The Hollow Metal Manual - Ron Blank and Associates, Inc.

advertisement

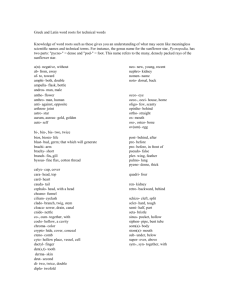

© Ron Blank & Associates, Inc. 2011 Please note: you will need to complete the conclusion quiz online at ronblank.com to receive credit The Hollow Metal Manual: Progressive Solutions for Hollow Metal Doors and Frames An AIA Continuing Education Program Credit for this course is 1 AIA HSW CE Hour Building a Solid Future on the Foundation of Our Successful Past V HMM HOLLOW METAL MANUFACTURERS A S S O C I A T I O N Course: hmm08c 800 Roosevelt Rd. Bldg. C, Ste. 312 Glen Ellyn, IL 60137 630.942.6591 www.hollowmetal.org An American Institute of Architects (AIA) Continuing Education Program Approved Promotional Statement: Ron Blank & Associates, Inc. is a registered provider with The American Institute of Architects Continuing Education System. Credit earned upon completion of this program will be reported to CES Records for AIA members. Certificates of Completion are available for all course participants upon completion of the course conclusion quiz with +80%. Please view the following slide for more information on Certificates of Completion through RBA This program is registered with the AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA or Ron Blank & Associates, Inc. of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. An American Institute of Architects (AIA) Continuing Education Program • • • • Course Format: This is a structured, web-based, self study course with a final exam. Course Credit: 1 AIA Health Safety & Welfare (HSW) CE Hour Completion Certificate: A confirmation is sent to you by email and you can print one upon successful completion of a course or from your RonBlank.com transcript. If you have any difficulties printing or receiving your Certificate please send requests to certificate@ronblank.com Design professionals, please remember to print or save your certificate of completion after successfully completing a course conclusion quiz. Email confirmations will be sent to the email address you have provided in your RonBlank.com account. Please note: you will need to complete the conclusion quiz online at ronblank.com to receive credit Course Description Become better acquainted with the benefits of hollow metal doors. Gain crucial knowledge for specifying hollow metal doors and frames through an overview of the Hollow Metal Manual including fabrication, standards, and applications. Learning Objectives Upon completion of this course the Design Professional will be able to: • List the fire test requirements, processes and procedures for obtaining ratings on fire rated doors and frames. • Explain the hardware requirements and configurations for use in fire rated doors and frames. • Describe fire door classifications, listings, labels, and certifications. • Explain the various fire rated door and frame applications including requirements for glazing, transoms and other components. • Navigate the Hollow Metal Manual. • Describe hollow metals components and options. • Specify Hollow Metal and Steel Doors in accordance with guidelines published in the Hollow Metal Manual. Note: References to pages and figures shown on slides refer to the pages and figures of the subject standards Technical Summary 890-06 Technical Summary • • • The Hollow Metal Manual is presented in 14 separate sections, in CD-ROM format or downloadable from the internet. . The Manual provides design professionals the most current information on manufacturing, door and frame designs and details, hardware preparation and location, installation and storage, fire-rated applications, common terms, plus the guide specifications. The Hollow Metal Manual guide specifications cover a broad range of door and frame applications. Hollow Metal Manual: – 860 addresses doors and frames for light traffic areas. – 861 covers doors and frames appropriate for use in higher traffic, commercial applications. – 862 details doors and frames for commercial security applications; – 863 covers detention security doors and frames. – 865 is a guide for swinging sound control doors and frames. – 866 covers stainless steel hollow metal doors and frames. – 867 covers hollow metal doors and frames with laminated cores. These are the Guide Specifications, not general Standards documents. Introduction to Custom Hollow Metal • The term "hollow metal work” refers to many of those components of building construction that are made of cold formed sheet metal. • The variety of door designs available is limited only by the architect's ingenuity that complies with all governing bodies (codes) & the limits of the manufacturing process. • The history of the development of hollow metal doors and frames is a profile of the genius for combining beauty with good functional design while offering an improved product at reduced cost. Overview of Hollow Metal • • • The major advantage of custom hollow metal is the architect's design freedom. Where special requirements so dictate, thicker material may be used for either doors or