Consolidating Concrete

in Congested Areas

Special design considerations and construction

techniques can ease congestion problems

ome design requirements

for concrete construction,

such as seismic provisions

and post-tensioning, can

result in congested areas within the

formwork that are difficult to consolidate. Reinforcing steel, embedments, boxouts, prestress ducts,

and anchorages all contribute to

congestion. Certain form shapes also can make concrete difficult to

place and consolidate.

Incomplete consolidation in

congested areas can lead to structural inadequacy and time-consuming, expensive remedial work.

Honeycombed concrete can occur

because vibrators can’t consolidate

concrete around and through the

congestion and out to the form

face. Incomplete consolidation also

S

can result in excessive amounts of

entrapped air, which reduces concrete strength and increases permeability.

Successful concreting in highly

congested areas requires special

design considerations, concrete

mixtures, and placement and consolidation techniques. Here are

some factors that contribute to

congestion and ways to minimize

congestion problems.

Causes of Congestion

Reinforcing steel. Congestion

can be a problem when the clear

spacing between rebar or between

a bar and the form is less than 11⁄3

times the maximum size of coarse

aggregate used in the concrete mixture. This condition is more likely

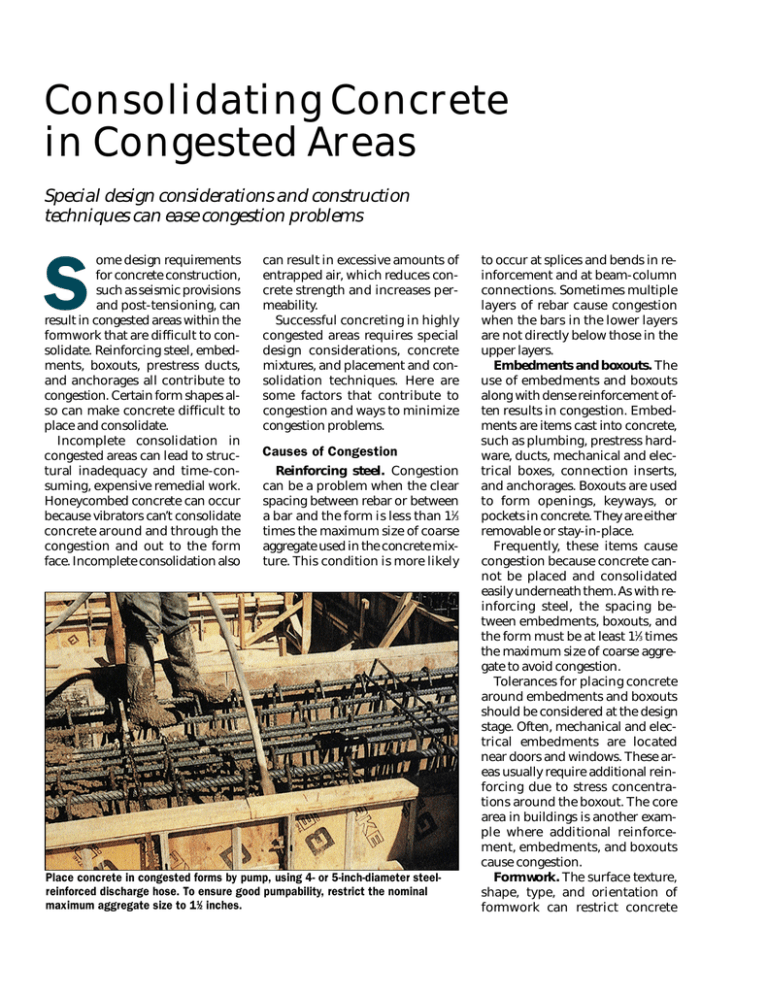

Place concrete in congested forms by pump, using 4- or 5-inch-diameter steelreinforced discharge hose. To ensure good pumpability, restrict the nominal

maximum aggregate size to 112⁄ inches.

to occur at splices and bends in reinforcement and at beam-column

connections. Sometimes multiple

layers of rebar cause congestion

when the bars in the lower layers

are not directly below those in the

upper layers.

Embedments and boxouts. The

use of embedments and boxouts

along with dense reinforcement often results in congestion. Embedments are items cast into concrete,

such as plumbing, prestress hardware, ducts, mechanical and electrical boxes, connection inserts,

and anchorages. Boxouts are used

to form openings, keyways, or

pockets in concrete. They are either

removable or stay-in-place.

