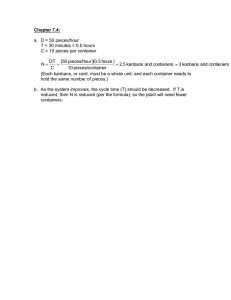

The Pot-in-Pot (PNP) Production System

advertisement