Survey of grid-connected photovoltaic inverters and related systems

advertisement

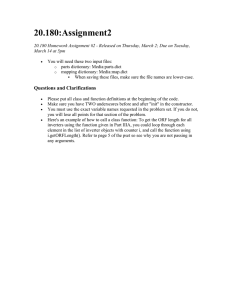

Clean Techn Environ Policy (2012) 14:521–533 DOI 10.1007/s10098-011-0411-z REVIEW Survey of grid-connected photovoltaic inverters and related systems N. A. Rahim • R. Saidur • K. H. Solangi M. Othman • N. Amin • Received: 23 February 2011 / Accepted: 4 August 2011 / Published online: 19 August 2011 Springer-Verlag 2011 Abstract Grid-connected photovoltaic (PV) inverter technology has advanced since it first attracted the attention of policy makers. The objective of this article is to present a survey of grid-connected PV inverters and their present technology in Malaysia. Surveyed here are 186 PV inverter products from 22 manufacturers, their power factors, system THDs, efficiencies, power inputs (from PV array), costs, sizes, and protections investigated, and their datasheets collected from various manufacturers in Europe, North America, and Asia. The data are compared within regions and subject headings. Discussed are the lowering of cost, the raising of efficiency levels, and reliability improvement. Keywords PV policy Inverter PV system PV technology Introduction Solar energy has become the most popular source of renewable energy, expected to produce by 2050 about 30% of global energy (Ruoss et al. 2009; Bugutekin 2011). It is clean, easy to harvest, environment friendly, and free. Also, unstable fossil-fuel price and concern about global warming have drawn attention to alternative-energy electricity N. A. Rahim M. Othman N. Amin University of Malaya Power Energy Dedicated Advanced Centre (UMPEDAC), Level 4 of Engineering Tower, Kuala Lumpur, Malaysia R. Saidur K. H. Solangi (&) Department of Mechanical Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia e-mail: solangi.quest@gmail.com (Saidur et al. 2007a, b),Taufiq et al. 2007 making renewable energy a solution to be considered (Saidur et al. 2010a; Ralegaonkar and Gupta 2010; Taleghani et al. 2010) as, e.g., about 89 Petawatts (89 9 1015 W) of sunlight strikes the earth but only about 15 Terawatts (15 9 1012 W) (which is only 16%) of it are used (Smil 2006). PV cells can capture solar energy and convert it into electricity, thus solar energy technology (known also as solar PV technology) is essential to every country. A PV system is connected to the grid by an inverter, which converts the DC power generated from PV modules to the AC power used in ordinary power supply of electrical equipment. The inverter is therefore an important element in grid-connected PV systems. PV inverter technology has grown rapidly over the past few decades, in line with PV development in Europe, US, and Japan; Malaysia has a considerable number of gridconnected PV installations such as small-scale buildingintegrated systems (MBIPV 2009; Camdali 2010 Photovoltaic prices have dropped 50% over the decade, and efficiency and reliability improved; in future, new, reduced cost-to-efficiency inverter designs can be expected in the market (Abella and Chenlo 2004). In Malaysia, on 11 May 2001, in a bid to encourage and intensify the use of renewable energy in power generation, the government launched the Small Renewable Energy Power Program (SREP) (Saidur et al. 2010a; Newton 2007; Demirbas 2010). Small, renewable energy-generating power plants can apply to sell electricity to utilities through the grid distribution system, as per renewable energy agreement between renewable energy producers and power utility companies (Saidur et al. 2010b; Zgorena 1741; Saidur et al. 2009) included are all types of renewable energy, including biomass, biogas, municipal waste, solar, mini-hydro, and wind (Saidur et al. 2010b; KTAK 2009; Demirbas 2007; 123 522 N. A. Rahim et al. Jayed et al. 2009. To maximize implementation effectiveness, this survey was designed so that useful and sufficient information on PV design specification efforts could be provided (Knier et al. 2009). Over-load current/voltage Polarity-reversal protection • International standards Safety, equipment, and grid • Further information Methodology The survey was done among 186 PV inverter products from 22 manufacturers. The inverters surveyed were divided into two power ranges: \10 kW and [10 kW. Data on their performance and prices were collected through a website questionnaire in a survey done among companies and suppliers, and from the ‘‘Photon’’ international magazine. The data were then analyzed according to their geographical locations (North America, Europe, and Asia Pacific); see Fig. 1. Analysis was done through a summary of all the manufacturer data collected, and according to the following