Instruction Bulletin

Bulletin 6055-16

June 1999

Smyrna, TN, USA

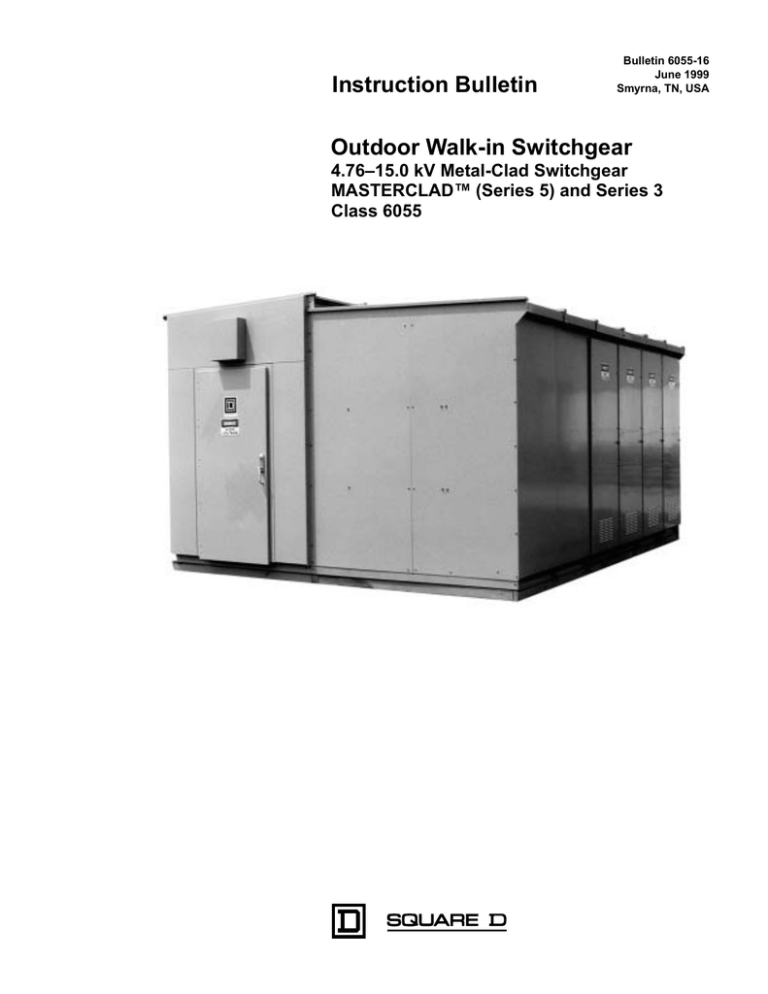

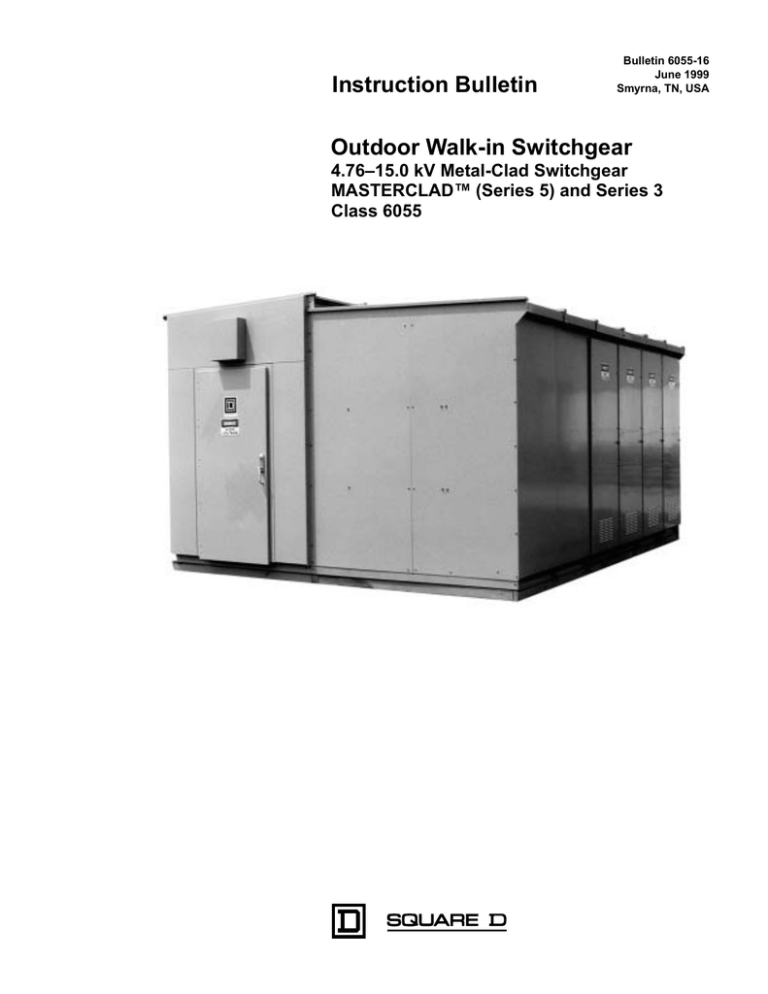

Outdoor Walk-in Switchgear

4.76–15.0 kV Metal-Clad Switchgear

MASTERCLAD™ (Series 5) and Series 3

Class 6055

Bulletin No. 6055-16

June 1999

CONTENTS

© 1992 Square D All Rights Reserved

Outdoor Walk-in Switchgear

Contents

SECTION 1—INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SECTION 2—SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION 3—RECEIVING, HANDLING, AND STORAGE . . . . . . . . . . . . . 3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Foundation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Single Aisle Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical Common Aisle Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 4—INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Single Aisle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Common Aisle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Common Aisle Assembly Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SECTION 5—ELECTRICAL HOOK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 6—INSPECTION AND MAINTENANCE . . . . . . . . . . . . . . . . . 19

SECTION 7—STANDARD COMPONENTS AND PARTS . . . . . . . . . . . . 20

SECTION 8—OUTLINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 9—INSTALLATION AND MAINTENANCE LOG . . . . . . . . . . . 22

iii

Outdoor Walk-in Switchgear

Figures and Tables

Bulletin No. 6055-16

June 1999

FIGURES

Figure 1:

Figure 2:

Figure 3:

Figure 4:

Figure 5:

Figure 6:

Figure 7:

Figure 8:

Figure 9:

Figure 10:

Figure 11:

Figure 12:

Figure 13:

Figure 14:

Figure 15:

