F H M 2 - Western Enterprises

advertisement

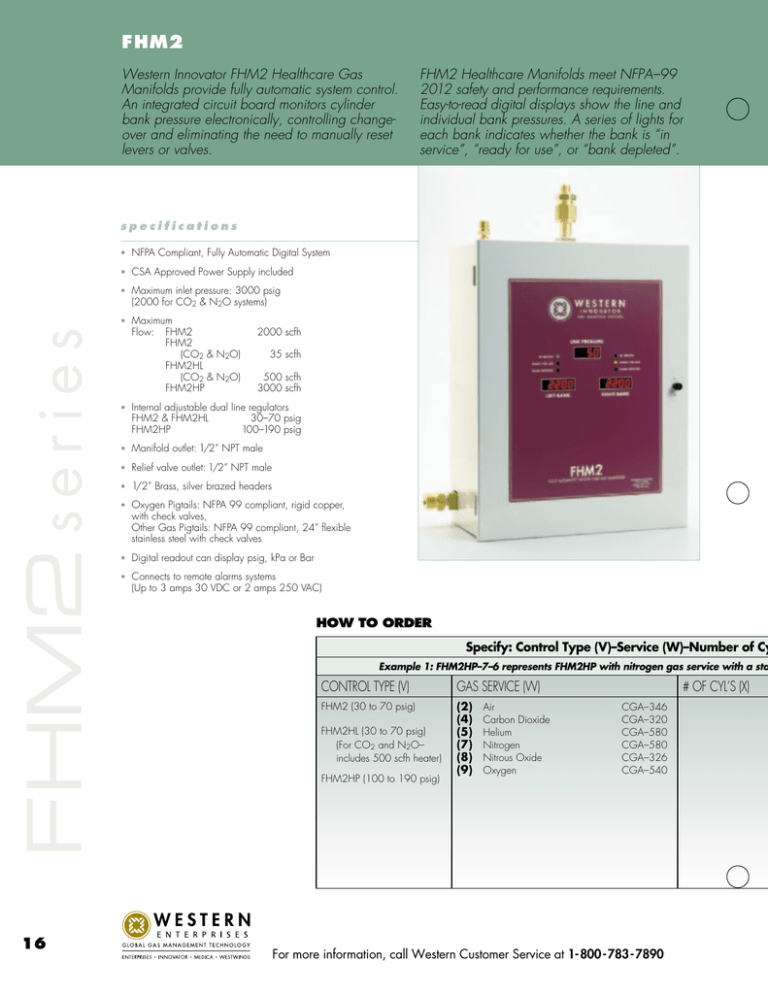

F HM2 W estern InnovatorFH M 2 H ealthcare G as M anifolds provide fully autom atic system control. An integrated circuitboard m onitors cylinder bank pressure electronically,controlling changeoverand elim inating the need to m anually reset levers orvalves. FH M 2 H ealthcare M anifolds m eetN FPA–99 2012 safety and perform ance requirem ents. Easy-to-read digitaldisplays show the line and individualbank pressures.A series oflights for each bank indicates w hetherthe bank is “in service”,“ready foruse”,or“bank depleted”. specifications t NFPA Compliant, Fully Automatic Digital System t CSA Approved Pow er Supply included t M aximum inlet pressure: 3 0 0 0 psig (20 0 0 for CO 2 & N2O systems) FHM2 s e r i e s t M aximum 16 Flow : FH M 2 FH M 2 (CO 2 & N2O ) FH M 2H L (CO 2 & N2O ) FH M 2H P 20 0 0 scfh 3 5 scfh 5 0 0 scfh 3 0 0 0 scfh t Internal adjustable dual line regulators FH M 2 & FH M 2H L FH M 2H P 3 0 –7 0 psig 10 0 –19 0 psig t M anifold outlet:1/2” NPT male t Relief valve outlet:1/2” NPT male t 1/2” Brass, silver brazed headers t O xygen Pigtails: NFPA 9 9 compliant, rigid copper, w ith check valves, O ther G as Pigtails: NFPA 9 9 compliant, 24 ” flexible stainless steel w ith check valves t Digital readout can display psig, kPa or Bar t Connects to remote alarms systems (U p to 3 amps 3 0 VDC or 2 amps 25 0 VAC) HO W TO O R D ER Specify: Control Type (V)–Service (W)–Number of Cy Example 1: FHM2HP–7–6 represents FHM2HP with nitrogen gas service with a sta CO NTRO L TYPE (V) G AS SERVICE (W ) FH M 2 (3 0 to 7 0 psig) (2 ) (4 ) (5 ) (7 ) (8 ) (9 ) FH M 2H L (3 0 to 7 0 psig) (For CO 2 and N2O – includes 5 0 0 scfh heater) FH M 2H P (1 0 0 to 1 9 0 psig) Air Carbon Dioxide H elium Nitrogen Nitrous O xide O xygen # O F CYL’S (X) CG CG CG CG CG CG A–3 4 6 A–3 20 A–5 8 0 A–5 8 0 A–3 26 A–5 4 0 For m ore inform ation, callW estern C ustom er Service at1-800-783-7890 O verall M anifold Length 21 ” M anifold D epth:10 ” C abinet W eight: 6 5 lbs 16 ” 5” forstaggered 10” forstandard, crossoverand verticalcrossover. 45” Example: FH M 2–9–4–O xygen (9=C G A–540)M anifold for4 C ylinders D es ig n Len g t h s TO TA L N O . O F C Y LIN D E R S 4 6 8 10 12 16 20 Standard (1 0 ” Centers) O verall M anifold Length 5 ’–1 1 ” (1 .8 0 m) 7 ’–7 ” (2.3 1 m) 9 ’–3 ” (2.8 2m) 1 0 ’–1 1 ” (3 .3 3 m) 1 2’–7 ” (3 .8 4 m) 1 5 ’–1 1 ” (4 .8 5 m) 1 9 ’–3 ” (5 .8 7 m) Staggered Design (5 ” Centers) O verall M anifold Length 5 ’–1 ” (1 .5 5 m) 5 ’–1 1 ” (1 .8 0 m) 6 ’–9 ” (2.0 6 m) 7 ’–7 ” (2.3 1 m) 8 ’–5 ” (2.5 7 m) 1 0 ’–1 ” (3 .0 7 m) 1 1 ’–9 ” (3 .5 8 m) Vertical Crossover (1 0 ” Centers) O verall M anifold Length 4 ’–3 ” (1 .3 0 m) N/ A 5 ’–1 1 ” (1 .8 0 m) N/ A 7 ’–7 ” (2.3 1 m) 9 ’–3 ” (2.8 2m) 1 0 ’–1 1 ” (3 .3 3 m) Crossover (1 0 ” Centers) O verall M anifold Length 4 ’–3 ” (1 .3 0 m) N/ A 5 ’–1 1 ” (1 .8 0 m) N/ A 7 ’–7 ” (2.3 1 m) 9 ’–3 ” (2.8 2m) 1 0 ’–1 1 ” (3 .3 3 m) ylinders (X)–Header Configuration (Y)–Mounting (Z) andard header configuration of 3 cylinders per side which is mounted on the wall. H EADER CO NFIG U RATIO N (Y) B LA NK –Standard 1 0 ” on Center M O U NTING (Z) B LA NK = W all mount F = Floor mounted V–Vertical crossover 1 0 ” on Center S–Staggered 5 ” on Center C–Crossover 1 0 ” on Center U –Sh aped – Draw ing Required L–Sh aped – Draw ing Required 17