. Terms such as oil resistant, fat resistant, acid resistant, alkaline resistant, or skid resistant do not mean slip resistant. The objective of a slip-resistant sole is to maximize contact between the outsole and the walkway surface through tread design and construction. Shoe soles labeled “slip resistant” in the U.S. are commonly recognized in the restaurant and food service industries, but there are no mandatory sole design or friction requirements that must be met in order to classify a sole as “slip resistant,” only general guidelines. Most restaurant slip-resistant shoe manufacturers measure their products using the Brungraber Mark II, Portable Inclinable Articulated Strut Tribometer (PIAST), and perform their tests using a greasy/soiled quarry tile. These tests are unique to the manufacturer and follow no industry standard test method. ISO 13287-2006, Personal Protective Equipment — Footwear — Test Method for Slip Resistance, using the SATRA slip-resistant tester4, 5 is used mostly in Europe and by some U.S. manufacturers who sell products overseas. In 2011, ASTM International published standard F2913, Standard Test Method for Measuring the Coefficient of Friction for Evaluation of Slip Performance of Footwear and Test Surfaces/Flooring Using a Whole Shoe Tester, which introduces a test method also using the SATRA tester.6 ASTM F2412, Standard Test Methods For Foot Protection and ASTM F2413, Standard Specification For Performance Requirements for Foot Protection replaced the withdrawn ANSI Z41, Standard for Personal Protection Protective Footwear, but at this writing, there is no slip test requirement for PPE footwear in the US. Tread Design Slip-resistant tread design is intended to maximize contact with the walkway surface by pushing or “squeezing” water and contaminants away from the sole at the heel strike, mid stance, and toe-off phases of the gait cycle. Tread Material Shoe sole construction (e.g., type of rubber, cleat design, and performance in various climate conditions, including cold) is important for traction, durability, and slip resistance. Most shoe soles are constructed of a blend of rubber polymers to achieve the highest performance possible for the product’s intended use, whether for athletic purposes, hiking, work, etc. Styrene butadiene rubber (SBR), nitrile-butadiene rubber (NBR), and polyurethanes are some of the more commonly used footwear soling materials.7 The harder or less flexible the rubber is, the less potential it has for helping with slip performance. In cold temperatures (e.g., 10°F), NBR rubbers can harden quickly, thereby reducing slip performance. Other polymers get harder even faster in cold temperatures. Some rubber blends remain softer in cold temperatures, and thus produce better slip results in cold environments. Organizations should work with footwear companies to customize a sole to meet the needs of traction, slip performance, and durability for the expected environment. Implementing a Slip-Resistant Footwear Program A slip-resistant footwear program should be in writing and should include a written policy for footwear selection, purchase, reimbursement, and replacement. A slip-resistant footwear policy should be customized to meet the specific needs of your organization. Before implementing a slipresistant footwear program, it is a good idea to have legal counsel review the policy for potential legal exposures. Purchasing slip-resistant footwear and specifying who pays is an important decision. The following are common footwear purchase options: ■■ ■■ ■■ Company purchase: Employer purchases slip-resistant footwear from a specified vendor and workers then pick their sizes. Employer subsidizes the entire cost and the specifies the look and style of footwear that employees wear. Employee purchase: Workers purchase their own footwear from specified vendors, or any vendor that meets the specifications defined in the employer’s policy. Discounts might be offered for work purchase of shoes from retail outlets or mail order. Payroll deduction plan: Employees order their own footwear from specified vendors according to the policy and the cost is automatically deducted from employees' paychecks. Footwear vendors work with the company to track purchases and provide information for payroll deduction. Summary Using slip-resistant footwear can be an effective strategy in preventing slips and falls. It is important that the features, benefits, and limitations of slip-resistant footwear be understood by managers before a program is implemented. Slip-resistant footwear, in combination with good housekeeping, can offer a comprehensive approach to managing slips and falls in the workplace. 1 Verma S.K., Chang W.R., Courtney T.K., Lombardi D.A., Huang Y.H., Brennan M.J., et al., A Prospective Study of Floor Surface, Shoes, Floor Cleaning and Slipping in U.S. Limited-Service Restaurant Workers, Occupational and Environmental Medicine; 68(4), 2011, 279-85. 2 Leamon, T.B., Murphy, P.L., Occupational Slips and Falls: More Than a Trivial Problem, Ergonomics, Vol. 38, No. 3, 1995, 487-498. 3 Murphy, P.L. and Courtney, T.K., Low Back Pain Disability: Relative Costs by Antecedent and Industry Group, American Journal of Industrial Medicine, Vol. 37, 2000, 558-571. 4 ISO 13287-2006, Personal Protective Equipment Footwear — Test Method for Slip Resistance. 5 SATRA Technology Centre, TM 144, Slip Resistance Test Method, and STM 603, Slip Resistance Testing Machine. 6 ASTM F2913, Standard Test Method for Measuring the Coefficient of Friction (Slip Resistance) of Footwear and Test Surfaces/Flooring Using a Whole Shoe Tester, ASTM International, West Conshohocken, PA 19428. 7 Di Pilla, S., Slip and Fall Prevention: A Practical Handbook, 2nd Edition, Taylor and Francis Group, CRC Press, 2010. helmsmantpa.com The illustrations, instructions and principles contained in the material are general in scope and, to the best of our knowledge, current at the time of publication. No attempt has been made to interpret any referenced codes, standards or regulations. Please refer to the appropriate code-, standard-, or regulation-making authority for interpretation or clarification. Provided that you always reproduce our copyright notice and any other notice of rights, disclaimers, and limitations, and provided that no copy in whole or in part is transferred, sold, lent, or leased to any third party, you may make and distribute copies of this publication for your internal use. © 2015 Liberty Mutual Insurance, 175 Berkeley Street, Boston, MA 02116. 04/15