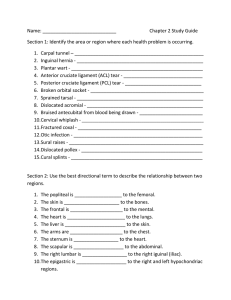

KICK-OFF MEETING - SRF FOR ELLIPTICAL CAVITIES

advertisement

KICK-OFF MEETING - SRF FOR ELLIPTICAL CAVITIES HIGH BETA CAVITIES PROTOTYPES TESTED AT SACLAY 23/06/2015 Franck PEAUGER On behalf of CEA Saclay team MECHANICAL FEATURES OF HIGH BETA CAVITY PROTOTYPES Half cells, beam pipes and ports in pure Niobium RRR > 250 He tank in Titanium grade 2 Flanges in NbTi with hexagonal aluminium gaskets Assembly by electron beam welding (no brazing) HELIUM RETURN HOM port Fint =48.2 mm (for RF measurements only, removed on series cavities) Ti INTERFACE PIECES FOR TUNER BEAM FLANGE 1 Fint=140 mm TANK STIFFENERS Ti HYDROFORMED BELLOW BEAM FLANGE 2 Fint=140 mm Ti HELIUM TANK 5 CELLS CAVITY FPC Fint=100 mm CELL STIFFENERS HELIUM SUPPLY Total mass: 150 kg (including screws, flanges and handling tooling) Overall dimensions: 1316 mm length, 500 mm diameter CAVITY MANUFACTURING Niobium from Tokyo Denkai, 4.5 mm thickness instead of 3.8 mm (before etching) Kick-off in Sept. 2012 Trimming operations of dumbbells in presence of CEA staff ESS086-P01 ESS086-P02 received after 13 months received after 18 months Fp = 703.704 MHz (-0.118 MHz) L = 1322.9 mm (+6.7 mm) Fp = 703.553 MHz (-0.269 MHz) L = 1321.7 mm (+5.5 mm) Field flatness: 86% Field flatness: 60% Target frequency, at 300 K before chemical etching: Fp = 703.822 MHz, target length = 1316.3 mm FIELD FLATNESS TOOLING AT CEA ESS 086 P01 (Zanon) « Manual tuning » Field flatness of 92 % after ~10 iterations ESS 086 P02 (RI) Automatic calculation of length adjustments Field flatness of 90 % after ~20 iterations 4 FIELD FLATNESS SENSITIVITY After mechanical deformation of +/-1 mm applied on the beam flanges: the field flatness is measured at each step and stays around 92.5 %. Beadpull measurements done after the two first BCP treatments: no significant difference ESS 086 P01 cavity (Zanon) BCP CHEMICAL TREATMENT SET-UP • • Cavities etched with a buffered chemical solution (‘BCP’ polishing using HydrofluoricNitric-Phosphoric acids with ratio, 1:1:2.4) in three steps Acid temperature was kept below 15 °C to avoid any hydrogen contamination of the niobium Acid inlet Acid inlet → Two independant installations at CEA Saclay compatible with 704 MHz cavities (and one is fully qualified) 6 EFFECT OF BCP Coupler port down Coupler port up Niobium thickness of ESS086 P01 after chemical etching (BCP) 2 3 4 5 6 7 8 -30 kHz/10µm 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 Niobium tickness removed (mm) 0 Iris 1 -0.1 Iris 2 Iris 3 Iris 4 -0.2 19/02/14( 1er chimie) 25/02/14 (2nd chimie) 29/04/14 (3rd chimie) -0.3 Niobium thickness of ESS086 P02 ler port -0.4 2 0 3 4 5 6 7 8 Tuning system 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 Iris 1 Niobium tickness removed (mm) -0.5 -0,1 Iris 2 Iris 3 Iris 4 -0.6 -0,2 apres 1er chimie après 2eme chimie après 3ème chimie -0,3 -0,4 SAF COUPLEUR -0,5 -0,6 Removal speed = 0.5 µm/min Average of 200 µm removed CAVITY CLEAN ROOM ASSEMBLY WITH HIGH PRESSURE RINSING The last BCP treatment is always followed by a filling of the cavity with pure water and a transfer to the CEA clean room High Pressure Rinsing performed at 100 bars with ultrapure water and using a new HPR rod installed on the existing set-up (the new rod has a shorter length). The following sequence has been applied: 1. Cavity with power coupler down, orientation = 0° 2. Cavity with power coupler