JetCat RX Turbines V10 ECU User Manual

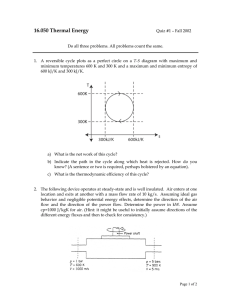

advertisement