Figure 16:

Figure 17:

Figure 18:

Figure 19:

Figure 20:

Figure 21:

Figure 22:

Figure 23:

Figure 24:

Figure 25:

Figure 26:

Figure 27:

Figure 28:

Figure 29:

Figure 30:

Figure 31:

Outdoor Walk-in Switchgear . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lifting Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Single Aisle Foundation . . . . . . . . . . . . . . . . . . . . . . 5

Typical Common Aisle Foundation . . . . . . . . . . . . . . . . . . . . 6

Preparing to Unload Shipping Sections . . . . . . . . . . . . . . . . 7

Unloading a Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing Shipping Covers . . . . . . . . . . . . . . . . . . . . . . . . . 8

Placing First Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unloading Second Section . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Securing Switchgear Sections. . . . . . . . . . . . . . . . . . . . . . . . 9

Securing Equipment Space to Switchgear . . . . . . . . . . . . . . 9

Braced Front Aisle Section . . . . . . . . . . . . . . . . . . . . . . . . . 10

Aligning Aisle With Switchgear Section . . . . . . . . . . . . . . . 10

Attaching Aisle Roof Support Bracket to Switchgear . . . . . 11

Moving Sections With Braces in Place . . . . . . . . . . . . . . . . 11

Placing Second Aisle Section . . . . . . . . . . . . . . . . . . . . . . . 12

Switchgear With All Sections in Place . . . . . . . . . . . . . . . . 12

Attaching Second Aisle Section to First Aisle Section . . . . 13

Aisle and Switchgear Base Connection . . . . . . . . . . . . . . . 13

Roof Cap Mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Checking Enclosure for Openings in Seal . . . . . . . . . . . . . 14

