2, rue Balzac - 75008 Paris - France Tel.: +33 1 40 74 83 00

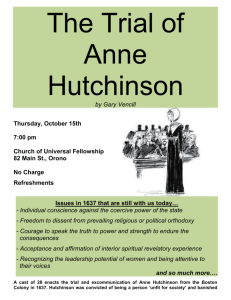

advertisement

http://www.hutchinsonworldwide.com © HUTCHINSON- 06/2007 - Photos : AIRBUS S.A.S. 2006 Photo by exm company / H. GOUSS, Arianespace, Bombardier-CRJ, D.Sarraute, Hutchinson. - Design & Production: 2, rue Balzac - 75008 Paris - France Tel.: +33 1 40 74 83 00 - Fax: +33 1 43 59 97 11 T e a m i ng u p f o r sa f et y, co m f o r t a n d p e r f o r m a nc e H utchinson has been involved in aviation practically since the dawn of the industry. Starting with special rubbers and fabrics, we gradually added a number of other capabilities, from engine mounts to advanced insulation. We have now grouped all of our aerospace businesses under one umbrella organization, Hutchinson Aerospace. We are very proud of the critical components and materials that we supply to leading players in the aerospace and defense industries. Jacques Maigné, Director, Hutchinson Aerospace These capabilities have made us the European or world leader in just about all of our core businesses: antivibration, thermal/ acoustic insulation, sealing systems, coatings, fluid transfer, displays, control panels and racks. Looking ahead, we are developing our capabilities to meet the full spectrum of customer needs, from technical materials to complete subassemblies and test systems. And we are expanding our footprint as well, to keep pace with today’s global market. Our products are not necessarily the most visible part of the airplane, but they play vital roles and have to be as reliable as the engines or avionics. They are present from nose to tail, in just about every part of the plane. We’re a major supplier on almost all types of platforms, through all of our businesses. Hutchinson Aerospace gives you service you can count on, anywhere in the world. As you well know, there are no compromises in aerospace. When it comes to our areas of expertise, we take care of all the details. Because our legacy of excellence reaches back nearly 100 years. Today, our engineers keep their fingers on the pulse of the market to give you the practical solutions needed to meet evolving requirements. Join us at Hutchinson Aerospace for a safe, comfortable flight! d edicaTed To safeTy and dependabiliTy our core values our goals > Deliver unrivaled expertise in complex materials From rubber & metal to composites and superlight sealants, unrivaled R&D capabilities. > Anticipate trends and support our From special fabrics for airships to sophisticated components on the A380 and B787, Hutchinson Aerospace has always delivered innovative solutions to the international aerospace industry. Solutions designed to enhance safety and dependability for our customers … and their passengers. Aircraft and spacecraft are made up of many different parts, and they all have to work perfectly, each and every time. Everything we make – sealing systems, sealants and coatings, antivibration mounts, thermal and acoustic insulation, deicing, control and display systems, fluid transfer systems – is designed and manufactured with this in mind. customers as their businesses evolve Increasingly global, increasingly integrated. > Meet growing requirements for safety and > Entrepreneurship and innovation > Customer-focused > Knowledge sharing > Teamwork > Environmental awareness security In-house test facilities in compliance with the latest regulations. our markeTs legacy of eXcellence American industrialist Hiram Hutchinson built his first European rubber vulcanization plant in Langlée, south of Paris, back in 1853. > commercial aviaTion 4 > regional aviaTion > gener al aviaTion huTchinson aerospace worldwide asia 3 locations europe 14 locations (Buffalo, Burbank, Trenton, Hopkinton, Ithaca) Mexico (Suzhou) (Amiens, Bezons, Châteaudun, Cernay, Etrépagny, Fleury-les-Aubrais, Lisses, Montargis, Toulouse, Chemillé) United States Tunisia (Ensenada) China France norTh america 6 locations (Tunis) Hutchinson Aerospace is part of Hutchinson Worldwide, a global corporation Japan (Tokyo) India (Bangalore) > Sales: € 2.9 billion > Capital expenditures: 137 million € > R&D: €149 million Germany (Renningen) > Employees: 26,357 Spain (Madrid) > 117 sites in 25 countries United Kingdom (Slough) Poland (Lodz) souTh america 1 location Brazil (Monte Alto) > b u s i n e s s aviaTion > heli co p T e r s > defense > space 5 c uTTing edge Technology for a difference you can feel safeTy-criTical componenTs, from nose To Tail sealing sysTems • Molded seals • Seal plates - access panels • EMI shielding products • Diaphragms • Sealants for fuselages & fuel tanks • Adhesives & coatings innovaTion, The compeTiTive edge Research & Development