Following the Flow - Measurement Standards Laboratory of New

advertisement

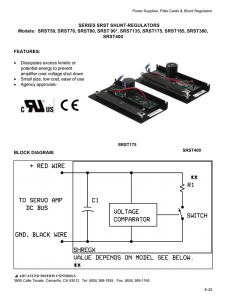

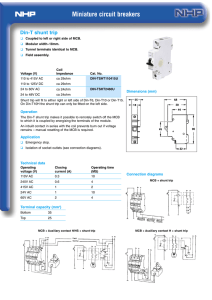

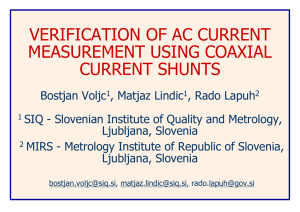

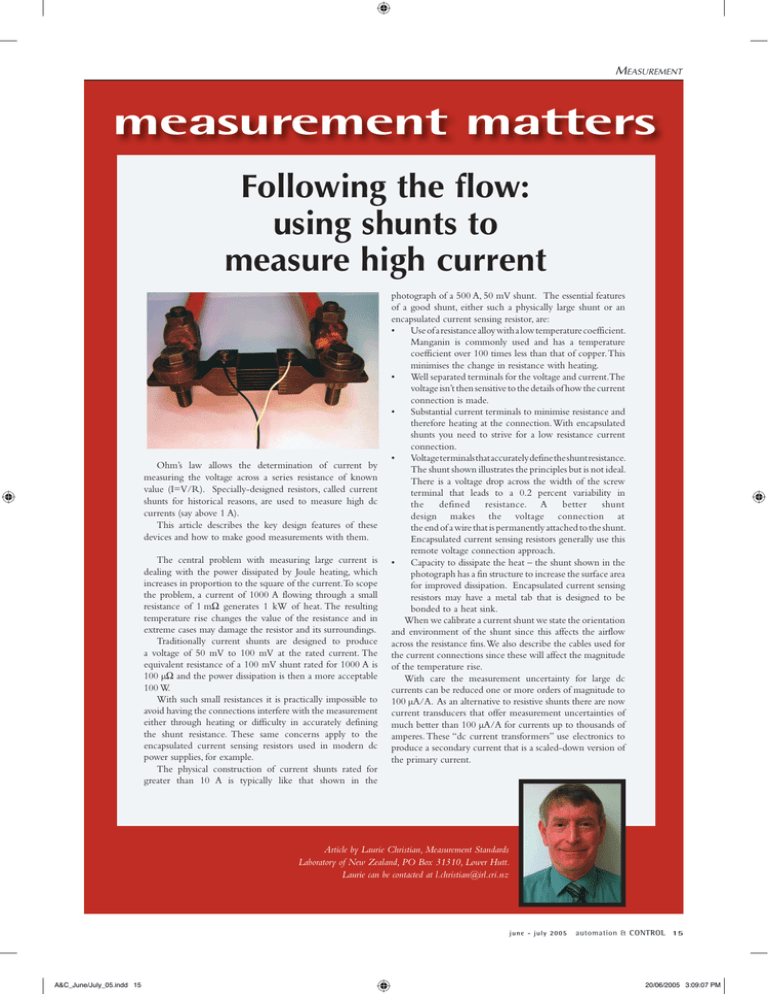

MEASUREMENT measurement matters Following the flow: using shunts to measure high current Ohm’s law allows the determination of current by measuring the voltage across a series resistance of known value (I=V/R). Specially-designed resistors, called current shunts for historical reasons, are used to measure high dc currents (say above 1 A). This article describes the key design features of these devices and how to make good measurements with them. The central problem with measuring large current is dealing with the power dissipated by Joule heating, which increases in proportion to the square of the current. To scope the problem, a current of 1000 A flowing through a small resistance of 1 mΩ generates 1 kW of heat. The resulting temperature rise changes the value of the resistance and in extreme cases may damage the resistor and its surroundings. Traditionally current shunts are designed to produce a voltage of 50 mV to 100 mV at the rated current. The equivalent resistance of a 100 mV shunt rated for 1000 A is 100 µΩ and the power dissipation is then a more acceptable 100 W. With such small resistances it is practically impossible to avoid having the connections interfere with the measurement either through heating or difficulty in accurately defining the shunt resistance. These same concerns apply to the encapsulated current sensing resistors used in modern dc power supplies, for example. The physical construction of current shunts rated for greater than 10 A is typically like that shown in the photograph of a 500 A, 50 mV shunt. The essential features of a good shunt, either such a physically large shunt or an encapsulated current sensing resistor, are: • Use of a resistance alloy with a low temperature coefficient. Manganin is commonly used and has a temperature coefficient over 100 times less than that of copper. This minimises the change in resistance with heating. • Well separated terminals for the voltage and current.The voltage isn’t then sensitive to the details of how the current connection is made. • Substantial current terminals to minimise resistance and therefore heating at the connection. With encapsulated shunts you need to strive for a low resistance current connection. • Voltage terminals that accurately define the shunt resistance. The shunt shown illustrates the principles but is not ideal. There is a voltage drop across the width of the screw terminal that leads to a 0.2 percent variability in the defined resistance. A better shunt design makes the voltage connection at the end of a wire that is permanently attached to the shunt. Encapsulated current sensing resistors generally use this remote voltage connection approach. • Capacity to dissipate the heat – the shunt shown in the photograph has a fin structure to increase the surface area for improved dissipation. Encapsulated current sensing resistors may have a metal tab that is designed to be bonded to a heat sink. When we calibrate a current shunt we state the orientation and environment of the shunt since this affects the airflow across the resistance fins. We also describe the cables used for the current connections since these will affect the magnitude of the temperature rise. With care the measurement uncertainty for large dc currents can be reduced one or more orders of magnitude to 100 µA/A. As an alternative to resistive shunts there are now current transducers that offer measurement uncertainties of much better than 100 µA/A for currents up to thousands of amperes. These “dc current transformers” use electronics to produce a secondary current that is a scaled-down version of the primary current. Article by Laurie Christian, Measurement Standards Laboratory of New Zealand, PO Box 31310, Lower Hutt. Laurie can be contacted at l.christian@irl.cri.nz j une - j ul y 2 0 0 5 A&C_June/July_05.indd 15 automation & CONTROL 15 20/06/2005 3:09:07 PM