frames, and special reinforcements are readily provided. Most frames, whether for a single door or a larger opening have accurately fitted and welded corners, and are shipped as rigidly assembled units. Another inherent advantage of custom work is that shop drawings of all items are submitted for the architect's approval. Glossary of Terms for Hollow Metal Doors and Frames The American National Standards Institute does not develop standards and will in no circumstances give an interpretation of any American National Standard. Moreover, no person shall have the right or authority to issue an interpretation of an American National Standard in the name of the American National Standards Institute. The glossary is used as a resource, not an interpretation tool. Interpretation requests should be sent to the contact listed with the standard found in the manual. Glossary Examples • Anchor, Rough Buck a steel channel which attaches to both vertical sides and head of a prepared wall opening and the finished Hollow Metal Frame, either by application of screws or by welding • Gage (Gauge) an outdated numeric value used to define a range of thickness of material; replaced by “thickness” • Wicket Door a swinging door within a door Hollow Metal Manufacturing Hollow Metal Manufacturing • • • • • Hot-rolled steel Cold-rolled steel Zinc-coated steel Stainless steel Applications Note: the weight of coating in oz./sq.ft. and g/sq.m refers to the total coating on both surfaces Four Basic Types Carbon Steel: Four Basic Types • • • • Hot-Rolled -- generally 16 gage and thicker (hot rolling process) Cold-Rolled -- cold rolling processes hotrolled sheets to desired thickness (most commonly used material for hollow metal applications) Zinc-Coated -- sheets are hot dipped to produce galvanized and annealed steel Stainless Steel -- moderately to highly polished surfaces (for areas where cleanliness and corrosion resistance are critical) Fabrication Again, hollow metal permits the architect freedom of design. It is important to have an understanding of materials used and the fabrication process. The common methods of cutting, forming, and assembling for hollow metal products are therefore of concern to the architect. These operations include shearing, blanking, brake forming and welding. shearing blanking or punching forming or bending welding finishing Fabrication • SHEARING Most raw material stock for hollow metal is purchased by the fabricator in the form of flat sheets which, prior to forming, must be cut to exact sizes. Shearing is the simplest method of obtaining straight cuts. It is typically done on a machine called a shear, which consists of a tablelike “bed” on which the sheet to be cut is positioned. • BLANKING Blanking (punching or laser cutting) operations are employed to make the numerous cutouts in the flat sheared pieces of metal that will later be formed into hollow metal components. Punching operations are accomplished by positioning the metal between the upper and lower components of a die set, usually consisting of lower stationary “die” and an upper movable punch. Fabrication FORMING • The basic method of forming is common to all sheet metals and is performed on a machine called a press brake. Fabricators of hollow metal work use a variety of press brakes in the manufacturing of their products as this machine offers the widest range of adaptability to forming requirements. It does have certain limitations, however, as will be explained. • Only straight-line bends can be made on the press brake. The bend radius and angle, which are a function of die design, can be varied over a wide range. Fabrication GENERAL FABRICATION CAPABLITITIES • One of the inherent characteristics of any cold formed sheet section is that external corners are rounded and the inside radius for most angular bends is generally equal to the approximate thickness of the metal being bent. • There are also certain other dimensional limitations to be observed in the design of typical frame members. • The minimum recommended face dimension of a framing member is 1" (25.4 mm). • The minimum hole size to be punched in any part needs to be equal or greater than the thickness of the material being punched. Fabrication WELDING • Hollow metal products are generally assembled by welding. Several types of both fusion welding and resistance welding are commonly employed in the industry. The usual fusion welding method is metal-arc welding, which is either shielded or unshielded. – Fusion Welding The metal-arc method, using a consumable fluxcoated rod, is commonly used to weld the miter and butt joints at the frame corners with the welds usually being placed on the concealed inner face of the frame members. – Gas welding is a fusion method with limited use. Fabrication • Spot welding and projection welding are the most commonly used resistance welding methods. – Spot Welding Spot welding is a type of resistance welding commonly used in the industry to join two overlapping pieces of metal, face to face. – Projection Welding Projection