criteria: • AC/DC analysis Applicable grid conditions (voltage, frequency, and phase) Inverter power ratings Harmonic current Power factor Conversion efficiency Inverter control • Research instrument A series of questions on PV inverter was emailed to manufacturers of inverters. Those who responded supplied all the requested data. Statistical method Design concept Switching concept • Operating environment Cost of inverter systems Size and weight of inverter systems Displays Warranty Cooling method Protective functions Isolation between AC and DC AC/DC protective functions Transient over-voltage protection Islanding protection (Wikipedia et al. 2009) Fig. 1 Flow chart of survey methodology Finding Data Website, Questionnaire, Photon International Analyze data Statistical analysis was used to extract from the manufacturer datasheets, quantitative information such as population. The data were then grouped according to parameters such as AC/DC analysis, inverter design, price, and protection. The AC/DC analysis included power rating, efficiency, power factor, etc. If the quantity of the same subject varied, average values were used. To indicate price, mean values were used, calculated through the following equation (Table 1 gives an example of the calculation): n 1 X x ¼ xi ð1Þ n i¼1 where n is the number of sample and xi is the sample value Result findings and discussion The data gathered were summarized according to the information provided by manufacturers of the PV inverters. Technical data were grouped into DC/AC part, efficiency, design concept, and ambience. Analysis of the main segments was based on power ranges: up to 10 kW (\10 kW), and above 10 kW ([10 kW). Analysis of the data was based on geographical sub-segments including North America (including Canada), Europe, and Asia Pacific, as follows: (i) Summarize Graph, chart, Table 123 North America • • Kaco (USA) Xantrex (Canada) Survey of grid-connected photovoltaic inverters Table 1 Average price of PV inverters 523 Power rating (kW) Price (USD) Ave price (USD) Price/kW 3 2153 1951.39 650.46 Average price/kW 1075.43 1332.16 2369.00 1 555.08 555.08 555.08 2 1750 1305.70 652.85 2951.65 894.44 3778.16 1079.47 2446.21 978.49 3606.67 901.67 1178.5 1094.28 1200 3.3 2543.31 2650.82 2543.31 2650.82 4370 3.5 5320 2585.95 4637.68 2569.00 2.5 4070 2050.95 1294.90 2369 4 2835 2665 5320 4.1 5320.00 5320.00 1297.56 4.2 5001.00 5001.00 1190.71 4.5 2955.00 2955.00 656.67 4.6 3530.95 3968.27 862.67 3275.89 3412.58 3275.89 3412.58 5480 5390 4.8 3485.95 3485.95 726.24 5.1 3085.00 3085.00 604.90 5.2 3590.95 3590.95 690.57 6 3717 3189.252 531.54 1878.30 1138.37 1075.43 2661.50 1.65 1836.84 1919.77 1836.84 1919.77 1.60 2587.78 2587.78 1617.36 1.80 3370 3370 1872.22 0.50 0.70 800.44 1151.95 800.44 1151.95 1600.88 1645.64 1.30 3074 3074 2364.62 1.50 1200 1720.67 1147.12 123 524 N. A. Rahim et al. • • (ii) PV Powered (USA) Outback (USA) Europe • • • • • • (iii) SMA (Germany) Sunways (Germany) Fronius (Austria) Mastervolt (Netherlands) Danfoss (Denmark) Sunset (Germany) Asia Pacific • • • • • • • • Sharp (Japan) Mitsubishi (Japan) Sanyo (Japan) Sungrow (China) Seashine Forest (China) Green Giant Tech (China) Carspa (China) Leonics (Thailand) Figure 2 is a breakdown of the manufacturers of the PV inverters surveyed. European countries constitute the major PV producers. The dominant brands are SMA (Sunny Boy) in Europe, Xantrex in North America, Mitsubishi in Japan, and Sungrow in China. Figure 3 shows the distribution of AC (output) power rating for the inverters surveyed; the two highest numbers of inverters registering in the 2.5–3.5 kW and the 4.5–5.5 kW ranges. Switching devices and control circuit High-frequency switching by semiconductor switching device is an essential element in PWM inverter control. Line-commutated inverters, based on thyristors, were at first developed for the first grid-connected applications, later replaced by self-commutated inverters that use insulated gate bipolar transistors (IGBTs), or field-effect Asia 22% Europe 50% North America 28% Fig. 2 Regional distribution of the PV inverters surveyed 123 transistors (FETs), in low-power applications. Currently, popular switching devices in performing high-frequency switching are IGBT, Metal Oxide Semiconductor Field Effect Transistor (MOSFET), and HERIC (Highly Efficient & Reliable Inverter Concept), a new inverter topology with innovative switching, implemented by Sunways, its efficiency greater than that of other PWM controls (Sunways 2009). Survey of the 186 products showed 102 products having information about the switching concept. For instance, about 52% used IGBT, 9% used MOSFET, 33% used both