down, orientation = 180° 3. Cavity with power coupler up, orientation = 0° 4. Cavity with power coupler up, orientation = 180° After this sequence the cavity is dried under class 100 laminar flow during a full night. The flanges, the two feedthroughs with pick-up antennas and the vacuum valve have been tightened at 20 N/m with their corresponding aluminum gaskets. CALIBRATION OF PICK-UP ANTENNA COUPLING • N type feedthrough in CF16 flange • Set of antennas with different lengths • Antenna diameter = 8 mm Incident power Pi in FPC port Transmitted power Pt in beam tube port (tuner side) 1E+13 Transmitted Pick-up Pt L 1E+04 Qt = 6e12 1E+13 1E+05 1E+12 1E+03 1E+12 1E+04 1E+11 1E+02 1E+11 1E+03 1E+10 1E+01 1E+10 1E+09 1E+00 1E+09 1E+01 1E+08 1E-01 1E+08 1E+00 Qi = 6e9 1E+02 Qext 1E+07 1E-02 1E+06 Qext 1E+07 β pour Qo (5E10) à froid 1E-01 β pour Qo (5E10) à froid 1E-03 1E+06 L (mm) 1E-02 0 10 20 30 40 L (mm) 50 60 → Calibration to be done on the pick-up port 70 Incident Pick-up Pi TESTS IN VERTICAL CRYOSTAT Tests done at CEA in the CV2 cryostat of the supratech platform Tests done on bare cavities only (without the tank) in vertical position (advantageous cooling configuration) New cavity supporting system developed New RF power amplifier purchased (500 W) New biological protection installed New RF regulation system (PLL) anticipated (0.5 GHz – 2 GHz) System developed at IPN Orsay (C. Joly) COOL-DOWN AT 4.2 K AND 2 K Cavity instrumented with 16 thermal sensors (Cernox) Fast cool down performed before each RF test to avoid 100 K effect Acquisition des températures en différents endoits de la cavité ESS P01(Zanon) le 15/05/2014 320 Acquisition des températures en différents endoits de la cavité ESS P01(Zanon) le 15/05/2014 300 Sonde 16 160 Sonde 15 280 Sonde 14 260 140 SondeSonde 16 Sonde 12 Sonde 14 Sonde 10 Sonde 11 SondeSonde 10 100 9 Sonde 9 Sonde 8 Sonde 8 SondeSonde 7 ~ 30 minutes between 150 and 50 K 160 80 140 120 11 Sonde 12 Température (K) Température (K) 180 SondeSonde 13 120 220 200 13 Sonde 15 240 7 Sonde 6 Sonde 6 Sonde 5 SondeSonde 4 5 Sonde 3 Sonde 4 Sonde 2 60 SondeSonde 1 100 3 Sonde 2 80 40 0 60 10 20 30 40 Temps (mn) 40 20 0 Date 50 60 70 Sonde 1 SURFACE RESISTANCE Measured residual resistance: Rres = 7.5 nOhm, compatible with usual measured values on 704 MHz cavities 2 R BCS 2 10 4 1 f 17.67 / T e T 1.5 VERTICAL TEST RESULTS AT 2K Test results (from May 2014 to Jan. 2015): • Both prototype cavities already met the ESS requirements after the first test: → Very encouraging results • only one multipactor barrier at 11 MV/m, easily processed • heavy field emission from 10 MV/m to max gradient, but easily processed after few minutes AFTER DEHYDROGENIZATION TREATMENT AT 650°C • Slight degradation of the performances after thermal treatment (pollution?) STATIC LORENTZ FORCE DETUNING MEASUREMENT Measured LFD coefficient: KL = -7.65 Hz/(MV/m)², close to the calculated value of -8.9 Hz/(MV/m)² in free ends conditions FREQUENCY SENSITIVITY OF ACCELERATING MODE 704.4 MHZ Tuning sensitivity DF/Dz (kHz/mm) ESS086 Calculated 197 Measured 190 Stiffness (kN/mm) ESS086 Calculated 2.59 (3.6 mm thick) 3.3 (4.5 mm thick) Measured 3 Frequency shift DF due to cooldown and vacuum (kHz) 300K to 4.2 K Calculated Measured Calculated Measured Displacement measurement ESS086 +1.00138 Ɛr to Ɛo +0.211 300K to 4.2K ~ +1.08 Ɛr to Ɛo +0.015 Frequency shift DF due to cooldown and pressure (kHz) Weight on cavity (up to 157 kg) ESS086 4.2 K to 2 K ~ + 0.207 Insert for CV test DANGEROUS HIGHER ORDER MODE CLOSE TO 1408.8 MHZ Both high beta prototype cavities are not conform with the ESS HOM Requirement Reminder: HOM shall be at more than 5 MHz from beamline frequencies Slater coefficient analysis which represents frequency sensitivity to volume changes: 704 MHz 1421,32 MHz 3D measurements of the cavity shape have been done Shape have been reconstructed in the simulation software HFSS Calculated with Calculated with Measured on measured measured ESS086-P02 shape (HFSS) shape (HFSS) Design (at 300K) Measured on ESS086-P01 1418.178 1402.254 1403.8 1407.848 1418.674 1404.666 1406.8 1408.258 On P01 cavity (from ZANON), a strong internal shape deviation in this dome region (more than 1 mm instead of 0.3 mm) explains very well the frequency decrease of the two dangerous HOM Study under progress on P02 cavity (from RI) Cells reshaping has to be implemented in the fabrication process of future cavities HOM BEAD PULL AND TUNING TENTATIVE Good identification of the HOM but unsuccessful tests to reshape the cavities with the field flatness tool. Bead pull on ESS086 P02 (03/11/2014) after +/- 0,5mm traction / compression of cell 1 Not possible to shift the HOM frequencies far enough by traction / compression of the cells TANK INTEGRATION OF ESS086-P01 AT ZANON DF = - 47 kHz only due to tank welding and pressure test (703.043 -> 702.989 MHz) Pressure and leak test done successfully Field flatness OK PROBLEMS SOLVED BEFORE OR DURING THE TESTS Problems Solutions 1 Melting (2 times on SPL cavity) of RF N-type right angle connector for incident coupling antenna during CV test at full power (200W) Change of the coupling factor Qx of the incident pick-up antenna 2 Large X-rays radiation level during CV tests Modification of the cryostat configuration (deeper underground) and adding of concrete blocks 3 Slight deformation of the field flatness tooling during measurement of tuning sensitivity Change of the measurement method (adding of masses on cavity in vertical position) 4 Degradation of the silver coating on screws Change of the manufacturer 5 Accidental manipulation of the cavity on the insert (cavity back to atmospheric pressure) Additional clean room assembly 6 Leakage in clean room after pumping on HOM port Replace stainless steel screws by silver coated screws No vacuum leakage observed at cold temperature CONCLUSION AND NEXT PLANS The two high beta prototypes have been successfully tested in vertical cryostat and reached an accelerating gradient of 20 to 24 MV/m and a Q0 above the specification of 5e9 Important parameters such as frequency shifts, tuning sensitivity and LFD have been measured and are conform to the predictions Some dangerous HOM have been unexpectedly measured too close to beam harmonics. The problem is partially understood Next plans: Vertical test at 2 K of the Zanon cavity equiped with Helium tank (Sept. 2015) Follow-up of the He tank welding at RI (July/August 2015) and vertical test at 2 K o Assembly of cold tuner and test at cold temperature ? o Vertical electropolishing try ? o Vertical test at INFN and STFC ? THANK YOU ESS high beta Cavity prototype team: CEA: E. Cenni F. Peauger G. Devanz J. Plouin D. Roudier L. Maurice P. Carbonnier F. Eozenou C. Servouin ESS: C. Darve V. Hennion Ph. Hardy F. Leseigneur P. Bosland P. Sahuquet O. Piquet