Removing Large Lifting Lugs . . . . . . . . . . . . . . . . . . . . . . . 15

Removing Small Lifting Lugs . . . . . . . . . . . . . . . . . . . . . . . 15

Plugging Holes With Bolts/Sealwashers. . . . . . . . . . . . . . . 15

Outdoor Walk-in Switchgear with Common Aisle . . . . . . . . 16

Common Aisle Configuration . . . . . . . . . . . . . . . . . . . . . . . 17

Lights, Receptacle, and Fan . . . . . . . . . . . . . . . . . . . . . . . . 18

Heater/Thermostat (Optional) . . . . . . . . . . . . . . . . . . . . . . . 18

Panelboard (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Outline of Single Aisle Walk-in . . . . . . . . . . . . . . . . . . . . . . 21

Outline of Common Aisle Walk-in . . . . . . . . . . . . . . . . . . . . 21

TABLES

Table 1:

Replacement Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

iv

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

SECTION 1—INTRODUCTION

Outdoor Walk-in Switchgear

Section 1—Introduction

This bulletin contains instructions for receiving, handling, storage, and

installation (including foundation preparation) for outdoor, walk-in switchgear.

The walk-in enclosure detailed in this bulletin is built around the standard

Metal-Clad Indoor Switchgear.

NOTE: For more information on Square D Indoor Metal-Clad Switchgear

(Series 5), refer to instruction bulletin 6055-30.

The outdoor walk-in switchgear assembly is a combination of switchgear and

aisle space subassembly components that are attached during installation.

The switchgear components are always shipped fully assembled. The aisle

spaces for the single aisle configuration are shipped as fully assembled

components, while the aisle space for the common aisle needs to be

assembled during installation. Installation instructions for both aisle types are

included in this bulletin.

Read these instructions and inspect the equipment carefully. Become

familiar with the device before trying to install, operate, or maintain it.

Figure 1:

© 1992 Square D All Rights Reserved

Outdoor Walk-in Switchgear

1

Outdoor Walk-in Switchgear

Section 2—Safety Precautions

Bulletin No. 6055-16

June 1999

SECTION 2—SAFETY PRECAUTIONS

DANGER

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

• Only qualified electrical personnel familiar with medium voltage

circuits are to perform work described in this set of instructions.

Workers must understand the hazards involved in working with or

near medium voltage equipment.

• Perform such work only after reading and understanding all of the

instructions contained in this bulletin.

• Before performing visual inspections, tests, or maintenance on this

device, disconnect all sources of electric power. Assume all circuits

are live until they are completely de-energized, tested, grounded,

and tagged. Pay particular attention to the design of the power

system. Consider all sources of power, including the possibility of

backfeeding.

• Always use a properly rated voltage sensing device to confirm that

power is off.

• Replace all devices, doors, and covers before turning on the power

to this equipment.

• Handle this equipment carefully and install, operate and maintain it

correctly in order for it to function properly. Neglecting fundamental

installation and maintenance requirements may lead to personal

injury, as well as damage to electrical equipment or other property.

• Be aware of potential hazards, wear personal protective equipment,

and take adequate safety precautions.

• Do not make any modifications to the equipment or operate the

system with interlocks removed. Contact your local Square D

representative for additional instructions if the equipment does not

function as described in this manual.

• Carefully inspect your work area and remove any tools and objects

left inside the equipment.

• All instructions in this manual are written with the assumption that

the customer has taken these measures before performing

maintenance or testing.

• Avoid exposing internal components of the switchgear to outdoor

conditions.

Failure to follow these instructions will result in death or serious

injury.

2

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 3—Receiving, Handling, and Storage

SECTION 3—RECEIVING, HANDLING,

AND STORAGE

Receiving

Upon receipt, check the packing list against the equipment received to

ensure the order and shipment are complete. Claims for shortages or errors

must be made in writing to Square D within 15 days after delivery. Failure to

give such notice will constitute unqualified acceptance and a waiver of all

such claims by the purchaser.

Immediately inspect the switchgear sections for any damage which may have

occurred in transit. If damage is found or suspected, file a claim with the

carrier immediately and notify Square D. Delivery of equipment to a carrier at

any of the Square D plants or other shipping point constitutes delivery to the

purchaser regardless of freight payment and title. All risk of loss or damage

pass to the purchaser at that time.

Handling

The shipping sections are designed to be lifted by a crane. Attach

a sling to the lifting lugs on the roof of each of the shipping sections as

shown in Figure 2. A spreader bar may be necessary to maintain proper

lifting angles. If a crane is not available, contact Square D for special

arrangements for unloading the switchgear sections.

