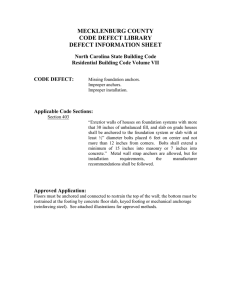

House Architectural Plan: Foundation & First Floor Layout

advertisement

40'-8" 20'-4" 40'-0" 10'-2" 5'-3" 4040 SL. (EGRESS) 4040 SL. (EGRESS) SUMP PIT V.I.F. 7'-10" 6068 SL. GLS. DR. (TEMPERED) 3050 SH. 10'-0" DVFP PER BLDR 5'-4" 5'-0" 2-2X12 OPTIONAL FIREPLACE 5'-41 2" 13'-1" 13'-51 2" 14'-1" OPTIONAL TRAY CEILING 1'-6" TYP. SINK DISP 5'-6" L.T. 11'-0" 4" BRICK LEDGE UNEXCAVATED 5'-0" BI-FOLD UNEX. BEDROOM #2 10'-0" X 11'-0" 7'-8" 10'-01 2" LEAD WALL AS REQUIRED BY OVERDIG 4" BRICK LEDGE 14'-0" 2'-2" SD/C 19'-6" 5'-8" 21'-0" 3068 DR w/ 12" SIDELIGHTS (2) 1 3/4 X 9 1/4 ML PORCH 2'-1" STEPS & RAIL'G PER CODE & GRADE CONDITIONS 6'-8" 6'-8" 13'-4" FIRST FLOOR PLAN SCALE: 1/4" = 1'-0" SCALE: 1/4" = 1'-0" 10" THICK 8'-0" W/ OPT. 9'-0"HIGH POURED CONCRETE WALL WITH (2) #4 CONTINUOUS REINFORCING BARS AT TOP ON 10"x20" POURED CONCRETE FOOTING WITH (2) #4 CONTINUOUS REINFORCING BARS. TRENCH FOOTING: 12" THICK x 42" DEEP BELOW GRADE POURED CONCRETE TRENCH FOOTING (TO BEAR ON UNDISTURBED SOIL) WITH ONE COURSE OF GARAGE GRADE 4"x8" BLOCK (AS REQUIRED). DEPRESS TRENCH FOOTING 3" AT GARAGE DOOR LOCATIONS. 3'-2" 10'-2" 3'-2" 6'-4" 10'-2" 20'-4" 40'-0" FOUNDATION PLAN FOUNDATION WALL: 16'-0"x7'-0" O.H DOOR 3 1 2" x 15" GLULAM 3060 S.H. (EGRESS) 40'-8" FOUNDATION NOTES 22"x30" ATTIC ACCESS WOOD TRUSSES @ 24" O.C. OVER 2-2X12 2'-2" LINEN 10'-7" 19'-8" 3'-4" 6'-4" GIRDER TRUSS 16'-0" 4X3 SHWR FOYER 10'-0" CEILING 1'-0" 4'-0" 6'-10" 7'-8" 4" SLAB BEARING 3'-21 2" 8'-8" 5'-0" SD RS 18'-11" 2'-6" CLOSET 6'-9" 3'-3" 68 6'-2" 5'-5" 7'-1" GARAGE 6'-5" 1'-0" 28 6'-2" PLAN NOTES 1. ALL COLUMNS SHOWN SHALL BE 3" DIAMETER ON 30"x30"x16" POURED CONCRETE PAD. TOP OF CONCRETE PAD TO BE 4" BELOW FINISH BASEMENT SLAB. (TYPICAL UNLESS NOTED OTHERWISE) 2. ALL STRUCTURAL STEEL BEAMS SHALL HAVE A 2x4 TOP PLATE SECURED TO BEAM WITH TWO ROWS OF 1/2" BOLTS @ 64" O.C. (STAGGER ROWS) OR SHOT-IN ANCHORS @ 48" O.C. (STAGGER ROWS) 3. WHERE STEEL BEAMS REST ON FOUNDATION WALLS, SIZE BEAM POCKET APPROPRIATELY AND SHIM AS REQUIRED. 4. AT BASEMENT POUR 4" CONCRETE SLAB WITH 6 MIL VAPOR BARRIER ON 4" COMPACTED GRANULAR FILL. 5. AT PORCH POUR 4" CONCRETE SLAB WITH 6x6 #10 W.W.M. ON COMPACTED GRANULAR FILL. 6. AT GARAGE POUR 4" CONCRETE SLAB ON 4" COMPACTED GRANULAR FILL. SLOPE SLAB 2" TOWARDS OVERHEAD DOORS. 7. WHERE ADJACENT TO FOUNDATION WALLS, REINFORCE GARAGE SLAB WITH #4 REINFORCING BARS @ 24" O.C. (10' LONG BARS) 8. AS REQUIRED DROP FOYER FLOOR SHEATHING 3/4" FOR MUDSET TILE INSTALLATION 9. VERIFY ALL UTILITY LOCATIONS IN FIELD. 10. PROVIDE GUARDRAIL AT STAIRS DURING CONSTRUCTION. INTERIOR WALLS: 1/2" GYPSUM WALL BOARD ON EACH SIDE OF 2x4 WOOD STUDS @ 16" O.C. 4 1/2" THICK TYPICAL (UNLESS NOTED OTHERWISE). EXTERIOR WALLS: SIDING AND/OR BRICK WITH AIRSPACE, MOISTURE BARRIER PAPER (HOUSE WRAP) ON 7/16" O.S.B. SHEATHING ON 2x WOOD STUDS @ 16" O.C., 3 1/2" BATT INSULATION R-13, 1/2" GYPSUM WALL BOARD (GLUE & SCREW). BRICK SUPPLIER TO SIZE AND PROVIDE STEEL LINTELS AT MASONRY OPENINGS AS REQUIRED. 4 1/2" THICK WITH SIDING AND 9" THICK WITH BRICK (TYPICAL UNLESS NOTED OTHERWISE). 1. TRUSSES TO BEAR ON EXTERIOR WALLS ONLY UNLESS NOTED OTHERWISE. 2. AT GARAGE AND RESIDENCE COMMON WALLS AND CEILING APPLY ONE LAYER OF 5/8" TYPE "X" GYPSUM WALL BOARD (GARAGE SIDE). 3. OPENINGS BETWEEN THE GARAGE AND RESIDENCE SHALL BE EQUIPPED WITH 20-MINUTE FIRE RATED DOORS (OR EQUIVALENT PER 2003 MRC SECTION R309.1). 4. VENT ALL EXHAUST FANS TO EXTERIOR. 5. WHEN POSSIBLE DIRECT ALL FLUES AND VENTS THAT PENETRATE ROOF BEHIND MAIN RIDGE. 6. INSTALL WATER SUPPLY AND DRAIN BOX (GREY BOX) AT WASHING MACHINE LOCATION. 7. USE GREENBOARD AT ALL AREAS SUSCEPTIBLE TO MOISTURE. 50'-0" RS 5'-81 2" RS 6'-1" 3'-4" 5'-91 2" SILL 68 26 3'-1" D W 22'-6" 11'-0" BATH W.I.C MIN. 20 MINUTE RATED DR. 2'-0" 14'-01 2" LEAD WALL AS REQUIRED BY OVERDIG 68 4" SLAB BEARING EF 7'-1" 2-2X10 26 4" SLAB BEARING 2'-1" LAUNDRY 3'-0" 5' TUB SHWR UNIT 5'-0" 18'-11" 3'-0" MIN. 6'-9" 68 28 8 12'-4" 4'-9" 9'-0" 2'-41 2" 3'-9" 2'-8" CLOSET 3'-5" 6 28 SD 68 28 BEAM POCKET 3'-4" SILL RS CLOSET RS 10'-6" 49'-0" 2-2X10 W 10X22 BEDROOM #3 10'-0" X 10'-6" M. BATH EF 6'-21 2" 68 W 10X22 4" BRICK LEDGE LD 18 W 10X22 3050 SH. BEAM POCKET 50'-0" 13'-2" SD/C 13R DN 68 26 50'-8" 13'-2" 68 28 68 26 12'-8" FO SILL RAILING 5'-41 2" 2'-2" BI SD 42" HALF WALL UP 13R (2) 2X10 8'-8" 28 68 SD PANTRY 10'-0" 