M2-D

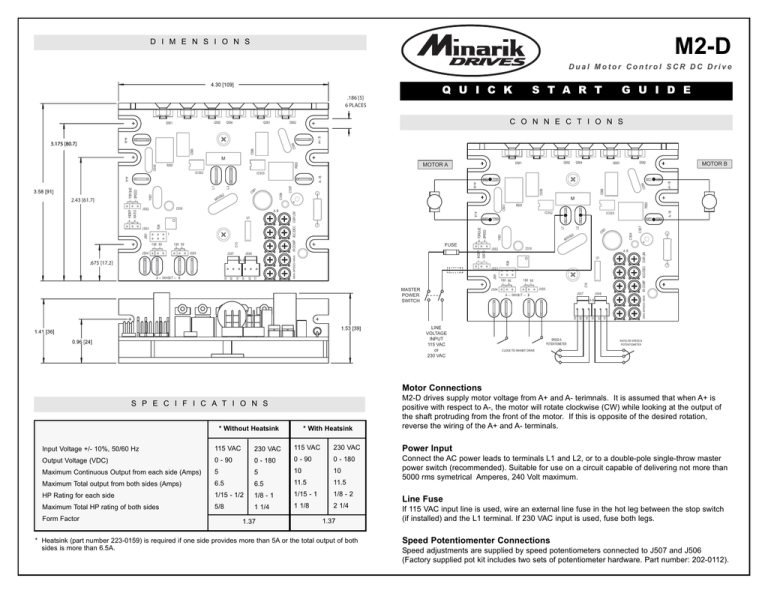

D I M E N S I O N S

Dual Motor Control SCR DC Drive

Q U I C K

S T A R T

G U I D E

.186 [5]

6 PLACES

Q504

C505

C506

C504

A+/A

IC502

S3 S2

S1 S3

S2 S1

C504

C506

C505

C507

R503

C510

J502

A- / B

AB

U1

J503

MASTER

POWER

SWITCH

1

180 90

180 90

J505

J504

J507

A -- INHIBIT -- B

J506

C507

C508

L1

L2

C503

Y501

SPEED

TORQUE

FUSE

01

C5

502

V

MO

IR COMP ACC/DEC CUR LIM

A -- INHIBIT -- B

IC503

MIN-SPEED-MAX

.675 [17.2]

IC502

C15

A-B

R501

R38

J506

J501

J507

INDEP.

J505

A+ / B

A- / B

180 90

J504

IR COMP ACC/DEC CUR LIM

180 90

C15

J501

1

M

MIN-SPEED-MAX

C508

L2

L1

Y501

AB

R38

TORQUE

SPEED

RATIO

C510

A-/A

INDEP.

01

U1

J503

MOTOR B

D502

Q503

A+/A

C5

2

V50

MO

J502

Q504

IC503

A-/A

2.43 [61.7]

Q502

D501

MOTOR A

R503

C503

M

R501

RATIO

3.175 [80.7]

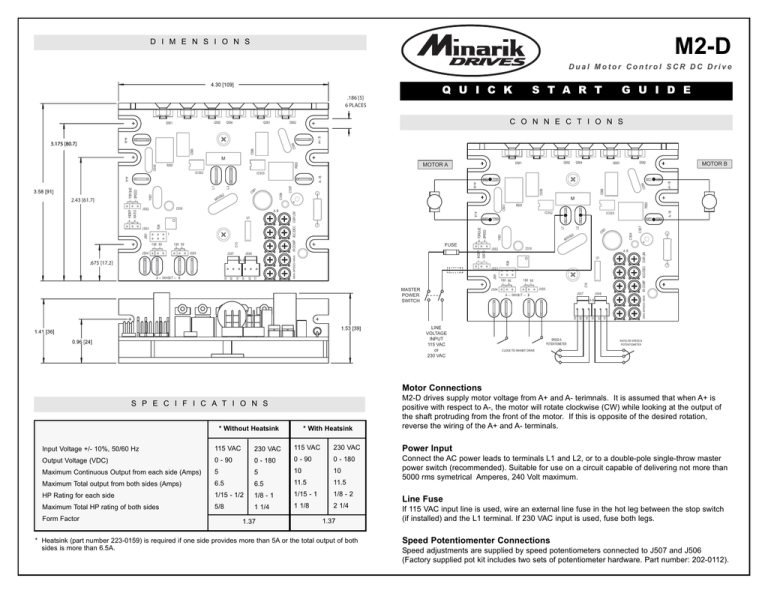

C O N N E C T I O N S

D502

Q503

A+ / B

Q502

D501

A-B

S3 S2

LINE

VOLTAGE

INPUT

115 VAC

or

230 VAC

SPEED A

POTENTIOMETER

S1 S3

S2 S1

RATIO OR SPEED B

POTENTIOMETER

CLOSE TO INHIBIT DRIVE

Motor Connections

S P E C I F I C A T I O N S

* With Heatsink

* Without Heatsink

M2-D drives supply motor voltage from A+ and A- terimnals. It is assumed that when A+ is

positive with respect to A-, the motor will rotate clockwise (CW) while looking at the output of

the shaft protruding from the front of the motor. If this is opposite of the desired rotation,

reverse the wiring of the A+ and A- terminals.