CAUTION

IMPROPER LIFTING OF EQUIPMENT CAN DAMAGE LIFTING EYES

The interior angle of lifting sling should not exceed 90°. Angles greater

than 90° apply greater inward pressure on lifting eyes which can damage

and dislodge eyes from switchgear.

Failure to follow this instruction can result in injury or equipment

damage.

Sling

90° Maximum

90° Maximum

Figure 2:

© 1992 Square D All Rights Reserved

Lifting Method

3

Outdoor Walk-in Switchgear

Section 3—Receiving, Handling, and Storage

Storage

Bulletin No. 6055-16

June 1999

The timing of the shipment should be coordinated so that the foundation is

completed before delivery so that the switchgear and aisle sections can be

lifted from the truck to their permanent positions. If this is not possible and

you must store this equipment, follow the following guidelines. The

switchgear and front aisle shipping sections are packaged for protection

during shipment. This packaging is not suitable for outdoor storage. If

the switchgear must be stored, store it indoors or under a shelter protected

from rain, snow, dirt, and dust, until final assembly is completed.

Unsatisfactory storage conditions can cause damage to the bussing and

sensitive electrical and/or electronic components. Inspect the gear regularly

during storage for signs of damage. When storing, consider the following:

• Supporting Foundation

To prevent distortion, the storage foundation must be level and flat. If the

base is made of a material other than concrete, elevate the gear above

ground level to minimize the effects of ground moisture. If pier mounting

is required contact Square D’s After Shipment Customer Service Group.

• Ventilation

If extended storage is required, switchgear vents must be unobstructed

for free air circulation.

• Heat

If extended storage is required and the storage building is not heated,

heat switchgear sections. To do so, connect the internal space heaters

(see wiring diagrams) or place heaters in the front and rear of the

switchgear.

Foundation Requirements

4

The standard walk-in enclosure is designed for installation on a concrete pad.

Refer to the factory order drawings for any additional mounting details which

may be required on specific orders. The pad must be flat and leveled to 1/8

in. per square yard to ensure proper alignment and to prevent distortion of

the gear.

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 3—Receiving, Handling, and Storage

Figure 3 and Figure 4 on page 6 illustrate typical floor plans. Refer to the

applicable drawings before using the typical foundation specifications.

Conduit Location

Conduits should be stubbed a maximum of one inch above floor steel.

Conduit placement should be very accurate to ensure no mechanical

interference with the switchgear floor steel.

Avoid continuous loops of reinforcing rod or structural steel around any single

conductor three-phase power circuit.

8.0

5.0

8.0 6.0

20.0

203

36.0

203 152

508

Rear

Aisle 48.0

Space 1219

6.0

914

152

5.0

127

2.5

127

64

9.0

229

7.8

198

12.0 20.0

305

508

15.0

9.0 9.0

381

30.0

762

3.0

3.0

5.0

76

127

9.0

13.5

229

343

229

343

1.9

48

Control

Power

381

Switchgear 92.5

2348

Conduit

Area

Conduit

Location

Conduit

Area

7.8

15.0

Conduit

Location

13.5

76

198

229

1.9

48

Control

Power

10.0 8.0 8.0 10.0

254 203 203

254

8.0

8.0

169.1

203

203

4293

36.0 Meter Bay

2.5

2.5

63

63

Aisle

24.0

18.0

457

64

279

36.0

48.0

22.0

Switchgear Bay

Meter Bay

Transition Bay

559

1219

914

1942

2.5

11.0

607

76.5

Location of

Anchor Bolts

by Customer

(min. 3/4 in. diameter

hardware suggested)

Dual measurements

Figure 3:

© 1992 Square D All Rights Reserved

inches

millimeters

Typical Single Aisle Floor Plan

(Not for construction.)