welding is another form of resistance welding often used to fasten hinge and strike reinforcements on doors and frames, and floor anchors to the backsides of frames. The part to be attached by projection welding must first have a small projection of the proper size formed at the point where the weld is to be made. Several welds can be made simultaneously at each such projection. Steel Tables • • Prior to 1970, sheet steel thickness was referred to as gage. ASTM and ANSI currently do not list gage numbers in their standards. Like many generic terms, gage (or gauge) is ingrained in many vocabularies and is misunderstood as a term for thickness. Published in this manual is a minimum thickness table to be used in place of discontinued gage numbers. The decimal inch values shown (next slide) were taken from the Underwriters Laboratories, Inc. publication for gage number and equivalent thickness. Corresponding metric values are included for reference purposes only. Steel Tables Hollow Metal Doors Doors may be classified by their method of operation. There are four basic types: swinging, sliding, rolling steel, and revolving. Though revolving doors are seldom, if ever, made of carbon steel, sliding and rolling steel may be hollow metal. This standard applies to hollow metal doors that are side-hinged swinging and mounted on either hinges or pivots. Door Hand Designation Representative Door Designs Representative Core Construction There are two basic types of door constructions: • STEEL STIFFENERS – Vertical steel stiffeners, which can be channel, zee, hat, or similar shaped sections, support the face sheets. The stiffeners are attached to the face sheets by spot or projection welding. • LAMINATED CORE – This is a sandwich construction in which the face sheets are separated by a core comprised of honeycomb (“Kraft” paper), polyurethane, polyisocyanurate, polystyrene, coreboard, or steel stiffeners. The core is laminated to the faces by means of an adhesive. Foamed-inplace polyurethane cores are self-bonding and do not require additional adhesive. Door Edge Construction VERTICAL EDGE DETAILS STILE & EDGE DETAILS BOTTOM EDGE DETAILS TOP EDGE DETAILS FLUSH TRANSOM PANEL DETAILS TOP EDGE Typical Hardware Preparation Hollow Metal Frames The primary function of the door frame is to provide support for the door and the components required for proper operation of the opening. Hollow metal frames serve other aesthetic or functional purposes, such as trimming a wall opening having no door, or enclosing glazed areas that provide throughwall visibility, or admitting light and/or air. Hollow metal frames, which are strong, sturdy and durable, serve all such functions economically. Profile Configurations Custom hollow metal frames are available in a broad array of configurations. Illustrated here are some of the more common and representative types. The following pages show typical details of frame construction and assembly. Hollow Metal Frames Basic Door Frame Profiles and Parts Grouting Hollow Metal Frames: Grout, when used in accordance with industry guidelines, can improve frame durability and sound deadening, and can increase frame anchorage strength (depending on wall construction). Basic Door Frame Profiles and Parts Grouting of the frame is not required for fire-rated frames. For most commercial applications, grouting of mullions and other closed sections is not recommended. Basic Door Frame Profiles and Parts • Perimeter joints of a continuously welded frame shall have all elements of the frame member continuously welded: soffits, stops, rabbets, faces and returns. Faces and returns may be welded either internally or externally. Soffits, stops, and rabbets shall be welded internally. • Some frame configurations require slopped jambs or heads. Mitered corner joints may not be available. • Occasionally, the face surface of the sill is designed to be recessed from the face of the other frame members. As this is a perimeter joint, all elements of the frame members should be continuously welded. Due to design and/or construction requirements, this is not feasible; therefore, it is necessary to alter construction methods. Basic Door Frame Profiles and Parts Indented joints at internal frame members shall be internally reinforced and welded. Joints at faces, soffits, stops and rabbets are not welded and appear as hairline seams. Mullions are constructed with an overlapping seam. Hardware Selection for Hollow Metal Doors and Frames The hardware used not only determines how well a door functions, but is also an important factor in the working life of the opening. Among the many benefits of custom hollow metal is the virtually unlimited choice of hardware that can be used. The architect is free to select those items which will provide the operational features, aesthetics, and quality desired, such as the use of electrical hardware, pivots or anchor hinges, concealed closers, concealed vertical rod devices, separate deadlocks, preassembled locks, and other architectural hardware. Hanging Devices Barrel & Gear Full Mortise Offset Pivot Locks, Latches & Deadlocks The locks shown here are those most commonly used. The names serve to identify either the type of lock construction or installation. Each may be provided with a knob or lever handle. Panic / Fire Exit Hardware Mortise Rim Vertical Rod Panic hardware is tested and labeled for life safety only, whereas fire exit hardware is tested for both life safety and fire resistance. Only the latter may be used where fire-rated doors are required. Both types are always operable from the inside by depressing a cross bar. The mortise type and the concealed vertical rod type are the least conspicuous, and are readily applicable to custom-hollow metal doors. Closing & Controlling Devices • Closer devices control the closing of a door. They are available in a range of sizes for various door sizes, locations, and job conditions. The hardware manufacturer’s recommendations should always be followed in determining size and type. • Where surface mounted closers or concealed components are specified, internal reinforcement plates are provided in the door and frame by the hollow metal manufacturer. Surface Concealed Overhead Floor Mounted Hardware Locations Hardware Locations for Hollow Metal Doors & Frames All hardware items, except the upper and intermediate hinges, are located by fixed dimensions from the finished floor to the centerline of the item, making the locations of all user-handled items at the same level for all door heights. Finish floor level is defined as the top surface of the floor, with the exception of resilient tile or carpet, which is then considered the top surface of the underlying concrete. These standards are recommended by the custom hollow metal industry as representing the long accepted usual preferences of both architects and users under normal conditions of use. Hardware Locations for Hollow Metal Doors & Frames HINGE LOCATIONS On custom doors, the top and bottom hinges have fixed locations rather than the varying locations used on standard doors. The three hinges shown on the drawing are recommended for doors up to and including 7 ft. 6 in. (2286mm) in height. For doors of greater heights, where four or more hinges are used, the top and bottom hinges are located as shown, with the intermediate hinges being equally spaced between them. The hinge backset (distance from back of cutout to back face of door) is 1/4 in (6.4mm). Hardware Locations for Hollow Metal Doors & Frames KNOB AND CROSS BAR LOCATIONS Regardless of the type of lock or latch used, the knob is located at the same standard 38 in. (965mm) from the finish floor, for the convenience of the user. The cross bar of exit hardware is also centered at this height. This will result in some variation in the strike location, depending on the type of lock, latch, or exit device used. However, this is considered preferable to standardizing the location of the strike, as recommended for standard doors, with resulting variations in the location of the user-handled items. Installation & Storage of Hollow Metal Doors & Frames Hollow metal work is fabricated in accordance with the shop drawings, approved by the architect or engineer. Preparation for hardware and other items is provided in accordance with the information furnished to the hollow metal manufacturer. The hollow metal manufacturer is a material supplier, not a subcontractor. The manufacturer does not include the installation of their product in the building, but only shipment in good condition from the factory. Receiving & Storage of Material The following procedures shall always be observed in storing hollow metal doors and frames at the job site: 1. Store all materials in a dry area, under cover. All products shall be stored where they will not be exposed to, or come in contact with the elements. 2. Do not use non-vented plastic or canvas. These materials create a humidity chamber, which promotes blistering and corrosion. 3. Store doors and frames in an upright position. Receiving & Storage of Material 4. Place no more than 5 doors or welded frames in a group. Small groups not only minimize the likelihood of damage due to excess handling, but also facilitate selection from the group for installation. In the case of multi-opening frames, no more than three units should be stored in a group to avoid serious damage to the bottom most frame. 