3'ARCH 36"REF 68 26 49'-8" 4'-7" (3) 2X10 (3) 2X10 8'-4" SD 3'-4" 1'-1" 8 13'-8" KITCHEN 10'-0" X 10'-9" 6 24 (2) 2X10 81 2" 6'-1" BEAM POCKET BEAM POCKET 4 DW 3'-6" W 10X22 30" RANGE W 10X22 12 MASTER BDRM. 13'-1" X 14'-1" 26'-6" W 10X22 LINE OF OPT. CLG. PROFILE 1'-6" TYP. 10" 13'-21 4" 13'-2" LINE OF CLG. PROFILE 4" BRICK LEDGE 3050 S.H. (EGRESS) 2-2X10 FAMILY ROOM 15'-8" X 19'-5" 12'-73 4" 10" 3050 S.H. (EGRESS) BREAKFAST 10'-0" X 9'-9" BASEMENT GFI 6'-111 2 " 3050 SH. 2-2X10 2-2X12 4" BRICK LEDGE 9'-71 2" 10'-4" 2'-0" 10'-2" CONTINUOUS RIDGE VENT CL 12 DORMER 12 12 12 ELEVATION NOTES 4'-0" ASPHALT SHINGLES 4'-0" 6" 1 X 6 FASCIA 12 12 1 X 6 FRIEZE FXD 2030 12 12 12 4'-0" BRICK SOLDIER CRS. (PROJ. 1") 5'-0" BRICK HDR. SURROUND (PROJ. 1") SUNBURST TRIM BRG. HGT. 36" HALF ROUND FALSE VENT w/ 6" TRIM 10" X 10" TAPERED L'STONE KEY (PROJ. 1-1/2") 1 X 6 FASCIA WINDOW HDR. 8'-0" SASH HT. 9'-11 8" BRG. HT. 1'-0" 1'-0" 3060 S.H. (EGRESS) BRICK 3068 DR w/ 12" SIDELIGHTS 7'-91 2" LINE OF CONC. TRENCH FTG. FRONT ELEVATION SCALE: 1/4" = 1'-0" 12 DORMER 7 CONTINUOUS RIDGE VENT CONTINUOUS RIDGE VENT 7 12 6" PT. OF ROOF ORIGIN 1 x 6 RAKE 1 X 6 FASCIA 1 x 6 SUBRAKE 1 X 6 FRIEZE 12 BRG. HGT. 12 WINDOW HDR. 8'-0" SASH HT. 9'-11 8" BRG. HT. 1'-0" 1'-0" HORIZONTAL SIDING 2'-4" 1'-0" 1'-0" BRICK, (TYP.) 3050 SH. 4" TRIM BRICK ROWLOCK 10" BRG. HGT. 7'-91 2" GRADE GRADE LINE OF POURED CONC. FOUND. WALL & FOOTING (TYP.) FINISHED SLAB EGRESS WINDOW W/ WINDOW WELL (SEE SHEET A2 FOR CODE NOTES) 4. METAL FLASHING AS REQUIRED BY CODE. 5. ROOF & SOFFIT VENTS AS REQUIRED BY CODE. 6. WINDOW NOMENCLATURE: 3050 = 3'-0" x 5'-0" 7. BRICK MANUFACTURER TO SIZE AND PROVIDE STEEL LINTELS AT MASONRY OPENINGS AS REQUIRED. WINDOW WELL SHALL HAVE HORIZ. DIMENSIONS THAT PROVIDE A MIN. NET CLEAR AREA OF 9 SQ. FT. WITH A MIN HORIZ. PROJECTION AND WIDTH OF 36". 16'=0" x 7'-0" O.H. GARAGE DOOR STONE SILL LINE OF POURED CONC. FOUND. WALL & FOOTING (TYP.) FINISHED FLR. FIREPLACE FLUE TO BE MIN 2'-0" ABOVE ANY ROOF SURFACE WITHIN 10'-0" HORIZONTALLY, MIN 3'-0" PENETRATION ABOVE ROOF TOP. WINDOW WELLS WITH A DEPTH GREATER THAN 44" BELOW GRADE SHALL BE EQUIPPED WITH A PERMANENTLY AFFIXED LADDER OR STEPS USABLE WITH THE WINDOW IN THE FULLY OPEN POSITION. STEPS & RAIL'G PER CODE & GRADE CONDITIONS CANTILEVER FIREPLACE 3. RAILING OR METAL REMOVABLE GRATE & LADDER OVER TOP (AS CODE REQUIRES) BRICK HDR. CRS. (PROJ. 1") GRADE FINISHED SLAB PROVIDE ICE & WATER SHIELD MIN. 6'-0" COVERAGE AT ALL VALLEYS WINDOW WELL TO BE FILLED W/ PEA GRAVEL DOWN TO TOP OF HOUSE DRAIN TILE. TIE DRAIN INTO HOUSE DRAIN TILE FROM BOTTOM OF WINDOW WELL 10" BRG. HGT. 2. EGRESS WINDOW WELL BRICK SOLDIER CRS. (PROJ. 1") BRICK ROWLOCK SILL FINISHED FLR. 1 X 6 FRIEZE SHUTTER 1/2 WINDOW WIDTH BRICK ALL ROOF SADDLES TO BE PLYWOOD SHEATHED WITH ICE & WATER SHIELD AND SHINGLES. 12 12 12 ASPHALT SHINGLES 1. LEFT ELEVATION SCALE: 1/4" = 1'-0" LINE OF CONC. TRENCH FTG. CONTINUOUS RIDGE VENT ASPHALT SHINGLES ASPHALT SHINGLES 1 X 6 FASCIA 1 X 6 FASCIA 1 X 6 FRIEZE 1 X 6 FRIEZE BRG. HGT. WINDOW HDR. 8'-0" SASH HT. 9'-11 8" BRG. HT. 21 2" HORIZONTAL SIDING 3050 S.H. (EGRESS) 3050 S.H. (EGRESS) 4" TRIM 6068 SL. GLS. DR. (TEMPERED) 3050 SH. HORIZONTAL SIDING 3050 SH. 4" TRIM BRICK ROWLOCK BRICK, (TYP.) BRICK ROWLOCK GRADE GRADE 10" FINISHED FLR. EGRESS WINDOW W/ WINDOW WELL (SEE SHEET A2 FOR CODE NOTES) 7'-91 2" BRG. HGT. 4040 SL. (EGRESS) BRICK, (TYP.) DIRECT VENT FIRE PLACE EGRESS WINDOW W/ WINDOW WELL (SEE SHEET A2 FOR CODE NOTES) LINE OF POURED CONC. FOUND. WALL & FOOTING (TYP.) FINISHED SLAB 4040 SL. (EGRESS) LINE OF POURED CONC. FOUND. WALL & FOOTING (TYP.) FRONT ELEVATION SCALE: 1/4" = 1'-0" 7 12 CONTINUOUS RIDGE VENT 12 7 6" LINE OF OPT. TRAY CLG. @ MASTER BDRM. BEYOND 1 X 6 FASCIA 1 x 6 RAKE 1 X 6 FRIEZE 1 x 6 SUBRAKE BRG. HGT. WINDOW HDR. 8'-0" SASH HT. 9'-11 8" BRG. HT. BRICK, (TYP.) 1'-0" 1'-0" 1'-0" 4" TRIM 3'-4" HORIZONTAL SIDING HORIZONTAL SIDING CANTILEVER FIREPLACE 3'-0" BRICK ROWLOCK BRG. HGT. 10" FINISHED FLR. GRADE GRADE 7'-91 2" BRICK, (TYP.) FINISHED SLAB LINE OF CONC. TRENCH FTG. LEAD WALL AS REQUIRED BY OVERDIG LEFT ELEVATION SCALE: 1/4" = 1'-0" LEAD WALL AS REQUIRED BY OVERDIG LINE OF POURED CONC. FOUND. WALL & FOOTING (TYP.) EGRESS WINDOW W/ WINDOW WELL (SEE SHEET A2 FOR CODE NOTES) GENERAL NOTES Exceptions: 1. The use of a volute, turnout or starting easing shall be allowed over the lowest tread. 