IGBT and MOSFET, and 6% used HERIC. For power rating[10 kW, 88% used IGBT, 10% used both IGBT and MOSFET, and 2% used HERIC; see Fig. 4. The findings show the IGBT switching frequency to be around 20 kHz, and therefore IGBT can be used for medium-to-high-power inverters exceeding 100 kW. In contrast, the switching frequency of MOSFET is 30–32 kHz and up to 800 kHz at higher frequencies, but its power capacity is low. The survey also shows that IGBTs with a low switching frequency (e.g., 6, 15, and 16 kHz) are usually used for inverters of [10 kW rating. For the output power range 1 to 10 kW, the switching frequency is 20 kHz. Both IGBT and MOSFET can thus be used. High-frequency switching can thus be said to reduce an inverter’s output-current harmonics, size, and weight (Ralegaonkar and Gupta 2010; Ishikawa 2002) Operational AC/DC analysis Operational AC voltage and frequency range Operational AC voltage is the output of a PV inverter, fed into the utility grid. Voltage and frequency generated from the inverter are to operate smoothly, matching the required voltage and frequency of the utility grid. Standard voltages and frequencies of a single-phase circuit vary with region: 230 V and 50 Hz in Europe, 101/202 V and 50/60 Hz in Japan, and 120/240 V and 60 Hz in USA. Also, the standard voltage and frequency for a three-phase circuit are 380/400 V and 50 Hz in Europe, 202 V and 50/60 Hz in Japan, and 480 V and 60 Hz in the USA. At these values, the inverter can be operated substantially without problem and within tolerances of ?10% and -15% for the voltage, and ±0.4 to 1% for the frequency (Taufiq et al. 2007; Ishikawa 2002) Manufacturers must provide the information as there are differences in voltage and frequency of utility grids depending on country. The survey shows the three frequencies (50, 50/60, and 60 Hz) determining which country can use which type of PV inverter. Survey of grid-connected photovoltaic inverters Fig. 3 Distribution of power ratings (AC Output) of the products surveyed 525 28 30 26 Number 25 21 20 13 15 10 7 4 5 4 1 0 2 9.5 -1 0 .5 8.5 -9 . 5 7.5 -8 . 5 6.5 -7 . 5 5.5 -6 . 5 4.5 -5 . 5 3.5 -4 . 5 2.5 -3 . 5 1.5 -2 . 5 0.5 -1 . 5 0 Power Rating (AC output) in kW Fig. 4 Switching concepts of the products surveyed Power rating < 10kW IGBT & FET 33% Power rating > 10 kW HERIC 6% IGBT 88% IGBT 52% FET 9% HERIC 2% IGBT & FET 10% Operational DC voltage range Applicable PV array power Operational DC voltage is the input voltage at the DC side, fed from the PV array. Inverters thus differ in their range of operational DC voltage, according to their rated power and the grid’s rated voltage. Table 2 shows the DC voltages for a range of rated power capacities. Clearly, the wider the voltage range, the more voltage the inverter can accept from a PV array/string, allowing various ranges of voltages from the PV array/string to be connected to the inverter. Figure 5 is the survey result for ratio of applicable rated power of PV arrays to rated output power of inverters. Ratios of the PV array’s average output power to the inverter’s average rated output power are estimated to be 1.06 (\10 kW power rating) and 1.04 ([10 kW power rating). These, however, are unconditional, as the array output powers differed according to conditions (latitude, angle of inclination of module, etc.) at the area where the Table 2 Ranges of the PV inverter DC voltages versus their power ratings Inverter rated power (AC) Operational DC voltage range \1 kW 1–5 kW 5–10 kW [10 kW 40–130 100–500 180–480 150–400 150–700 330–550 125–200 100–600 195–550 180–380 165–300 330–600 110–350 200–380 240–450 200–780 333–500 125–400 140–450 200–400 200–450 240–450 350–600 210–420 220–380 350–600 400–1150 150–380 200–780 80–350 230–500 400–780 150–400 205–450 250–480 250–600 400–800 150–450 212–380 300–650 250–800 420–800 150–450 250–480 250–480 270–600 420–850 150–600 300–650 350–600 300–480 430–800 160–650 350–600 220–380 300–600 450–800 165–300 80–350 300–650 450–820 180–380 123 Normalised PV rated power kWp/kW 526 N. A. Rahim et al. because avoiding disturbances (such as voltage fluctuation) to the power system is important. The power factor was seen to increase if THD decreased (see Fig. 6), achievable via current-control scheme in the inverter circuit (a simple control circuit and transient current suppression allow high power factors) (Kissell 2006). 