5

Outdoor Walk-in Switchgear

Section 3—Receiving, Handling, and Storage

Bulletin No. 6055-16

June 1999

8.0

8.0 6.0

20.0

203

5.0

36.0

203 152

508

Rear

Aisle 48.0

Space 1219

6.0

914

152

127

5.0

2.5

127

64

9.0

229

7.8

198

12.0 20.0

305

508

9.0 9.0

15.0

381

30.0

762

3.0

3.0

5.0

76

127

9.0

13.5

229

343

229 229

343

1.9 Control

48

Power

Switchgear 92.6

2350

Conduit

Area

Conduit

Location

Conduit

Area

7.8

381

Conduit

Location

13.5

76

198

15.0

1.9 Control

48

Power

10.0 8.0 8.0 10.0

254 203 203

254

8.0

8.0

203

203

36.0 Meter Bay

2.5

2.5

63

63

262.2

6656

Aisle

77.0

1955

Switchgear 92.6

2350

18.0

24.0

457

Dual measurements

inches

millimeters

64

279

36.0

48.0

22.0

Switchgear Bay

Meter Bay

Transition Bay

1219

914

Figure 4:

6

2.5

11.0

607

559

Location of Anchor

Bolts by Customer

(min. 3/4 in. diameter

hardware suggested)

Typical Common Aisle Floor Plan

(Not for construction.)

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 4—Installation

SECTION 4—INSTALLATION

Standard Components and Parts

The following components and parts are shipped standard with each unit:

• Caulk to be used only to seal cracks found after final installation

• 1/2 in. (13 mm) gasket for repair if the unit gasket is damaged during

shipment

• One set per shipping section of four 1/2–13 bolts and seal washers for

replacing bolts which held the lifting lugs on the roof

NOTE: See instruction bulletin 6055-30 for components shipped with the

indoor switchgear.

Single Aisle Installation

Follow instructions below for single aisle installation of outdoor walk-in

switchgear. For common aisle installation see “Common Aisle” on page 16.

1. Verify that the conduit placement on the foundation is accurate according

to customer drawings. Error in conduit placement may prohibit the proper

installation of switchgear as described in this section (see NOTE of

Step 4 below).

Figure 5:

Preparing to Unload Shipping Sections

2. Unload the switchgear shipping sections from the delivery truck.

The shipping sections are designed to be lifted by a crane. Attach a

sling to the lifting lugs on the roof of each of the shipping sections as

shown in Figure 2. A spreader bar may be necessary to maintain proper

lifting angles. If a crane is not available, contact Square D for special

arrangements for unloading the switchgear sections.

CAUTION

IMPROPER LIFTING OF EQUIPMENT CAN DAMAGE LIFTING EYES

The interior included angle of lifting sling should not exceed 90°. Angles

greater than 90° apply greater inward pressure on lifting eyes which can

damage and dislodge eyes from switchgear.

Failure to follow this instruction can result in injury or equipment

damage.

© 1992 Square D All Rights Reserved

7

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

Bulletin No. 6055-16

June 1999

3. Remove the shipping covers. Be careful not to damage the

instrumentation on the front doors when removing shipping covers.

Figure 6:

Unloading a Section

Figure 7:

Removing Shipping

Covers

NOTE: Covering for the shipment may vary from the wooden panels

shown in Figure 6.

4. Install the end switchgear shipping section (see Figure 8). Carefully align

the openings on the bottom of the switchgear sections with conduits on

the foundation before lowering the switchgear into place.

NOTE: When more than two shipping sections are involved, any error in

conduit location can cause a cumulative error significant enough to

prohibit the proper installation by the assembly sequence described in

this section. To lessen cumulative error, unload and install the center

shipping section first and work toward either end.

Figure 8:

8

Placing First Section

Figure 9:

Unloading Second Section

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

5. Level the switchgear shipping section using steel shims if necessary.

6. Verify that the factory-installed gasket attached to one side of the

shipping section is in place before installing the subsequent shipping

sections. If damaged or missing, repair it using the gasket material

provided. Make sure there is no gap between splices if repairs are made.

7. Using a crane, install the second switchgear shipping section (see

Figure 9 on page 8).

8. Level the switchgear shipping section using steel shims if necessary.

9. Verify that the switchgear sections are level, aligned, and fit snugly

together. If the sections do not fit properly, lift the most recently placed

section by crane, remove any obstructions, and re-install.

Figure 10:

Securing Switchgear Sections.

10. Secure the second section to the previously installed section with the

3/8-16 x 1.0 carriage bolts located on the front of the switchgear, rear of

the switchgear, and across the roof of the switchgear (see Figure 10).

11. Install the equipment space sections (as shown at right in Figure 11).

Equipment space sections are designed similar to switchgear units and

can be unloaded and installed in the same manner.