2. When handrail fittings or bendings are used to provide continuous transition between flights, the transition from handrail to guardrail, or used at the start of a flight, the handrail height at the fittings or bendings shall be permitted to exceed the maximum height. 2. 1. 2. 3. 4. 5. 6. 7. Trusses are to be handled with particular care during fabrication, bundling, loading, delivery, unloading and installation in order to avoid damage and weakening of the trusses. Temporary and permanent bracing for holding the trusses in a straight and plumb position is always required and shall be designed and installed by the erecting contractor. Temporary bracing during installation, includes cross bracing between the trusses to prevent toppling or "dominoing" of the trusses. Permanent bracing shall be installed in accordance with the latest of the "National Design Standard", as published by the American Forest & Paper Association and H.I.B.-91 and D.S.B.-85 as published by the truss plate institute. Permanent bracing consists of lateral and diagonal bracing not to exceed spacing requirements of the truss fabricator. Top chords of trusses must be continuously braced by roof sheathing unless otherwise note on the truss shop drawings. Bottom chords must be braced at intervals not to exceed 10' o.c. or as noted on the truss fabricators drawings. Construction loads greater than the design loads of the trusses shall not be applied to the trusses at any time. No loads shall be applied to the truss until all fastening and required bracing is installed. The supervision of the truss erecting shall be under the direct control of persons(s) experienced in the installation and proper bracing of wood trusses. Field modification or cutting of pre-engineered roof trusses is strictly prohibited without expressed prior written consent and details from a licensed professional structural engineer experienced in wood truss design and modifications. SOIL REQUIREMENTS & EARTH WORK AND CONCRETE 1. 2. 3. 1. All top soil, organic and vegetative material should be removed prior to construction. Any required fill shall be clean, granular material compacted to at least 95%%% of maximum dry density as determined by ASTM D-1557. Foundations bearing on existing soils have been designed for a minimum allowable soil bearing capacity of 3000 psf, u.n.o. Notify the engineer/architect if the allowable soil bearing capacity is less than 3000 psf so that the foundations can be redesigned for the new allowable bearing capacity. R404.1.7 Backfill placement. Backfill shall not be placed against the wall until the wall has sufficient strength and has been anchored to the floor above or has been sufficiently braced to prevent damage by the backfill. R506.2.1. Fill. ill material shall be free of vegetation and foreign material. The fill shall be compacted to assure uniform support of the slab, and except where approved, the fill depths shall not exceed 24 inches for clean sand or gravel and 8 inches for earth. R506.2.3 Vapor retarder. A 6 mil polyethylene or approved vapor retarder with joints lapped not less than 6 inches shall be placed between the concrete floor slab and the base course or the prepared subgrade where no base course exists. 1. 2. 3. Concrete work shall conform to the requirements of ACI 301-96, "Specifications for Structural Concrete for Buildings", except as modified as supplemental requirements. Concrete shall have a minimum of 3000 psi, 28 day compressive strength, unless noted otherwise, (4 sacks) & a water/cement ratio not to exceed 6 gallons per sack). Exterior concrete slabs shall have a minimum of 4000 psi, 28 day compressive strength, & 4%%% air entrainment. The use of additives such as fly ash or calcium chloride is not allowed without prior review from the architect. R405.1 Concrete or masonry foundations. Drains shall be provided around all concrete or masonry foundations that retain earth and enclose habitable or usable spaces located below grade. Drainage tiles, gravel or crushed stone drains, perforated pipe or other approved systems or materials shall be installed at or below the area to be protected and shall discharge by gravity or mechanical means into an approved drainage system. Gravel or crushed stone drains shall extend at least 1 foot beyond the outside edge of the footing and 6 inches above the top of the footing and