1.40 <10kW >10kW 1.20 1.00 Inverter conversion efficiency 0.80 0.1 1 10 100 Inverter Power Rating (kW) 1000 Fig. 5 Distribution of rated powers of the PVs PV power systems were installed (Knier et al. 2009; Rahim et al. 2010). AC harmonic current from inverter In terms of AC harmonic current from inverter, the findings of this survey show the Total Harmonic Distortion (THD) range to be less than 5%, which translates to low harmonics and good performance (Haeberlin 2001; Mekhilef et al. 2007). The values that remain low resulting from present inverter technology which uses PWM control scheme to control output waveform can reduce (with fewer problems) an inverter’s harmonic current, because even with a few harmonics, a grid inverter can be operated without any problems, avoiding disturbance to the grid line (Kissell 2006; Mahlia et al. 2005). Note that THD of current generated by a PV inverter is regulated by the International IEC 61000-3-2 Standard. Power factor The survey looked at power factors, which ranged from 0.98 to 1; the former is considered good as long as the inverter’s AC output power factor is not let to drop, Fig. 6 Current THD versus power factor 123 Inverter efficiency is defined as the relationship between PDC and PAC, used to measure a PV inverter’s performance. According to the maximum/peak efficiencies and the European and Californian (CEC) efficiencies that the manufacturers provided in their product datasheets, overall maximum efficiencies of the inverters surveyed showed their distribution ranging from 90 to 97%; none was less than 90%, or higher than 98%. Inverters with efficiencies ranging from 94 to 96% were found to be the highest in number for both the maximum and the European efficiencies. Figure 7 breaks down the efficiencies of the products surveyed, showing the highest number of inverters to be in the 95% to 96% efficiency range, followed by the 94 to 95% and the 96 to 97% ranges. Figure 8 shows inverters from European countries having the highest average efficiency (95.25%), with North American inverters coming in a close second (95.11%) and Asian inverters next (94.43%). Interestingly, the highest average efficiency of the Chinese inverter Sungrow is 98.5%, as is the highest average efficiency of European inverters manufactured by SMS (also 98.5%), and as is the highest average efficiency of North American inverters manufactured by Solaron (almost the same as that of EU countries) (Saidur et al. 2009). Figure 9 further breaks down efficiency according to the inverters’ isolation design. The maximum efficiency appropriated with the isolation type; among the high-frequency transformer, low-frequency transformer, and transformerless types, the transformerless has the highest efficiency. Figures 10a and b are breakdowns of the inverter efficiencies of two power ratings. The findings show that inverters from European countries have the highest efficiency (96.3%, low-frequency transformer), whereas the ones from Asian countries have the lowest efficiency (91.17%, high-frequency transformer). For transformerless type, the highest efficiency is 98.37% (power rating [ 10 kW). There are no low-frequency transformer data from North America for each of the power ratings because low-frequency-transformer isolation is no longer popular in North American market (it enlarges an inverter system) (Mahlia et al. 2011). Power loss in a transformer affects an inverter system’s efficiency entirely; transformerless inverter systems can thus be said to be the most efficient. Survey of grid-connected photovoltaic inverters Fig. 7 Survey distribution of the maximum and the European efficiencies 527 Max and Europen Efficiency distribution survey 35 Max efficiency Number 30 EU efficiency 25 20 15 10 5 0 <90 90-91 91-92 92-93 93-94 94-95 95-96 96-97 97-98 >98 Maximum efficiency % European Efficiency Max Efficiency 95.5 95.25 95.11 Efficiency (%) 95 94.81 94.43 94.5 94.2 94 93.74 93.5 93 Europe Asia N. America Region Fig. 8 Average maximum and European efficiencies of the products surveyed Transformerless Low Frequency High Frequency 100 99 97.48 Efficiency (%) 98 IEC 60529 (of the International Organization for Standardization). Figure 11 shows that waterproofing and dust proofing are required in outdoor installations. The survey found most of the \10 kW inverters to be suitable for outdoor installation, subject to 71% dust proofing and waterproofing. Only 46% installations of inverters [10 kW required dust proofing and waterproofing. PV power systems with high power rating for grid interconnection and generally installed in houses are assumed to be often installed indoors, where dust proofing and waterproofing are not required. Dust proofing and waterproofing are still not required in some outdoor installation specifications, so, in such situations, the inverters are installed in external boxes. Table 3, listing the maximum and the minimum temperatures of indoor and outdoor inverter installations, show solar inverters as generally installed outdoors; they can withstand extreme temperature. Still, inverter system operation are unsuitable at temperatures above operating conditions, as overheating, fire, or damaged insulation can result (Tuladhar et al. 2008; Sanjay Kumar et al. 2009). 