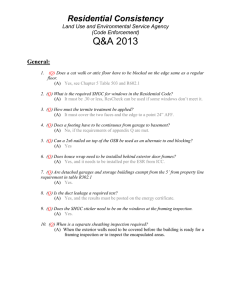

chapter 3 use and occupancy classification

advertisement