Shrink method Horizontal shrink systems Cone cleaners Coolant

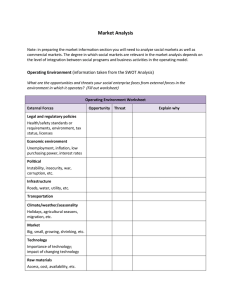

advertisement

GB_2013_Abt2-1.fm Seite 576 Montag, 10. März 2014 9:00 09 Shrink method Horizontal shrink systems Continued next page Cone cleaners Application: For cleaning tool holding fixtures on machine spindles, taper sockets or taper gauges. Design: •taper shank MT •taper shank ST •hollow taper shank HSK [ for taper and grinding face Clamping tools MT 1 010 O. R. Version Unit price Number Version Unit price SK No. 23500 23500 Number Ident. No. E MT 2 020 O. R. MT 3 030 O. R. MT 4 040 O. R. MT 5 050 O. R. 32/A-C 020 O. R. 40/A-C 030 O. R. 50/A-C 040 O. R. 23500 SK 50 Ident. No. 120 E O. R. SK 60 130 O. R. MT 6 060 O. R. SK 30 100 O. R. SK 40 110 O. R. 80/A-C 060 O. R. 100/A-C 070 O. R. 23780 i Tool holding fixtures selection overview page 519. 63/A-C 050 O. R. Prod. Gr. 206 Continued next page Coolant transfer pipes for HSK tool holding fixtures Hollow taper shank Dimension D1 Thread length l Overall length L1 Thread G HSK mm mm mm 23715 Ident. No. Unit price E A63 12 11,5 36,2 M18 x 1 050 A100 16 15,5 43,6 M24 x 1,5 070 O. R. O. R. i Tool holding fixtures selection overview page 519. L1 L g d1 Prod. Gr. 290 Continued next page Socket spanners for coolant transfer pipe 23716 HSK mm mm Ident. No. A63 16,5 122 050 A100 22,0 141 070 Unit price E O. R. (O. R.) Hollow taper shank Dimension D1 Overall length L1 i Tool holding fixtures selection overview page 519. L1 d1 Prod. Gr. 290 Continued next page Thermal tensioning of tools The worldwide trade mark ThermoGrip® stands for the following characteristics: •tools can be changed in a matter of seconds by induction or electrical heating with high energy density •ThermoGrip® shrink-fit chucks are made from special resistant steel; as the result of the special hardening and tempering process they have a particularly long life and high dimensional stability •reversible shrinking process, can be repeated as often as required. Even after more than 5000 shrinking processes, ThermoGrip® shrink-fit chucks retain concentricity, clamping force and elasticity •induction shrinking of HSS and carbide shanks is possible in ThermoGrip® chucks •shrinking process of max. 10 s when using the ISG 3200 induction shrinking equipment •only tool nose heated. By local heat induction with minimal heating of the chuck body, the cooling time is < 30 s Chuck in cooling adapter 576 Edition 5 GB_2013_Abt2-1.fm Seite 577 Montag, 10. März 2014 9:00 09 Shrink method Horizontal shrink systems Continued next page Induction micro shrinking devices MS 502 Model Power supply Voltage Capacity Width x Depth x Height Weight without coolant 23400 Unit price 23403 Air cooler Unit price V max. A kW mm Kg Ident. No. MS 502 220 16 3 220 x 520 x 350 15 021d E Ident. No. (O. R.) 021 E (O. R.) Clamping tools Application: For shrinking carbide steel shanks Chuck with standard geometry Ø 3-16 mm Chuck with slim geometry Ø 3-20 mm Design: Shrinking device: especially developed for slim, thin-walled and extremely short shrink-fit chucks. This version also allows to shrink in standard chucks with a diameter up to 16 mm. The variable generator output allows for gentle heating of the chuck. Even with very low-mass chucks the equipment switches off reliably and safely for the process before overheating can occur. Air cooler: docked onto the device MS 502. Once the tool has been shrunk to fit, the tool holding fixture is turned and pushed into the cooler. The patented way the flow of air is directed ensures the tool is cooled down quickly and effectively. Delivery: incl. 1 pair of protective gloves and 1 support plate. Prod. Gr. 226 Product video: use your mobile phone to scan the QR code. Continued next page Inductive shrinking devices HS 1100 Application: For shrinking HSS and carbide steel shanks in the Ø range from 3-32 mm and 6-32 mm (HSS). All shrinkfit chucks of all manufacturers up to a length of 420 mm can be shrunk. Design: Shrinking device: thanks to the modular design of the tool-positioning system, flexibility of the modification of HSK40 to HSK100 and of SK30/BT30 to SK50/BT50. The horizontal design of the device permits a simple positioning of the cutting tool. In addition, broken tools can be expelled with the help of the integrated push-off device. For precise adjustment of the length, the additional device for horizontal adjustment of the length can be set up at any time. Delivery scope: device with inductive coil, 5 exchange discs and protective gloves Model Power supply Voltage Capacity Width x Depth x Height Weight without coolant 23400 Unit price 23404 Unit price