is a top priority at Hutchinson Aerospace. We invest up to 8 percent of our revenues in R&D, to give our customers unrivalled solutions for a competitive edge, anywhere in the world. We can call on Hutchinson’s corporate research center in Montargis, south of Paris, for cross-disciplinary research. Each business unit also carries out R&D targeted to its own requirements, while teaming up with other businesses for specific projects. Thermal and acousTic insulaTion • Thermal/acoustic insulation materials • Flexible & metallic insulation assemblies • Cabin insulation kits • Noise attenuation foams • Materials & assemblies for space • Illuminated control panels • Integrated switch panels • Control boxes • Information signs and formation lights • NVG compatible equipment anTivibraTion • Laminated bearings • Lead lag and fluid dampers • Elastomeric rod-ends • Antivibration mounts • Commercial and wired trays • Noise attenuation foams and skin damping materials deicing • Thermoelectric deicing systems 6 conTrol & display sysTems avionics racking sysTems • Arinc 404 & Arinc 600 trays • Integrated racking enclosures • Consoles • Wired trays fluid Transfer • Band clamps • Lightweight hoses • PTFE and rubber hose assemblies • Clamps • Air ducting 7 ealing sysTems Hutchinson Aerospace makes an extremely wide range of seals and sealants for the aerospace and defense industry. We hold clear market leadership in Europe, and serve some 600 clients worldwide, including Dassault, EADS, Boeing, Alenia, Embraer, Bombardier and Rolls Royce. Hutchinson has worked with the aerospace industry for years to develop sealants that meet evolving demands. Primarily used in aircraft construction, on fuselages and fuel tanks, they have to combine low density with resistance to extreme temperature fluctuations and corrosive fluids, plus the ability to adhere to all types of materials. The materials used in our seals have also evolved, from the original rubber and metal, to custom compounds such as silicone, polychloroprene, nitrile, EPDM, etc., which operate at -75°C to +315°C. They are certified to all major standards. Hutchinson engineers a wide variety of seals and other parts on the outside of planes which play an important role in overall aerodynamic performance. This is a key design factor. Hutchinson continues to develop sealing systems that offer greater strength and fire resistance, longer life, lighter weight and faster curing. They will also be multifunctional and more integrated, for easier installation and servicing – an all-important advantage in today’s cost-driven environment. 8 molded seals seal plaTes – access panels Metal retainers with bonded elastomer seals, used in engine static seals and wing access doors, for instance. spliced and fabricaTed seals For more demanding applications, such as doors, engine pylons, slat or flap/ wing and wing/fuselage connections, inflatable seals. Designed and manufactured to any specification, using a variety of processes. Molded seals include o-rings, gaskets, etc. Faster time-to-market based on proven expertise in computer modeling to predict performance in service. DIAPHRAGMS Fabric-reinforced diaphragms for high and low-pressure applications in aerospace. EMI shielding products Special sealants, adhesives, coatings Electrically conductive seals, based on silicone and flurosilicone with filler materials. Electrically-conductive sealants; special easy-to-remove sealants for access doors; polymer-based sealants for hot zones; rugged coatings for fuel tanks. Fuselage and fuel tank sealants Sealants designed to adhere to any kind of surface, from aluminum to alloys to composites. Offering lower density, plus excellent anticorrosion and endurance properties, and shorter application and drying times. Innovation in the air A lightweight sealant developed for the A380 that provides weight savings of 400 kg per aircraft! f luid Transfer ulTra-lighTweighT air ducTing Hutchinson Aerospace has provided fluid transfer products to the aerospace industry for over 50 years, with a complete range of air ducts, clamps of all types and flexible and rigid hose assemblies. Hutchinson offers full design, production and testing capabilities, plus long experience with the different materials that are combined to make these products, from rubber and steel to thermoplastics and plastomers. We’re also up to speed on the two major trends shaping our business: the transition from metallic to synthetic products, and increasing demand for integrated assemblies and complete functions, which make life easier for today’s aircraft manufacturers! Using our computer-aided design and modeling systems, we develop parts that are tailored to exact operating conditions, and deliver predictable performance. EDI connections with our customers ensure quick, secure data interchange at every step in the process. Composite parts combine greater strength, longer life and lower weight. In addition, they offer greater fire resistance and electrical safety, while making it easier to develop integrated functions. We are also developing our range of integrated assemblies, such as pipes fitted with insulation. And we will be expanding market coverage, based on an increasing number of manufacturer approvals. 