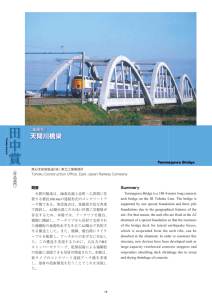

Chapter 8 - Railway Structures

advertisement