Unipolar Pulse Width Modulation Inverter

advertisement

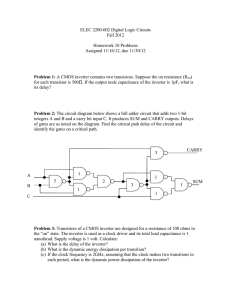

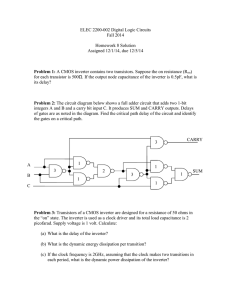

Unipolar Pulse Width Modulation Inverter By Randy Baggao & Gabriel Tam Senior Project ELECTRICAL ENGINEERING DEPARTMENT California Polytechnic State University San Luis Obispo 2013 Table of Contents Section Abstract……………………………………………………………………………………............ 4 Acknowledgements……………………………………………………………………………….. 5 I. Introduction……………………………………………………………………………….. 6 II. Background……………………………………………………………………………….. 8 III. Requirements & Specification...………………………………………………………… 11 IV. Design…………………………………………………………………………….............14 A. Control Unit………………….………………………….………………………………. 14 B. Firing Circuit……………………………………………………………………………. 18 C. H-Bridge………………………………………………………………………………… 22 V. Testing & Results………………………………………………………………………...25 A. Control Unit………………………………………………………………………………25 B. Firing Circuit……………………………………………………………………………...30 C. H-Bridge…………………………………………………………………………………. 35 VI. Conclusion & Recommendations………………………………………………………...39 Appendices A. Datasheets………………………………………………………………………………...41 B. Gantt Chart………………………………………………………………………………. 47 C. Parts List, Costs, and Time Schedule Allocation………………………………………...48 D. References……………………………………………………………………………….. 50 -1- Page Locations of Tables, Figures, & Schematics List of Tables Table 3-1: Unipolar and Switching PWM Logic…………………………….……….................. 12 Table 3-2: Summary of PWM Inverter Functional Description………………………................ 13 Table 3-3: Requirement Specifications of the PWM Inverter for testing…………………..…… 13 List of Figures Figure 2-1: A Commercial Tripp-Lite Power Inverter for Mobile Vehicles………………..……. 8 Figure 2-2: Photovoltaic Grid System Left-Installation Right- Photo of Solar Panels installed on a School Gym…………………………………………………….................. 9 Figure 3-1: Block Diagram of the Pulse Width Modulation Inverter…………….….…...............12 Figure 3-2: Full Bridge Circuit Topology of the PWM Inverter Source Indication……...............12 Figure 5-1: PWM Inverter Wired for testing……………………………………………………..25 Figure 5-2: Filtered Triangle Output…………………………………………….….………….. 26 Figure 5-3: Output Control Voltages , and , with respect to -12V reference and Vcont = 0 (ie. = 0)…………………………………….…………27 Figure 5-4: and - with respect to proto board common………………….………... 28 Figure 5-5: Output Control Voltage V(A+, A-) on top and V(B+, B-) on bottom with respect to -12V, where positive……………………………….........................................29 Figure 5-6: Control Voltage V(A+, A-) on top and V(B+, B-) on bottom with respect to -12V, where negative………………………………………………................. 29 Figure 5-7: Idealized VLOAD at Overmodulation Region………………………………............... 30 Figure 5-8: V(A+,A-) on top and Optocoupler A+ output on bottom…………………............... 32 -2- Figure 5-9: V(A+, A-) on top and Optocoupler A- output on bottom…………………............... 32 Figure 5-10: Optocoupler Outputs A+ (top) and A- (bottom)……………………………………33 Figure 5-11: V(A+, A-) on top and Driver A+ on bottom………………………………………. 34 Figure 5-12: V(A+, A-) on top and Driver A- on bottom……………………………..………… 34 Figure 5-13: Driver A+ on top and Driver A- on bottom………………………...………………35 Figure 5-14: MOSFET A+ on top and MOSFET A- on bottom……………………....................36 Figure 5-15: MOSFET B+ on top and MOSFET B- on bottom………………………………… 36 Figure 5-16: Unfiltered AC Voltage Output…………………………………………………….. 37 Figure 5-17: Filtered AC Voltage Output……………………………………………………….. 38 Figure 5-18: Final Product of Unipolar PWM Inverter…………………………………………. 38 List of Schematics Schematic 4-1: PWM Inverter Control Circuit………………………………………………….. 17 Schematic 4-2: Isolated Firing Circuit with Optocoupler and Gate Drivers……………………..20 Schematic 4-3: Terminal Connections for all 4 Firing Circuits…………………….……………21 Schematic 4-4: H-Bridge of the Inverter………………………………………………………....23 Schematic 4-5: Physical Layout of Inverter…………………………………………………….. 24 -3- Abstract This project portrays the design and construction of a pulse width modulation (PWM) inverter. The inverter is implemented as a unipolar converter. The inverter provides a steady single-phase sinusoidal 60Hz AC voltage output from a DC input. This is a basic DC-AC power converter that is built in 3 separate phases and integrated altogether at the end. The inverter can be broken down into the control unit, firing circuit, and the H-bridge. By using the PWM method, one can control the frequency and amplitude of the output by using a reference signal. This method will also avoid using a transformer because transformers have high power losses. This project will be dedicated to EE-410 power electronics students as an experiment to observe and experience the fundamental operations of a PWM inverter circuit at Cal Poly. -4- Acknowledgments We would like to express thanks to Jaime Carmo, the