5. Place all material on planking or blocking at least 4 in. (100 mm) off the ground, 2 in. (50 mm) off a paved area or the floor slab. 6. Provide at least 1/4 in. (6.4 mm) space between all units to permit air circulation. Typical Installation Procedures Typical Installation Procedures Installation of a hollow metal frame in a steel stud wall (refer to Hollow Metal Manual 820 – Hollow Metal Frames for additional anchorage methods) Installation of a hollow metal frame in a wood stud wall (refer to Hollow Metal Manual 820 – Hollow Metal Frames for additional anchorage methods) Typical Installation Procedures Installation of a hollow metal frame in a masonry wall (refer to Hollow Metal Manual 820 – Hollow Metal Frames for additional anchorage methods) Adjustable Strap-and Stirrup Anchor A stirrup is welded to the back of the jamb, and a perforated or corrugated strap provides for embedding into masonry joints. The stirrup provides sufficient adjustment for masonry coursing as well as access for full grouting of jambs. Typical Installation Procedures Frames are not designed to act as forms for grout. Grout must have a maximum 4 in. slump and be hand troweled in place. Bracing of the frame may be necessary prior to grouting to prevent sagging of the header or bowing of the jamb due to weight or pressure of the grout. Grout should not be installed after gypsum wallboard is installed, as the liquid within the grout will deteriorate the wallboard. When dictated by temperatures, anti-freezing agents for mortar may be recommended by specifications. These agents can adversely affect metal, and all surfaces in contact with the grout must be coated with a corrosion resistant material. It is recommended that general contractor be responsible for the grouting and for any required barrier coating. It is also their responsibility to use care in the application of the grout. Tolerances & Clearances for Commercial Hollow Metal Doors & Frames Accurate fabrication and installation are essential to the performance of doors and frame product. The requirements for manufacturing and installation are given in the following Sections. The manufacturer is responsible for producing door and framing products that comply with these Sections. However, it is important to recognize that proper installation is not the responsibility of the hollow metal manufacturer. For this reason, the requirements for installation should be included in the Section of the specifications where installation work is specified. It shall be the responsibility of the general contractor, using experienced installers, to perform the work outlined. Operating Clearance Frame Tolerances Profile Tolerances Cross Section Tolerances Door Tolerances Installation Tolerances Fire-Rated Hollow Metal Doors & Frames Hollow metal door and frame assemblies play a crucial role in providing the fire and life safety protection required in any building. There are, however, a number of variations in the designs and performance levels of these products. Therefore, in order to make the proper selection, it is essential that specifiers have adequate information on the different fire door and frame assemblies available. Classification of Fire Doors • • Fire doors are classified by hourly ratings as well as in minutes. The hourly rating indicates the duration of the fire test exposure and is called the “fire protection rating”. This table provides the relationship between the door location, wall rating, and the required hourly rating for the opening protected (door and frame). The local building code specifies the hourly rating for any location. Generally, fire doors and frames that qualify for a specific rating also qualify for all lower ratings. Fire Tests The hourly fire ratings for fire door assemblies (doors, frames and hardware) are determined by the length of time the assemblies satisfactorily withstand a standard fire test. Model and Building Codes, which specify the Standards used to test and evaluate fire door assemblies, are undergoing significant changes. Fire door assemblies, since the early 1900’s, have been tested to what have evolved into the ANSI/UL10b and ANSI/NFPA 252 Standards. These describe both the test method and pass/fail criteria. The neutral pressure plane for these Standards has historically been located at the top of the fire door assembly. Fire & Water Pressure Tests Immediately following the required period of fire exposure, the assembly is removed from the furnace and subjected to the impact, erosion, and cooling effects of a stream of water of specified nozzle pressure from a 2-1/2 inch (63 millimeters) hose with a 1-1/8 inch (28 millimeters) nozzle, commonly known as the “hose stream test”. The water pressure and duration of application for different ratings are shown in Table 3. Fire tests of 1/3 hour duration may be conducted without the hose stream. Fire window frames and glazing materials are tested in accordance with Underwriters Laboratories ANSI/UL9 or ANSI/NFPA 257 for negative pressure requirements. UBC 74 (1997) is the positive pressure equivalent, with a UL standard being proposed. Listing, Labeling and Certification Organizations Qualified fire doors, frames and windows shall be identified as such only by the presence of a label issued by a certification organization such as Underwriters Laboratories, Inc. (UL), Intertek Testing Services/Warnock Hersey (ITS/WHI) or Factory Mutual (FM). Labels appropriate for various conditions and requirements are provided as evidence that these products have passed a standard fire test. Certification organizations have developed independent policies regarding the information which is required on their labels. All fire labels indicate: • The