Gas Distribution Systems - The Harris Products Group

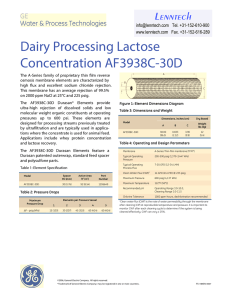

advertisement