97 96.07 95.94 96 Protection function 95.25 94.63 95 Isolation AC/DC 94 93.35 93 < 10 kW > 10 kW Power Rating Fig. 9 Average maximum efficiencies according to isolation type Operating conditions Operating conditions such as indoor and outdoor installation specifications, ambient temperature, waterproofing, and dust proofing, are important flexibility issues. Waterproofing and dust proofing requirements for power ratings \10 kW and [10 kW are summarized next. The coding systems for environmental rating of enclosures are NEMA and the IP rating system according to Figures 12a and b show the distribution of various AC/DC transformer categories. Figure 12a shows the high-frequency transformers (44%) and the low-frequency transformers (36%) constituting most of the \10 kW PV inverters. Constitution of the [10 kW inverters (Fig. 12b) are 54% inverters with low-frequency transformers, 27% transformerless inverters, and 19% inverters with highfrequency transformers (Wong 2004). Figures 13a and b segregate the inverters by region. European inverters with high-frequency transformers in the \10 kW range are found to have the most transformer isolation. European inverters with low-frequency transformer in the [10 kW range again have the most transformer isolation. 123 528 N. A. Rahim et al. Fig. 10 Averages of maximum efficiencies according to isolation type, for power rating a \10 kW, b [10 kW power rating (a) 97 Transformerless 96.25 96.3 95.65 96 Efficiency (%) Low Frequency 94.93 95 High Frequency 95.93 95.13 94.4 94 93 92 91.17 91 90 Europe N.America Asia Region (b) Transformerless Low Frequency High Frequency 100 99 Efficiency (%) 98 98.37 97.44 97.15 97 96.07 96 95.18 95 94.64 95 94 93 92 92 91 Europe N.America Asia Region Fig. 11 Breakdown of installation environments, power rating a \10 kW, b power rating [10 kW (a) (b) No Dust proof, Water proof 15% Dust Proof, Waterproof 46% Indoor Installation Temperature minimum (C) Outdoor Installation Temperature minimum (C) Minimum temperature (C) Maximum temperature (C) 10 40 -25 50 -20 -25 45 55 -20 -15 55 60 0 60 -10 65 Anti-islanding protection The survey’s findings suggest most (73%) of the inverters use the ENS (impedance measurement) anti-islanding detection method; the remaining used the active or the 123 Dust Proof, Waterpro of 71% No Dust proof, No water proof 4% No Dust proof, No water proof 39% Table 3 Maximum and minimum temperatures of indoor and outdoor installations of inverters No Dust proof, Water proof 25% passive method. In the passive method, the detection of islanding depends on grid voltage and grid frequency; rate of change of voltage and of frequency are detected, and three-phase voltage drop is monitored. Passive method could be insufficient in preventing islanding under perfect Survey of grid-connected photovoltaic inverters 529 High Freq Transformer 44% (a) Low Freq Transformer 36% Transformerless 20% High Freq Transformer 19% (b) Low Freq Transformer 54% Transformerless 27% Fig. 12 Distribution of inverter DC/AC isolations, power rating a \10 kW, b [10 kW (a) Transformerless High freq transformer Low freq transformer 16 14 Number 12 10 8 6 4 2 0 Europe North America injection, monitoring of phase jumps, harmonics, positive feedback methods or unstable current, and phase controllers, is suggested (Abella and Chenlo 2004; Ozbalta and Ozbalta 2010). All the anti-islanding protections surveyed comply with UL1741, IEEE1547, IEEE-929:2000, AS 4777, DIN VDE 0126. Other protection functions All the inverters surveyed had their own AC/DC protection functions on their DC and AC sides. Protection for the DC side includes against reverse DC voltage, DC over-power, over-current, and DC grounding fault. Protection for the AC side includes against AC over/under-voltages, AC over-current, frequency increase/drop, and detection of AC grounding, also detection of any of the direct current occurring in some transformerless systems (Rajamohan et al. 2010). Another function is the detection of temperature rise, where protection accompanies operation of the inverter system, and voltage and current are detected and used in the control circuit, as are information from various types of sensors. Protection functions are integral with the inverter system. In an overload, this includes Operating Point Change (OPC), Power Limit (PL), Power Reduction (PR), Switch Off (SO), and Current Limit (CL). Figure 14 breaks down the inverters’ protection behavior when overloaded; for both power ratings, OPC and PL seem to dominate. Reverse DC-voltage protection is done by an internal diode in the inverter circuit. Protection against lightning and surge voltage are performed by a surge arrester and a varistor on both the DC and the AC sides. Asia Region (b) Transformerless High freq Transformer Low freq Transformer 25 Number 20 15 10 5 0 Europe North America Asia Region Fig. 13 Distribution of types of inverter isolation by region, power rating a \10 kW, b [10 kW balanced load conditions in both active and reactive powers, so its combination with active method, which is based on e.g., frequency shift, impedance monitoring by current Cost of inverter systems The findings clearly show that an exact average price per kW for PV inverters is difficult to determine, because an inverter’s rated power is not the only price determiner, but factors influencing the cost of inverter production (manufacturing technology, efficiency, performance, size, weight, reliability, type of isolation design, etc.) are, too. Visual display, data monitoring, data storage, and communication capabilities also contribute to price. Figure 15a shows the average price of inverters as concordant with their power ratings. Figure 15b shows the average price per kW of 0.5–6 kW inverters as $1075.43 (i.e., $1.075/W). Inverter size affects cost, so the price does not fully reflect the inverter’s improvements. 4.2 kW inverter, for instance, is about 54% cheaper than a 1.3 kW inverter. Prices of inverters with high power ratings can thus be stated as cheaper than those with low power ratings. 123 530 N. A. Rahim et al. Fig. 14 Breakdown of protection types 40 OPC,PL Number 35 30 OPC 25 SO,PL 20 PL 15 PL,PR 10 5 0 <10kW >10kW Power rating Normalised Inverter cost (USD/kW) 35.00 6000 5000 4000 3000 2000 1000 0 0 1 2 3 4 5 6 Rated power (kW) (b) 2500 Normalize weight (kg / kW) Average Inverter cost (USD) (a) Transformerless High Freq Transformer Low Freq Transformer 30.00 25.00 20.00 15.00 10.00 5.00 0.00 0 2000 2 4 6 8 10 12 Rated Power (kW) 1500 Fig. 16 Weights of the inverter systems 1000 Display 500 0 0 1 2 3 4 5 6 Rated power (kW) Fig. 15 a Average cost of PV inverters. b Average price per kW of PV Inverters Size and weight of inverter systems In PV system installations, an inverter’s size and weight matter. As stated in isolation protection, the presence or absence of an isolation transformer in an inverter system is the main contributor to system size and weight. Manufacturers, however, mostly use transformerless or high-frequency transformer for isolation to reduce the weight and size of their inverter systems. For now, size and weight are reduced via the use of a high-frequency transformer, because high frequency minimizes the size of the cable used in the transformer, reducing size of both the transformer and the inverter system. Figure 16 is the distribution of the inverter systems, based on their weight (Radzi and Rahim 2009), the average weight for transformerless shown as 6.22 kg/kW, for high-frequency transformer as 5.64 kg/kW, and for low-frequency transformer as 14.69 kg/kW. 123 Information about the display’s number of lines, characters, and pixels was found through analysis of the survey data, which showed the display as being essential to conveyance of information on e.g., system parameters, and to the monitoring of system functions. The displays are supposedly liquid crystal display (LCD) or LED displays, some including features such as background illumination and color display. Warranty The findings show that product warranty is important proof of performance reliability. The manufacturer warranties range from 2 (minimum) to 5 years (maximum). A few offer 10 years warranty out of the 20 years of a PV panel’s life. The manufacturers, though, do not expect a full 20-year lifetime, because an inverter must be replaced every 10 years (; NREL 2006; Demirci Sankir et al. 2011) Yuan and Zhang 2006 so its performance is maintained. Any inverter having lived the 20 years of its life would be promising to the future of building-integrated PV applications (Ozbalta and Ozbalta 2010). Survey of grid-connected photovoltaic inverters 531 Fig. 17 Sunny Webbox Data logging, communication, and diagnostic characteristics The survey discovered the latest inverters’ features such as data logging and communication capabilities. Inverter manufacturers provided the software required to process inverter-sent data, allowing quick diagnostics when the system does not operate properly, so the user is able to adjust to optimal