Electrical Engineering Department’s Electronic Technician, for devoting his time to the faculty and students and especially for helping create a case for our senior project. We would also like to express thanks to our project advisors Taufik and Ahmad Nafisi for teaching us the concepts of Electrical Engineering through our college careers and also guiding us through these last few quarters to making a successful working product. -5- I. Introduction Power Engineering has seen a rapid growth in efficient energy solutions. Power electronics focuses on processing electrical power using electronics with high efficiency and less power loss. Power electronics is found in applications of modified electrical energy. Some examples include low voltage cellular devices and high voltage transmission lines. Efficiency plays a large role in power electronics whereas inefficient systems are impractical and result in wasted energy and higher costs in utilities or reliability of components. Some types of efficient source conversions include AC-to-AC, DC-to-DC, AC-to-DC, and DC-to-AC source conversions. AC-to-DC converters are best known as rectifiers while DCto-AC converters are known as inverters [1]. Today’s popular power conversion type includes the use of photovoltaic (PV) solar panels to take in DC Power and convert it to supply household AC power sources. Computers, cell phones, televisions, microwaves, etc. have been sourced by AC power through some sort of energy conversion which will allow these appliances to function without “blowing up” on startup. With the conversion of AC-to-DC sources, a solution of using house hold appliances on the go took place that lead to the use of power inverters. This allowed the reverse conversion of DC-to-AC inverter power supply sources giving designers and customers the option of using larger scale DC batteries to power household appliances at any specified voltage rating. It is important for electrical engineering students who are focusing on power electronic conversions, to learn the basics on inverter circuits as it is one of the four major conversion types. At Cal Poly, the course that covers the foundation of the four basic conversion processes is EE410: Introduction to Power Electronics. The course has a lab portion where students get the hands-on experience on several basic power converters. Currently however, the lab lacks one -6- important experiment in which students can learn the operation and performance of an inverter circuit. This senior design project aims to develop an inverter circuit experiment which addresses several concepts and techniques used in covering DC to AC inverters. -7- II. Background DC-to-AC inverters are seeing a rapid growth in contributing renewable energy sources. An example of a DC-to-AC inverter application may include uninterruptible power supplies known as backup generators that supply power from the use of batteries (DC source) and invert it (previously converted and stored again as a DC power) into AC power [9]. A simpler way to understand inverters is the application of converting DC power into AC power using a commercially available car inverter that is used for car electrical outlets to allow household electronics to be used by a car battery source as seen in Figure 2-1. Figure 2-1: A Commercial Tripp-Lite Power Inverter for Mobile Vehicles [12] In air conditioning, an inverter can adjust the input frequency to control the speed of its motor. The desired room temperature is achieved by adjusting the output frequency of the inverting control unit. There are many types of control units that may be selected according to the designers preferred choice of specifications that will make the product run efficiently and with lower cost [3]. -8- Inverters play an important role in Power Electronics as it applies to larger device applications that help change the development of electronic machinery. The increase use of inverters are due to increasing use of grid tied residential PV. Figure 2-2 shows how a photovoltaic grid system is installed. Figure 2-2: Photovoltaic Grid System Left-Installation Right-Photo of Solar Panels installed on a School Gym [10][11]. The power electronic classes provided by California Polytechnic State University help prepare students in the power industry. There are currently four power electronics courses offered as technical elective courses for electrical engineering majors. The four courses are EE410 (Power Electronics I), EE411 (Power Electronics II), EE433 (Introduction to Magnetic Design), and EE527 (Advanced Topics in Power Electronics). Many lab experiments include concepts of rectification using single and three phase source inputs, non-isolated converters like buck and boost as well as isolated converters such as a fly-back circuit, magnetic design and various computer simulation exercises [1], [2]. The labs provide