10 pTfe and rubber hose assemblies A complete range of assemblies for fuel, hydraulics, pressure gauges, deicing, lubrication, water and oxygen systems. In compliance with MIL-H, AS, BNAe and ISO standards, and with European, American and international end-fittings. Flexible and semi-rigid ducting solutions: lightweight, cost-effective, space-efficient, easy to install and service. Semirigid ducting, acoustic silencers and thermal insulation can be provided as well, in compliance with international fire and smoke toxicity standards. band clamps Stainless-steel band clamps designed to customer specifications for airconditioning systems. Light and leaktight. Our fluid transfer products reflect the transition from metal to synthetics, for weight savings and enhanced safety. clips and v-band clamps Clips and clamps for all types of hose assemblies: P-clips, hinged clips, etc., for operating temperatures from -65°C to +650°C. V-band couplings to connect high-temperature metallic assemblies. fleXible and rigid meTallic ducTing Flexible and rigid metallic hoses are used at temperatures ranging from -260°C to +650°C. innovaTion in The air inTegraTed synTheTic pipe/clamp assembly, complianT wiTh far25 fire-resisTance sTandard. 11 a nTivibraTion Hutchinson Aerospace offers the largest range of anti-vibration products from a single supplier. Our product line includes engine & APU mounts, helicopter laminated bearings, lead lag and fluid dampers, silicone foams, damping materials and integrated solutions. These components are used in commercial, regional, business, military and general aviation, as well as space vehicles, for customers around the world. Over 60 years of experience working closely with the aerospace industry have given us unrivaled expertise, backed by a global presence. We work closely with our clients to give them the solutions needed, calling on powerful design and modeling systems including Catia, NISA and ARC3D, plus inhouse software for dynamic modeling, and extensive environmental and test facilities. The market is going global, but it is still anchored by a local presence, which is Hutchinson’s strength. As the market evolves, we will be working closely with other Hutchinson Aerospace units to expand our geographical reach to new markets and deliver integrated solutions. Our anti-vibration business combines French flair and Anglo-American pragmatism to meet a single goal: deliver the right components at the right price, with outstanding performance and appropriate aftermarket support. 12 roTary-wing aircrafT noise and vibraTion aTTenuaTion - Active controlled actuators for bulkheads - Active or passive engine mounts. - Silicone dampers - Fluid-filled lead lag dampers - Laminated bearings and elastomeric rod ends. avionics Anti-shock/vibration mounts and accessories, based on elastomer-metal or metallic technologies. The largest range of aerospace anti-vibration products from one supplier. fiXed-wing aircrafT, general, regional, business, miliTary & commercial aviaTion - Engine mounts - APU suspension - Active noise reduction systems. Comprehensive MRO and support services: - Worldwide presence for global spares availability - Full repair & overhaul extended capability around the engine - Rotable assets & technical solutions. defense Radar wave absorbent coatings, based on elastomers loaded with pigments, for fighters, helicopters, missiles, etc. space Laminated bearing for Vega and Ariane 5 launchers. innovaTion in The air a new all meTal anTi-vibraTion engine mounTing for a miliTary surveillance aircrafT. This innovaTive sysTem won The briTish aerospace chairman’s award. 