be covered with an approved filter membrane material. The top of open joints of drain tiles shall be protected with strips of building paper, and the drainage tiles or perforated pipe shall be placed on a minimum of 2 inches of washed gravel or crushed rock at least one sieve size larger than the tile joint opening or perforation and covered with not less than 6 inches of the same material. Exception: A drainage system is not required when the foundation is installed on well-drained ground or sand-gravel mixture soils according to the Unified Soil Classification System, Group I Soils, as detailed in Table R405.1. STRUCTURAL STEEL SPECIFICATIONS 1. Structural steel shapes, plates, bars, etc. Are to be ASTM A-36 (unless noted other wise) designed and constructed per the 1989 AISC "Specifications For The Design, Fabrication, And Erection Of Steel For Buildings", and the latest edition of the AISC "Manual Of Steel Construction". 2. Steel columns shall be ASTM A-501, Fy=36 KSI. Structural tubing shall be ASTM A500, grade B, Fy=46 KSI. 3. Welds shall conform with the latest AWS D1.1 "Specifications For Welding In Building Construction", And shall utilize E70XX electrodes unless noted otherwise. 4. Bolted connections shall utilize ASTM A-325 bolts tightened to a "snug fit" condition (unless noted otherwise). REINFORCING STEEL SPECIFICATIONS 1. 2. 3. 4. 5. Reinforcing bars, dowels and ties shall conform to ASTM-615 grade 60 requirements and shall be free of rust, dirt, and mud. Welded wire fabric shall conform to ASTM a-185 and be positioned at the mid height of slabs U.N.O. Reinforcing shall be placed and securely tied in place sufficiently ahead of placing of concrete to allow inspection and correction, if necessary without delaying the concrete placement. Extend reinforcing bars a minimum of 36'' around corners and lap bars at splices a minimum of 24'' U.N.O. Welding of reinforcing steel is not allowed. R314.3 Smoke Alarms Smoke alarms shall be installed in the following locations: 1. In each sleeping room. 2. Outside each separate sleeping area in the immediate vicinity of the bedrooms. 3. On each additional story of the dwelling, including basements and habitable attics but not including crawl spaces and uninhabitable attics. In dwellings or dwelling units with split levels and without an intervening door between the adjacent levels, a smoke alarm installed on the upper level shall suffice for the adjacent lower level provided that the lower level is less than one full story below the upper level. When more than one smoke alarm is required to be installed within an individual dwelling unit the alarm devices shall be interconnected in such a manner that the actuation of one alarm will activate all of the alarms in the individual unit. FLASHING AND WEEPHOLES R703.7.5 Flashing. Flashing shall be located beneath the first course of masonry above finished ground level above the foundation wall or slab and at other points of support, including structural floors, shelf angles and lintels when masonry veneers are designed in accordance with Section R703.7. See Section R703.8 for additional requirements. R703.7.6 Weepholes. Weepholes shall be provided in the outside wythe of masonry walls at a maximum spacing of 33 inches (838 mm) on center. Weepholes shall not be less than 3/16 inch (5 mm) in diameter. Weepholes shall be located immediately above the flashing. R703.8 Flashing. Approved corrosion-resistant flashing shall be applied shingle-fashion in a manner to prevent entry of water into the wall cavity or penetration of water to the building structural framing components. Self-adhered membranes used as flashing shall comply with AAMA 711. The flashing shall extend to the surface of the exterior wall finish. Approved corrosion- resistant flashings shall be installed at all of the following locations: 1. Exterior window and door openings. Flashing at exterior window and door openings shall extend to the surface of the exterior wall finish or to the water-resistive barrier for subsequent drainage. 2. At the intersection of chimneys or other masonry construction with frame or stucco walls, with projecting lips on both sides under stucco copings. 3. Under and at the ends of masonry, wood or metal copings and sills. 4. Continuously above all projecting wood trim. 5. Where exterior porches, decks or stairs attach to a wall or floor assembly of wood-frame construction. 