little hands-on experience to concepts explained in lecture which sometimes are further explored in computer simulation. Some of the experiments created are provided by students that have had the privileges to taking these classes and have their senior projects to help improve the experience in the power electronics labs. -9- This senior project is an example of such an effort. More specifically, this senior project has the objective to improve a previous effort by another senior project team to design and develop a lab experiment in switching PWM inverter [5]. The following chapter details the many aspects this senior project will improve. - 10 - III. Requirements & Specifications The project consists of the design and development of a PWM inverter that amplifies a small input signal Vcont and outputting voltages +VDC, –VDC or 0 at the load depending on how +VCont or -VCont compares to the reference triangle waveform VTri. VCont is provided by an AC Wall Wart that produces 4.5VRMS at a steady 60Hz frequency and adjustable by a trimmer knob of up to 500Ω. One of the op-amps to the TLE2072CP componen of the control unit uses an inverting amplifier to invert the VCont signal and produce –VCont. The inputs VDC are from isolated rail DC voltages at +12V and -12V, provided by multiple DC-DC converter chips that are supplied from a DC power supply. The waveform generator chip outputs 22kHz triangle-wave VTri after it is powered by the rail voltages. The LM339AN comparator chip performs the PWM logic comparison and is also powered by the control circuit’s isolated rail voltage. The output load voltage is similar to VCont but contains harmonics centered at even multiples between the ratio of the triangular waveform frequency fTri and the continuous waveform fCont which is also known as frequency modulation mf. The three circuits (Control, Firing and H-bridge circuits) are built onto a single proto circuit board. Each circuit is isolated from one another by using DC-to-DC converter chips and isolated grounds. This allows easy testing and troubleshooting at each different circuit. The physical area of the board is about 5”x7”x2”. After extensive testing, the circuit will be encased in plexiglass about 8”x10”x5”. The circuit will be powered by a DC Power Supply to power the control and firing circuit, a DC wall wart to provide the input of the inversion, and an AC wall wart to create the continuous sinusoidal waveform. The output that is monitored is an AC sinusoidal signal based on the amplitude modulation ma which is the ratio of VCont and VTri controlled by a trimmer knob - 11 - to set the output to be either linear overmodulation, or saturation. The second output is the unfiltered AC output to confirm unipolar measurements of V+ to 0 or V- to 0. Figure 3-1: Block diagram of the Pulse Width Modulation Inverter. Figure 3-2: Full Bridge Circuit Topology of the PWM inverter Source Indications [1] Table 3-1: Unipolar Switching PWM Logic [1] [4] Switches [On] S1 S2 S3 S4 Unipolar Switching Logarithm 0 ! " ! ! " 0 - 12 - Table 3-2: Summary of PWM Inverter Functional Description Module Inputs Outputs Functionality Unipolar PWM Inverter DC Input: +/-12 V DC Rail from Power Supply supplies the entire circuit PWM Control Input: Produces the Characteristic Waveform to be modulated by the chip within a grand scale switching frequency range from 10kHz to 25kHz. Test data should show similar results when an input triangular waveform is compared with a sinusoidal input controlled waveform. AC Output: Should produce a 60Hz constant output signal from the inverting DC-toAC device. The DC power is held by the DC-to-DC chip which will readily be modified through the inverting chip. The output waveform should follow a unipolar PWM waveform. The Pulse Width Modulation Inverter will take a +/-12V DC input and compare a controlled sinusoidal waveform with an input triangular waveform to produce a PWM output inverter. Table 3-3: Requirement Specifications of the PWM Inverter for testing Marketing Requirements 2,5 1,3,4 1,4,5 3,4 Engineering Requirements 1. Total Harmonic Distortion of PWM should be < 5-10% 2. System must be compact, portable, and safer to use compared to older version. 3. System should be able to work as inverter: 20-40 V DC input source Variable AC Output 4. The system must be built on PCB board with no extra materials i.e. wood, plastic. Justification The high-speed amplifiers can easily achieve this kind of THD. No complicated steps necessary to turn on the product and should be safe for the customer. Standard Inverter conversion of DC to AC wall warts. Compared to the previous version, the circuit board was held together with a block of wood. Simplify connections and use only electrical boards. Marketing Requirements 1. Should be easy to use. 2. Should use PWM. 3. Should have 3 parts: firing, control, inverter circuits. 