Heating cable VC

advertisement

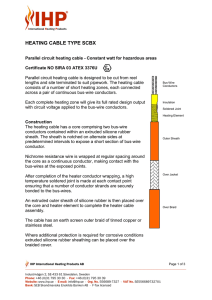

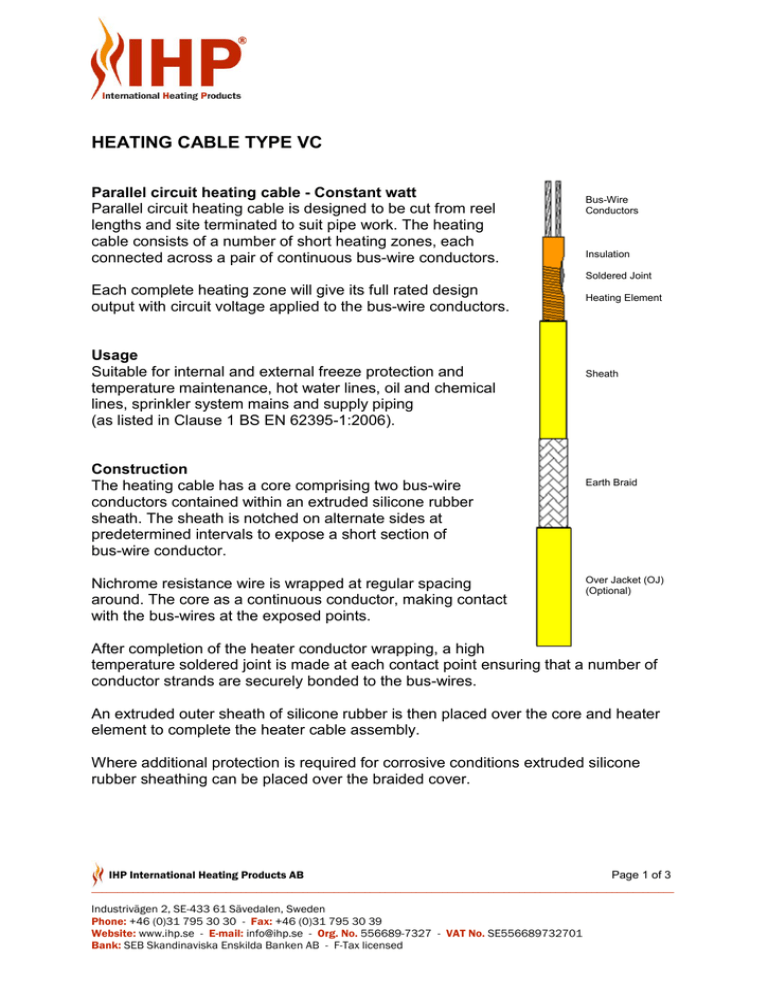

HEATING CABLE TYPE VC Parallel circuit heating cable - Constant watt Parallel circuit heating cable is designed to be cut from reel lengths and site terminated to suit pipe work. The heating cable consists of a number of short heating zones, each connected across a pair of continuous bus-wire conductors. Bus-Wire Conductors Insulation Soldered Joint Each complete heating zone will give its full rated design output with circuit voltage applied to the bus-wire conductors. Usage Suitable for internal and external freeze protection and temperature maintenance, hot water lines, oil and chemical lines, sprinkler system mains and supply piping (as listed in Clause 1 BS EN 62395-1:2006). Construction The heating cable has a core comprising two bus-wire conductors contained within an extruded silicone rubber sheath. The sheath is notched on alternate sides at predetermined intervals to expose a short section of bus-wire conductor. Nichrome resistance wire is wrapped at regular spacing around. The core as a continuous conductor, making contact with the bus-wires at the exposed points. Heating Element Sheath Earth Braid Over Jacket (OJ) (Optional) After completion of the heater conductor wrapping, a high temperature soldered joint is made at each contact point ensuring that a number of conductor strands are securely bonded to the bus-wires. An extruded outer sheath of silicone rubber is then placed over the core and heater element to complete the heater cable assembly. Where additional protection is required for corrosive conditions extruded silicone rubber sheathing can be placed over the braided cover. IHP International Heating Products AB Page 1 of 3 _________________________________________________________________________________________________________________ Industrivägen 2, SE-433 61 Sävedalen, Sweden Phone: +46 (0)31 795 30 30 - Fax: +46 (0)31 795 30 39 Website: www.ihp.se - E-mail: info@ihp.se - Org. No. 556689-7327 - VAT No. SE556689732701 Bank: SEB Skandinaviska Enskilda Banken AB - F-Tax licensed Specification Conductors ........................................ Copper stranded flexible 30/0.25mm (1.5mm²) Core ................................................... Silicone rubber Heater element ................................. Nickel/chrome 80/20 Solder ................................................ High melting point 296°C Outer Sheath ..................................... Silicone rubber Width ................................................. 