Length adjustment, measuring range 420 mm V max. A kW mm Kg Ident. No. HS 1100 400 16 11 450 x 600 x 357 36 022 E Ident. No. (O. R.) 020 E (O. R.) Prod. Gr. 226 Edition 5 577 GB_2013_Abt2-1.fm Seite 578 Montag, 10. März 2014 9:00 09 Shrink method Vertical shrink systems Continued next page Tool holding fixtures for HS1100 with length stop and ejector pin Application: for shrinking device MS 1100 Tool holding fixture 23401 Ident. No. E (O. R.) Unit price Clamping tools 23405 (O. R.) (O. R.) (O. R.) Shield rings/ferrite disc 100 Ø 14-20 E Ident. No. (O. R.) 110 Ø 25 E Ident. No. (O. R.) 125 Ø 32 E Ident. No. (O. R.) 132 E (O. R.) Unit price 23405 (O. R.) Ident. No. Unit price 23405 (O. R.) Ø 6-12 Unit price 23405 HSK 40 HSK 50 HSK 63 HSK 80 HSK100 SK/BT30 SK/BT40 SK/BT50 100 110 120 130 141 142 160 170 Unit price (O. R.) (O. R.) Prod. Gr. 226 Continued next page Tool holding fixtures with length stop and ejector pin Application: for shrinking device MS 502 Tool holding fixture 23401 Ident. No. Unit price E HSK 25 005 HSK 32 010 HSK 40 015 HSK 50 020 HSK 63 025 SK 30 060 (O. R.) (O. R.) (O. R.) (O. R.) (O. R.) (O. R.) SK 40 070 (O. R.) Prod. Gr. 226 Continued next page Induction shrinking devices ISG 2202 (without cooling) suitable for cooling station model FKS 03 No. 23403 Application: For shrinking carbide shanks Ø 3-20 mm and HSS steel shanks Ø 6-20 mm Design: In connection with the above-mentioned cooling station model FKS 03, one can shrink, cool and clean in seconds. For quick cooling and cleaning the shrink-fit chuck, the liquid cooler FKS 03 No. 23403 is used. Advantages: Safe screening of the magnetic field and optimum efficiency by means of patented ferrite disc, shrinking period 4 seconds, cooling time 30 seconds in liquid cooler FKS 03 possible Delivery: Device complete with inductive coil, three replacement discs and one tool holding fixture, fitting HSK 63, HSK 80 and HSK 100 Colour: RAL 9002, grey white Model Power supply Voltage Capacity Width x Depth x Height Weight without coolant 23400 V max. A kW mm Kg Ident. No. Unit price E Tool holding fixture to adapt the steep taper holders see No. 23403, page 580. ISG 2202 400 16 7,5 310 x 390 x 640 25 035 (O. R.) Prod. Gr. 226 Product video: use your mobile phone to scan the QR code. 578 Edition 5 GB_2013_Abt2-1.fm Seite 579 Montag, 10. März 2014 9:00 09 Shrink method Vertical shrink systems Continued next page Induction shrinking devices ISG 3400 TWK Model Power supply Voltage Capacity Width x Depth x Height Weight without coolant 23400 V max. A kW mm Kg Ident. No. Unit price E d = Delivered ex works, postage and packaging excluded. ISG 3400 TWK 3 x 400 16 11 800 x 580 x 960 60 070d (O. R.) Clamping tools tabletop unit with integrated water cooling Application: For shrinking carbide shanks Ø 3-32 mm and HSS steel shanks Ø 6-32 mm. All shrink-fit chucks from all manufacturers can be shrunk up to a length of 450 mm and cooled up to a length of 350 mm. Design: In the case of manual shrinking, the tool diameter is selected on the display and a suitable interchangeable disc is put in the coil. The tool is inserted in the tool holder and then the coil is inserted manually in the tool holder. After pressing the start button, the tool holder is heated by the induction coil, the shrinking process is shown on the display and it continues for maximum 5 sec. The next work cycle is shown on the display, the coil is moved upwards and the cooling device with bellows is moved manually in the cooling position. After activation of the start button for the cooling process, the duration of the cooling is shown on the display in the form of a bar chart. At the end, the cooling device returns to its initial position. Advantages: Safe screening of the magnetic field and optimum efficiency with patented ferrite discs. Shrinking < 5 seconds, cooling < 30 seconds in one system. Contour-independent cooling. Manual setting makes it possible to adjust the tool parameters customer-specifically and then save them in tool memory. Shrink-fit chucks to ensure no overheating. Dialog-control with simple menu navigation on a graphical display, adjustable cooling processes, corrosion protection of the shrink-fit chuck by the use of cooling emulsion, the largest shrinking length up to 450 mm, maximum cooling length 350 mm, easy putting into operation. Service-friendly electronic modules that can be easily changed by the user. Delivery: Inductive shrinking device with coil, 1 pair of Kevlar gloves, 2 litres of concentrate for cooling emulsion, 4 ferrite discs for Ø 3-32, work plate with trays for ferrite discs Colour: RAL 7047, telegrey 4 Product video: use your