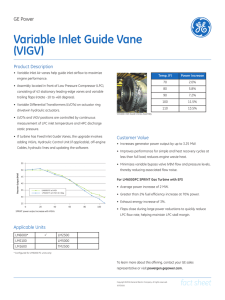

1. Can a positive displacement compressor self-regulate it’s capacity? No, a reciprocating compressor cannot self-regulate it’s capacity against a given discharge pressure. As it’s characteristic is constant volume, it will continue to displace gas until it receives a signal not to do so. 2. What are the functions of compressor control and protection systems in dynamic compressors? Provide stable control and operation at all the operating conditions in datasheet Provide protection against operation in surge area of the performance curve 3. What are the most commonly used head-capacity control methods for centrifugal compressor? Speed Control Adjustable Inlet Guide Vanes Suction throttling Discharge throttling Blow-off Recycle 4. Centrifugal Compressor Curve for speed control If the compressor is operating at the constant pressure point, Y (flow rate Qy), and if the process requires a higher gas flow, the discharge pressure immediately falls and the operating point moves to the right and downward along the characteristic curve for the given speed. The pressure transmitter will sense the lowering pressure, and the pressure controller will send a control signal to the turbine governor. The governor will increase the speed of the compressor (through an increase in turbine speed), which results in an increase in the system pressure back to the pressure setpoint. The new operating point would be located on the desired pressure line but further to the right. If the process required less gas flow, the discharge pressure would begin to increase and the control system would decrease the speed of the compressor (through a decrease in turbine speed) until the pressure setpoint is restored. The flow could be reduced until point X was reached. Point X is set at the minimum operating point before the surge line (surge control line). Antisurge controls, which are discussed later in this module, will prevent the operating point from moving to the left of point X on each speed curve. If the process required a flow rate of only point Z, the volume of gas (Qx - Qz) would have to be blown off or recycled. The operating control would have to be shifted from variable-speed control to blow-off control, which is the only control that is available when the process requires flows that are below the stable operating range. 5. Centrifugal Compressor Curve for inlet guide vane control Adjustable guide vanes are used for the control of axial and single-stage centrifugal compressors. Single-stage compressors frequently incorporate an axial inlet, and they do not require fixed guide vanes. Pre-rotation adjustable guide vanes pre-whirl the gas that enters the compressor stage in the direction of rotation, which develops less head than at design. Between full open and maximum pre-whirl position, adjustable guide vanes provide some degree of reduced horsepower over the suction throttling valve. Counter-rotation adjustable guide vanes are used to extend the useful operating range of any dynamic compressor. The range of operation is extended through a change of the angle of attack and the inlet gas velocity to the impeller blade. For the high flow region, the angle of attack is increased to eliminate flow separation and to effect an increase in the produced head of the impeller or blade. The elimination of flow separation and an increase in the produced head will increase the capacity range of the impeller. Adjustable inlet guide vanes are expensive, limited in effectiveness, and present many maintenance and operational problems. At Saudi Aramco, centrifugal compressor adjustable inlet guide vanes have proven to be mechanically unreliable in general services; therefore, prior to control selection, the economics of inlet guide vanes must be considered because of their higher initial cost, complex mechanism, maintenance, and requirement for frequent adjustment. Adjustable inlet guide vanes should not be used on process centrifugal compressors, and they should never be used in any sour gas service. Saudi Aramco primarily uses adjustable inlet guide vanes for axial and single-stage centrifugal air compressors. 6. When is suction throttling control used in centrifugal compressors? When the compressor does not have inlet guide vanes and is driven by a constant speed drive.