6. At wall and roof intersections. 1.7. At built-in gutters. FIREPLACES R1001.10 Hearth extension dimensions. Hearth extensions shall extend at least 16 inches (406 mm)in front of and at least 8 inches (203 mm) beyond each side of the fireplace opening. ) or larger, 2 Where the fireplace opening is 6 square feet (0.6 m the hearth extension shall extend at least 20 inches (508 mm) in front of and at least 12 inches (305 mm) beyond each side of the fireplace opening. EGRESS WINDOW REQUIREMENTS HEIGHT (FEET) 6. 7. All glazing in railings regardless of area or height above a walking surface. Included are structural baluster panels and nonstructural in fill panels. Glazing in enclosures for or walls facing hot tubs, whirlpools, saunas, steam rooms, bathtubs and showers where the bottom exposed edge of the glazing in less than 60 inches (1524 mm) measured vertically above any standing or walking surface. B. C. * Max. sill ht. above finish floor of 44 inches AREAS THAT REQUIRE SAFETY GLAZING R308.4 Hazardous locations. The following shall be considered specific hazardous locations for the purposes of glazing: 1. Glazing in all fixed and operable panels of swinging, sliding and bifold doors. Exceptions: A. Glazed openings of a size through which a 3-inch diameter (76 mm) sphere is unable to pass. B. Decorative glazing. 12 8 >10 2x4 2x4 2x4 2x4 12 2x6 2x4 2x4 2x4 14 2x6 2x6 2x6 2x4 16 2x6 2x6 2x6 2x4 18 NA a 2x6 2x6 2x6 20 NA a NA a 2x6 2x6 24 NA a NA a NA a 2x6 2x6 2x4 2x4 2x4 Glazing in walls and fences adjacent to indoor and outdoor swimming pools, hot tubs, and spas where the bottom edge of the glazing is less than 60 inches (1524 mm) above a walking surface and with in 60 inches (1524 mm), measured horizontally and in a straight line, of the water's edge. this shall apply to single glazing and all panes in multiple glazing. 12 2x6 2x6 2x6 2x4 14 2x6 2x6 2x6 2x6 16 NA a 2x6 2x6 2x6 18 NA a 2x6 2x6 2x6 Glazing adjacent to stairways, landings, and ramps with 36 inches (914 mm) horizontally of a walking surface when the exposed surface of the glazing is less than 60 inches (1524 mm) above the plane of the adjacent walking surface. 20 NA a NA a 2x6 2x6 24 NA a NA a NA a 2x6 When a rail is installed on the accessible side(s) of the glazing 34 to 38 inches (864 to 965 mm) above the walking surface. The rail shall be capable of withstanding a horizontal load of 50 pounds per linear foot (730 N/m) without contacting the glass and be a minimum of 1-1/2 inches (38 mm) in cross sectional height. The side of the stairway has a guardrail or handrail, including balusters or in-fill panels, complying with Sections R311.7.7 and R312 and the plane of the glazing is more than 18 inches (457 mm) from the railing; or When a solid wall or panel extends from the plane of the adjacent walking surface to 34 inches (863 mm) to 36 inches (914 mm) above the walking surface and the construction at the top of that wall or panel is capable of withstanding the same horizontal load as a guard. 12 7 50# ICE & WATER SHEILD TYPICAL ROOF CONSTRUCTION 2'-0" ASPHALT SHINGLES ON 15# FELT ON 7/16" O.S.B. ROOF SHEATHING ON PRE-ENGINEERED WOOD ROOF TRUSSES @ 24" O.C. W/ 2x4 CONTINUOUS LATERAL BRACING CONTINUOUS RIDGE VENTS AS REQUIRED BY LOCAL AND STATE CODES R-30 INSULATION STYROFOAM THERMAL BAFFLES AT EACH TRUSS SPACE 1/2" GYPSUM WALL BOARD (GLUE AND SCREW) TRUSS MANUFACTURER TO VERIFY HEEL HEIGHTS SUPPORTING TWO FLOORS AND A ROOF a. b. c. PITCH MAY VARY (SEE ELEVATIONS) >10 2x6 2x6 2x4 2x4 12 2x6 2x6 2x6 2x6 14 2x6 2x6 2x6 2x6 16 NA a NA a 2x6 2x6 18 NA a NA a 2x6 2x6 20 NA a NA a NA a 2x6 22 NA a NA a NA a NA a 24 NA a NA a NA a NA a TYPICAL EAVE CONSTRUCTION VARIES SEE ELEVATIONS Design required Applicability of this table assumes the following: Snow load not exceeding 25 psf, but not less than 1310 psi determined by multiplying the AF&PA NDS tabular base design value by the repetitive use factor, and by the size factor for all species except southern pine, E not less than 1.6 by 106 psi, tributary dimensions for floors and roofs not exceeding 6 feet, maximum span for floors and roofs not exceeding 12 feet, eaves not greater than 2 feet in dimension and exterior sheathing. Where the conditions are not within these parameters, design is required. Utility, standard, stud and no. 3 grade lumber of any species are not permitted. TABLE R602.3.