Frequently, these items cause

congestion because concrete cannot be placed and consolidated

easily underneath them. As with reinforcing steel, the spacing between embedments, boxouts, and

the form must be at least 11⁄3 times

the maximum size of coarse aggregate to avoid congestion.

Tolerances for placing concrete

around embedments and boxouts

should be considered at the design

stage. Often, mechanical and electrical embedments are located

near doors and windows. These areas usually require additional reinforcing due to stress concentrations around the boxout. The core

area in buildings is another example where additional re i n f o rc ement, embedments, and boxouts

cause congestion.

Fo rm wo rk . The surface texture,

shape, type, and orientation of

f o rm w o rk can restrict concrete

placement. Used or poorly oiled

wood forms are more likely to

cause problems than steel or plastic-lined forms. The frictional resistance of wood forms can impede

concrete flow.

Battered form faces or counterforts can result in areas of poor consolidation. Their sloped profile restricts concrete placement, vibrator

access, and air migration during vibration. Corbels and haunches also

are common areas of congestion.

Design Considerations

Before work begins, carefully review design drawings with the engineer to ensure that appro p ri a t e

allowances have been included in

congested areas. Best results are

achieved when the intent of the design can be met under field conditions. Pay careful attention to the

following factors:

Reinforcing steel arrangement

and splicing. Reinforcing steel

should be arranged to provide

enough space for concrete placement into the form. The engineer

may have to increase the member

size over that required by design

calculations to provide sufficient

space. In extreme cases, it may be

necessary to include access ways

through the reinforcing steel.

Lap splicing of rebar can cause

congestion problems in areas with

high densities of reinforcing steel.

Sometimes this problem can be

solved by mechanically connecting

rebar, as described in Reference 1. In

special cases, rebar may be spliced

by welded connections. However, a

mechanical or welded connection

will produce some localized increase in rebar diameter. This

should be considered when detailing clearances and bar spacing.

Embedment

and

boxout

a r ra n g e m e n t. Embedment and

boxout configuration should consider reinforcing details, concrete

mix pro p o rt i o n s, and nominal

maximum aggregate size.

To eliminate form penetrations,

use void forms. If the forms are

large (more than 2 feet in either direction), placement and vibration

tubes should be provided. These are pipes

through the formed

blockout that permit access for concrete placement and vibration.

Boxouts that are to be

removed and exceed 2

feet in either direction

also should have placement and vibration

tubes. Stay-in-place boxout forms, such as hol- Use flowing concrete, with a slump of 71⁄2 inches or

low metal door and win- more, in highly congested areas where less workable

dow

frames,

often concrete mixtures can’t be properly placed and

require bracing and can- consolidated.

not be cut to accommosuch as around multiple embeddate placement and vibration

ments or dense reinforcement. The

tubes. Where possible, use stay-inmodified mixture may include adplace boxouts having tolerances

justments in aggregate size and cethat allow them to be shifted.

ment content and the use of adWhere the boxout spans from

mixtures and fly ash.

one form face to the other, provide

No rm a l l y, engineers will specify

access through the bottom of the

the largest nominal maximumboxout. As the concrete reaches the

s i ze - a g g regate mixtures that are

bottom of the boxout, the access

readily available and can be consolcan be closed off with a preformed

idated by conventional methods.

insert, which is then bolted to the

For congested areas, howe ve r, engiboxout form.

neers may specify smaller maxiFo rm wo rk design. Fo rm w o rk

mum-size aggregate depending on

design can contribute significantly

the degree of congestion.

to congestion if it does not take

For example, when concrete with

other factors into account. These

a nominal maximum-size aggreinclude:

gate of 1 1⁄2 inches is specified, the

• Number, location, and size of tie

engineer may allow substitution of

rods

3

⁄4-inch maximum-size aggregate in

• Location of embedments and

a portion of the concrete. Where

blockouts

the design mixture specifies nomi• Location of trunks or concrete

nal maximum-size aggregate of 3⁄4

hose

inch for extremely congested areas,

• Form height

the engineer may allow substitu• Use of side ports

tion of 1⁄2-inch maximum aggregate

In narrow, congested walls, exterin a portion of the placement.

nal tie rods can help reduce congesWhen the maximum aggregate size

tion. The tie rods are attached to the

of a specified mix is reduced, the

bulkhead walers at the ends of the

mix has to be modified to maintain

wall. Another way to ease congesthe specified water-cement ratio

tion is to increase the spacing of

and design strength. This can be

loadbearing members and use highdone by adjusting cement and waer capacity ties and form sheathing.

ter contents.