certification organization name and "mark" (logo) • The manufacturer name, logo, or control number • Wording such as "Listed," "Approved," or "Classified" • A description of the product such as "Swinging Fire Door," "Fire Door Frame," or "Fire Window Frame" • A serial or control number All fire door labels must indicate the maximum fire rating. Fire door frame labels may include the maximum fire rating as well. Labeled frame products installed in drywall partitions are rated up to 1-1/2 hours unless otherwise indicated on the label. Labeled frame products in all other types of walls are rated up to 3 hours unless otherwise stated on the label. UL & WHI Labels Representative types of doors and frames offered by leading manufacturers of fire rated doors and frames are shown on the following slide. Each company provides its own product literature describing in detail the items it produces. Before specifying fire door assemblies, the literature of the intended supplier should always be consulted. The NAAMM website (www.naamm.org) contains a directory with links to member companies. Hollow Metal Fire Doors Fire Endurance Rating, Maximum Areas Hollow metal fire doors of all ratings and various designs, as well as a variety of frame types, are supplied by member manufacturers. Many manufacturers offer a wide variety, others a more limited choice. Because the requirements for 3-hour assemblies are more severe than those of assemblies having lower ratings, the choice in such applications is limited to flush unglazed doors or, in certain jurisdictions, lights not exceeding 100 square inches (0.065 square meters). Fire Door Frames Fire Endurance Rating, Maximum Areas Fire endurance rating widths and heights of commercially available materials are labeled by either UL or WHI for use in transom, sidelight and window assemblies. Users are advised to consult individual glazing manufacturer’s listings for specific limitations, restrictions and requirements. The Hollow Metal Manual These specifications have been prepared in accordance with the CSI recommended format with Part 1- General, Part 2-Product, and Part 3Execution. Explanatory notes or instructions are shown in italics. Guide specifications are intended to be used as the basis for developing job specifications and must be edited to fit specific job requirements. Spec. for Hollow Metal Doors & Frames 1. Application – Light commercial 2. Door construction: • Thickness: – Interior: 20 gage (0.032”) (0.81mm) – Exterior: 18 gage (0.042”) (1.06mm) • Core – steel stiffened • Edge – visible or welded 3. Frame construction: • Thickness – 16 gage (0.053") (1.34mm) interior or exterior • Miters – KD or welded Spec. for Commercial Hollow Metal Doors & Frames 1. Application – Commercial 2. Door construction: • Thickness: – Interior: 18 gage (0.042”) (1.06mm) – Exterior: 16 gage (0.053”) (1.34mm) • Core – steel stiffened • Edge – welded 3. Frame construction: • Thickness – 16 gage (0.053") (1.34mm) or 14 gage (0.067”) (1.70mm) interior or exterior • Miters – welded Spec. for Commercial Laminated Hollow Metal Doors & Frames 1. Application – Commercial 2. Door construction: • Thickness: – Interior: 20 gage (0.032”) (0.81mm) – Exterior: 18 gage (0.042”) (1.06mm) • Core – varies • Edge – visible seam or welded 3. Frame construction: • Thickness – 16 gage (0.053") (1.34mm) interior or exterior • Miters – KD or welded Guide Spec Review 1. Application 2. Core 3. Beveled Edge Light traffic Commercial Steel stiffened Steel stiffened Visible seam or welded Welded Commercial Laminated & steel stiffened Visible seam or welded Spec. for Commercial Security Hollow Metal Doors & Frames • • For many years, hollow metal door and framing systems have been used as the primary and initial defense against forced entry. Architects, specifiers, and end users have come to understand the advantages of using hollow metal doors and frames in commercial security applications (airports, convention centers, hotels, offices) and in foreign and domestic government buildings (embassies, offices, barracks). Six Levels of Security Spec. for Detention Security Hollow Metal Doors & Frames To understand the advantages of hollow metal construction, consider first the hardware installation for the swinging door of a typical bar-grille cell front. The security hinges and lock encasement are actually accessible to the inmate since he is able to reach through the bars. Therefore, in many cases, the lock encasement must be continuously welded assemblies with cover plates welded in place to prevent inmate tampering. This situation makes repairs and maintenance both difficult and expensive. For example: to repair a lock, it is necessary to cut the cover plate loose with a torch, repair or replace the lock, then weld a new cover plate back in place. Spec. for Detention Security Hollow Metal Doors & Frames Spec. for Swinging Sound Control Hollow Metal Doors & Frames These specifications are comprehensive in regard to steel swinging sound control doors, door frames, sidelight, transom, and fixed