mobile phone to scan the QR code. Prod. Gr. 226 Continued next page Induction shrinking devices ISG 3400 WK / WK-WS with integrated water cooling Application: For shrinking carbide shanks Ø 3-32 mm and HSS steel shanks Ø 6-32 mm Design: With the fully automatic, controlled ISG 3400 WK, the user only needs to select the tool diameter from the display and insert the replaceable disc into the coil. As soon as the start button is actuated, the induction coil travels across the tool holding fixtures, heats it up and returns to the top as soon as the shrinking process has been completed. Parallel to this, the shrink-fit chuck travels down to the cooling tank and returns to its original position after approx. 20 s cooled, dried and preserved. Safe screening of the magnetic field and optimum efficiency by means of patented ferrite disc. Shrinking < 4 seconds and cooling < 25 seconds in one work step. No contact with the hot shrink-fit chuck. Contourindependent cooling and no damage of the tool cutting edge by the cooling adapter. Use of stored parameters to protect the shrink-fit chucks from overheating. Parameters adjustable for special geometric dimensions. Dialog control with user-friendly menu guidance in graphic display. Adjustable dwell period before the cooling process. With special coil shrinking up to Ø 50 mm possible. Maximum shrinking length up to 450 mm, maximum cooling length 400 mm, simple commissioning. Service-friendly electronic modules which can be conveniently replaced by the user. Insensitive and easycare stainless steel worktop. Do not touch the hot shrink-fit chuck. Delivery: Inductive shrinking device with coil and 4 replacement discs, support plate for tool holder, replacement discs and milling cutter. 2 litres of liquid concentrate and protective gloves. Colour: RAL 7047, telegrey 4 Model Power supply Voltage Capacity Width x Depth x Height Weight without coolant Compressed air Coolant tank Max. shrinking Ø Weight 23400 V max. A kW mm Kg bar L mm Kg Ident. No. Unit price E ISG 3400 WK 3 x 400 16 10 700 x 620 x 1700 30 4 30 32 4 080d ISG 3400 WK-WS* 3 x 400 16 10 701 x 620 x 1700 30 4 30 32 (50*) 4 090d (O. R.) (O. R.) * Only the shrinking device ISG 3400 WK-WS is equipped with change coil technology. h Other accessories on request. d = Delivered ex works, postage and packaging excluded. Edition 5 Prod. Gr. 226 579 GB_2013_Abt2-1.fm Seite 580 Montag, 10. März 2014 9:00 09 Shrink method Shrink accessories Continued next page Tool holders Application: for shrinking device ISG 3400 TWK and ISG 3400 WK and WK-WS Tool holding fixture 23401 Ident. No. SK 40 140 SK 50 150 HSK 32 332 HSK 40 340 HSK 50 350 HSK 63 363 Unit price E (O. R.) (O. R.) (O. R.) (O. R.) (O. R.) (O. R.) HSK 100 390 (O. R.) Prod. Gr. 226 Clamping tools Continued next page Pressure fixtures for broken tools Application: With this pressure fixture, broken shafts of a miller can be removed even if the broken point is in the drill area. Also tool shanks where the tolerance on fit is over the tolerance limit can be cut off. For this, place the device on the ISG and during the warm-up with the eccentric turning handle, impress through the press pin set before to the correct height. Delivery: Basic holder with union nut, hexagon key and adjustable press pin Tool holding fixture 23416 Ident. No. Unit price E HSK 32 032 HSK 40 040 HSK 50 050 HSK 63 063 HSK 100 100 SK 40 140 (O. R.) (O. R.) (O. R.) (O. R.) (O. R.) (O. R.) SK 50 150 (O. R.) Prod. Gr. 226 Continued next page Length adjustment sets Application: Adjustment sleeve for the safe and quick clamping of the tool to be shrunk. Via the scale the tool is adjusted to the desired long unclamping length and fixed by means of a stud. After heating the shrink adapter the tool is placed into the older until the sleeve sits at the holder. Advantages: •quick and safe length adjustment during shrinking •various sleeve sizes, thus intermediate sizes can also be adjusted •complicated handling of measuring equipment is no longer necessary •six sleeves (Ø 6-20 mm) in the holder block Scope of delivery: 6 length adjustment sleeves, older block, hex. key 23401 Ident. No. 080 Set price E O. R. Adjusting the shrinking depth Ready for shrinking Prod. Gr. 295 Continued next page Tool holders Application: as adapter for shrinking systems ISG 2202 and for liquid cooler FKS 03 46 65 85 1,6 Ø114,5 20 Ident. No. 112 Tool holding fixture 23403 Ident. No. Unit price E ST 30/40 111 SK 50 112 HSK-A 25/32 120 HSK-A 40/50 121 (O. R.) (O. R.) (O. R.) (O. R.) For HSK 63/80/100 is no tool adapter required. 580 Ø35 Ident. No. 120 137 125 Ident. No. 111 Ø35 Ident. No. 121 Prod. Gr. 226 Edition 5