Figure 11:

© 1992 Square D All Rights Reserved

Securing Equipment Space to Switchgear

9

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

Bulletin No. 6055-16

June 1999

12. After the switchgear and equipment space sections have been installed,

verify that all of the sections are aligned accurately, and that the bases

and roof lines are level. Use a water level and a straight-edge to do so.

13. The floor of the front aisle will be level only if the switchgear is level.

14. Secure the equipment space sections to the adjoining switchgear

shipping section with the bolts located on the front of the switchgear, rear

of the switchgear, and across the roof of the switchgear.

15. Using a crane, install the first aisle section.

16. The front aisle is shipped in sections of up to four bay sections. The

sections are braced with temporary shipping sheet metal angles, bars,

and channels (see Figure 12).

NOTE: Do not remove any of these braces until the shipping section is in

place and bolted to the switchgear section.

Figure 12:

Braced Front Aisle Section

17. Verify that the vertical sections, the base, and the roof are aligned with

the switchgear shipping sections. Use steel shims if necessary. It is

important that the bolt holes on the aisle roof support brackets align with

the corresponding holes on the front of switchgear sections.

Figure 13:

10

Aligning Aisle with Switchgear Section

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

18. Attach the aisle section to the switchgear by bolting each bay’s aisle roof

support bracket to the front of the switchgear and the aisle roof to the

switchgear roof (see Figure 14).

NOTE: Insert the connecting bolts loosely until all are in place;

then tighten.

3/8-16 Hardware

(attaches aisle roof to

switchgear roof)

Aisle Roof

Gasket

Switchgear Roof

Aisle Roof Support

3/8 -16 Hardware

(attaches aisle roof

support bracket to front of

switchgear)

Figure 14:

Attaching Aisle Roof Support Bracket to Switchgear

19. Bolt the aisle base to the switchgear base with 3/8-16 x 1.0 in. bolts (see

Figure 15). If required, pry the aisle base in place with an alignment bar.

Alignment Bar Hole

Switchgear Door

Aisle Base

3/8-16 x 1.0 Bolt

Flat and Lock Washer

Switchgear Base

Bolting Pad

Figure 15:

© 1992 Square D All Rights Reserved

Aisle and Switchgear Base Connection

11

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

Bulletin No. 6055-16

June 1999

20. After the aisle section is in place and attached to the switchgear section,

remove the end shipping braces (see attached aisle section in Figure 16).

Do not remove the braces from in front of the switchgear as it may be

necessary to lift the aisle section again if it does not align properly.

21. Using a crane, set the second aisle section onto the concrete pad

approximately 12 in. (305 mm) from the section in place

(see Figure 17).

Figure 16:

Moving Sections with Braces in Place

22. Remove the end braces from the new section and lift it carefully by crane

into place (see Figure 17).

NOTE: Do not remove the end braces before it is sitting on the pad; doing

so may distort the assembly.

Figure 17:

12

Placing Second Aisle Section

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

23. Attach the second aisle section to the switchgear by bolting each bay’s

aisle roof support bracket to the front of switchgear and the aisle roof to

the switchgear roof (see Figure 14 on page 11).

NOTE: Insert the connecting bolts loosely until all are in place;

then tighten.

Figure 18:

Switchgear with All Sections in Place

24. Attach the second aisle section to the first aisle section by bolting the

aisle roof supports together (see Figure 19).

Aisle Roof

Gasket

1/4-20 Carriage Bolt

(attaches two aisle bay

sections together)

Aisle Roof Support

Figure 19:

Attaching Second Aisle Section to First Aisle Section

25. Bolt the aisle base to the switchgear base with 3/8-16 x 1.0 in. bolts (see

Figure 15 on page 11). If required, pry the aisle base in place with an

alignment bar.

26. After all aisle sections are bolted in place, remove the aisle shipping

braces in front of the switchgear.

© 1992 Square D All Rights Reserved

13

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

Bulletin No. 6055-16

June 1999

27. Mount the aisle roof caps to the roof at each end, using 1/4-20 threadforming washerhead screws supplied (see Figure 20).

28. Mount the switchgear roof cap to the roof at each end, using 1/4-20

thread-forming washerhead screws; then to the aisle roof support using

two 1/4-20 carriage bolts, seal washers, and locknuts (see Figure 20).