Mix Proportioning

Proper placement of concrete in

congested areas usually requires a

The use of modified mix propormaterial with flowing chara c t e ri stions may be necessary to achieve

tics. Flowing concrete typically has

proper consolidation in congested

a slump of 71⁄2 inches or more and

a re a s. This mixture need only reremains cohesive without excessive

place the original mix proportions

bleeding or segregation (Ref. 2).

in zones of extreme congestion,

Use flowing concrete in areas

where less workable concrete mixtures cannot be properly placed

and consolidated due to lack of

mobility and vibrator access.

Producing flowing concrete only

by adding extra water results in

lower-quality concrete. Instead, use

chemical admixtures that meet

ASTM C 494 and ASTM C 1017 requirements. These include:

• High-range water-reducing admixtures (superplasticizers),

ASTM C 494, Types F or G

• A high-range water-reducing

admixture and a water-reducing

and retarding admixture, ASTM

C 494, Type D, or water-reducing and accelerating admixture,

ASTM C 494, Type E

• High dosages of a water-reducing normal-set admixture,

ASTM C 494, Type A, plus a water-reducing and accelerating

admixture, ASTM C 494, Type E

Where flowing concrete is required, prepare trial mixtures made

with the materials to be used in the

project. Test each mixture under

the environmental conditions expected on the project. Trial mixtures should have initial slumps resulting from the maximum

allowable specified water-cement

ratio. Vary chemical admixture

dosages to achieve the desired

slump range.

Some specifications also allow

the addition of fly ash to enhance

workability. Typically, an addition

of fly ash equal to 5% of the cement

weight will significantly increase

concrete flow.

Placing Methods

Review reinforcing steel, embedment, and formwork drawings and

select placing meth-ods to suit conditions. Using cranes and buckets

along with hoppers and trunks to

place concrete often is not possible

if forms are congested. Most concrete is placed in congested forms

by pump or placing booms using 4or 5-inch-diameter steel-reinforced

hose. To ensure good pumpability,

restrict the nominal maximum aggregate size to 11⁄2 inches.

Most concrete can

be placed in congested forms by lowe ring the discharg e

hose through the rei n fo rcement

to

within 6 feet of the surface, then disc h a rg i n g

concrete for that lift

thickness. Raise and

re i n s e rt the hose a t

10-foot centers. In

n a r row wall form s

w h e re it is not possible to lower the

hose through the

re i n f o rcement, attach lie-flat hose to

the end of the d i sc h a rge hose. Ma d e

of

a

pliable,

p o l y v i n y l - c h l o ri d e reinforced material,

lie-flat hose can

t ransfer concre t e

ve rtically thro u g h

very narrow spaces.