operation, the system parameters. For data logging, some manufacturers provide memory for up to 1 GB, and for communication, some provide interfaces such as RS232, RS485, USB, Bluetooth, GSM, GPRS, and modem, allowing users to connect the inverter with other devices such as notebook, controller, and mobile phone. Figure 17 is an example of an inverter communication device; it allows users to access their system performance data anytime, anywhere in the world, via a web server (SMA 2009). Cooling method Inverter cooling is an important consideration for an inverter’s reliability, long life, and ability to operate at full power over a wide range of temperatures. The survey’s findings show that a suitable cooling method is by either a fan or natural air convection. Inverters with a wide range of ambient temperatures (-25 to 65C) usually do not use a fan as its cooling method, but inverters with ambient temperatures between -25 and 45C do. At this point, cooling can be summarized as depending on the range of ambient temperatures. Of the inverters surveyed, about 56% of power rating \10 kW and 52% of power rating[10 kW used fans. A fan cooling system has been suggested as not necessarily having to be continuously ON but can turn ON automatically when temperature or power output reaches a particular level, reducing noise, improving the inverter’s efficiency. Conclusions Technology for PV grid inverters has advanced with rapidly increasing world market demand for solar energy in line with growth of PV. The rise of technologies of recent PV inverters has brought down price, increased efficiency, and improved reliability and availability. The PV grid inverters surveyed generally performed rather well in terms of conversion efficiency: 95% overall average efficiency, a power-factor that is close to unity over a wide operating range, and capable of keeping current harmonic THD at less than 5%. Transformer power loss makes transformerless designs more effective than ones with transformers (whether low, or high, frequency). Also, a transformer increases size and 123 532 N. A. Rahim et al. weight of an inverter system, but a high-frequency transformer or a transformerless system can reduce transformer size and weight, minimizing size and weight of entire inverter systems. High power rating has been claimed to lower price. A warranty of 5 to 10 years seems to be sufficient convincing of an inverter’s reliability and durability. A PV inverter must have flexible waterproofing and dust proofing. Features such as data logging, system monitoring, and memory storage capacity for data acquisition and communication are preferred considerations. Suitable fan cooling matters to assessment of inverter lifespan and reliability. Future work could consider the following: • • • • Improve survey ethics, which, when lacking, can cause difficulties when collecting data. Use of database system software to make survey more systematic and user friendly. Arrange costs of the PV inverters in present survey against those obtained through previous surveys. Increase the number of survey respondents. References Abella MA, Chenlo F (2004) Photovoltaics, choosing the right inverter. Renewable Energy World, March–April 2004 Bugutekin A (2011) Effect of the collector diameter on solar chimney power plants. Energy Educ Sci Technol A 27(1):155–168 Camdali U (2010) Economic analysis of photovoltaic systems for household applications in Turkey. Energy Educ Sci Technol A 24(2):125–135 Demirbas A (2007) Progress and recent trends in biofuels. Prog Energy Combust Sci 33:1–18 Demirbas B (2010) Biomass business and operating. Energy Educ Sci Technol A 26:37–47 Demirci Sankir N, Tezel T, Dogan B (2011) Flexible CdS photoelectrodes for photoelectrochemical solar cell applications. Energy Educ Sci Technol A 27(1):63–78 Haeberlin H (2001) Evolution of inverters for grid connected PV systems. In 17th european photovoltaic solar energy conference, Munich, Germany Ishikawa T (2002) Grid connected photovoltaics power system: survey of inverter and related protection equipments. Central Research Institute of Electric Power Industry. http://www. iea-pvps.org Jayed MH, Masjuki HH, Saidur R, Kalam MA, Jahirul MI (2009) Environmental aspects and challenges of oilseed produced biodiesel in Southeast Asia. Renew Sustain Energy Rev 13:2452–2462 Kissell TE (2003) Industrial electronics, 3rd edn. Prentice Hall, India Knier G (2007) Science@NASA. How do phovoltaics work. http://science.nasa.gov/headlines/y2002/solarcells.htm. Retrieved on 19 Sept 2009 KTAK (2009) Ministry of Green Technology and Water. Small energy power program. http://www.ktak.gov.my/template01. asp?contentid=163. Retrieved 