(5) SIZE, HEIGHT AND SPACING OF WOOD STUDS a. BEARING WALLS STUD SIZE (inches) NONBEARING WALLS Laterally Laterally Maximum Maximum Maximum Maximum unsupported spacing when spacing when spacing when spacing when unsupported stud height 'a' stud height 'a' supporting supporting supporting two supporting (feet) (feet) roof and one floor, roof floors, roof and one floor only ceiling only and ceiling ceiling only (inches) only (inches) (inches) (inches) Maximum spacing (inches) 2x3 b - - - - - 10 16 2x4 10 24 16 - 24 14 24 3x4 10 24 24 16 24 14 24 2x5 10 24 24 - 24 16 24 2x6 10 24 24 16 24 20 24 a. Listed heights are distances between points of lateral support placed perpendicular to the plane of the wall. Increases in unsupported height are permitted where justified by analysis. b. Shall not be used in exterior walls. NO STORY ABOVE ONE STORY ABOVE TWO STORIES ABOVE NO. OF 21" OR EQUIVALENT REINFORCING BARS c 3x3x41 6'-0" 4'-6" 3'-0" 1 4x3x41 8'-0" 6'-0" 4'-6" 1 5 5x321x16 10'-0" 8'-0" 6'-0" 2 5 6x321x16 14'-0" 9'-6" 7'-0" 2 5 2-6x321x16 20'-0" 12'-0" 9'-6" 4 a. Long leg of angle shall be placed in a vertical position. b. Depth of reinforcing lintels shall not be less than 8 inches and all cells of hollow masonry lintels shall be grouted solid. Reinforcing bars shall extend not less than 8 inches into the support. c. Steel members indicated are adequate typical examples; other steel members meeting structural design requirements may be used. MOISTURE BARRIER PAPER (HOUSE WRAP) ON 7/16" O.S.B. SHEATHING ON 2x WOOD STUDS @ 16"O.C., 3 1/2" BATT INSULATION R-13, 1/2" GYPSUM WALL BOARD (GLUE & SCREW), TYPICAL FLOOR CONSTRUCTION FINISH FLOOR ON 3/4" T&G SUBFLOOR GLUED & NAILED TO FLOOR JOISTS (SEE PLAN FOR SIZE & SPACING), R-19 BATT INSULATION, RIM BOARD, LAP MOISTURE BARRIER PAPER OVER BASE FLASHING TYPICAL SILL PLATE 3 1/2" R-13 BOND INSULATION SILL ANCHORS @ 32" O.C. (WITHIN 12" OF ANY CORNER OR OPENING) 2X6 TREATED SILL PLATE W/ SILL SEALER TYPICAL BRICK LEDGE CONSTRUCTION 6" 4" NOTE: FOOTING SIZES ARE BASED ON ASSUMED SOIL BEARING CAPACITY OF 3000 PSF. ANY DISCREPANCY DISCOVERED IN FIELD SHALL BE REVIEWED BY A STRUCTURAL ENGINEER. The exposed area of an individual pane is larger than 9 square feet (0.836 m2) The bottom edge of the glazing is less than 18 inches (457 mm) above the floor; and The top edge of the glazing is more than 36 inches (914 mm) above the floor; and One or more walking surfaces are within 36 inches (914 mm), measured horizontally and in a straight line, of the glazing. GRADE TYPICAL FOUNDATION WALL ONE COAT DAMPROOFING AT FACE OF EXTERIOR WALL AND BRICKLEDGE, 10" THICK POURED CONCRETE WALL (SEE PLANS FOR WALL HEIGHT AND FOOTING DIMENSIONS) 4" CONCRETE SLAB WITH 6 MIL VAPOR BARRIER ON 4" COMPACTED GRANULAR FILL PROVIDE 1/2" EXPANSION JOINTS AT WALLS * RIDGE BEAM SIZE WILL BE EQUAL TO THE RAFTER CUT EDGE * RAFTER SPANS LUMBER SIZE 0'-0" - 4'-0" 4'-0" - 8'-0" 8'-0" - 12'-0" 12'-0" - 16'-0" 2x4 2x6 2x8 2x12 TYPICAL PAD FOOTING POURED CONCRETE PAD FOOTING (SEE FOUNDATION PLAN FOR SIZE) WITH (2) #4 REINFORCING BARS & CONTINUOUSLY FORMED KEYWAY Exceptions: Decorative glazing. A. When there is an intervening wall or other permanent barrier between the door and the glazing. B. Glazing in walls on the latch side of and perpendicular to the plane of the door in a closed position. C. Glazing adjacent to a door where access through the door is to a closet or storage area 3 feet (914 mm) or less in depth. D. Glazing that is adjacent to the fixed panel of patio doors. Glazing in an individual fixed or operable panel that meets all of the following conditions: CONFIRM GRADES WITH CIVIL ENGINEER GROUT COLLAR SOLID BELOW FLASHING, WEEP HOLES AT 32" O.C., FLASHING MEMBRANE TYPICAL BASEMENT FLOOR CONSTRUCTION TYPICAL CONVENTIONAL ROOF FRAMING 2. Glazing in an individual fixed or operable panel adjacent to a door where the nearest vertical edge is within a 24-inch (610 mm) arc of the door in a closed position and whose bottom edge is less than 60 inches (1524 mm) above the floor or walking surface. 