1 hermal/acousTic insulaTion Hutchinson Aerospace offers high-tech, customtailored materials and assemblies that are an integral part of all aircraft and spacecraft, in particular meeting today’s increasingly stringent fire-resistance and acoustic regulations. Designed for thermal and fluid resistance, mechanical strength, lightness and non-toxicity, these materials and assemblies are used in today’s leading airplanes, helicopters and launch vehicles. We have worked with major customers such as Dassault, Airbus, Boeing, Embraer, Aircelle, Snecma and Arianespace for many years, building a relationship of mutual trust. For instance, we supply engine and propellant tank insulation on Ariane 5, Europe’s market-leading commercial launch vehicle. In addition to our understanding of a wide range of materials used in insulation (including new porous materials and composite skins), we have developed unrivaled modeling tools and knowledge of psychoacoustics. Hutchinson operates one of only three approved thermal test facilities in Europe, which means we can deliver fully-tested materials, ready to install. Plus, this facility is used by all companies in the group, expanding our market coverage. Our scope of business will expand even more in the future, as our thermal/acoustic business teams up with other Hutchinson units to offer integrated packages. 14 Thermal and acousTic insulaTion maTerials Used in insulation for fuselages and air-conditioning circuits: - Reinforced films - Adhesives - Coated fabrics - Skin damping - Lightweight foams. meTallic Thermal insulaTion assemblies fleXible Thermal/ acousTic insulaTion assemblies Flexible assemblies for airconditioning ducts, walls and sub-floors on military and commercial aircraft, plus thermal protection for structures. A thin metallic casing around a mineral-base insulator, used on: - Hot sections of propulsion systems: jet, turboprop engines, nacelles and thrust reversers - Insulation of engines and engine mounting areas. - Blankets for hot structures and ducting. Advanced materials plus in-house test facilities for end-to-end service. Thermal protection materials and assemblies for space Noise attenuation foams Cabin insulation kits Complete insulation kits for aircraft cabins, engineered in-house for top performance. Used on all Dassault Falcon business jets, as well as the Gulfstream G150 and the Eurocopter Dauphin and Super Puma helicopters. A full range of fire-retardant acoustic foams dedicated to noise reduction. Semi-closed cells, silicone foams for passive noise control at low or high frequencies (100 hz – 10 Khz) in various thicknesses and weights. - Insulation of cryogenic tanks and engines - Hot areas in launchers - Atmospheric reentry protection systems. Innovation in the air The first film to meet the new FAR25-856(b) burn-through standard: resists an 1100°C flame for 4 minutes. 15 c onTrol & display sysTems inTegraTed conTrol boXes Control units integrating electronics and software. inTegraTed swiTch panels Hutchinson Aerospace is a leading supplier of both illuminated control panels and display systems, a position backed by over 40 years of experience in international markets. Our control and display products range from simple edge-lit panels to complete control panels, integrating electronics and software, for both fixed and rotary-wing civil and military aircraft – including night vision compatibility. Hutchinson is one of the few companies in this field to offer complete end-to-end expertise, from design to production, and spanning mechanical, electronic and software aspects. 16 illuminaTed conTrol panels Based on light emitting diodes (LED), incandescent lamps or electroluminescent lamps. Custom-made integrated switch panels for civil or military aircraft, featuring ergonomic design, and “key touch” tailored to user demand. a a Combining mechanical and electrical design and manufacturing capabilities for increasingly integrated solutions. vionics racking sysTems Hutchinson is also one of the few companies that can deliver “fully dressed” racks, trays and cabinets including wiring, connectors, cooling fans and vibration dampers. The solutions we offer are custom designed to meet our customers’ requirements. They are used in a wide range of aircraft including turboprops, commercial and business jets, helicopters, and high performance combat aircraft, where our products have to stand up to severe operating conditions. As electronics become an increasingly important part of all aircraft — from avionics to in-flight entertainment (IFE) — Hutchinson will supply the racks to meet this demand. racks, Trays A complete range of products from simple racks or trays to integrated packages including cooling fans, connectors, wire harnesses and mounts. Hutchinson works with leading aircraft and avionics OEMs and repair centers in the U.S. and Europe. cabineTs Designed to withstand high levels of vibration and shock and to protect electronic equipment with integration of shock mounts. innovaTion in The air new soluTions using composiTe Technology 17 Deicing systems are a key to all-weather flight, especially critical on helicopters flying SAR missions. eicing Hutchinson Aerospace has over 40 years of experience