17 Oct 2009 123 Mahlia TMI, Masjuki HH, Taha FM, Rahim NA, Saidur R (2005) Energy labeling for electric fans in Malaysia. Energy Policy 33(1):63–68 Mahlia TMI, Saidur R, Yanti PAA, Masjuki HH (2011) Role of energy guide labels in consumers purchase decision for household electrical appliances. Energy Educ Sci Technol A 27(1): 95–104 MBIPV (2009) Malaysia building integrated photovoltaic (mbipv) technology application project, Pusat Tenaga Malaysia. http://www.mbipv.net.my/C2Ov.html. Retrieved 2 Oct 2009 Mekhilef S, Omar AM, Rahim NA (2007) Modeling of three-phase uniform symmetrical sampling digital PWM for power converter. IEEE Trans Ind Electron 54(1):427–432 Newton M (2007) Net metering is a win–win for utilities and local communities. Colorado Renew Energy Soc. http://www.cresenergy.org/blogs/blogs_newton_07apr.html. Retrieved 20 Oct 2009 NREL (National Renewable Energy Laboratory (2006) A review of PV inverter technology cost and performance projections. Navigant Consulting Inc., Burlington Ozbalta TG, Ozbalta N (2010) Theoretical and experimental analysis of the solar energy gain of transparent insulated external wall in climatic conditions of Izmir. Energy Educ Sci Technol A 25(1–2):69–86 Radzi MAM, Rahim NA (2009) Neural network and bandless hysteresis approach to control switched capacitor active power filter for reduction of harmonics. IEEE Trans Ind Electron 56(5):1477–1484 Rahim NA, Selvaraj J, Krismadinata C (2010) Five-level inverter with dual reference modulation technique for grid-connected PV system. Renewable Energy 35(3):712–720 Rajamohan P, Rajasekhar RVJ, Shanmugan S, Ramanathan K (2010) Energy and economic evaluation of fixed focus type solar parabolic concentrator for community cooking applications. Energy Educ Sci Technol A 26(1):49–59 Ralegaonkar RV, Gupta R (2010) Application of passive solar architecture for intelligent building construction: a review. Energy Educ Sci Technol A 26(1):75–85 Ruoss D, Gulabrai L, Chen WN, Mohd Nazri Mat Nawi, MIDA, J. LeClaire (2009) PV Industry handbook: Malaysia building integrated photovoltaic project Saidur R, Masjuki HH, Jamaluddin MY, Ahmed S (2007a) Energy and associated greenhouse gas emissions from household appliances in Malaysia. Energy Policy 35(3):1648–1657 Saidur R, Masjuki HH, Jamaluddin MY (2007b) An application of energy and exergy analysis in residential sector of Malaysia. Energy Policy 35(2):1050–1063 Saidur R, Rahim NA, Masjuki HH, Mekhilef S, Ping HW, Jamaluddin MF (2009a) End-use energy analysis in the Malaysian industrial sector. Energy 34(2):153–158 Saidur R, Rahim NA, Ping HW, Jahirul MI, Mekhilef S, Masjuki HH (2009b) Energy and emission analysis for industrial motors in Malaysia. Energy Policy 37(9):3650–3658 Saidur R, Islam MR, Rahim NA, Solangi KH (2010a) A review on global wind energy policy. Renew Sustain Energy Rev 14(7):1744–1762 Saidur R, Ahmed JU, Masjuki HH (2010b) Energy, exergy and economic analysis for industrial boilers for Malaysia. Energy Policy 38(5):2188–2197 Sanjay Kumar T, Mittal V, Thakur NS, Kumar A (2009) Performance evaluation of a smooth flat plate solar air heater. Energy Educ Sci Technol A 23(1–2):105–117 SMA (2009) SMA product catalog. http://www.sma-america.com/en_ US/products/monitoring-systems/sunny-webbox.html. Retrieved 20 Oct 2009 Survey of grid-connected photovoltaic inverters Smil V (2006) Energy at the crossroads. http://www.oecd.org/ dataoecd/52/25/36760950.pdf#search=worldwideconsumptionof energy13TWsmil. Retrieved on 18 Sept 2009 Sunways (2009) HERIC topologie. Sunways photovoltaic technology. www.sunways.de. Retrieved 10 Oct 2009 Taleghani M, Ansari HR, Jennings P (2010) Renewable energy education in sustainable architecture: lessons from developed and developing countries. Energy Educ Sci Technol B 2: 111–131 Taufiq BN, Masjuki HH, Mahlia TMI, Saidur R, Faizul MS, Mohamad EN (2007) Second law analysis for optimal thermal design of radial fin geometry by convection. Appl Therm Eng 27(8–9):1363–1370 Tuladhar A (2008) Grid interactive solar inverters and their impact on power system safety and quality 533 Wikipedia (2009) Islanding. http://en.wikipedia.org/wiki/Islanding. Retrieved 8 Aug 2009 Wong FK (2004) High frequency transformer for switching mode power supplies. School of Microelectronic Engineering and Information Technology, Griffith University, Brisbane, Australia. Available at: http://tech.dianyuan.com/bbs/u/68/504711218680 108.pdf Yuan X, Zhang Y (2006) Status and opportunities of photovoltaic inverters in grid-tied and micro-grid systems. In: IEEE photovoltaic specialists conference 2006 Zgorena T (2004) UL1741 update a safety standard for distributed generation 123