3. TYPICAL EXTERIOR WALL CONSTRUCTION BRICK WITH AIRSPACE W/ 22 U.S. GAGE x 7/8" CORRUGATED METAL BRICK TIES @ 24" O.C. HORIZONTALLY SUPPORTING NO MORE THAN 3 1/4 SQ. FT., 3/16" DIA. WEEP HOLES @ 32" O.C. (MIN.) FLASHING MEMBRANE BENEATH THE FIRST COURSE OF MASONRY CONTINUED ABOVE FINISHED GROUND LEVEL ALLOWABLE SPANS FOR LINTELS SUPPORTING MASONRY VENEER a,b,c SIZE OF STEEL ANGLE a,c (inches) METAL DRIP EDGE 1x6 FASCIA BOARD (OR ALUMINUM WRAP) 3/8" PLYWOOD SOFFIT WITH 8"x16" SOFFIT VENTS AS REQUIRED 1x6 FRIEZE BOARD WHERE NOTED VINYL SIDING PER BUILDER TABLE R703.7.3 * Min. net clear opening of 5.0 sq. ft. (first floor bedrooms only) * Min. net clear opening width of 20 inches 16 >10 * Min. net clear opening of 5.7 sq. ft. (second floor bedrooms) * Min. net clear opening ht. of 24 inches 24 SUPPORTING ONE FLOOR AND A ROOF Exceptions: A. ON-CENTER SPACING (INCHES) SUPPORTING A ROOF ONLY Exceptions: A. Glazing that is more than 60 inches (1524 mm), measured horizontally and in a straight line, form the waters edge of a hot tube, whirlpool or bathtub. SMOKE ALARMS HANDLING AND ERECTION SPECIFICATIONS MAXIMUM ALLOWABLE LENGTH OF WOOD STUDS EXPOSED TO WIND SPEEDS OF 100 MPH OR LESS IN SEISMIC DESIGN CATEGORIES A, B, C, AND D1 b,c 8" MIN. R311.7.7.1 Height. Handrail height, measured vertically from the sloped plane adjoining the tread nosing, or finish surface of ramp slope, shall be not less than 34 inches (864 mm) and not more than 38 inches (965 mm). 1. TABLE R602.3.1 6'-8" SASH HEIGHT REFER TO PLANS FOR ALTERNATE SASH HEIGHTS R311.7.7 Handrails. Handrails shall be provided on at least one side of each continuous run of treads or flight with four or more risers. Exceptions: A. Decorative glazing. B. When a horizontal rail is installed on the accessible side(s) of the glazing 34 to 38 inches (864 to 965) above the walking surface. The rail shall be capable of withstanding a horizontal load of 50 pounds per linear foot (750 N/m) with our contacting the glass and be a minimum of 1-1/2 inches (38 mm) in cross sectional height. C. Outboard panes in insulating glass units and other multiple glazed panels when the bottom edge of the glass in 25 feet (7620 mm) or more above grade, a roof, walking surfaces, or other horizontal [ within 45 degrees (0.79 rad.) of horizontal ] surface adjacent to the glass exterior. REFER TO PLANS FOR ALTERNATE BEARING CONDITIONS R311.7.1 Width. Stairways shall not be less than 36 inches (914 mm) in clear width at all points above the permitted handrail height and below the required headroom height. Handrails shall not project more than 4.5 inches (114 mm) on either side of the stairway and the minimum clear width of the stairway at and below the handrail height, including treads and landings, shall not be less than 3-1/2 (787 mm) where a handrail is installed on one side and 27 inches (698 mm) where handrails are provided on both sides. The width of spiral stairways shall be in accordance with Section R3.11.7.9.1. Exception: The width of spiral stairways shall be in accordance with Section R311.7.9.1. 8'-11 8" BEARING 1. Designs shall conform with the latest versions of (NDS), "National Design Specification for Wood Construction" by the American Forest & Paper Association, and Design Standard for Metal Plate Connected Wood Truss Construction by the American Standard (ANSI) and the Truss Plate Institute (T.P.I.) and the local code jurisdiction. 2. Trusses shall be spaced as indicated on the plans unless the designer determines that different spacing is required to meet deflection requirements. 3. Maximum deflection of floor trusses shall be limited to l/360 for total load and l/480 for live load. Maximum deflection of roof trusses shall be limited to l/240 for total loads and l/360 for live load u.n.o. 4. Adequate camber shall be built into floor and parallel chord roof trusses to compensate for normal dead load deflection. 5. Design loads: Roof: 30 p.s.f. top chord live load * (or per "Michigan Residential Code" snow load) 7 p.s.f. top chord 10 p.s.f. bottom chord dead load ** floor: 40 p.s.f. live load (per "Michigan Residential Code") 10 p.s.f. top chord dead load *** 5 p.s.f. bottom chord dead load * A 15% increase on allowable stresses for short term loading is allowed. Drift loading shall be accounted for per the current "Michigan Residential Code" requirements. ** Add additional attic storage live loads per the current "Michigan Residential Code" requirements. *** Tile, marble, or other special features shall be designed using the appropriate dead loads and deflection limitations. Partition loads shall also be considered where appropriate. 