window assemblies only. They do not cover sliding sound control doors or other related components. Due to the complexity of the field of acoustics, it is advisable to retain an acoustical consultant or acoustician. Spec. for Swinging Sound Control Hollow Metal Doors & Frames Spec. for Stainless Steel Hollow Metal Doors & Frames It is important to understand that stainless steel alloys and the finishes that are applied to them are independent of one another. For example, if a high degree of aesthetic appearance and high corrosive resistance are both required, then this can be accomplished by the application of a high aesthetic finish to a Type 316 stainless steel constructed door. A complete range of finishes, including #4-satin and #8-mirror, may be selected and applied to the stainless steel sheet. Alternatively, the stainless sheet may remain unfinished (i.e. #2B-mill finish). The mill finish sheet may be supplied “as is” or may be chemically treated to allow for factory applied prime paint, then field applied finish paint. Spec. for Stainless Steel Hollow Metal Doors & Frames • • • Highly Corrosive: Doors and frames are constructed using all Type 316 stainless steel internal parts and face sheets. This construction is for severely corrosive applications where corrosion resistance is the primary concern, such as in public swimming pools which are highly chlorinated. Moderately Corrosive: Doors and frames are constructed using all Type 304 stainless steel internal parts and face sheets. This construction is for moderately corrosive applications where corrosion resistance and aesthetic appearance are of equal concern. Aesthetic: Frame sections (hinge jambs, strike jambs, headers, etc.) and door face sheets are constructed using Type 304 stainless steel. All other parts for both frames and doors are permitted to be fabricated from coldrolled, hot-rolled pickled and oiled (HRPO), or A60 (ZF180) galvanneal as opposed to Type 304 stainless steel parts. This construction is for applications where aesthetic appearance is of primary concern. Defining Undercuts • Typically, frames are intended to be installed directly on the floor. When no floor coverings or thresholds are used, the dimension for “Undercut” is the same as for “Floor Clearance.” • Floor coverings, such as carpet and resilient or ceramic tile, are typically installed on top of the floor, fitted around the frame, and under the door. In this situation, the formula for figuring Undercut is the total of the Floor Clearance + Floor Covering Thickness. Defining Undercuts • • • In situations with specialized floors such as thick ceramic tile or terrazzo, the frame is typically installed prior to the installation of the floor. Both illustrate a raised frame condition in which the bottom of frame is positioned to be directly on top of the floor after the floor is installed. In this situation, the dimension measured for Undercut is also the same as Floor Clearance. Another method, called “below floor installation,” is to install the frame directly on the rough slab. After the frame is installed, the floor is then installed around the frame. Grouting Hollow Metal Frames The Hollow Metal Manual also provides helpful technotes which address special aspects of installation. • Field application – Protect frame – Can promote rusting • Why Grout? – Specified field application – Can improve frame performance • Use mortar grout – Plaster grout not recommended Continuously Welded Frames Definitions and Nomenclature • Frame Member • Frame Elements • Perimeter Joint Glazing Hollow Metal Transoms, Sidelights and Windows • Exterior Application • Air/Water Infiltration • Tested to Standards Painting Hollow Metal Products • • • • • • Proper storage Moisture build up Repair damaged primer Primer and top coat compatibility Avoid high gloss finish paints Follow manufacturers’ instructions Course Summary Now the Design Professional will be able to: • List the fire test requirements, processes and procedures for obtaining ratings on fire rated doors and frames. • Explain the hardware requirements and configurations for use in fire rated doors and frames. • Describe fire door classifications, listings, labels, and certifications. • Explain the various fire rated door and frame applications including requirements for glazing, transoms and other components. • Navigate the Hollow Metal Manual. • Describe hollow metals components and options. • Specify Hollow Metal and Steel Doors in accordance with guidelines published in the Hollow Metal Manual. © Ron Blank & Associates, Inc. 2011 Please note: you will need to complete the conclusion quiz online at ronblank.com to receive credit The Hollow Metal Manual: Progressive Solutions for Hollow Metal Doors and Frames An AIA Continuing Education Program Credit for this course is 1 AIA HSW CE Hour Building a Solid Future on the Foundation of Our Successful Past V HMM HOLLOW METAL MANUFACTURERS A S S O C I A T I O N Course: hmm08c 800 Roosevelt Rd. Bldg. C, Ste. 312 Glen Ellyn, IL 60137 630.942.6591 www.hollowmetal.org