4. Should be simplified and portable. 5. Should be able to get desired an adjustable AC Voltage at a steady 60 Hz Output. - 13 - IV. Design Control Unit The control unit of the inverter is used to produce firing signals to the four MOSFETs in the H-bridge. Schematic 4-1 displays the schematic of the control unit. The DC power supply will provide + #$ % to the DC-DC converter to transmit isolated & #$ % to the waveform generator, op-amp, and comparator. The waveform generator will provide a triangle waveform at pin 3. The frequency of the triangle output waveform can be controlled by a timing capacitor at pin 10. The 500Ω trimmer will determine the rise time and fall time of the triangle waveform. There is a high-pass filter to allow only DC signal of the triangle wave to go through. The inverting op-amp inverts the small AC signal to the negative AC signal ! . The AC signal, , can be used to amplify the amplitude of ( at the output with the 500Ω potentiometer. The 1kΩ trimmer can be adjusted to vary the amplitude of ! to sync with . The comparator will be used to perform the PWM logic by comparing the triangle and sine wave to create pulses that will send current to the optocouplers to switch them on and off accordingly. The comparator will send pulses to the firing circuits of ( , ( that controls MOSFETs ( & ( and * , * that controls MOSFETs * & * [6]. - 14 - Specifications • Input: +12Vdc regulated from 2W DC converter chip • Reference: -12Vdc regulated from 2W DC converter chip • Vcontrol = 60Hz, 4.5Vrms AC signal and 500Ω potentiometer • Protoboard common connected to 0V output pin 2W, DC converter chip Waveform Generator – Model NTE864 Ratings: 15mA max Min: 10V Max: 30V Trimmer (500Ω) – Pins 4 & 5 • Vsupply = Vd = 12V • Need: ~6 ./0 • - • Two Resistors (1kΩ each) will be in series with trimmer. 12 20004 Timing Capacitor – Pin 10 • According to datasheet: Ra = Rb = 1.5kΩ • Vd = 12V • Need: Operating Frequency = 22kHz ./0 • 5 • • • Need: Fairly large capacitor. Ideal capacitor = 0.01uF Actual size: 16nF ..678 8 Inverting Op Amp – Model TLE2072CP Ratings: Supply 3.1mA Output: 20mA Voltage Supply: 2.25V ~ 19V - 15 - Trimmer (1kΩ) – Pin 2 • Standard Range: 10Ω to 1MΩ • Used: 9.53kΩ to output 6mA • :; Max Variable Gain = :< :/ :. = =.6;78 .78 Comparator – Model LM339 Quad Ratings: 2V~ 36 5ABCD -EAFG Current Max: 18mA Vd = 12V Vgnd = -12V reference - 16 - 9.53 Schematic 4-1: PWM Inverter Control Circuit +12Vdc regulated from 2W, DC-DC converter V(A+, A-) V(B+,B-) Vcc- 1.5kΩ, 1/2 W DC - DC +12V from DC power 1 2 4 5 6 1.5kΩ, 1/2 W High-pass filter to block DC Filtered and buffered triangle wave 0.01uF 270kΩ 100kΩ 16nF (Freq. Control) 1kΩ 14 8 Waveform Generator 8 5 OP AMP 1 1 4 7 14 8 COMPARATOR 1 7 10kΩ 270kΩ 1kΩ .. 1kΩ 9.53kΩ 22kHz triangle wave 500Ω Trimmer 1kΩ -Vcont Vcont -12Vdc regulated from 2W, DC-DC converter Refer to Appendix for IC pin configurations 1kΩ Trimmer 500Ω Potentiometer Proto board common ground, 0V 17 60 Hz, 4.5Vrms signal from function generator Firing Circuit There are four separate firing circuits that are used to drive the inverting and noninverting chips with pulses from ( , ( and * , * accordingly. The schematic of the full firing circuit is displayed in Schematic 4-2. The isolated DC-DC converters will be used to power the chips with H⁄! #$ % and isolate the firing circuit from the control unit and Hbridge. Each individual firing circuit will need an optocoupler, an inverting or non-inverting driver chip, a switching diode, and separate passive resistors and capacitors. The optocoupler will electrically isolate the PWM controller outputs from the gate terminal of the power MOSFET, so then the source terminal of the power MOSFET has a “floating” ground. The optocouplers have to be isolated from the PWM control circuit because the source terminal of the respective MOSFET must be connected to its local ground reference. It also isolates the higher voltage on the high power side of the H-bridge from the control circuit to prevent ICs from being damaged and noise turbulences. Schematic 4-3 displays 4 firing circuits that are connected similarly to one another [7]. 18 Specifications • Output of the control unit goes into the input of the optocoupler • Input: +12V that is isolated from PWM circuit • Reference: DC converter chip Optocoupler – Model Vishay 6N136 Ratings: Supply: -0.5V to 15V Output: -0.5V to 15V Max output current: 8mA to 16mA Pins 6 & 8 Want: I 1.19mA ./N I .OPΩ R 1.2mA MOSFET Driver – Model TC1426(Inverting) & TC1427(Non-Inverting) Ratings: Supply: +18V Range: 4.5V to 16V Output Current Peak: 1.2A Power Dissipation: 730mW Diode Snubber Circuit • Fast Switching Diode: 75V, 150mA • Small Resistance for Diode R10Ω • Parallel Resistance R 1kΩ 19 One firing circuit for each MOSFET. Switches A- and B- share a power supply and ground. However, A+ and B+ must use separate power supplies and grounds. Do not connect any of these grounds to the ground of the control circuit. MOSFET G D Schematic 4-2: Isolated Firing Circuit with Optocoupler and Gate Drivers S 100kΩ Grounds (isolated from control circuit) Switching diode 0.1uF 1.2kΩ 10Ω 5 Switches A+ and B+ use inverting drivers. 