10" STAIRWAYS AND HANDRAILS 7'-91 2" BEARING WOOD TRUSS SPECIFICATIONS TYPICAL FOUNDATION DRAINAGE TYPICAL WALL SECTION SCALE: 3/4" = 1'-0" 4" DIAMETER DRAIN TILE W/ FILTER MEMBRANE IN PEA GRAVEL BASE TYPICAL EXTERIOR WALL CONSTRUCTION BRICK WITH AIRSPACE W/ 22 U.S. GAGE x 7/8" CORRUGATED METAL BRICK TIES @ 24" O.C. HORIZONTALLY SUPPORTING NO MORE THAN 3 1/4 SQ. FT., MOISTURE BARRIER PAPER (HOUSE WRAP) ON 7/16" O.S.B. SHEATHING ON 2X4 WOOD STUDS @ 16"O.C., 1/2" GYPSUM WALL BOARD (GLUE & SCREW), 3/16" DIA. WEEP HOLES @ 32" O.C. (MIN.) FLASHING MEMBRANE BENEATH THE FIRST COURSE OF MASONRY CONTINUED ABOVE FINISHED GROUND LEVEL TYPICAL EXTERIOR WALL CONSTRUCTION SIDING, MOISTURE BARRIER PAPER (HOUSE WRAP) ON 7/16" O.S.B. SHEATHING ON 2X4 WOOD STUDS @ 16"O.C., 1/2" GYPSUM WALL BOARD (GLUE & SCREW), R312.1 GUARDS WITH RISE OF MORE THAN 30" SHALL HAVE GUARDS NOT LESS THAN 36" IN HEIGHT TYPICAL GARAGE FLOOR CONSTRUCTION TYPICAL GARAGE FLOOR CONSTRUCTION 4" CONCRETE SLAB ON 4" COMPACTED GRANULAR FILL 4" CONCRETE SLAB ON 4" COMPACTED GRANULAR FILL TYPICAL SILL CONSTRUCTION TYPICAL SILL CONSTRUCTION SILL ANCHORS @ 32" O.C. WITHIN 12" OF ANY CORNER OR OPENING, 2x4 TREATED SILL ON 4"X8"X16" C.M.U. R311.5.6 HANDRAILS SILL ANCHORS @ 32" O.C. WITHIN 12" OF ANY CORNER OR OPENING, 2x4 TREATED SILL ON 4"X8"X16" C.M.U. HANDRAILS THAT HAVE MINIMUM AND MAXIMUM HEIGHTS OF 34" AND 38" RESPECTIVELY, MEASURED VERTICALLY FROM THE NOSING OF THE TREAD. GRADE GRADE R311.5.3 STAIR TREADS AND RISERS HEIGHT @___" EACH WITH A TREAD DEPTH OF 9.00" EACH (NOSE TO NOSE). THE GREATEST RISER HEIGHT SHALL NOT EXCEED THE SHORTEST BY 3/8". LIKEWISE THE SHORTEST RUN SHALL NOT EXCEED THE GREATEST BY 3/8". TYPICAL TRENCH FOOTING CONSTRUCTION 12" THICK x 42" DEEP BELOW GRADE (MIN.) POURED CONCRETE TRENCH FOOTING TYPICAL STRINGERS 3'-6" BELOW GRADE (MIN.) 3'-6" BELOW GRADE (MIN.) LESS THAN 4" SPACING BETWEEN BALUSTRADES TYPICAL TRENCH FOOTING CONSTRUCTION 10" THICK x 42" DEEP BELOW GRADE (MIN.) POURED CONCRETE TRENCH FOOTING DOUBLE 2x12 MINIMUM STRINGERS AT ENDS AND ONE (1) STRINGER AT CENTER TYPICAL GARAGE FOOTING AND WALL DETAIL (BRICK) TYPICAL GARAGE FOOTING AND WALL DETAIL (SIDING) SCALE: 3/4" = 1'-0" SCALE: 3/4" = 1'-0" TYPICAL COMMON WALL CONSTRUCTION 5/8" TYPE "X" G.W.B. SCREW ONLY (NO GLUE) ON 7/16" O.S.B. WALL SHEATHING ON 2X4 WOOD STUDS @ 16"O.C. W/ 3 1/2" INSUL. R-13 1/2" G.W.B. (GLUED AND NAILED) R311.5.2 HEADROOM THE MINIMUM HEADROOM IN ALL PARTS OF THE STAIRWAY SHALL NOT BE LESS THAN 6'-8" MEASURED VERTICALLY FROM THE SLOPED PLANE ADJOINING THE TREAD NOSING OR FROM THE FLOOR SURFACE OF THE LANDING OR PLATFORM. TYPICAL FLOOR CONSTRUCTION FINISH FLOOR ON 3/4" T&G SUBFLOOR GLUED & NAILED TO FLOOR JOISTS (SEE PLAN FOR SIZE & SPACING) RIM BOARD TYPICAL SILL PLATE R311.5.6 HANDRAILS 3 1/2" R-13 BOND INSULATION SILL ANCHORS @ 32" O.C. (WITHIN 12" OF ANY CORNER OR OPENING) 2X6 TREATED SILL PLATE W/ SILL SEALER HANDRAILS THAT HAVE MINIMUM AND MAXIMUM HEIGHTS OF 34" AND 38" RESPECTIVELY, MEASURED VERTICALLY FROM THE NOSING OF THE TREAD. TYPICAL BRICK VENEER WALL CONSTRUCTION BRICK WITH AIRSPACE W/ 22 U.S. GAGE x 7/8" CORRUGATED METAL BRICK TIES @ 24" O.C. HORIZONTALLY SUPPORTING NO MORE THAN 3 1/4 SQ. FT., MOISTURE BARRIER PAPER (HOUSE WRAP) ON 7/16" O.S.B. SHEATHING ON 2X WOOD STUDS @ 16"O.C., 1/2" GYPSUM WALL BOARD (GLUE & SCREW), 3/16" DIA. WEEP HOLES @ 32" O.C. (MIN.) TYPICAL GARAGE FLOOR CONSTRUCTION 4" CONCRETE SLAB ON 4" COMPACTED GRANULAR FILL R311.5.3 STAIR TREADS AND RISERS HEIGHT @ 7 15/16" EACH WITH A TREAD DEPTH OF 10.00" EACH (NOSE TO NOSE). THE GREATEST RISER HEIGHT SHALL NOT EXCEED THE SHORTEST BY 3/8". LIKEWISE THE SHORTEST RUN SHALL NOT EXCEED THE GREATEST BY 3/8". FLOOR FRAMING (REFER TO PLAN FOR MEMBER SIZES) FLASHING W/ WEEPHOLE STEEL ANGLE NOT SECURED TO STUDS BASE FLASHING OVER COUNTER FLASHING TYPICAL STRINGERS DOUBLE 2x12 MINIMUM STRINGERS AT ENDS AND ONE (1) STRINGER AT CENTER TYPICAL FOUNDATION WALL TRIPPLE 2x6 RAFTERS. FIRST MEMBER SECURED TO EACH STUD WITH (3) 5 8" DIA. x 5" LONG LAG SCREWS. EACH ADDITIONAL ROOF MEMBER SHALL BE ANCHORED BY THE USE OF TWO 10d NAILS AT EVERY STUD ONE COAT DAMPROOFING AT FACE OF EXTERIOR WALL AND BRICKLEDGE, 10" THICK POURED CONCRETE WALL (SEE PLANS FOR WALL HEIGHT AND FOOTING DIMENSIONS) TYPICAL GARAGE COMMON WALL DETAIL TYPICAL STAIR DETAIL TYPICAL BRICK VENEER WALL OVER ROOF DETAIL SCALE: 3/4" = 1'-0" SCALE: 3/4" = 1'-0" SCALE: 3/4" = 1'-0" PER SECTION R703.7.2.2