GE Power

Variable Inlet Guide Vane

(VIGV)

Product Description

• Variable Inlet Air vanes help guide inlet airflow to maximize

engine performance.

• Assembly located in front of Low Pressure Compressor (LPC),

consisting of 43 stationary leading-edge vanes and variable

trailing flaps (rotate -10 to +60 degrees).

• Variable Differential Transformers (LVDTs) on actuator ring

drivetwin hydraulic actuators.

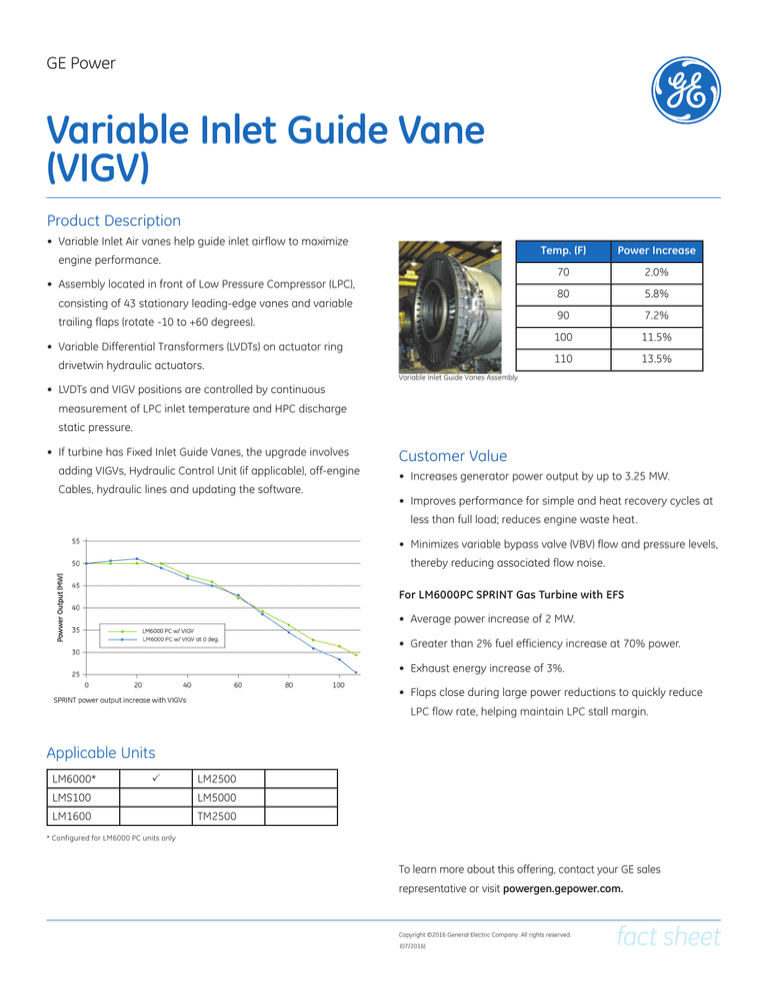

Temp. (F)

Power Increase

70

2.0%

80

5.8%

90

7.2%

100

11.5%

110

13.5%

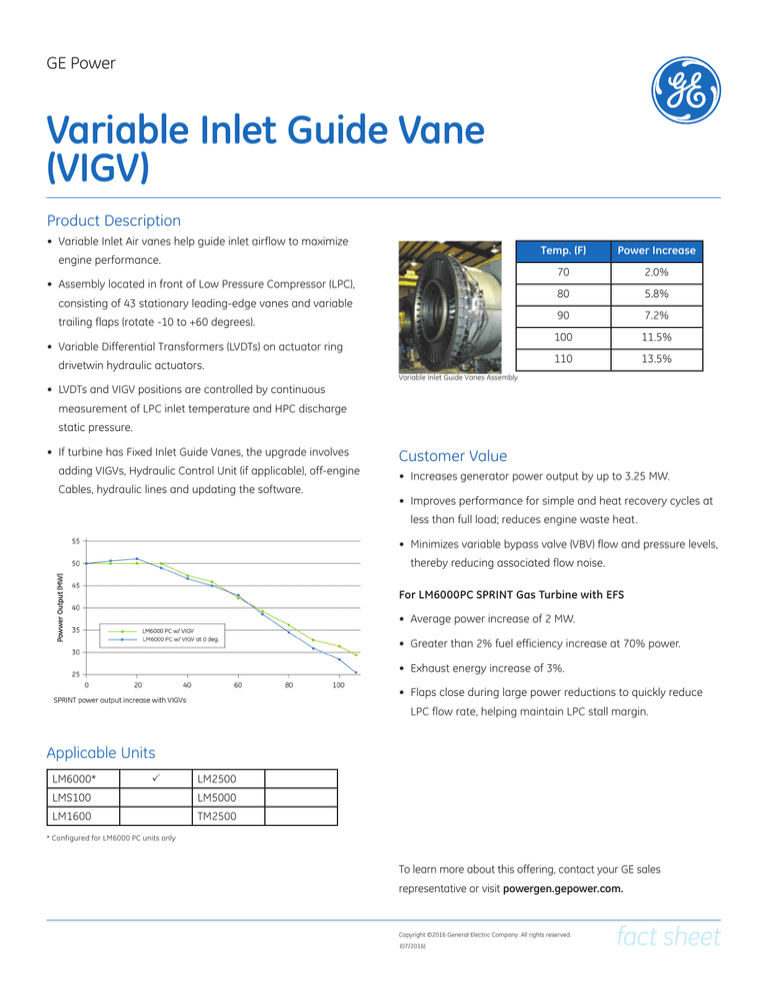

Variable Inlet Guide Vanes Assembly

• LVDTs and VIGV positions are controlled by continuous

measurement of LPC inlet temperature and HPC discharge

static pressure.

• If turbine has Fixed Inlet Guide Vanes, the upgrade involves

adding VIGVs, Hydraulic Control Unit (if applicable), off-engine

Cables, hydraulic lines and updating the software.

Customer Value

• Increases generator power output by up to 3.25 MW.

• Improves performance for simple and heat recovery cycles at

less than full load; reduces engine waste heat.

• Minimizes variable bypass valve (VBV) flow and pressure levels,

thereby reducing associated flow noise.

For LM6000PC SPRINT Gas Turbine with EFS

• Average power increase of 2 MW.

• Greater than 2% fuel efficiency increase at 70% power.

• Exhaust energy increase of 3%.

• Flaps close during large power reductions to quickly reduce

LPC flow rate, helping maintain LPC stall margin.

Applicable Units

LM6000*

P

LM2500

LMS100

LM5000

LM1600

TM2500

* Configured for LM6000 PC units only

To learn more about this offering, contact your GE sales

representative or visit powergen.gepower.com.

Copyright ©2016 General Electric Company. All rights reserved.

(07/2016)

fact sheet