Aisle Roof Cap

Figure 20:

Switchgear Roof Caps

Roof Cap Mountings

29. Inspect the walk-in switchgear for any openings that may expose

equipment to rain. To do this, enter the walk-in enclosure, close the

doors, and look for any light coming through the joints, mainly in the

corners (see Figure 21). Make note of them and seal them with caulk.

Look mainly for cracks which could be directly exposed to rain.

Figure 21:

14

Checking Enclosure for Openings in Seal

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

30. Remove lifting lugs located on the roof of switchgear (see Figure 22 and

Figure 23) and plug holes with the factory-supplied 1/2-13 bolts and seal

washers (see Figure 24) furnished with each shipping section.

CAUTION

HAZARD OF EQUIPMENT DAMAGE

Make sure that all 1/2-13 bolts and seal washers are in place; they not only

seal, but hold the roof to the switchgear.

Failure to follow this instruction can result in injury or equipment

damage.

© 1992 Square D All Rights Reserved

Figure 22:

Removing Large Lifting Lugs

Figure 23:

Removing Small Lifting Lugs

Figure 24:

Plugging Holes with Bolts/Seal Washers

15

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

Common Aisle

Bulletin No. 6055-16

June 1999

The same basic guidelines and assembly procedures used for single aisle

installation also apply to the common aisle. Refer to single aisle installation

procedures for general information. Specific procedures for common aisle

assembly are detailed in this section.

Figure 25:

Outdoor Walk-in Switchgear with Common Aisle

The common aisle switchgear is shipped with the “low side” and the “high

side” switchgear sections fully assembled and ready to set on a concrete

pad. The aisle will be shipped in sub-assemblies.

16

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Common Aisle Installation

Outdoor Walk-in Switchgear

Section 7—Standard Components and Parts

1. Install the switchgear “high side” shipping section (see Figure 26).

2. Line-up and bolt the bases to the “high side” switchgear.

3. Install the switchgear “low side” shipping section and bolt it to the base

(see Figure 26).

NOTE: The line-up of all switchgear sections and bases must be accurate

and square, and the floor must be level. Use shims if necessary.

4. Install the roof sub-assemblies, attaching them to the switchgear sections

(see Figure 26).

5. Add the end panel sub-assemblies. Use 3/8-16 x 1-1/2 in. carriage bolts

to attach them to the side sheet. Use 3/8-16 x 1 in. hex-head bolts to

attach the sub-assemblies to the roof.

6. Make sure the gaskets attached to one side of the roof and around all

bolted flanges are in place. If damaged, repair it using the factorysupplied 1/2 in. gasket material. Ensure that there is no gap between the

splices if repaired.

7. Attach the roof caps to the aisle and the switchgear roof.

8. Remove the lifting lugs and seal the holes with factory-supplied 1/2-13

bolts and seal washers.

CAUTION

HAZARD OF EQUIPMENT DAMAGE

Make sure that all 1/2-13 bolts and seal washers are in place; they not

only seal, but hold the roof to the switchgear (see Figures 21, 22, and

Figure 24 on page 15).

Failure to follow this instruction can result in injury or equipment

damage.

Roof Subassembly

Aisle Space

“High Side” Switchgear Assembly

“Low Side” Switchgear Assembly

Base Subassembly

Figure 26:

© 1992 Square D All Rights Reserved

Common Aisle Configuration

17

Outdoor Walk-in Switchgear

Section 5—Electrical Hook-Up

Bulletin No. 6055-16

June 1999

The electrical hook-up varies from unit to unit; it may be from a panelboard

(see Figure 29) or directly in the switchgear. Normally, there are three

circuits:

SECTION 5—ELECTRICAL

HOOK-UP

• Lights and fan with thermostat. Thermostat is set at set at 80 °F (27 °C).

• Receptacles (one at each end)

• Heater with thermostat (optional). Heater is set at 50 °F (10 °C)

Refer to the wiring diagrams furnished with the unit for the locations of the

circuit breakers and the electrical connections of the shipping sections.

Figure 27:

18

Lights, Receptacle, and Fan

Figure 28:

Heater/Thermostat (Optional)

Figure 29:

Panelboard (Optional)

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 6—Inspection and Maintenance

SECTION 6—INSPECTION AND

MAINTENANCE

DANGER

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

• Only qualified electrical personnel familiar with medium voltage

circuits are to perform work described in this set of instructions.