9.75mm Thickness .......................................... 5.25mm Heater zone ....................................... 0.5 or 1m according to design output Braid .................................................. Stainless steel/Plated copper Temperature ...................................... Min. -60°C – Max. +200°C Standard ............................................ BS EN 62395-1:2006 Min Bend Radius ............................... 50mm Range Type Volts Watt/m VC 8 VC 12 VC 16 VC 20 VC 8 VC 12 VC 16 VC 20 VC 30 VC 38 110 110 110 110 240 240 240 240 240 240 8 12 16 20 8 12 16 20 30 38 Heater zone Length (m) 1.0 1.0 0.5 0.5 1.0 1.0 1.0 1.0 1.0 1.0 Max circuit Length (m) 110 88 82 76 275 187 154 132 116 98 Max recommended Pipe Temp ºC 190 175 160 145 190 175 160 145 100 90 Electrical Heater Zone Heater Zone Insulated Bus-wire end Rated Voltage Rated Voltage – 220V/240V or 110V/120V AC/DC. Heater Zone (according to design) – 0.5/1.0m. IHP International Heating Products AB Page 2 of 3 _________________________________________________________________________________________________________________ Industrivägen 2, SE-433 61 Sävedalen, Sweden Phone: +46 (0)31 795 30 30 - Fax: +46 (0)31 795 30 39 Website: www.ihp.se - E-mail: info@ihp.se - Org. No. 556689-7327 - VAT No. SE556689732701 Bank: SEB Skandinaviska Enskilda Banken AB - F-Tax licensed A 30mA trip Residual Current Circuit Device (RCCB) or Earth Leakage Circuit Breaker (ELCB) is recommended for use with heating cables. Heat losses To calculate heat loss per meter of pipe: Heat losses W/m = Δt x ke x Loss Factor Pipe NB (mm) 13 25 38 50 75 100 150 Δt = Pipe temp. – Ambient temp. ke = Thermal conductivity Thermal Insulation Thickness (mm) 38 Loss Factor ( BS 6351) 4.13 5.36 6.63 7.69 10.15 12.30 16.82 25 5.16 6.91 8.74 10.28 13.90 17.08 23.82 50 3.58 4.56 5.54 6.36 8.24 9.88 13.30 Thermal Conductivity (ke) for Mineral/Glass Fiber: Δt°C Ke 30 0.034 40 0.035 60 0.036 80 0.037 100 0.038 120 0.040 140 0.042 160 0.044 To comply with BS 6351 allowance should be taken of maximum heater resistance tolerance (± 10%) and voltage variation (± 6%) = 1.1 = 1.25 x Heat Loss. (0.94)² A further design factor of 10% may be added. IHP International Heating Products AB Page 3 of 3 _________________________________________________________________________________________________________________ Industrivägen 2, SE-433 61 Sävedalen, Sweden Phone: +46 (0)31 795 30 30 - Fax: +46 (0)31 795 30 39 Website: www.ihp.se - E-mail: info@ihp.se - Org. No. 556689-7327 - VAT No. SE556689732701 Bank: SEB Skandinaviska Enskilda Banken AB - F-Tax licensed