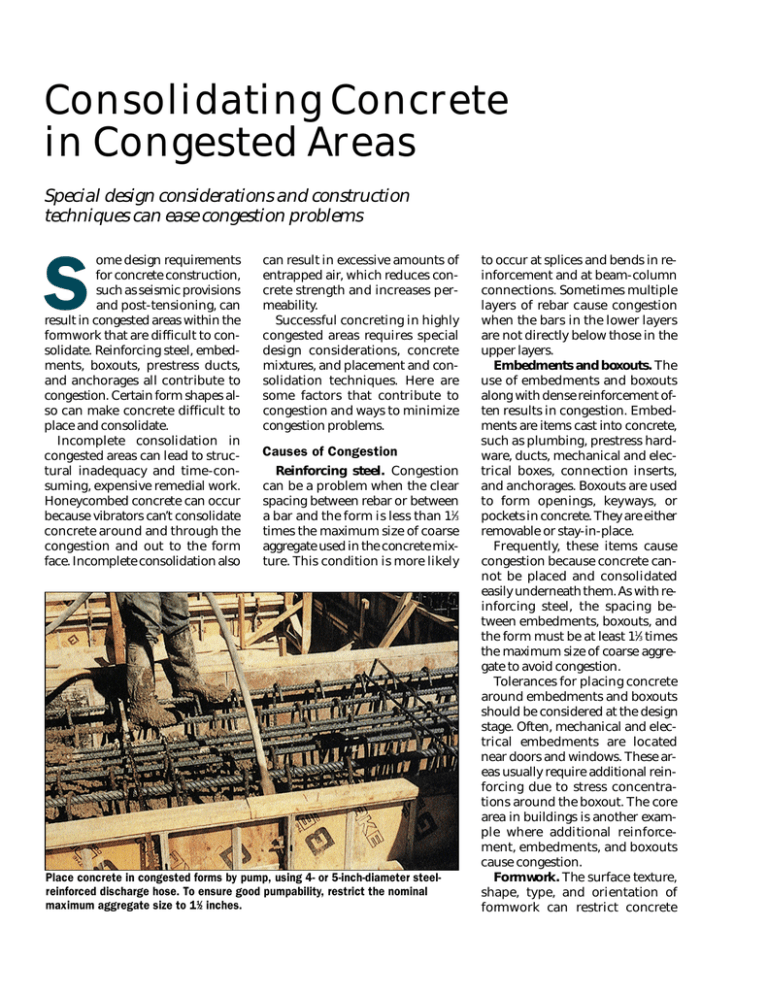

Where wall placements extend up to Often, it’s difficult to adequately place and consolidate

the underside of concrete underneath a boxout. As this project shows,

s t ru c t u ral

steel gaps can result. The problem could have been avoided

members or concrete by the use of placement and vibration tubes through

the boxout to permit access.

beams, place concrete under pressure

Un re s t ricted means that the conthrough slide valves. A slide valve is

crete is unimpeded all the way

a short piece of steel pipe with a

a

round the inside of the column

slide plate mounted in it. One end

and

there are no baffles restricting

of the pipe is bolted to the form and

u

pw

a

rd movement. If there is a verthe other end receives concrete

tical

steel

“H” section within a colfrom the discharge hose. Pump

umn,

concrete

will not pump if it

concrete through the open slide

enters

at

a

point

perpendicular to a

valve to fill the form. When the

flange

of

the

“H

.” It’s best to disform is full, close the slide plate and

c

h

a

rge

concrete

directly into the

disconnect the line. After concrete

web

of

the

“H

.”

has set, the slide valve and supportWhen pumping from the boting form are removed.

tom,

restrict the number and size of

Sometimes pumping concrete

embedments

or boxouts in the

from the bottom of the form works

f

o

rm.

They

can

restrict concrete

well. The shape of the element def

l

ow.

A

large

number

of dowels also

termines whether the technique is

can

re

s

t

rict

flow.

Provide

at least a

viable. Rectangles, squares, and

4-inch

clearance

between

an emother polygons require special

bedment

and

re

i

n

f

o

rcement

or 4

f o rm w o rk designs because presinches

free

at

the

top

of

the

placesure concentrates at the corners of

ment below the structural steel or

angles or point loading develops.

turned out reinforcement.

C i rc u l a r, unrestricted stru c t u re s,

such as columns, lend themselves

best to pumping from the bottom.

Consolidation

Plan all aspects of consolidation

before placing concrete. If used

p ro p e r l y, internal vibrators do the

best job of consolidation. Howe ve r,

external vibration may be needed

to supplement internal vibration in

congested areas.

Use small-diameter internal vibrators in the lower areas within

the forms when a high-range water-reducing admixture is used with

a modified concrete mixture. When

placing a normal concrete mixture

having larger maximum-size aggregate, use bigger vibrators (up to 3

inches in diameter).

When reinforcing steel limits access into a form, lower additional

vibrators down through the upper

reinforcing mat from the top of the

placement. This will encourage operators to keep vibrators in a nearly

vertical position instead of trying to

throw the vibrators hori zo n t a l l y

past interferences. Be careful not to

lodge or snag a vibrator within the

placement; it can be impossible to

extract.

In congested, narrow wall forms,

it may be necessary to place side

ports in one form. Side ports are

temporary openings in one side of

the form that allow workers to lower vibrators into the form and observe concrete placement. Typically, they are 2 feet square with a

spacing of 6 feet.

It’s also possible to lower smalldiameter vibrators between the

outer layer of reinforcement and

the form face. Howe ve r, in the case

of architectural faces, use external

vibrators.

Whatever consolidation method

is used, do not underv i b ra t e. Und e rv i b ration can result in honeycombed concrete, air pockets, and

lack of density in congested areas.

See Reference 2 for more information on consolidating and vibrating

concrete.

References

1. ACI 439.3R-83, “Mechanical Connections of Reinforcing Bars,” American Concrete Institute (ACI), Detroit.

2. ACI 309R-87, “Guide for Consolidation of Concrete,” ACI.

Acknowledgment

This article is adapted from “Guide to

Consolidation of Concrete in Congested Areas,” ACI Structural Journal,

September-October 1992.

PUBLICATION #C940228

Copyright © 1994, The Aberdeen Group

All rights reserved