Input Voltage +/- 10%, 50/60 Hz

115 VAC

230 VAC

115 VAC

230 VAC

Power Input

Output Voltage (VDC)

0 - 90

0 - 180

0 - 90

0 - 180

Maximum Continuous Output from each side (Amps)

5

5

10

10

Maximum Total output from both sides (Amps)

6.5

6.5

11.5

11.5

Connect the AC power leads to terminals L1 and L2, or to a double-pole single-throw master

power switch (recommended). Suitable for use on a circuit capable of delivering not more than

5000 rms symetrical Amperes, 240 Volt maximum.

HP Rating for each side

1/15 - 1/2

1/8 - 1

1/15 - 1

1/8 - 2

Maximum Total HP rating of both sides

5/8

1 1/4

1 1/8

2 1/4

Form Factor

1.37

1.37

* Heatsink (part number 223-0159) is required if one side provides more than 5A or the total output of both

sides is more than 6.5A.

Line Fuse

If 115 VAC input line is used, wire an external line fuse in the hot leg between the stop switch

(if installed) and the L1 terminal. If 230 VAC input is used, fuse both legs.

Speed Potentiomenter Connections

Speed adjustments are supplied by speed potentiometers connected to J507 and J506

(Factory supplied pot kit includes two sets of potentiometer hardware. Part number: 202-0112).

C A L I B R A T I O N

/

O P E R A T I O N

Rotation: CW = Clockwise CCW = Counterclockwise

M2-D POTENTIOMETER CONNECTIONS

PINS

1

INDEP.

TORQUE

180

180

RATIO

SPEED

90

90

U1

1. Turn the SPEED POTENTIOMETER A (B) to full CCW. Use MIN SPEED A (B) trimmer potentiometer

to adjust minimum speed for motor A (B).

2. Turn the SPEED POTENTIOMETER A (B) to full CW. Use MAX SPEED A (B) trimmer potentiometer to

adjust maximum speed for motor A (B). Repeat steps 1 and 2 a few times due to a level of interaction

between MIN SPEED and MAX SPEED pots.

3. Set the CUR LIM A (B) to full CCW. Turn the SPEED POTENTIOMETER A (B) to full CW. Stall the

motor shaft and turn the CUR LIM A (B) CW until the desired current limit is reached.

4. Set the IR COMP A (B) to full CCW. Set the motor speed at approximately half of the rated speed. Load

motor to its full load. Keep turning the IR COMP CW until the speed equals the no load speed.

5. Use ACC/DEC A (B) trimmer potentiometer to adjust acceleration (deceleration) ramp time.

RATIO MODE (Jumper on pins 2 & 3 of J503)

In RATIO MODE, SPEED POT A is used to adjust the speed of both motors, while SPEED POT B sets the ratio

between speeds. Turning the SPEED POT B CW will increase speed of motor B thus increasing the ratio

speed B/speed A. MIN SPEED B and MAX SPEED B are now used to adjust minimum and maximum ratio.

INHIBIT

Short inhibit terminals A(B) to bring motor A(B) to a stop. Inhibit A(B) is independant of inhibit B(A). The inhibit A

and inhibit B can be paralleled together.

J501

J501 is used by the factory to program the M2-D drive. Do NOT add any jumpers to J501.

TORQUE MODE (Jumper on pins 1 & 2 of J502 and pins 1 & 2 on J503)

TORQUE MODE regulates motor current (torque). In TORQUE MODE, the external potentiometer A (B) sets the

torque reference for Motor A (B) and the CUR LIM trimmer potentiometer A (B) sets the speed limit for Motor A

(B). The MIN SPEED A (B) and MAX SPEED A (B) are used to adjust the minimum and maximum torque

available.

C15

INDEPENDENT MODE (Jumper on pins 1 & 2 of J503)

There are two sets of potentiometers independently used to adjust each motor operation. Each set consists of

five on board trimmer potentiometers and one external potentiometer (commonly called SPEED POT). To

calibrate one side (A or B), use the following procedure for speed mode:

J507

J506

A-B

S3 S2

S1 S3

S2 S1

A- / B

C507

IR COMP ACC/DEC CUR LIM

AB

MOTOR VOLTAGE SELECTION

Use J504 to match the motor voltage rating for motor A and J505 for motor B. ( Jumper on pins 1 & 2 for 180

VDC, 2 & 3 for 90 VDC.

MIN-SPEED-MAX

J504

J505

J502

J503

01

C5

C508

3

R503

2

TRIMMER POTS

FOR MOTOR B

SPEED A

POTENTIOMETER

CW

TRIMMER POTS

FOR MOTOR A

RATIO SPEED B

POTENTIOMETER

CW

M I N A R I K D R I V E S

w w w . m i n a r i k d r i v e s . c o m

14300 De La Tour Drive, South Beloit, IL 61080;

Phone: (800) MINARIK (646-2745); Fax: (815) 624-6960

Document Number: 250-0402, Revision 1; Printed in the U.S.A. - May 2006

Copyright 2006 by Minarik Corporation - All rights reserved. No part of this document may be reproduced or transmitted in any form without

written permission from Minarik Corporation. The information and technical data in this document are subject to change without notice.

Minarik Corporation and its Divisions make no warranty of any kind with respect to this material, including, but not limited to, the implied

warranties of its merchantability and fitness for a given purpose. Minarik Corproation and its Divisions assume no responsibility for any

errors that may appear in this document and make no commitment to update or to keep current the information in this document.

mvd101403