4 Inverting Driver 8 1 5 4 Green for A+, B+ Black for A-, B- Optocoupler +12V isolated from the PWM control circuit 10Ω 8 Connects to Control Circuit 1 O+ DC - DC, 1W 1 2 3 4 DC - DC, 2W 1 2 4 Switches A- and Buse non-inverting drivers. 5 6 20 O- Vcc+ and GND supplied by DC power supply shares nodes with A- and B- A+ A- Firing Circuit + - B+ Firing Circuit + - B- Firing Circuit + - Firing Circuit + - -12V reference V(A+,A-) V(B+,B-) DC Supply Control Circuit AC Control Schematic 4-3: Terminal connections for all 4 firing circuits 21 H-Bridge The H-bridge of the inverter circuit can be shown in Schematic 4-4 and the layout consisting of all three circuits can be seen in Schematic 4-5. There are 4 separate power MOSFETs that are used to perform the switching in the H-bridge. Unipolar switching will require all 4 switches in order to have the output of the inverter to be switched from H to 0 or from ! to 0. An electrolytic capacitor is placed across the positive and negative terminals of the H input as a filter to provide current ripple into the inverter so the DC current will have fewer ripples. Two fuses are placed across the H input as safety to protect , and , respectively. One fuse feeds the , side of the inverter and the other fuse feeds the , side. An inductor and a capacitor are used as a tank circuit to decrease the damping waveform at the output to filter the pulses for . The inductor placed to prevent the output from shorting with the electrolytic capacitor at higher frequencies [8]. Specifications Convert 20-40VDC power to 60Hz VAC Low Pass Filter f = 60Hz TU 2VW 376.99 YEZ/\ L = 100uH C = 10uF 1 1 15.915dbe W] 2V√_` 2Va100Cb10Cc 22 + Vdc _ + Vac _ G D A+ S G D S G D B+ A- Schematic 4-4: H-Bridge of the Inverter 23 S G D B- S H-Bridge and Filters + + Vdc Vac - Individual heat sink for each MOSFET. HEAT SINKS MUST NOT TOUCH EACH OTHER BECAUSE THEY WILL HAVE DIFFERENT DRAIN POTENTIALS - + MOSFET MOSFET MOSFET MOSFET A+ A- B+ B- Firing A+ Firing A- Firing B+ Firing B- - + - + - + - -12V reference V(A+, A-) V(B+,B-) DC Supply Control Circuit AC Control Schematic 4-5: Physical Layout of Inverter 24 V. Testing Figure 5-1: PWM Inverter Wired for testing Figure 5-1 shows the inverter wired up for testing. The H-bridge, firing circuit and control circuit work together to invert the DC input signal into an AC output signal. In this section, each of the three circuits are tested individually to achieve the necessary inversion. Control Unit Step 1 The objective of the control unit is to have the waveform generator produce a triangle wave that will produce a clean signal with 7.8f 7f 7 by supplying the oscillator with +12V. The triangle wave should have a frequency of approximately 22kHz with minimized DC offset by adjusting the values of the frequency control of the waveform generator. The fall and rise time of the triangle wave should be equal by adjusting the 500Ω trimmer to get a duty cycle set to 50%. Figure 5-1 below displays a high-pass filtered triangle wave with minimized DC offset. 25 i 7 R 7.8 W R 22dbe Figure 5-2: Filtered Triangle Output Step 2 Before powering AC with 4.5:h , energize the circuit with the DC power supply and measure the terminals across , and , with respect to -12V reference and confirm that both waveforms are varying sharply from +24V to 0V with a 50% duty cycle. Figure 5-3 below displays the output control voltages , and , with = 0. 26 H, ! R 12Zm H, ! R 12Zm Figure 5-3: Output Control Voltages ( , ( and * , * with respect to -12V reference and Vcont = 0 (ie. jk = 0). Power up the AC to 4.5:h and raise the 500Ω potentiometer for maximum . The operational amplifier is an inverting amplifier that will invert to - that will be used to determine the switching in the firing circuit and H-bridge. Probe and - with respect to proto board common. The sinusoidal waveforms should be 180ᵒ out of phase of each other as shown in Figure 5-4. Use the 1kΩ trimmer to adjust - to make it the same RMS magnitude as . The AC voltage with E= maximum across l , - , ] should be approximately 21VAC. 27 Figure 5-4: and - with respect to proto board common. Lower the 500Ω potentiometer for minimum . Use the oscilloscope to make probe connections at , and , with respect to the -12V reference point. Gradually increase the 500Ω potentiometer so that increases from 0V to 3VRMS. Figures 5-5 and 5-6 display the output control voltages where is positive and where is negative. The “ON” period of one waveform gets wider whereas the other waveform gets narrower, and it’s vice-versa for the “OFF” period. These waveforms display pulses that were created by the comparator. The comparator in the control unit compares the triangle wave and the sine wave, and the output is switched from +VDC to 0 or from -VDC to 0. 