in producing electrothermal deicing systems. Hutchinson is a world leader in the helicopter market, supplying systems for main and tail rotors, plus engine air inlets. We also provide systems for fixed-wing aircraft, and we’re working with industry on the inevitable transition to “more electric” aircraft – where electrothermal systems will be a natural fit. These systems are now increasingly required as standard equipment by manufacturers and operators who have to offer all-weather flying. Many military transport helicopters are fitted with our deicing systems and are capable of flying under all known icing conditions. Our systems are easy to retrofit with minimal structural changes. Hutchinson continues to perfect conventional deicing technology, and we’re also working on new solutions such as carbon-fiber composites for better damage resistance. The other major trend is a demand for complete systems, and in this case several Hutchinson Aerospace units can team up to provide complete deicing systems, including the control electronics. Whether saving lives or keeping aircraft in the air, you can count on electrothermal deicing systems from Hutchinson. 18 sTrucTure elecTroThermal deicing sysTems - Propellers: metallic or composite. - Helicopters: main and tail rotor blades. - Fixed-wing aircraft: wing leading edges. - Engine or APU air intake. - Antitorque airflow anti-icer. Heating system encapsulated between two multilayer insulating materials. Plus anti-erosion polyurethane coatings or paint if needed. specificaTions - Operating temperature up to 120°C. - Outside temperature to -40°C. - Anti-icing (continuous) or deicing (cyclical). innovaTion in The air conTinuous improvemenT in maTerials and componenTs significanTly enhances lifespan, reliabiliTy and faTigue resisTance. c c onTacTs sealing sysTems anTivibraTion Europe and Asia Europe J.P.R. Rue André Durouchez 80015 AMIENS FRANCE Tel: + 33 (0)3 22 52 60 78 Fax: + 33 (0)3 22 52 60 01 E-mail: sealingsystemsaero@hutchinson.fr PAULSTRA VIBRACHOC-TECHLAM 59/61 rue Marius Aufan 92305 LEVALLOIS PERRET Cedex FRANCE Tel: + 33 (0)1 40 89 53 31 Fax: + 33 (0)1 47 57 28 96 E-mail: antivibrationaeroeurope@hutchinson.fr LJF 84/116 rue Salvador Allende 95870 BEZONS FRANCE Tel: + 33 (0)1 34 23 34 61 Fax: + 33 (0)1 34 23 34 30 E-mail: equipmentsealingsystemsaero@hutchinson.fr BARRY CONTROLS AEROSPACE 40 rue Raymond Grimaud 31700 BLAGNAC Cedex FRANCE Tel: + 33 (0)5 61 16 70 80 Fax: + 33 (0)5 61 16 74 40 E-mail: antivibrationaeroeurope@hutchinson.fr LJF – SEALANTS AND ADHESIVES 84-116 rue Salvador Allende 95870 BEZONS FRANCE Tel: + 33 (0)1 34 23 34 69 Fax: + 33 (0)1 34 23 35 25 E-mail: info@ljfm.com USA USA STILLMAN SEAL Corp. 4510 Vanowen street BURBANK, CA 91505 USA Tel: +1 818 843 1000 Fax: +1 818 973 2537 E-mail: info@stillmanseal.com fluid Transfer sysTems Worldwide contact ESPA 22 rue de Curembourg 45401 FLEURY LES AUBRAIS FRANCE Tel: + 33 (0)2 47 78 10 52 Fax: + 33 (0)2 38 84 77 59 E-mail: fluidtransfersystemsaero@hutchinson.fr BARRY CONTROLS AEROSPACE 4510 Vanowen Street BURBANK, CA. 91505 USA Tel: + 1 818 843 1000 Fax: + 1 818 843 58 70 E-mail: antivibrationaerousa@bcas.com Asia HUTCHINSON INDUSTRIAL RUBBER PRODUCTS 65 Loujiang Street Kuatang sub-district Suzhou-Industrial Park SUZHOU 215122 CHINA Tel: + 86 512 8518 8298 Fax: + 86 512 8518 8296 E-mail: antivibrationaeroasia@hutchinson.fr Thermal and acousTic insulaTion Europe and Asia JEHIER Route de Saint Lézin 49120 CHEMILLE FRANCE Tel: + 33 (0)2 41 64 54 00 Fax: + 33 (0)2 41 64 54 01 E-mail: info@jehier.fr USA BARRY CONTROLS AEROSPACE PO BOX 7710 4510 Vanowen Street CA 91510 - 7710 BURBANK CA - USA Tel: + 1 818 843 10 00 Fax: + 1 818 843 58 70 E-mail: sales@bcas.com conTrol and display sysTems USA JEHIER 4510 Vanowen street BURBANK, CA 91505 USA Tel: +1 818 843 1000 Fax: +1 818 845 6978 E-mail: info@jehier.fr avionics racking sysTems Europe PAULSTRA VIBRACHOC Parc d’Activités de l’Eglantier C.E. 2804 LISSES 91028 EVRY FRANCE Tel: + 33 (0)1 69 91 50 00 Fax: + 33 (0)64 97 50 28 Email: strcom@hutchinson.fr Worldwide contacts PAULSTRA VIBRACHOC Parc d’Activités de l’Eglantier CE 2804 LISSES 91028 EVRY CEDEX FRANCE Tel: + 33 (0)1 69 91 50 00 Fax: + 33 (0)1 64 97 50 28 E-mail: clacom@hutchinson.fr UK STOP CHOC Ltd. Banbury Avenue SLOUGH, BERKSHIRE - SL1 4LR UNITED KINGDOM Tel: + 44 (0)1 753 533223 Fax: + 44 (0)1 7 53 693724 E-mail: sales@stop-choc.co.uk deicing UK Worldwide contact STOP CHOC Ltd. Banbury Avenue SLOUGH - BERKSHIRE SL1 4LR UNITED KINGDOM Tel: + 44 17 53 607 150 Fax: + 44 17 53 693 724 PAULSTRA 61 rue Marius Aufan 92305 LEVALLOIS PERRET Cedex FRANCE Tel: + 33 (0)1 40 89 53 98 Fax: + 33 (0)1 47 57 44 20 E-mail: deicing@hutchinson.fr 1