Workers must understand the hazards involved in working with or

near medium voltage equipment.

• Perform inspection and maintenance only with the main sources of

power disconnected and locked open with a “work” lock.

• Always use a properly rated voltage sensing device to confirm that

power is off.

• Be sure there is no backfeed through any feeder circuit.

• Grounc the main and feeder circuits before touching the main bus,

bus pads, or primary contacts.

Failure to follow these instructions will result in death or serious

injury.

Inspection and maintenance for the walk-in enclosure should be performed

on the basis of environmental conditions and experience. Abnormal

operation or conditions may require immediate corrective action.

The inspection for the switchgear is outlined in detail in instruction bulletin

6055-30. The following instructions apply only to the walk-in enclosure.

Replace the air filters every six months or as applicable. Table 1 (below) lists

correct filter applications.

Table 1:

Replacement Air Filters

Filter Location*

Bay Width

Square D Part No.

Size (Inches)

22 in. (559 mm)

46005-679-01

11 in. x 13 in.

(279 mm x 330 mm)

36 in. (914 mm),

48 in. (1219 mm)

46005-243-01

11 in. x 19.5 in.

(279 mm x 495 mm)

22 in. (559 mm)

44005-679-02

3.3 in. x 20 in.

(84 mm x 508 mm)

36 in. (914 mm)

46005-243-03

3.3 in. x 34 in.

(84 mm x 864 mm)

48 in. (1219 mm)

46005-418-02

3.3 in. x 46 in.

(84 mm x 1168 mm)

Rear Door

Rear Eaves

*filter material is 1/2 in. (13 mm) thick rubberized hair filter pad or equivalent (Paratex™).

During regular inspection intervals, inspect for the following:

• Check for possible leaks in the front aisle, in each cable compartment, and

in the roof of the indoor switchgear. Check the roof, using a flashlight,

through the vent openings from the front aisle. If large puddles of water are

found at the doors, check the door gaskets.

• Check the seeping holes in the cable compartment doors to ensure they

are not clogged.

• Check the heater and fan in the front aisle for proper operation. Check the

thermostat settings (see “Section 5—Electrical Hook-Up” on page 18).

Verify that space heaters in the switchgear are operating.

• Check that the door panic latch (for use in an emergency) is working

properly.

© 1992 Square D All Rights Reserved

19

Outdoor Walk-in Switchgear

Section 7—Outlines

Bulletin No. 6055-16

June 1999

SECTION 7—OUTLINES

111.6

2833

102.2

104.5

2595

114.5

2907

2653

74.0

1879

77.0

92.5

1955

2348

Figure 30:

Outline of Single Aisle Walk-in

114.5

2907

104.5

102.2

2653

2595

75.0

1904

96.9

2460

77.0

96.9

1955

2460

270.8

6875

Switchgear Assembly - Low Side

Aisle Assembly

Figure 31:

20

Switchgear Assembly - High Side

Outline of Common Aisle Walk-in

© 1992 Square D All Rights Reserved

Bulletin No. 6055-16

June 1999

Outdoor Walk-in Switchgear

Section 8—Maintenance Log

SECTION 8—MAINTENANCE LOG

DATE

INITIALS

© 1992 Square D All Rights Reserved

ACTION

21

Outdoor Walk-in Switchgear

Section 8—Maintenance Log

Bulletin No. 6055-16

June 1999

MAINTENANCE LOG

DATE

22

INITIALS

ACTION

© 1992 Square D All Rights Reserved

Outdoor Walk-in Switchgear, 4.76—15.0kV Metal-Clad Switchgear, MASTERCLAD™, Series 3

Square D and

are registered trademarks and MASTERCLAD is a trademark of Square D

Company and related companies. All other trademarks are the intellectual property of their

respective companies

Square D Company

330 Weakley Road

Symrna, TN 37167 USA

(615) 459-5026

www.squared.com

Electrical equipment should be serviced only by qualified electrical maintenance personnel. No

responsibility is assumed by Square D for any consequences arising out of the use of this material.

Bulletin No. 6055-16 June 1999 © 1992 Square D All Rights Reserved.

Replaces 6055IM9203 dated 8/92.