28 Figure 5-5: Output Control Voltage V(A+, A-) on top and V(B+, B-) on bottom with respect to -12V, where positive. Figure 5-6: Control Voltage V(A+, A-) on top and V(B+, B-) on bottom with respect to -12V, where negative. 29 Figure 5-7 shows an oscilloscope capture of V(A+, A-) with reference to V(B+, B-) and the “split” portion in both half cycles. If the split cycles are not the same, then adjust the gain of ! with the 1kΩ trimmer. There is a lot of noise at the output because of long vulnerable wires. Figure 5-7: Idealized VLOAD at overmodulation region Firing Circuit Step 1 Before moving onto the firing circuit, perform power supply wiring continuity checks to confirm that: • The PWM control unit is isolated from the ground terminal of the DC power supply. • The 12V rail and ground terminal of the DC power supply is isolated from the +12V rail and ground of the A+ firing circuit board. 30 • The 12V rail and ground terminal of the DC power supply is connected to the +12V rail and ground of the A- firing circuit board. • The H⁄! 12 and ground rails of A+ and A- are isolated to each other. Perform the DC converter chip test by powering up the 12V supply. Check the voltage rails of the DC converter and make sure they output +12V and -12V. If the voltage drops more than 0.5V from your nominal voltage, then you most likely have two wires shorting each other in the circuit. If so, fix the problem before moving on or else it would cause the converter chip to fail and break. Step 2 Perform checks on the isolated A+ and A- firing circuits by disconnecting AC Vcont so that ma=0. Connect oscilloscope probe 1 to V(A+, A-) from the control unit and the ground with respect to the -12V reference. Also, connect oscilloscope probe 2 to the output of Opto A+ and the ground lead to the common ground of the firing circuit. It is okay to connect to any ground terminals on the firing circuit because the two signals are already isolated from each other. Figure 5-8 displays the result. 31 H, ! Zm R 1.7 Opto A+ Output Zm R 5.8 Figure 5-8: V(A+,A-) on top and Optocoupler A+ output on bottom Connect oscilloscope probe 2 and its ground terminal to the Optocoupler A- output to view the same waveforms as above. The result is shown in Figure 5-9. H, ! Zm R 1.7 Opto A- Output Zm R 6.3 Figure 5-9: V(A+, A-) on top and Optocoupler A- output on bottom 32 Connect probe 1 and its ground lead to the output of Optocoupler A+, and connect probe 2 and its ground lead to the output of Optocoupler A-. The waveforms are expected to be similar as Figure 5-10 below. Figure 5-10: Optocoupler Outputs A+ (top) and A- (bottom) Connect probe 1 and its ground lead to V(A+, A-) with respect to -12V reference. Connect probe 2 and its ground lead to the output of Driver A+. Figure 5-11 displays the correct waveform of the output. 33 H, ! Driver A+ Output Zm R 5.6 Figure 5-11: V(A+, A-) on top and Driver A+ on bottom Connect probe 2 to the output of Driver A+. Figure 5-12 displays the correct waveform of the output. It will be an inverting waveform because the driver receives inverting pulses from the control unit. H, ! Driver A- Output Zm R 6.7 Figure 5-12: V(A+, A-) on top and Driver A- on bottom 34 Connect probe 1 and its ground lead to the output of Driver A+. Leave probe 2 and its ground lead to the output of Driver A-. The two waveforms should be opposite of each other because one is inverting whereas the other isn’t. There should not be any visible overlap in “on” times because with ma = 0, their duty cycles should be close to 50%. This is illustrated in Figure 5-13. Figure 5-13: Driver A+ on top and Driver A- on bottom Step 3 Repeat step 2 for firing circuits B+ and B-. The waveforms of firing circuits B will be exactly the same as the waveforms in firing circuits A. After finishing firing circuits B+ and B-, disconnect both the DC supply and AC Vcont. H-Bridge Step 1 To test the H-bridge of the inverter, confirm that firing circuits A+ is isolated from A- and B+ is isolated from B-. Energize the firing circuit with the DC power supply, but leave AC Vcont off. 35 Attach oscilloscope probe 1 and its ground lead across VGS of MOSFET A+, and attach oscilloscope probe 2 and its ground lead across VGS of MOSFET A-. The waveforms should appear as shown in Figure 5-14. MOSFET A+ n R 4.5Zm MOSFET An R 4.5Zm Figure 5-14: MOSFET A+ on top and MOSFET A- on bottom Repeat the previous steps for B+ and B- to attain the waveform as shown in Figure 5-15. MOSFET B+ n R 4.5Zm MOSFET Bn R 4.5Zm Figure 5-15: MOSFET B+ on top and MOSFET B- on bottom 36 Step 2 Test the inverter by inputting a 20VDC into the H-bridge and it will output an AC voltage of approximately 142o . nominal at 60Hz at maximum . The