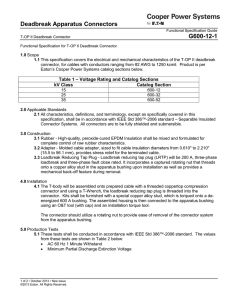

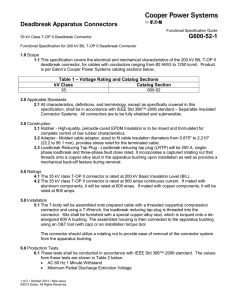

600-10 600 A 15/25 kV Class Bol

advertisement