Figures of 5-16 and 5-17 shows the waveforms of the unfiltered AC voltage output and filtered AC voltage output. By varying the 500Ω potentiometer, the can increase or decrease the magnitude of the output AC voltage. Figure 5-16: Unfiltered AC Voltage Output 37 Figure 5-17: Filtered AC Voltage Output The final product of the unipolar PWM inverter can be seen in Figure 5-18. Figure 5-18: Final Product of Unipolar PWM Inverter 38 VI. Conclusion & Improvements The PWM inverter was built to be a prototype in the laboratory for EE-410. This project was created into three sections: the control unit, firing circuit, and the H-bridge, which were all integrated to invert DC voltage into AC voltage and uses unipolar switching. The project was most practical for unipolar switching because the inverter utilizes the right number of components and more efficient for it. The inverter produced a clean AC output waveform that proves that the circuit works successfully. The circuit produced a steady 60Hz amplitude varying AC voltage at the output. The inverter was tested to only handle up to 50Vdc because anything higher than that caused the filter capacitors to explode. Future EE-410 students could utilize unipolar switching without any problems. The problems encountered that slowed the pace of our project were the wires and faulty chip components. Even though troubleshooting was not a big problem, the wires were the main cause for noise in our circuit. The comparator was our only component problem because it would breakdown easily if signals going in and out were corrupted. This was fixed by finding the most updated component that performs similar or even better than the previous component. The improvements made in comparison to the previous design include using a waveform generator chip NTE864 to output a triangle waveform which cuts the need of using multiple function generators in the lab. Another improvement made to the previous design was to use a single input for the 12V DC side to supply both the control circuit and the firing circuit which cuts the need for extra power supplies. One last improvement made to the design was to build 39 the circuit onto one circuit board which includes a low voltage circuit side and a high voltage circuit side and also cover the board with a protective visible case. Future improvement for this project would be to use a pre-made printed circuit board (PCB) so that components could be soldered on without having wires. This would be the most efficient way to have a cleaner and less expensive project. Even though soldering took a long time, it was the best way to troubleshoot for any errors that had occurred. Another improvement to consider in the design would be to use a controllable Boost Converter instead of using a DC wall wart to power the switches in the H-Bridge. This would eliminate the need for another piece of equipment by stepping up 12V power from the control and firing circuits’ supply sources and with user control, vary the input source of the H-Bridge while keeping the output the same. 40 Appendix A: Datasheets Pin # 1 2 4 5 6 Function +Vin GND -V 0V +V Murata Power Solutions NMH Series 2 Watt DC-DC Converter [15] 41 Murata Power Solutions NKE Series 1 Watt Isolated DC-DC Converter [18] 42 Pin # Symbol I/O Type Function 1 SA1 I Adjust Sine Waveform Input 1 2 SWO O Sine Wave Output 3 TWO O Triangle Wave Output 4 DCA1 I Duty Adjustment Input 1 5 DCA2 I Duty Adjustment Input 2 6 (+) Vcc 7 FM I Frequency Modulation 8 FS I Frequency Sweep 9 SQO O Square Wave Output 10 TC I Timing Capacitor Input 11 Vee 12 SA2 13 N.C. No Connection 14 N.C. No Connection Positive Power Supply Negative Power Supply I Adjust Sine Waveform Input 2 NTE864 Integrated Precision Circuit Waveform Data for Triangle Wave with reference to Intersil ICL8038 Precision Waveform Generator [13], [14] 43 Texas Instruments TLE2072 Excalibur Low-Noise High Speed Dual Op Amp [16] Texas Instruments LM339 Low Power Offset Voltage Quad Comparator [17] 44 Vishay 6N136 High Speed Octocoupler [19] Microchip Technology Inc. TC1426CPA Inverting MOSFET Driver [20] Microchip Technology Inc. TC1427CPA Non-Inverting MOSFET Driver [20] 45 International Rectifier IRFP140NPbF HEXFET Power MOSFET [21] 46 Appendix B: Gantt Chart FALL 2012 (EE460) Unipolar PWM DC-to-AC- INVERTER PROJECT Week Project Plan 1 2 3 4 5 6 7 HOLIDAY BREAK 8 9 10 1 2 3 WINTER 2013(EE463) 4 Abstract (Proposal) V1 Requirements and Specifications Block Diagram Literature search Gantt Chart Cost Estimates PWM Inverter Project Analysis Requirements and Specifications V2 Rough Draft Report Report V2 Research Power Inverter (DC-to-AC) Ordering/Inventory of Components PWM Power Inverter Applications Firing Circuit Control Circuit H-Inverter Contruction & Testing Finalize Circuit Layout Construct and Test Device If Version I fails to work, then.. Contruction & Testing (version II) Re-Design/Analysis Simulation & Sensitivity Analysis Purchase New Components Contruction & Testing Construct and Test Device Finalize Results and Prepare Data Interim Report Final Senior Project Report Rough Draft Advisor Review Second Rought Draft Advisor Review Final Senior Project Report 47 5 1 2 3 4 5 6 7 SPRING 2013(EE464) 8 9 10 1 2 3 4 5 6 7 8 9 10 Appendix C: Parts List Control Circuit • NTE864, Waveform Generator ,14 – pins (1) • TLE2072CP, Dual Op Amp, 8 – pins (1) • LM393N, Quad Comparator, 14 – pins (1) • NMH1212SC, 2W Dual Output DC-DC Converter (1) • 16nF, ceramic capacitor (1) • 0.01uF, ceramic capacitor (1) • 1kΩ, ¼ W resistor (4) • 100kΩ, ¼ W resistor (1) • 10kΩ, ¼ W resistor (1) • 9.53kΩ, ¼ W resistor (1) • 270kΩ, ¼ W resistor (2) • 1.5kΩ, ½ W resistor (2) • 500Ω ½ W Bourns trimmer (1) • 1kΩ ½ W Bourns trimmer (1) • 500Ω, 24 mm Potentiometer (1) Firing Circuit • 6N136, Optocouplers (4) • TC1426, MOSFET Inverting Driver Microchip (2) • TC1427, MOSFET Non-Inverting Driver Microchip (2) • NKE0505S, 1 W Dual Output DC-DC Converter (2) • D0-35 Case, 75V 150mA, High-Speed Switching Diode (4) • 0.1uF, ceramic capacitor (4) • 10kΩ, ¼ W resistor (4) • 10Ω, ¼ W resistor (4) • 1.2kΩ, ¼ W resistor (4) • 100kΩ, ¼ W resistor (4) H-Bridge • IRFP140N, 100V 33A, N-Channel Power MOSFET (4) • TO-218, Heat Sink Case (4) • 10uF, 50V High Frequency Bipolar Capacitors (2) • 100uH, 10A Inductor (1) • 10A, 10V Fast – Acting Fuses (2) • 10A, 250VAC, Chasis- Type ¼” x ¼” Fuse Holder (2) Other # • Proto board – p qrst u v $ qrst (1) • 14 – pin DIP sockets (2) • 8 – pin DIP sockets (9) 48 • • • 24 – pin SIP socket (1) Plexiglass Board & Box Cover (1) Computer Board Standoffs (4) Cost Estimation Item NTE864, Waveform Generator TLE2072CP, Dual Op AMP LM393N, Quad Comparator NMH1212SC, DCDC Converter 6N136, Optocoupler TC1426, MOSFET Inverting Driver Microchip TC1427, MOSFET Non-Inverting Driver Microchip NKE0505S, DC-DC Converter DO-35 Case Switching Diodes IRFP140N, N-Power MOSFET TO-218, Heat Sink Fast Acting Fuses Fuse Holders Capacitors Resistors Potentiometer Inductor IC Pin Sockets Trimmers Cost Per Unit $50.00 Quantity 1 Total $50.00 $3.07 1 $3.07 $0.98 1 $0.98 $13.42 1 $13.42 $1.32 $1.24 4 2 $5.28 $2.48 $1.24 2 $2.48 $7.74 2 $15.48 $0.35 4 $1.40 $2.07 4 $8.28 $3.02 4 $12.08 $2.49 $1.25 $0.40 $0.20 $3.00 $10.45 $1.00 $0.98 2 2 8 27 1 1 12 3 $5.00 $2.50 $3.20 $5.40 $3.00 $10.45 $12.00 $2.94 $159.44 Total: 49 Appendix D: References Books [1] Taufik, and Dale Dolan. Introduction to Power Electronics. Cal Poly State University. San Luis Obispo: 10th Revision, 2012. [2] Taufik, and Dale Dolan. Advanced Power Electronics. Cal Poly State University. San Luis Obispo: 6th Revision, 2013. [3] D. Grahame Holmes, Thomas A. Lipo, Pulse Width Modulation for Power Converters, Hoboken NJ, USA. 2003 [4] Bin Wu, High-Power Converters and AC Drives, Hoboken NJ, USA. 2006 Reports [5] Tran, Kelvin, and Ryan Sidarto. PWM Inverter. Print. San Luis Obispo: California Polytechnic State University, 20 May 2011. [6] EE362L, Power Electronics, PWM Inverter Control Circuit. Print. 20 October 2008. [7] EE362L, Power Electronics, Isolated Firing Circuit for H-Bridge Inverter. Print. 27 October 2008. [8] EE362L, Power Electronics, H-Bridge Inverter. Print. Print. 20 February 2008. Internet [9] Wikipedia (2012, October 13) Power Inverters http://en.wikipedia.org/Power_inverter [10] Energy Home (2013, May 17) Photovoltaic Cells http://www.energyeducation.tx.gov/renewables/section_3/topics/photovoltaic_cells/f.htm l [11] Consenergy Biotek (2013, May 17) Grid Connected PV Systems http://www.consenergybiotek.com/grid_connected.html [12] Tripp-Lite (2013, May 24) PowerVerter® 375W Ultra-Compact Inverter with 2 Outlets http://www.tripplite.com/en/products/model.cfm?txtModelID=2552 Datasheets [13] NTE Electronics, “NTE864 Integrated Circuit Precision Waveform Generator,” Data Sheet Rev. N/A, July 2007. 50 [14] Intersil, “ICL8038 Precision Waveform Generator/Voltage Controlled Oscillator,” Data Sheet Rev. 2864.4, April 2001. [15] Murata Power Solutions, “NMH Series Isolated 2W Dual Output DC/DC Converters,” Data Sheet Rev. KDC_NMH.E03, 2012. [16] Texas Instruments, “TLE2072 Excalibur Low-Noise High-Speed JFET-Input Op-Amp,” Data Sheet Rev. SLOS181A, March 2000. [17] Texas Instruments, “LM339 Low Power Offset Voltage Quad Comparators,” Data Sheet Rev. DS005706, March 2004. [18] Murata Power Solutions, “NKE Series Isolated Sub-Miniature 1W Single Output DC/DC Converters,” Data Sheet Rev. NDC_NKE.5, 2001. [19] Vishay, “6N136 High Speed Optocoupler, 1 MBd, Photodiode with Transistor Output,” Data Sheet Rev. 1.8, 05 September 2011. [20] Microchip Technology Inc. “TC1426/TC1427 1.2A Dual High-Speed MOSFET Drivers,” Data Sheet Rev. DS21393C, 2 February 2006. [21] International Rectifier, “IRFP140NPbF HEXFET Power MOSFET,” Data Sheet Rev. PD-95711, 2 August 2004 51